Patents

Literature

110results about "ABS polymer adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

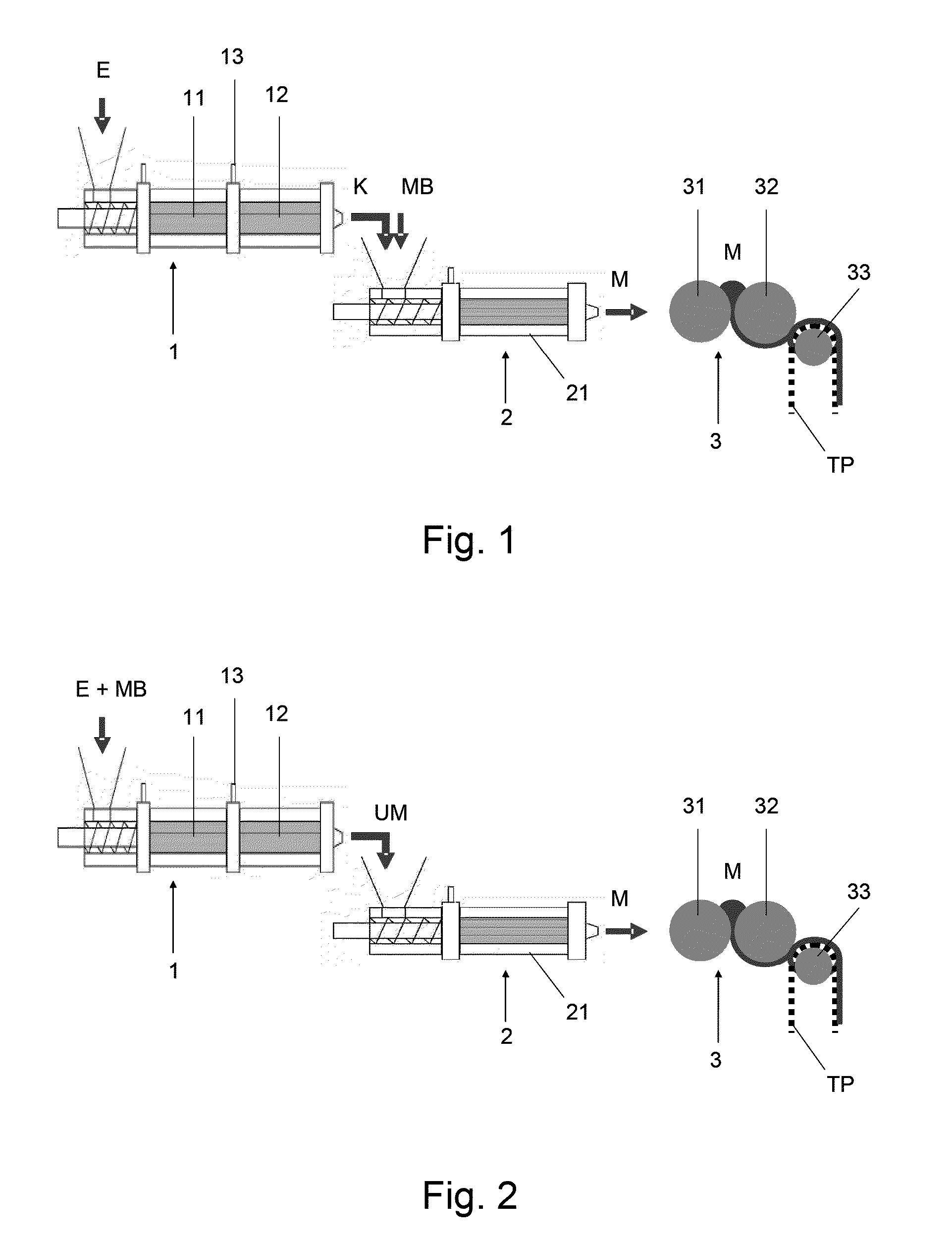

Foamed adhesive, more particularly pressure-sensitive adhesive, process for the production and also the use thereof

InactiveUS20090181250A1Natural rubber adhesivesMacromolecular adhesive additivesPolymer scienceMicrosphere

Adhesive, more particularly pressure-sensitive adhesive, which comprises expanded microballoons, the bond strength of the adhesive comprising the expanded microballoons being reduced by not more than 30%, preferably not more than 20%, more preferably 10%, in comparison to the bond strength of an adhesive of identical coatweight and formula which has been defoamed by the destruction of the voids produced by the expanded microballoons.

