A kind of preparation method of PVC plastic sole surface treatment agent

A surface treatment agent and plastic technology, applied in the field of materials, can solve problems such as unsatisfactory treatment effects and failure to meet the bonding requirements of the shoemaking industry, and achieve good treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

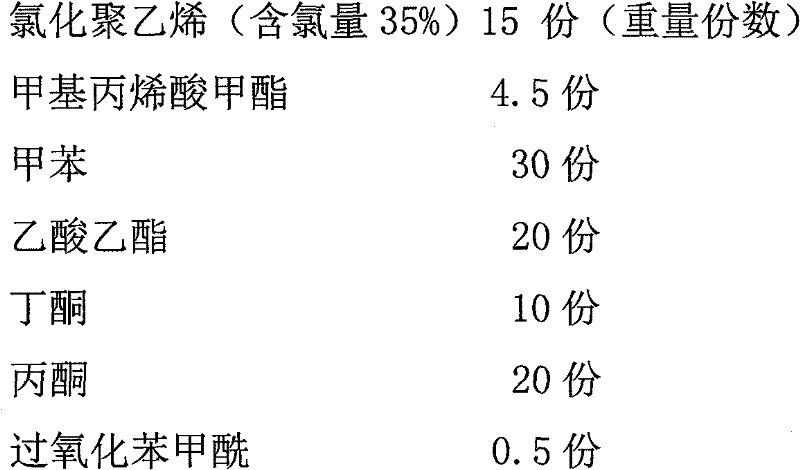

[0008] (1) Preparation of chlorinated polyethylene and methyl methacrylate copolymer:

[0009]

[0010] In the three-neck flask, add toluene, ethyl acetate, methyl ethyl ketone, acetone, methyl methacrylate, and chlorinated polyethylene according to the above proportions, stir well to dissolve the chlorinated polyethylene, and fill with N 2 Gas and heat up to 90°C, add benzoyl peroxide, react at constant temperature for 3 hours, then cool down to room temperature to obtain a copolymer of chlorinated polyethylene and methyl methacrylate.

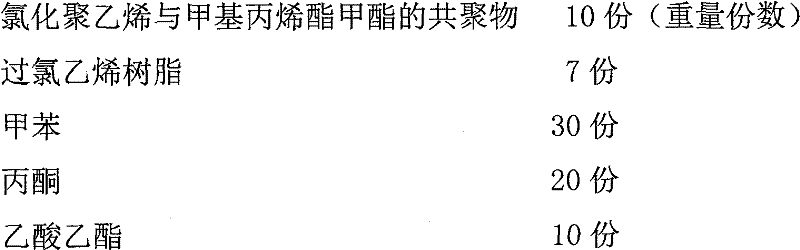

[0011] (2) Preparation of PVC plastic sole surface treatment agent:

[0012]

[0013]

[0014] Add the above-mentioned components into the reaction kettle in proportion, adjust the temperature of the reaction kettle to 50°C, and stir for 4 hours to make it into a uniform and transparent solution to obtain the finished product of the PVC plastic shoe sole surface treatment agent of the present invention.

Embodiment 2

[0016] (1) Preparation of chlorinated polyethylene and methyl methacrylate copolymer:

[0017]

[0018] In the three-neck flask, add toluene, ethyl acetate, methyl ethyl ketone, acetone, methyl methacrylate, and chlorinated polyethylene according to the above proportions, stir well to dissolve the chlorinated polyethylene, and fill with N 2 Gas and heat up to 70°C, add benzoyl peroxide, react at constant temperature for 6 hours, then cool down to room temperature to obtain chlorinated polyethylene and methyl methacrylate copolymer.

[0019] (2) Preparation of PVC plastic sole surface treatment agent:

[0020]

[0021] Add the above-mentioned components into the reaction kettle in proportion, adjust the temperature of the reaction kettle to 80°C, and stir for 2 hours to make it into a uniform and transparent solution to obtain the finished PVC plastic shoe sole surface treatment agent of the present invention.

Embodiment 3

[0023] (1) Preparation of chlorinated polyethylene and methyl methacrylate copolymer:

[0024]

[0025] In the three-neck flask, add toluene, ethyl acetate, methyl ethyl ketone, acetone, methyl methacrylate, and chlorinated polyethylene according to the above proportions, stir well to dissolve the chlorinated polyethylene, and fill with N 2 Gas and heat up to 80°C, add benzoyl peroxide, react at constant temperature for 4 hours, then cool down to room temperature to obtain a copolymer of chlorinated polyethylene and methyl methacrylate.

[0026] (2) Preparation of PVC plastic sole surface treatment agent:

[0027]

[0028] Add the above-mentioned components into the reaction kettle in proportion, adjust the temperature of the reaction kettle to 65°C, and stir for 3 hours to make it into a uniform and transparent solution to obtain the finished product of the PVC plastic shoe sole surface treatment agent of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com