Hybrid acrylate AB glue and preparation method thereof

A technology of acrylate and methacrylic acid, applied in the field of hybrid acrylate AB glue and its preparation, can solve the problems of poor fatigue resistance and creep resistance, can not meet the needs of use, poor adhesion and adhesion, and improve fatigue resistance. and creep resistance, good flexibility and adhesion, and the effect of reducing volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A hybrid acrylate AB glue, measured by mass percentage, comprises the following components:

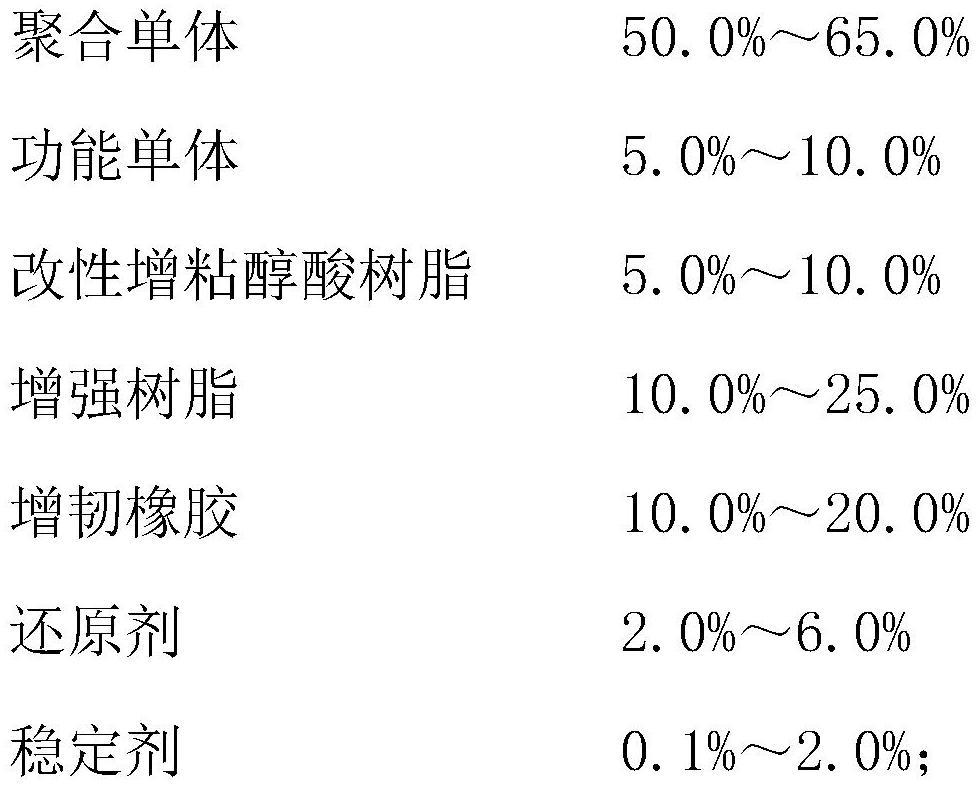

[0033] Component A:

[0034]

[0035] Component B:

[0036]

[0037]

Embodiment 2

[0039] A hybrid acrylate AB glue, measured by mass percentage, comprises the following components:

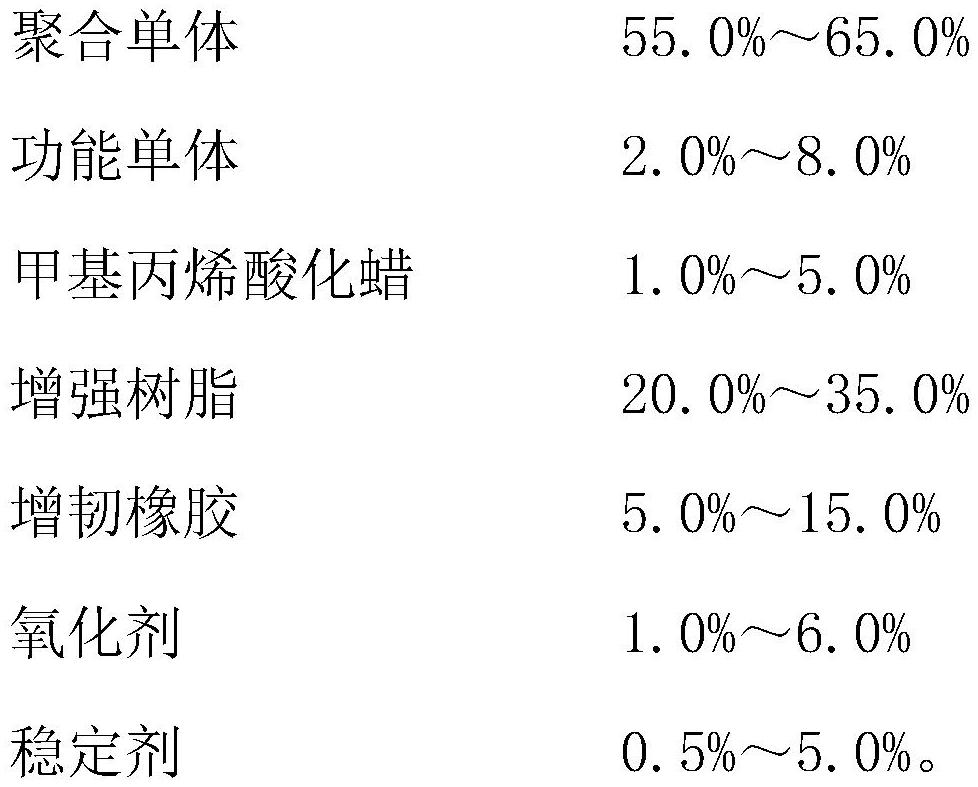

[0040] Component A:

[0041]

[0042] Component B:

[0043]

[0044] The preparation method of the hybrid acrylate AB glue of embodiment 1 and embodiment 2 specifically comprises the following steps:

[0045] Preparation of component A:

[0046] a, the preparation of modified tackifying alkyd resin (almond oil alkyd tackifying resin): weigh each raw material according to mass percentage, add glycerin in almond oil, stir and be warming up to 220 ℃, carry out alcoholysis reaction 1~ After 2 hours, the temperature was lowered to 160° C., maleic anhydride and nadic anhydride were added, the temperature was raised to 190° C. with stirring, and an alkyd polycondensation reaction was carried out for 5 to 6 hours. After cooling, the almond oil modified tackifying resin was obtained;

[0047] b, weigh each raw material according to the mass percentage, drop pentaerythritol tria...

Embodiment 3

[0053] A hybrid acrylate AB glue, measured by mass percentage, comprises the following components:

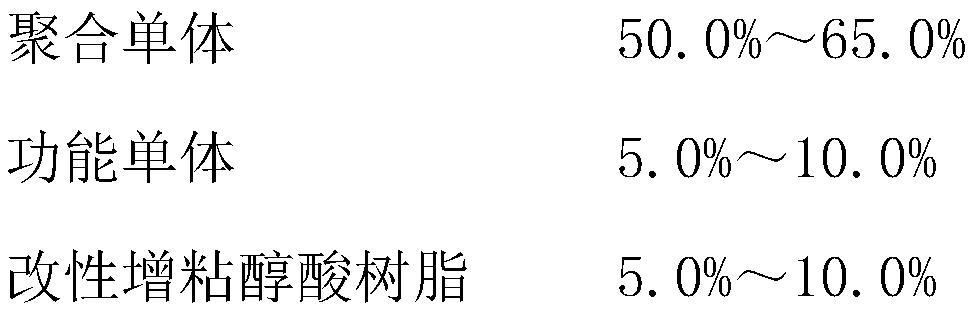

[0054] Component A:

[0055]

[0056]

[0057] Component B:

[0058]

[0059] The preparation method of the hybrid acrylate AB glue of embodiment 3, the concrete steps of this method are:

[0060] Preparation of Component A:

[0061] a, the preparation of modified tackifying alkyd resin (almond oil alkyd tackifying resin): weigh each raw material according to mass percentage, add glycerin in almond oil, stir and be warming up to 220 ℃, carry out alcoholysis reaction 1~ After 2 hours, the temperature was lowered to 160° C., maleic anhydride and nadic anhydride were added, the temperature was raised to 190° C. with stirring, and an alkyd polycondensation reaction was carried out for 5 to 6 hours. After cooling, the almond oil alkyd tackifying resin was obtained;

[0062] B, each raw material is weighed according to the mass percentage, polyethylene glycol dimethacryla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com