Owner:TESA SE

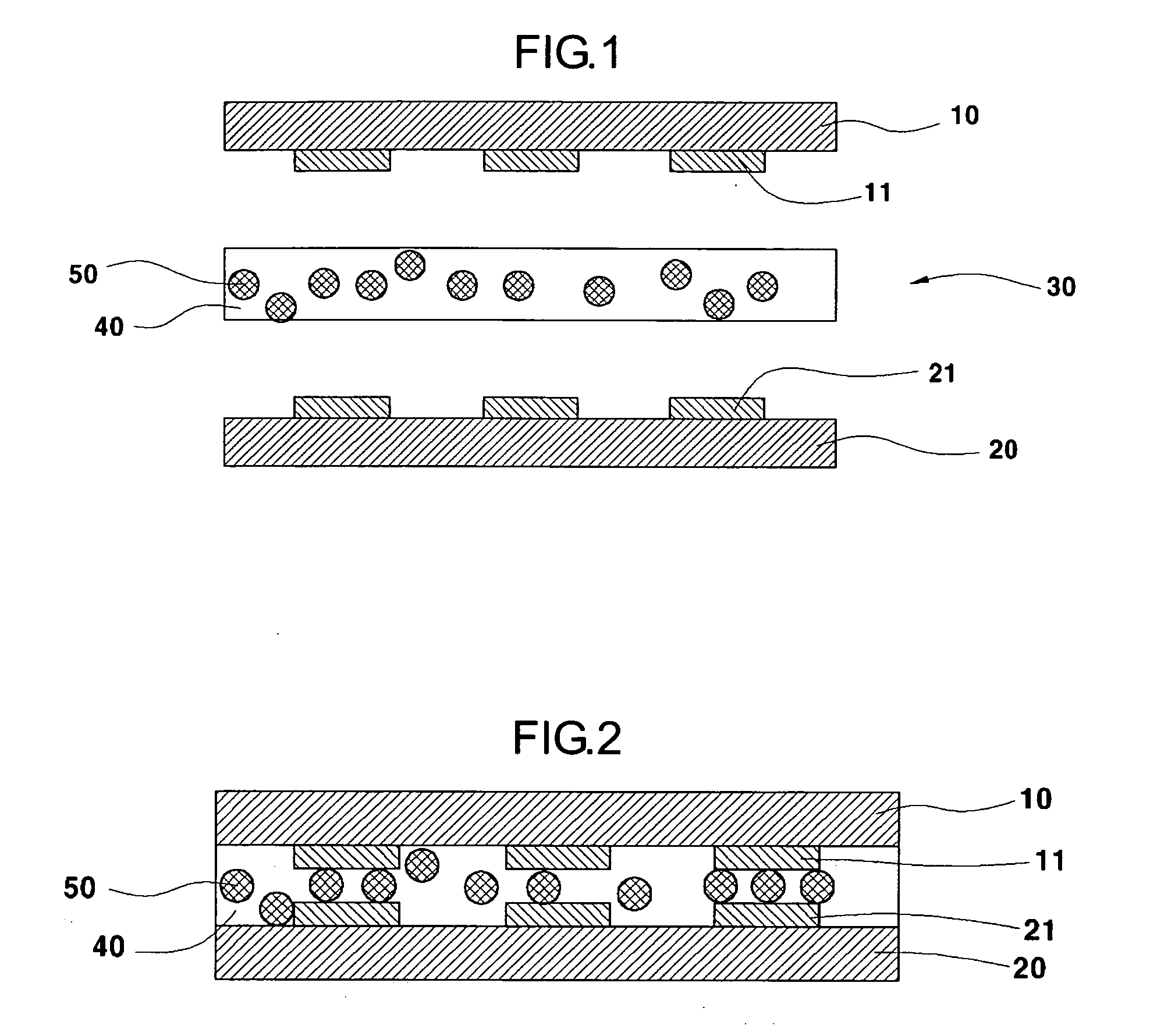

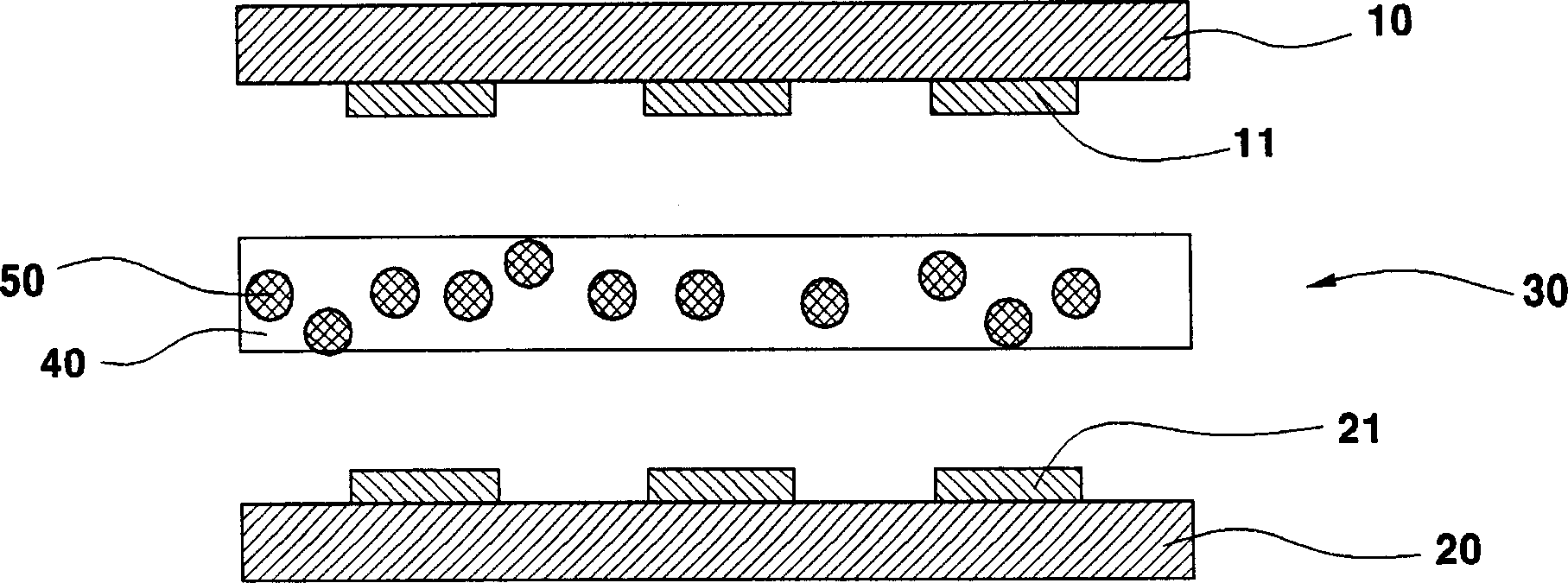

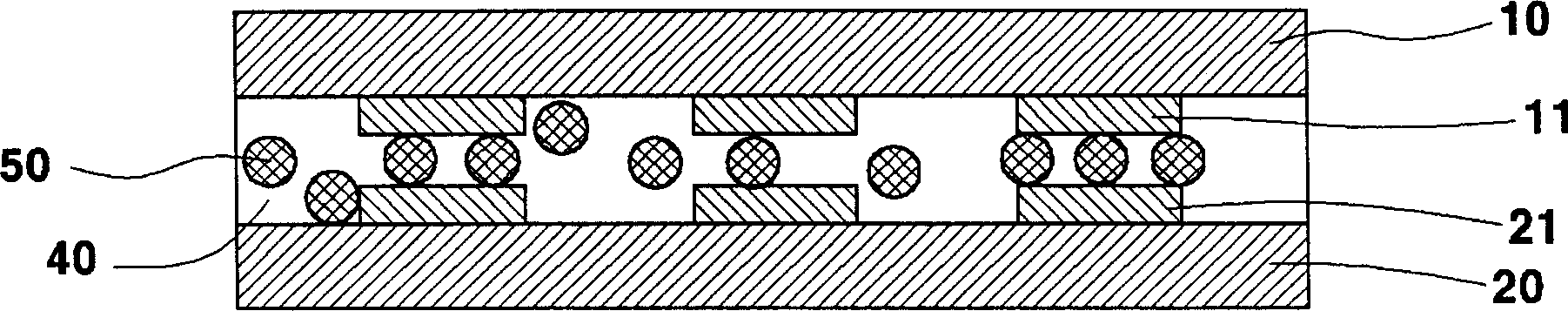

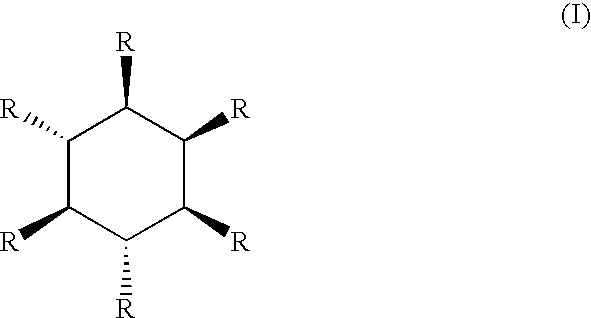

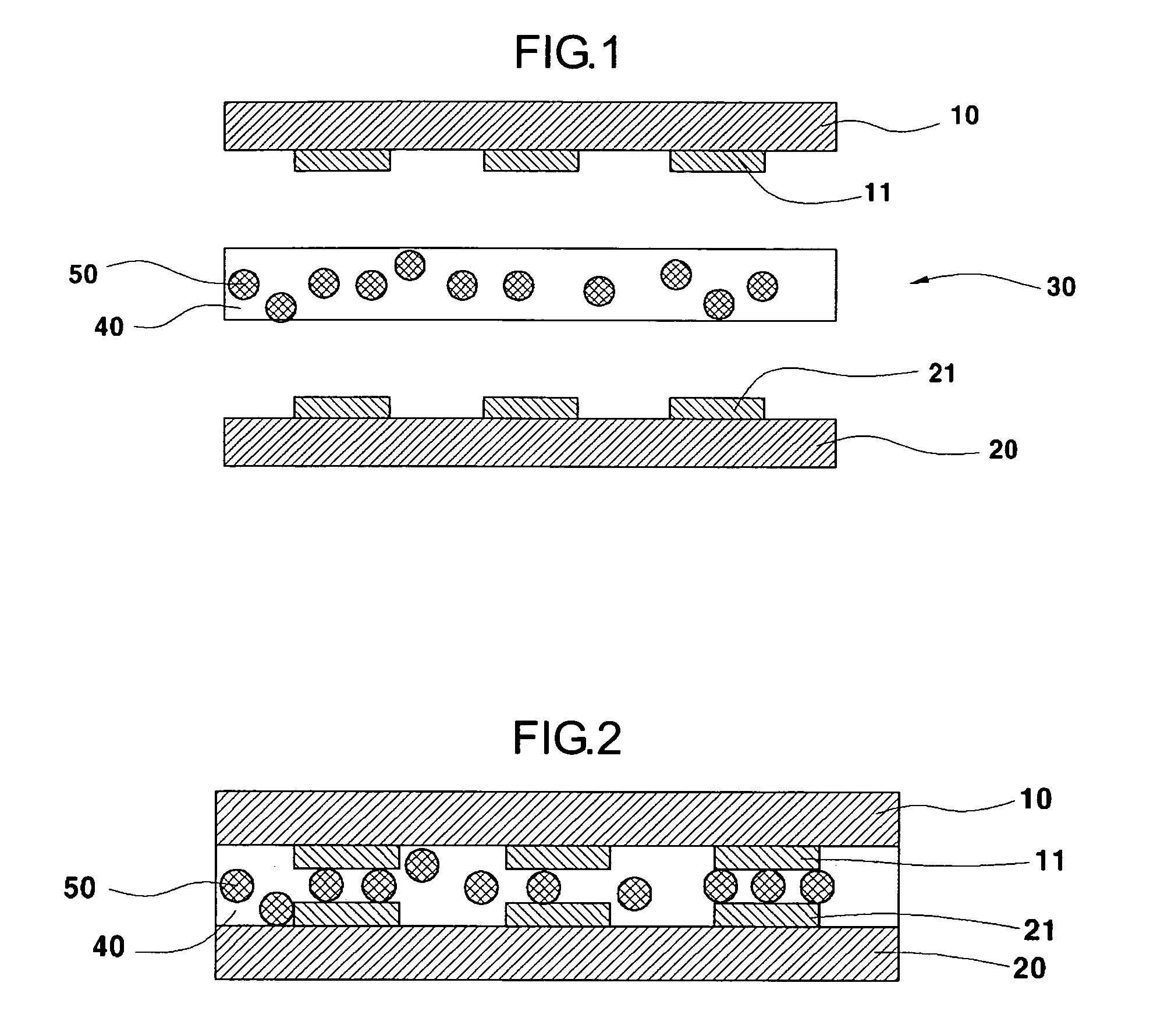

Isotropic conductive adhesive and adhesive film using the same

InactiveUS20050288427A1Minimizes its contractionImprove connection reliabilityImpression capsConductive materialAnisotropic conductive adhesiveIsotropic conductive adhesives

The present invention discloses an anisotropic conductive adhesive comprising an insulating adhesive component and a number of conductive particles dispersed in the insulating adhesive component, wherein the insulating adhesive component contains a crosslinked rubber resin. The anisotropic conductive adhesive of the present invention prevents exfoliation of an adhesive or reduction in adhesive strength of circuit by minimizing its the heat-contraction occurring in the process of a polymerization or a hardening reaction when connecting micro-circuits, whereby a short circuit between adjacent electrodes can be prevented when connecting the circuits, and excellent connection reliability according to a long-term use is achieved.

Owner:H&S HIGH TECH +1

Isotropic conductive adhesive and adhesive film using the same

InactiveCN1712483ASmall shrinkageAvoid short circuitPrinted circuit assemblingVinyl aromatic copolymer adhesivesAnisotropic conductive adhesiveIsotropic conductive adhesives

The present invention provides an anisotropic conductive adhesive comprising an insulating adhesive component and a large number of conductive particles dispersed in the insulating adhesive component, wherein the insulating adhesive component contains alternating Linked rubber resin. When connecting circuits, by minimizing the thermal shrinkage of the anisotropic conductive adhesive in the polymerization reaction or curing reaction, it is possible to prevent peeling of the adhesive or a decrease in the bonding strength of the circuit. It prevents short-circuit between adjacent electrodes and is excellent in long-term reliability.

Owner:H&S HIGHTECH

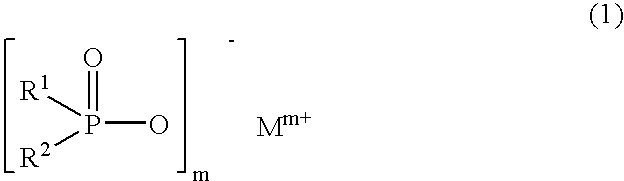

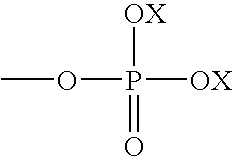

Flame retardant adhesive composition, and adhesive sheet, coverlay film and flexible copper-clad laminate using same

InactiveUS20060234045A1Excellent flame retardancy and electrical characteristicPromote migrationNon-macromolecular adhesive additivesNitrile polymer adhesivesEpoxyCopper foil

Provided is a flame retardant adhesive composition including (A) a halogen-free epoxy resin, (B) a thermoplastic resin and / or a synthetic rubber, (C) a curing agent, (D) an organophosphinate compound, and (E) a curing accelerator. Also provided are an adhesive sheet having a layer including the above composition, and a protective layer for covering the layer including the composition; a coverlay film having an electrically insulating film, and a layer including the above composition provided on top of the film; and a flexible copper-clad laminate having an electrically insulating film, a layer including the above composition provided on top of the film, and copper foil. Further provided are a process for producing the adhesive sheet, a process for producing the coverlay film, and a process for producing the flexible copper-clad laminate. The halogen-free adhesive composition yields a cured product, on curing, that exhibits excellent flame retardancy and electrical characteristics (anti-migration properties). The composition can be used for producing an adhesive sheet, a coverlay film, and a flexible copper-clad laminate.

Owner:SHIN ETSU CHEM IND CO LTD

Flame retardant adhesive composition, and adhesive sheet, coverlay film and flexible copper-clad laminate using same

InactiveUS20060234043A1Excellent flame retardancy and electrical characteristicExcellent characteristicsNon-macromolecular adhesive additivesAdhesive articlesEpoxyCopper foil

Provided is a flame retardant adhesive composition including (A) a halogen-free epoxy resin, (B) a thermoplastic resin and / or a synthetic rubber, (C) a curing agent, (D) a nitrogen-containing polyphosphate compound, and (E) a curing accelerator. Also provided are an adhesive sheet having a layer including the above composition, and a protective layer for covering the layer including the composition; a coverlay film having an electrically insulating film, and a layer including the above composition provided on top of the film; a flexible copper-clad laminate having an electrically insulating film, a layer including the above composition provided on top of the film, and copper foil; and a method of bonding two substrates, including the steps of sandwiching the above adhesive sheet between two substrates, and curing the adhesive sheet. Further provided are a process for producing the adhesive sheet, a process for producing the coverlay film, and a process for producing the flexible copper-clad laminate. The halogen-free adhesive composition yields a cured product, on curing, that exhibits excellent flame retardancy and anti-migration properties. The composition can be used for producing an adhesive sheet, a coverlay film, and a flexible copper-clad laminate. The adhesive sheet can be used for a method of bonding two substrates.

