Urea-dialdehyde starch-formaldehyde copolycondensed resin adhesive and preparation method therefor

A technology of co-condensation resin and dialdehyde starch, which is applied in the field of wood adhesives, can solve problems such as poor bonding performance and water resistance, high free formaldehyde content, and harm to health, and achieve excellent water resistance, reduce free formaldehyde content, The effect of short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

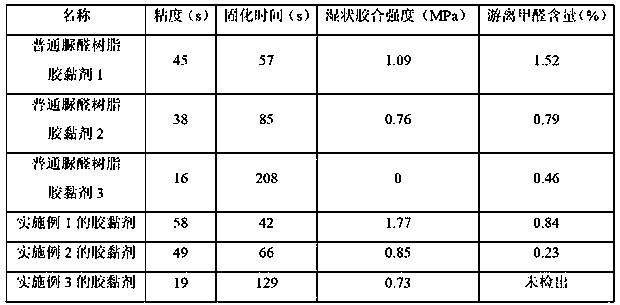

Examples

Embodiment 1

[0030] A urea-dialdehyde starch-formaldehyde co-condensation resin adhesive of the present invention, in parts by weight, its raw material components include: 60.06 parts of urea, 146.09 parts of formaldehyde aqueous solution with a mass fraction of 37%, 16.2 parts of aldehyde group content ≥80% dialdehyde starch, 0.6 parts melamine and 64.8 parts water.

[0031] The preparation method of the urea-dialdehyde starch-formaldehyde co-condensation resin adhesive of this embodiment comprises the following steps:

[0032] (1) Dissolve 16.2 parts by weight of dialdehyde starch in 64.8 parts by weight of water, prepare a dialdehyde starch milk solution with a mass fraction of 20%, add it to the reactor, and raise the temperature of the reactor to 60°C to make the dialdehyde starch paste After 0.5h, gelatinized dialdehyde starch milk solution was obtained.

[0033] (2) Adjust the pH value of the gelatinized dialdehyde starch milk solution obtained in step (1) to 9.0 using an aqueous s...

Embodiment 2

[0039] A urea-dialdehyde starch-formaldehyde co-condensation resin adhesive of the present invention, in parts by weight, its raw material components include: 60.06 parts of urea, 97.39 parts of formaldehyde aqueous solution with a mass fraction of 37%, 48.6 parts of aldehyde group content ≥80% dialdehyde starch, 1.8 parts melamine and 121.5 parts water.

[0040] The preparation method of the urea-dialdehyde starch-formaldehyde co-condensation resin adhesive of this embodiment comprises the following steps:

[0041] (1) Dissolve 48.6 parts by weight of dialdehyde starch in 72.9 parts by weight of water, prepare a dialdehyde starch milk solution with a mass fraction of 40%, add it to the reactor, and raise the temperature of the reactor to 70°C to make the dialdehyde starch paste After 1 h, gelatinized dialdehyde starch milk solution was obtained.

[0042] (2) Adjust the pH value of the gelatinized dialdehyde starch milk solution obtained in step (1) to 8.5 using an aqueous so...

Embodiment 3

[0047] A urea-dialdehyde starch-formaldehyde co-condensation resin adhesive of the present invention, in parts by weight, its raw material components include: 60.06 parts of urea, 40.58 parts of formaldehyde aqueous solution with a mass fraction of 37%, 81 parts of aldehyde group content ≥80% dialdehyde starch, 3 parts melamine and 189 parts water.

[0048] The preparation method of the urea-dialdehyde starch-formaldehyde co-condensation resin adhesive of this embodiment comprises the following steps:

[0049] (1) Dissolve 81 parts by weight of dialdehyde starch in 189 parts by weight of water, prepare a dialdehyde starch emulsion solution with a mass fraction of 30%, add it to the reactor, raise the temperature of the reactor to 80°C, and make the dialdehyde starch paste After 2 h, gelatinized dialdehyde starch milk solution was obtained.

[0050] (2) Adjust the pH value of the gelatinized dialdehyde starch milk solution obtained in step (1) to 8.0 using 30% sodium hydroxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com