Owner:SHIN ETSU CHEM IND CO LTD

High-impact-resistance acrylate structural adhesive

ActiveCN105713543AHigh strengthImprove impact resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesHigh resistanceMethacrylate

The invention belongs to the technical field of adhesives, and particularly relates to a high-impact-resistance acrylate structural adhesive. The high-impact-resistance acrylate structural adhesive contains rigid functional groups provided by hydrogenated bisphenol A and methacrylate functional groups which can enhance the curing pull strength and impact resistance. The toughening resin is added to greatly enhance the impact resistance. The high addition percent of the curing agent in the component B can ensure the whole system to quickly perform reaction and curing. After room curing is performed for 3-5 minutes, 70-DEG C hot pressing only takes 60 seconds. The high-impact-resistance acrylate structural adhesive has high impact resistance, can pass the disk knife test, and can still keep high bonding power after being cut a little. The structural adhesive has high forward pull strength, and the pull force test proves that the pull force at the copper nail is generally required to be greater than 20kg or the copper nail can shed. The structural adhesive has high temperature resistance and high humidity resistance, and the strength does not obviously decrease when the structural adhesive is at 60 DEG C under the 90% humidity condition for 7 days.

Owner:信泰永合(烟台)新材料有限公司

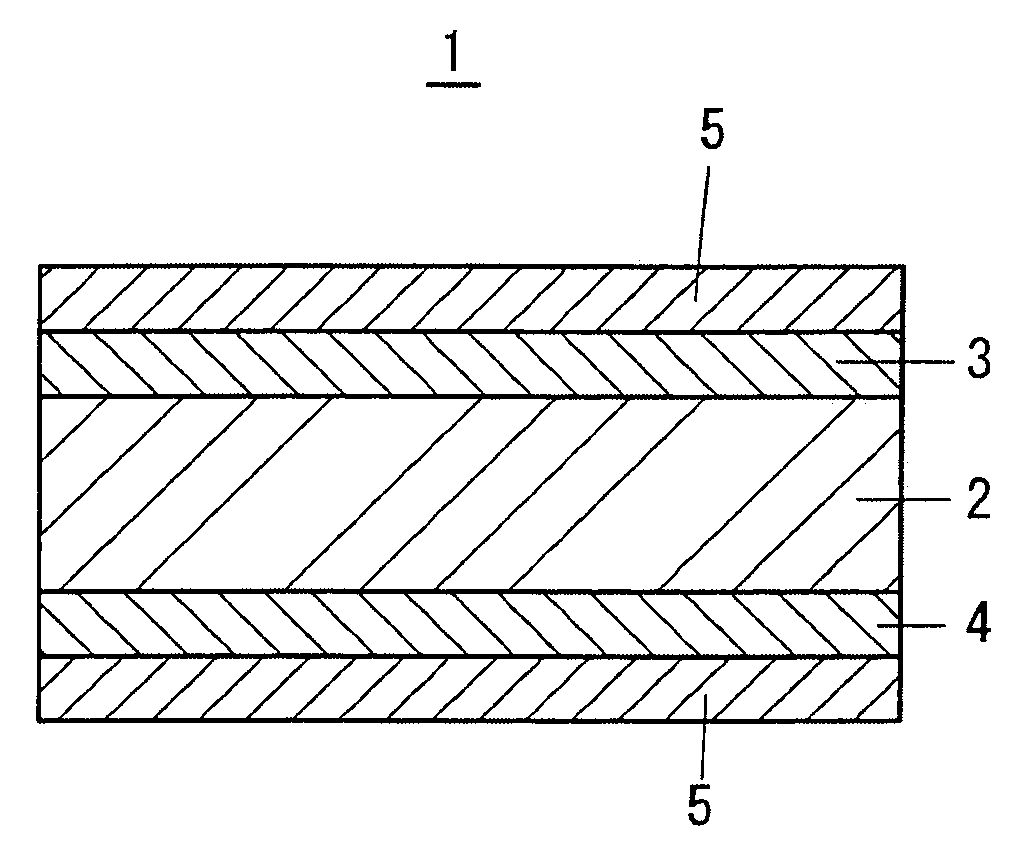

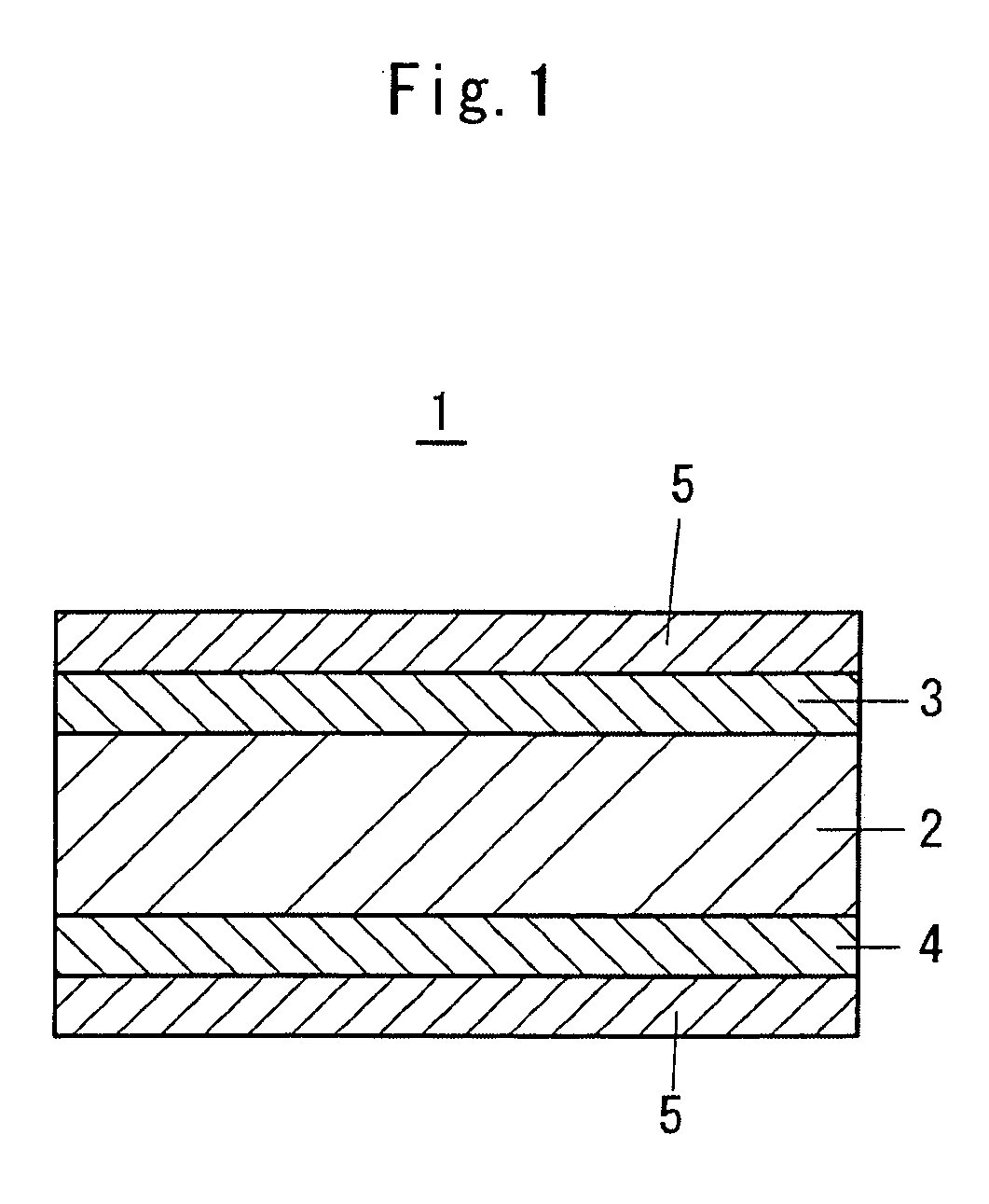

Double-Sided Adhesive Tape for Securing Polishing-Pad

InactiveUS20090098376A1High precisionReduce adverse effectsSynthetic resin layered productsLapping machinesPolyethylene terephthalateSolvent based

To provide a double-sided adhesive tape for securing a polishing-pad, the tape being capable of improving precision in polishing using a polishing-pad.The double-sided adhesive tape 1 for securing the polishing-pad includes a substrate 2 and adhesive layers 3 and 4, which are provided on both sides of the substrate 2, respectively. The substrate 2 is formed of a polyethylene terephthalate resin-film having a thickness of 150 to 300 μm, one of the adhesive layer 3 is formed of a synthetic rubber pressure sensitive adhesive, and the other adhesive layer 4 is formed of an acrylic solvent-based pressure sensitive adhesive.

Owner:SEKISUI CHEM CO LTD

Low-toxicity solvent adhesive for bonding of rigid PVC plastic pipeline system

InactiveCN1844286AImprove hygieneIn line with the trend of health and environmental protectionMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesAdhesivePolyvinyl chloride

The invention discloses a low-toxic solvent adhesive used in unplasticised polyvinyl chloride plastic duct system for adhesion. The adhesive of this invention consists of best matches of polychloroethylene basic resin, flexible polymer toughened and modified resin and low-toxic mixed solvent, also can include auxiliary agents auxiliary agent such as adhesion-promotion resin, anti-oxidant, thixotropic agent and bulk additive. Using the adhesive of this invention can make the adhesive site of the PVC-U pipe system possess good preliminary strength and final strength and have good sanitary performance. The invention is of simple process for preparing and low cost of manufacture.

Owner:GUANGDONG LIANSU TECH INDAL

Flame retardant adhesive composition, and adhesive sheet, coverlay film and flexible copper-clad laminate using same

InactiveCN1865382AImprove flame retardant performanceHigh peel strengthNon-macromolecular adhesive additivesAdhesive articlesPolymer sciencePolyphosphate

Provided is a flame retardant adhesive composition including (A) a halogen-free epoxy resin, (B) a thermoplastic resin and / or a synthetic rubber, (C) a curing agent, (D) a nitrogen-containing polyphosphate compound, and (E) a curing accelerator. Also provided are an adhesive sheet having a layer including the above composition, and a protective layer for covering the layer including the composition; a coverlay film having an electrically insulating film, and a layer including the above composition provided on top of the film; a flexible copper-clad laminate having an electrically insulating film, a layer including the above composition provided on top of the film, and copper foil; and a method of bonding two substrates, including the steps of sandwiching the above adhesive sheet between two substrates, and curing the adhesive sheet. Further provided are a process for producing the adhesive sheet, a process for producing the coverlay film, and a process for producing the flexible copper-clad laminate. The halogen-free adhesive composition yields a cured product, on curing, that exhibits excellent flame retardancy and anti-migration properties. The composition can be used for producing an adhesive sheet, a coverlay film, and a flexible copper-clad laminate. The adhesive sheet can be used for a method of bonding two substrates.

Owner:SHIN ETSU CHEM CO LTD

Low-water-absorptivity acrylate structural adhesive and preparation method thereof

InactiveCN102850973ALow water absorptionEasy to usePolyureas/polyurethane adhesivesEster polymer adhesivesAdhesive cementPolymer science

The invention relates to a double-component acrylate structural adhesive which is prepared by mixing a component A and a component B in a mass ratio of 1:1, wherein the component A is composed of 30-70 parts of acrylate monomer, 10-40 parts of toughening resin, 0.1-10 parts of initiator, 0.01-1 part of stabilizer, 0-6 parts of thixotropic agent and 0.1-2 parts of paraffin; and the component B is composed of 30-70 parts of acrylate monomer, 10-40 parts of toughening resin, 0.1-5 parts of accelerator, 0.01-1 part of stabilizer, 0-6 parts of thixotropic agent and 0.1-2 parts of paraffin. The adhesive provided by the invention has the advantages of low water absorptivity (lower than 2%), high curing speed, high initial adhesive force and high storage stability, and is convenient to use. The bonding strength of the bonded structural sample piece can still have the retentivity of 70% or so after the structural sample piece is boiled in water for 24 hours.

Owner:BEIJING HYSTIC NEW MATERIALS

Flame retardant adhesive composition, and adhesive sheet, coverlay film and flexible copper-clad laminate using same

InactiveUS20060234044A1Excellent flame retardancy and electrical characteristicExcellent characteristicsNon-macromolecular adhesive additivesAdhesive articlesEpoxyHalogen

Provided is a flame retardant adhesive composition including (A) a halogen-free epoxy resin, (B) a thermoplastic resin and / or a synthetic rubber, (C) a curing agent, (D) a phytate compound, and (E) a curing accelerator. Also provided are an adhesive sheet having a layer including the above composition, and a protective layer for covering the layer including the composition; a coverlay film having an electrically insulating film, and a layer including the above composition provided on top of the film; and a flexible copper-clad laminate having an electrically insulating film, a layer including the above composition provided on top of the film, and copper foil. Further provided are a process for producing the adhesive sheet, a process for producing the coverlay film, and a process for producing the flexible copper-clad laminate. The halogen-free adhesive composition yields a cured product, on curing, that exhibits excellent flame retardancy and electrical characteristics (anti-migration properties). The composition can be used for producing an adhesive sheet, a coverlay film, and a flexible copper-clad laminate.

Owner:SHIN ETSU CHEM IND CO LTD

Adhesive for powder injection forming and application method thereof

ActiveCN104559840AThe degreasing process is simple and easy to controlHigh degreasing efficiencyNon-macromolecular adhesive additivesWax adhesivesParaffin waxPolymer science

The invention discloses an adhesive for powder injection forming and a preparation method thereof. The adhesive comprises the following components in percentage by mass: 5-10% of liquid paraffin, 5-15% of naphthalene, 15-20% of solid paraffin, 10-20% of microcrystalline wax, 15-20% of carnauba wax, 15-30% of first high-molecular polymer, 10-20% of second high-molecular polymer and 1-5% of stearic acid. The first high-molecular polymer and second high-molecular polymer are selected from any two of polyethylene, polypropylene, polyacrylate and acrylonitrile-butadiene-styrene copolymer. The method comprises the following steps: after feeding materials of the adhesive, injecting a green compact, putting in a sintering furnace, and carrying out hot removal on the green compact in the furnace by heating to 600 DEG C at the rate of 2-5 DEG C / minute, thereby completely removing the adhesive; and heating for sintering according to the sintering technique, thereby obtaining the finished product. The adhesive has the advantages of simple and controllable degreasing process and high degreasing efficiency; and the degreasing process can not influence the quality of the green compact, and is clean and environment-friendly.

Owner:DONGGUAN HUAJING POWDER METALLURGY

Hot melt adhesive composition and preparation method thereof, and hot melt adhesive heat-conducting strip and preparation method thereof

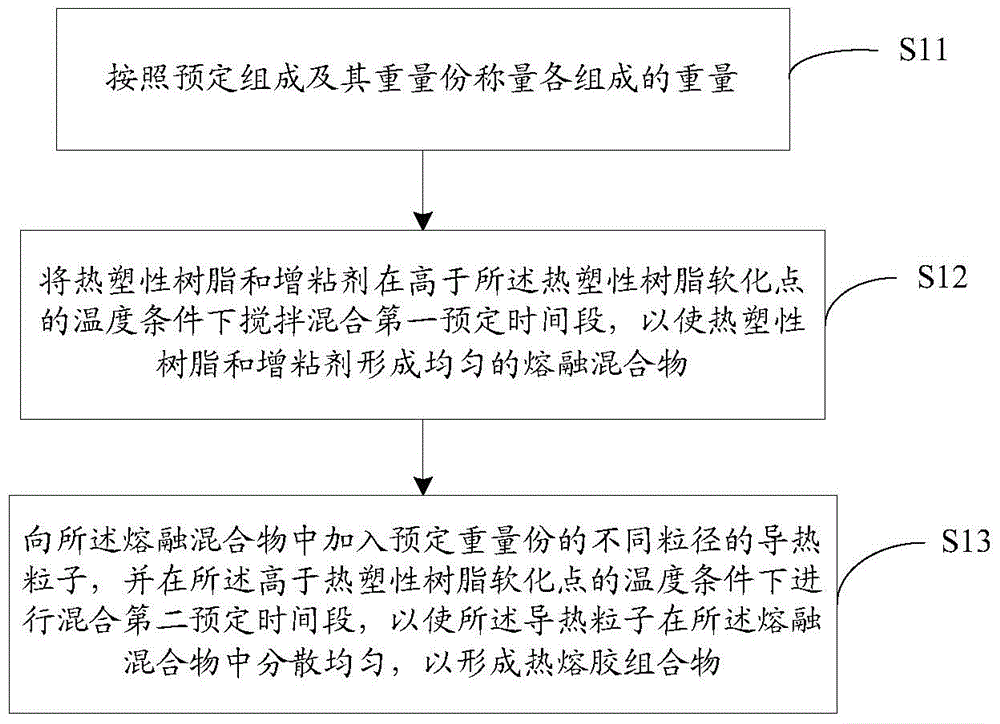

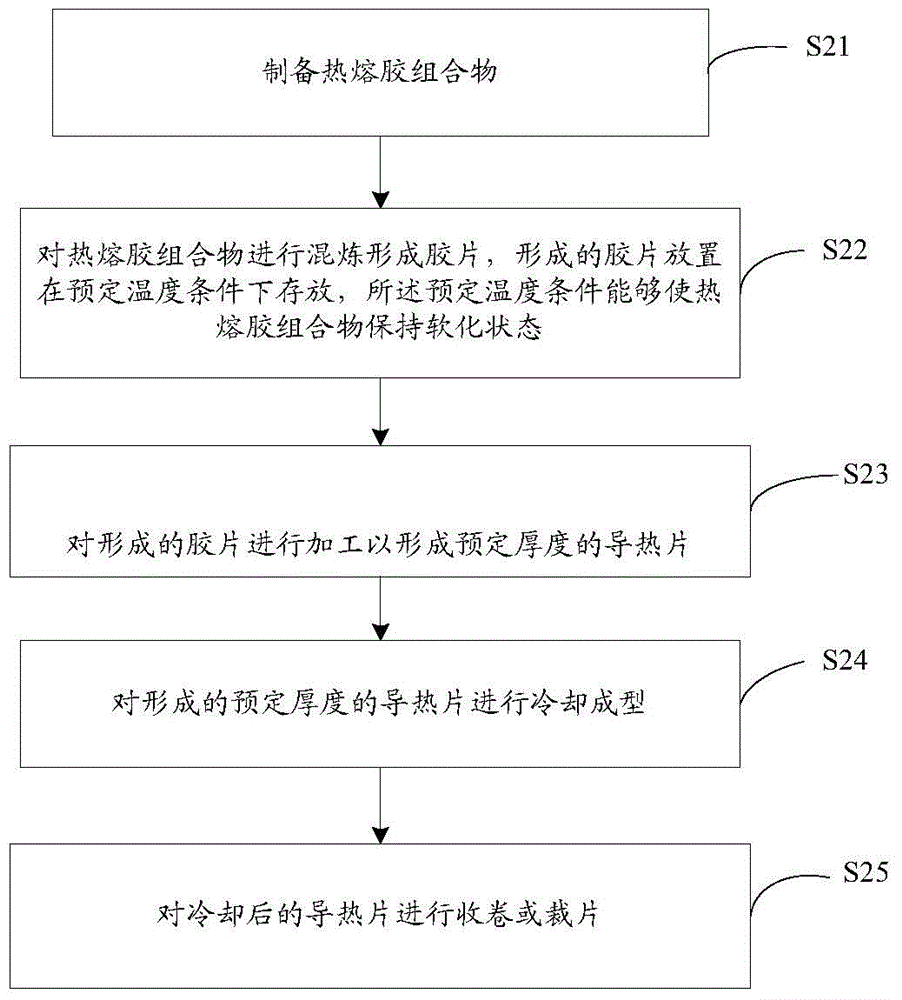

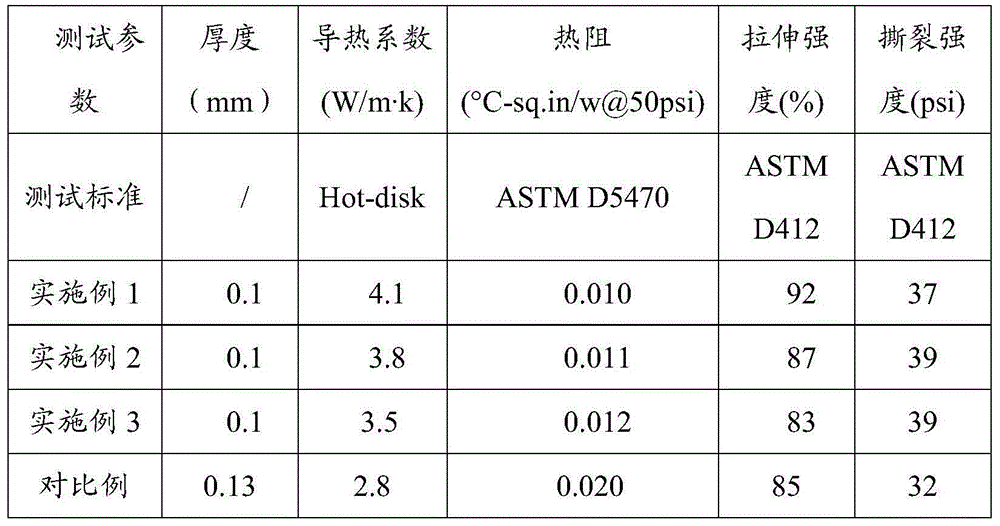

ActiveCN104789151AMolecular chain lengthNo flow deformationNon-macromolecular adhesive additivesFilm/foil adhesivesHeat conductingTackifier

The invention provides a hot melt adhesive composition and a preparation method thereof and further provides a hot melt adhesive heat-conducting strip and a preparation method thereof based on the hot melt adhesive composition. The hot melt adhesive composition at least comprises, by weight, 6 to 9 parts of thermoplastic resin with a softening point of 85 to 120 DEG C, 0.40 to 0.60 parts of a tackifier and 73 to 110 parts of a heat-conducting particle. Since the softening point of the thermoplastic resin is high in temperature, the softening point of the prepared hot melt adhesive composition is also high in temperature; and thus, the heat-conducting strip prepared from the hot melt adhesive composition does not flow or deform at a normal usage temperature. The disadvantages of easy flowing and deformation of heat-conducting strips in the prior art are overcome. Moreover, the heat-conducting strip provided by the invention has low thickness, so the heat conduction performance of the heat-conducting strip is improved.

Owner:ZHEJIANG SAINTYEAR ELECTRONICS TECH

Adhesive composition

An adhesive composition is described which has improved initial tack, long-term adhesion, water uptake and translucency characteristics and may be prepared by melt extrusion. Uses of these compositions are also described, for example, their use as blister pads and wound dressings.

Owner:CORIUM INT +1

Thermosetting acrylic structural adhesive and preparation method

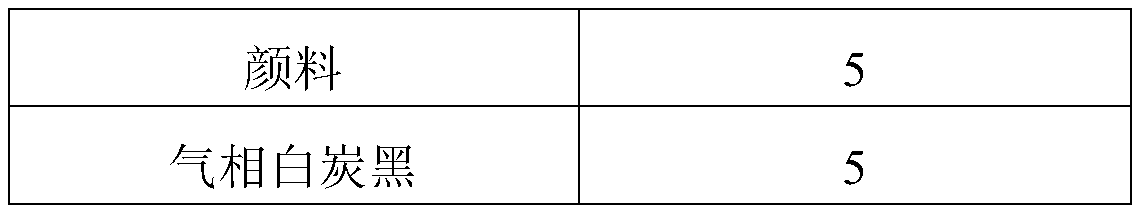

InactiveCN101781536AShort heat cure set timesReduce the temperatureEster polymer adhesivesConjugated diene hydrocarbon adhesivesAdhesiveFumed silica

The invention discloses a thermosetting acrylic structural adhesive and a preparation method thereof. Based on 100 parts by weight, the structural adhesive comprises the following components in parts by mass: 55-80 parts of acrylic monomers, 10-30 parts of toughening agent, 0.1-02 parts of stabilizing agent, 1-10 parts of peroxide, 0.1-5 parts of reducing agent, 0.1-0.5 part of paint, 1-5 parts of fumed silica, and 1-5 parts of other auxiliary agent. The preparation method comprises the following steps: (a) mixing the acrylic monomers uniformly; (b) adding the stabilizing agent; (c) adding the toughening agent to the mixture to prepare A component premix compound and B component premix compound of structural adhesive with similar components; (d) respectively adding the peroxide and the reducing agent to the A component premix compound and the B component premix compound; (e) adding the paint, the fumed silica and the auxiliary agent of paraffin to prepare the bi-component thermosetting acrylic structural adhesive by vacuum deaeration.

Owner:TONSAN ADHESIVES INC

Method of manufacture of styrene-butadiene latexes

ActiveUS20060263602A1Improve adhesionLiquid surface applicatorsPaper coatingMechanical stabilityEngineering

The present invention relates to a method of manufacture of styrene-butadiene latexes. The styrene-butadiene latex according to the present invention is characterized by having a superior adhesive force as the formation of films at an early stage is promoted by adjusting the gel content and molecular weight of the outermost layer, as well as a fast ink-drying speed and a high air permeability as the formation of paper films is maintained. It may be applied to paper coating very stably since the mechanical stability and chemical stability of the latex are superior.

Owner:LG CHEM LTD

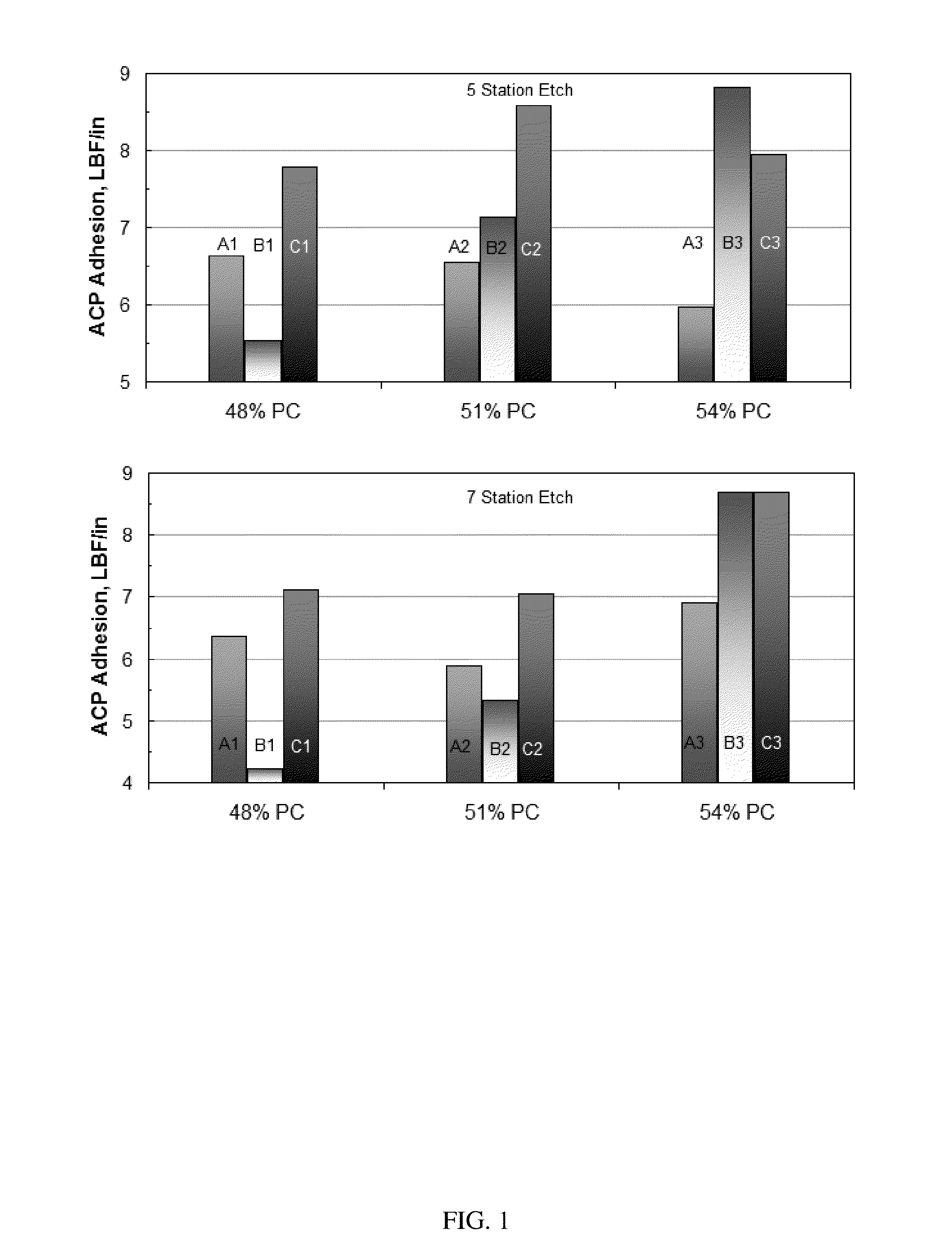

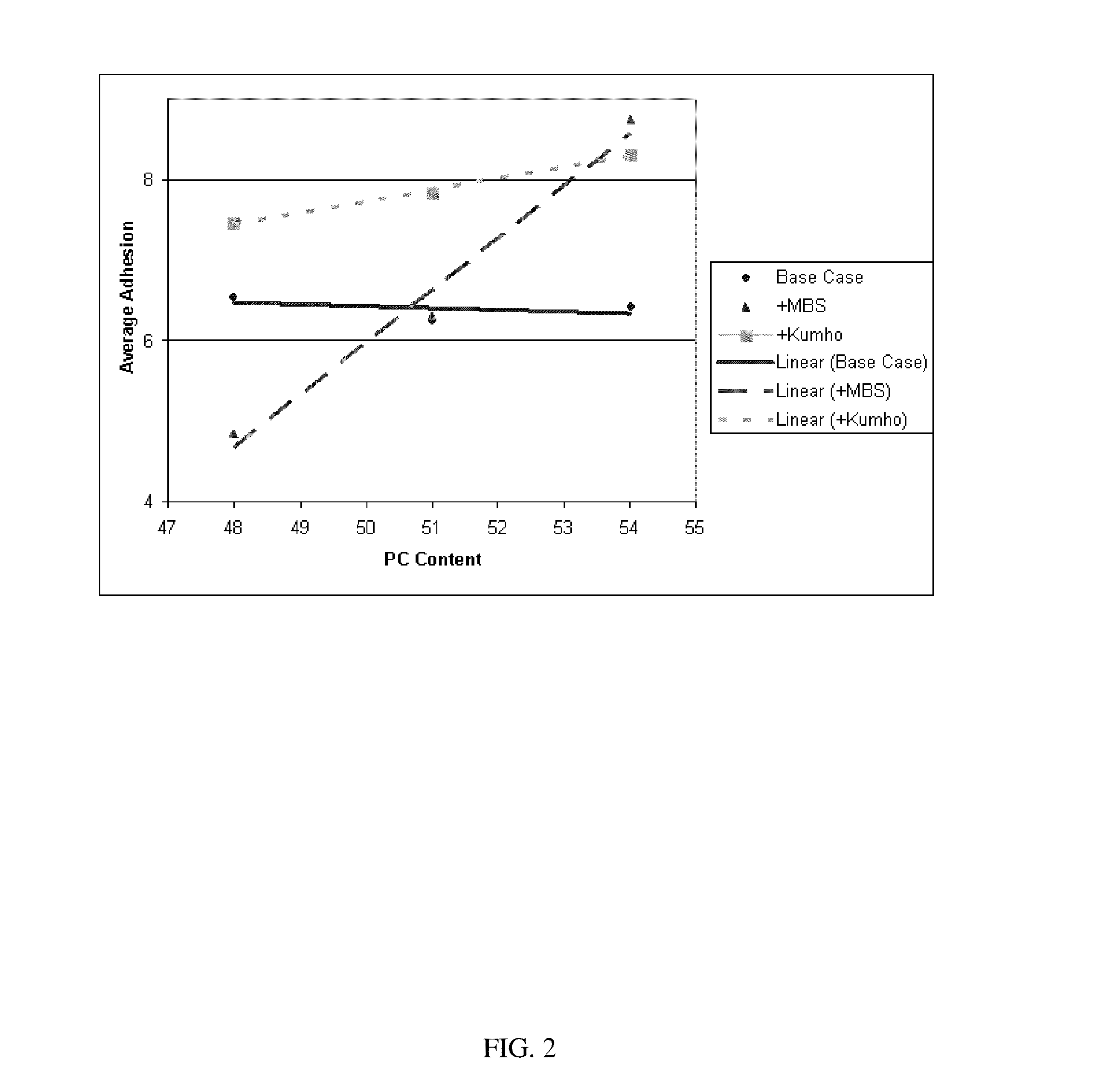

Polycarbonate blends having improved electroplate adhesion

ActiveUS20130203909A1Improved electroplate adhesion valueIncrease volumeImpression capsFilm/foil adhesivesPolycarbonatePolymer blend

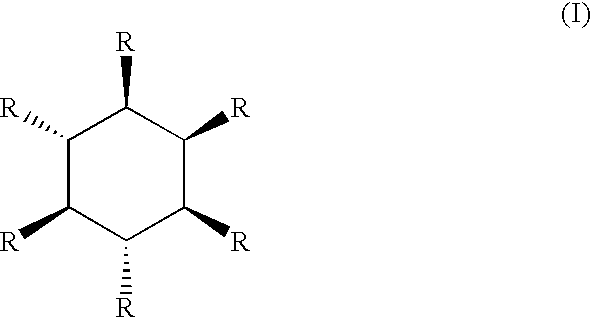

The present disclosure relates to thermoplastic polycarbonate blends compositions having, among other characteristics, improved electroplate adhesion properties. In particular, the disclosure relates to such polycarbonate compositions comprising a polycarbonate component, a primary ABS impact modifier, and a secondary impact modifier chemically different from the primary impact modifier. Also included herein are methods for preparing and / or using the same, as well as articles formed from such compositions / blends.

Owner:SABIC GLOBAL TECH BV

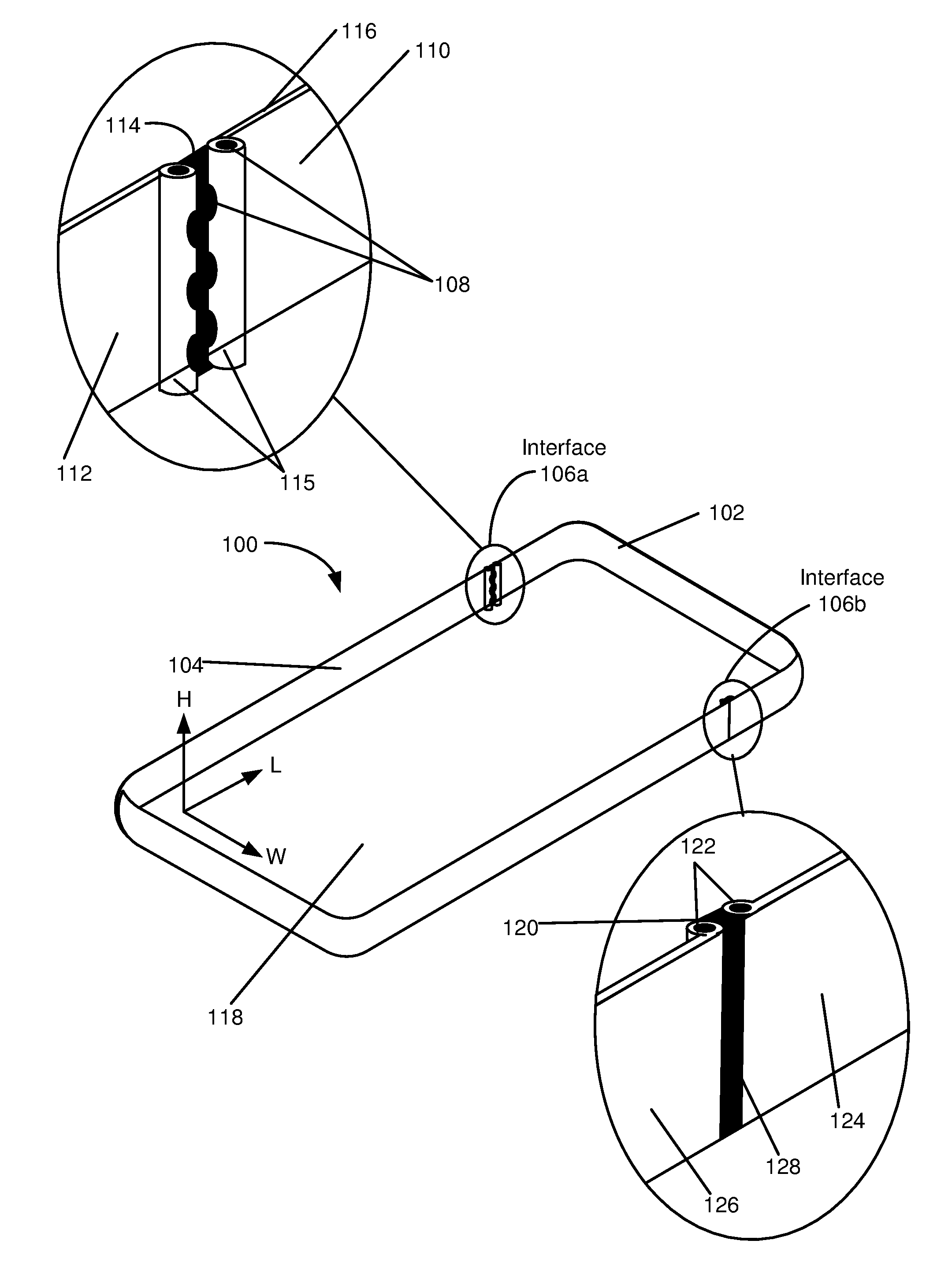

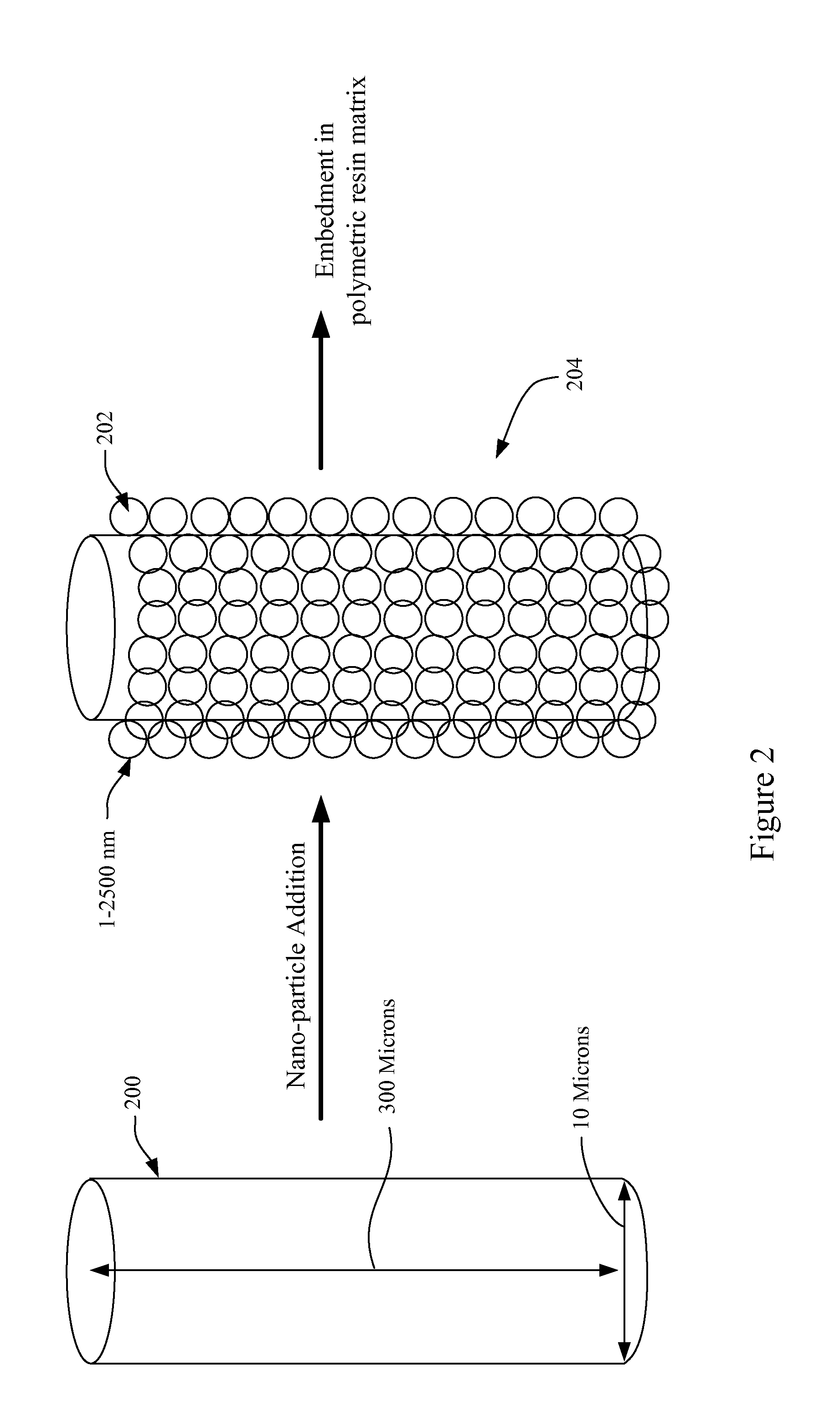

Functionalized nano-silica fiber coating for use as an adhesive layer for inorganic fibers in thermoplastic composites

InactiveUS20130034740A1Improve bindingMaterial nanotechnologyThin material handlingNanoparticleSilicon dioxide

Using nano-particles to topographically enhance the reacting surface of an inorganic fiber used as a reinforcement medium in an embedding matrix is described.

Owner:APPLE INC

Anisotropic conductive adhesive

InactiveUS7452923B2Minimizes its contractionPreventing a short circuitImpression capsConductive materialAnisotropic conductive adhesivePolymerization

The present invention discloses an anisotropic conductive adhesive comprising an insulating adhesive component and a number of conductive particles dispersed in the insulating adhesive component, wherein the insulating adhesive component contains a crosslinked rubber resin. The anisotropic conductive adhesive of the present invention prevents exfoliation of an adhesive or reduction in adhesive strength of circuit by minimizing its the heat-contraction occurring in the process of a polymerization or a hardening reaction when connecting micro-circuits, whereby a short circuit between adjacent electrodes can be prevented when connecting the circuits, and excellent connection reliability according to a long-term use is achieved.

Owner:H&S HIGH TECH +1

Photovoltaic encapsulating material with high light transmittance

InactiveCN108517188AHigh light transmittanceHigh refractive indexNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSolar lightPower flow

The invention relates to a photovoltaic encapsulating material with high light transmittance. The photovoltaic encapsulating material is prepared by premixing 100 parts by weight of matrix resin or grafting modified matrix resin of the photovoltaic encapsulating material, 0.01 to 20 parts by weight of highly transparent resin with high light transmittance and / or high refractive index, and other auxiliary agents, and then carrying out melting, extruding, tape casting, film forming, cooling, cutting, and rolling. By introducing the highly transparent resin with high light transmittance and / or high refractive index into the encapsulating material system, the refractive indexes of glass, the front-layer encapsulating material, and a battery sheet can be perfectly matched; the light transmittance of the photovoltaic encapsulating material is increased; the intensity of light projected on the battery sheet is enhanced, thus the utilization rate of solar light is increased; the current and output power of the battery are increased; and the photovoltaic conversion efficiency is optimized and increased.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Method of manufacture of styrene-butadiene latexes

The invention relates to a method for preparing styrene-butadiene latex. The styrene-butadiene latex according to the present invention is characterized by excellent adhesion due to promotion of early film formation by adjusting the gel content and molecular weight of the outermost layer, and excellent adhesion due to maintenance of paper film formation. With fast ink drying speed and high air permeability. Due to its excellent mechanical and chemical stability, latex can be used very stably for paper coatings.

Owner:LG CHEM LTD

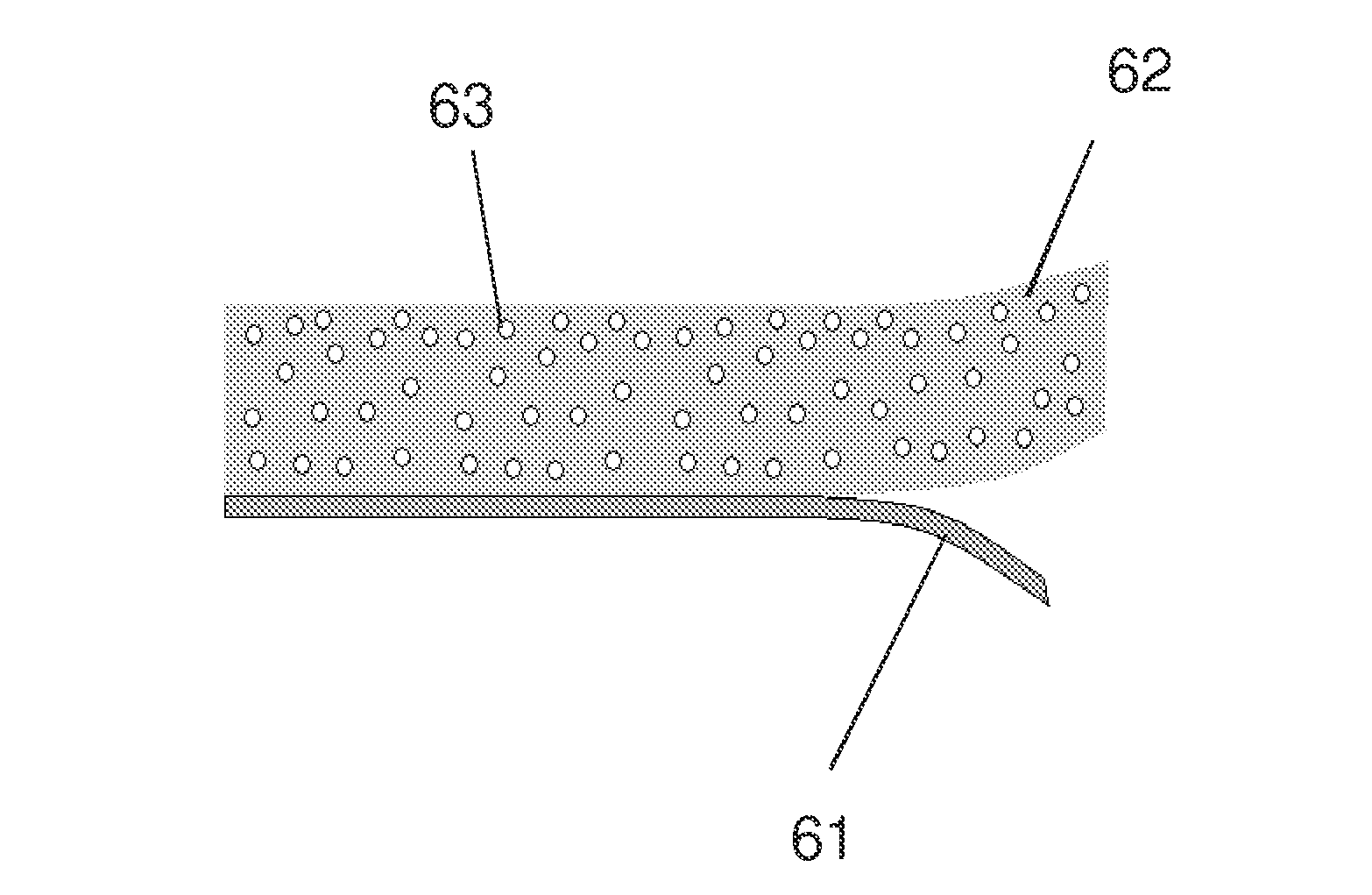

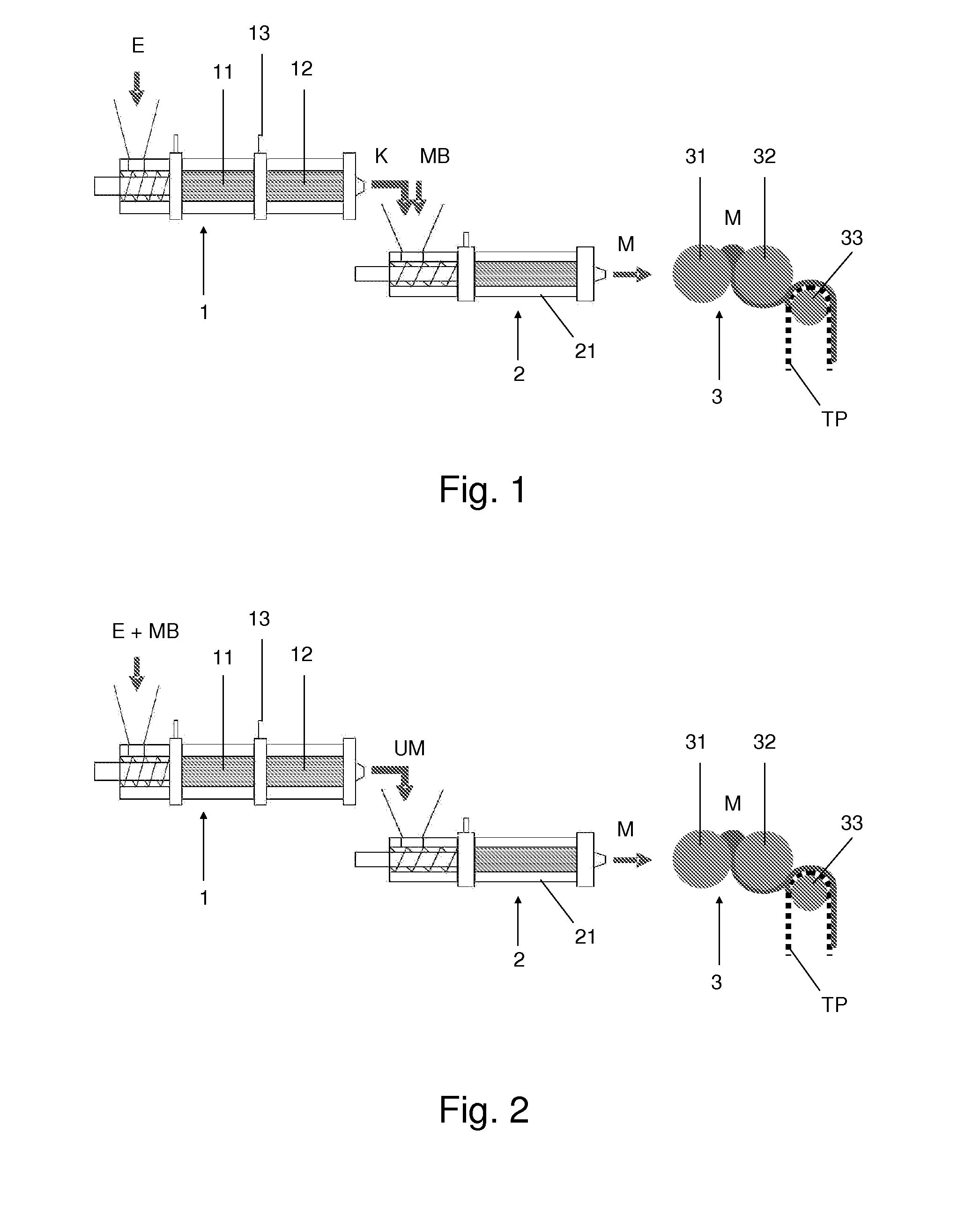

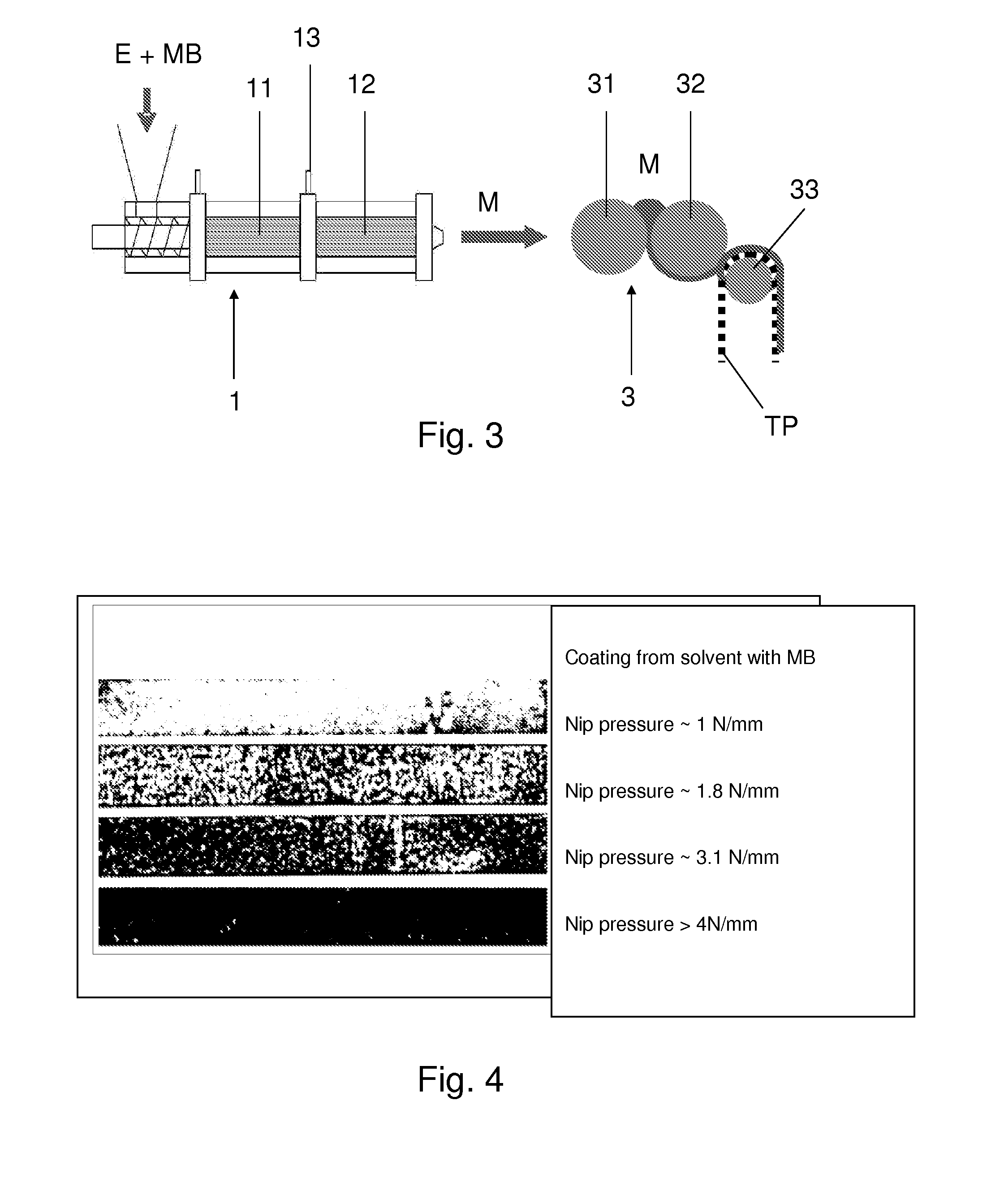

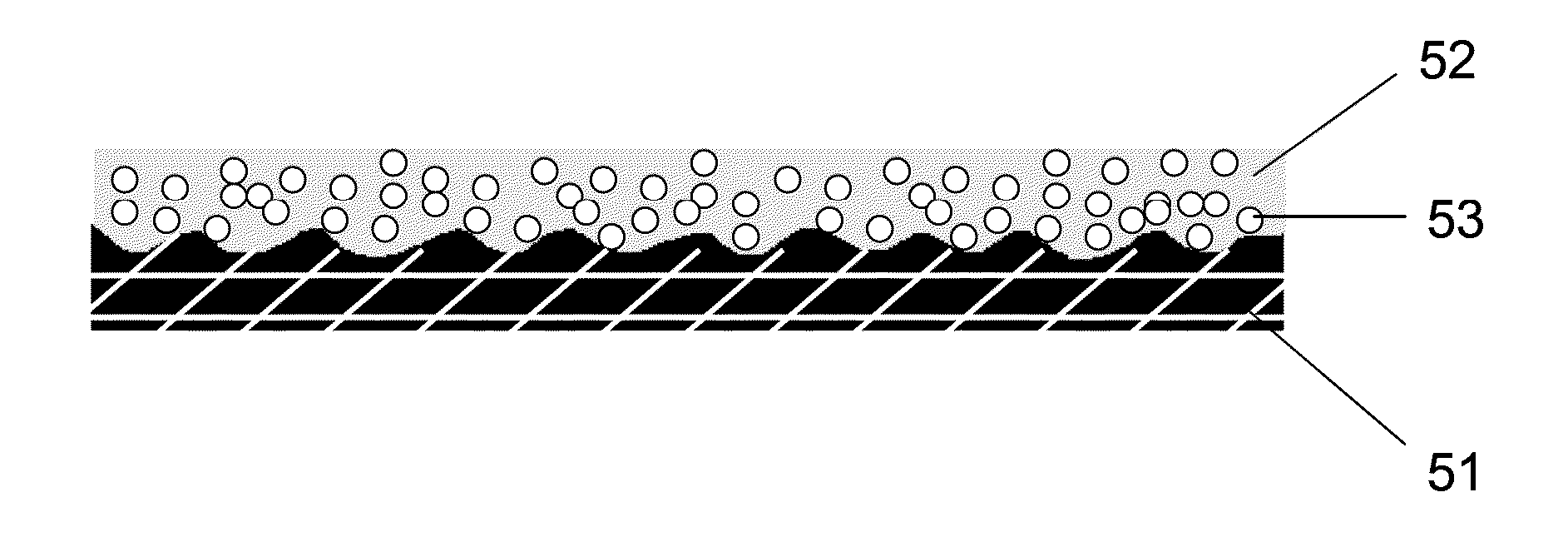

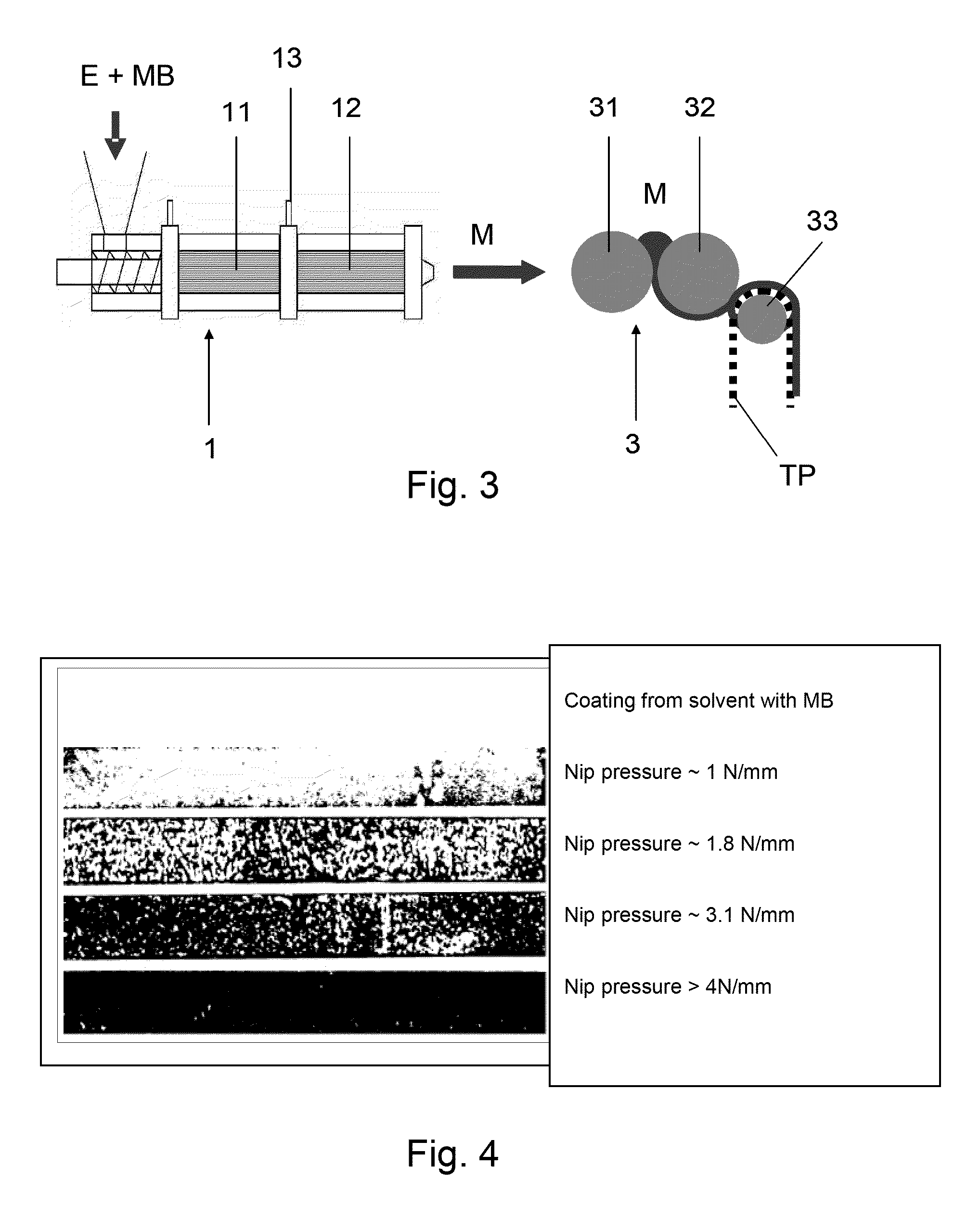

Foamed adhesive, more particularly pressure-sensitive adhesive, process for the production and also the use thereof

InactiveUS20160083549A1Natural rubber adhesivesMacromolecular adhesive additivesMicrosphereEngineering

Process for producing a pressure-sensitive adhesive comprising expanded microballoons, wherein the constituients for forming the adhesive are mixed in a first mixing assembly, the mixed adhesive is transferred into a second mixing assembly into which, at the same time, unexpanded microballoons are fed, the microballoons are expanded in the second mixing assembly or on exit from the second mixing assembly, the adhesive mixture with the expanded microballoons is shaped to a layer in a shaping assembly in which expanded microballoons which have broken through the surface are pressed into the layer surface and the layer of adhesive mixture together with the expanded microballoons are optionally applied to a weblike backing material.

Owner:TESA SE

PS-ABS (polystyrene-acrylonitrile butadiene styrene) solvent type adhesive

InactiveCN103059776AImprove hard and brittle propertiesHigh strengthHydrocarbon polymer adhesivesABS polymer adhesivesAdhesivePolystyrene

The invention relates to a PS-ABS (polystyrene-acrylonitrile butadiene styrene) solvent type adhesive. The PS-ABS solvent type adhesive is prepared from the following raw materials in parts by weight: 250-350 parts of PS resin, 40-60 parts of ABS resin and 600-700 parts of ethyl acetate. The PS-ABS resin co-mixing can greatly improve the hard and crisp performances of an adhesive layer, increase the range of applications of the adhesive disclosed by the invention and be used for adhering wood, ceramic, plastic, cloth, paper and other materials. According to the PS-ABS solvent type adhesive disclosed by the invention, the ethyl acetate is taken as a solvent, the toxicity is low, and the corrosion to a packaging material, namely a flexible aluminum pipe is small. The PS-ABS solvent type adhesive disclosed by the invention has the advantages of good adhesion with an adhered object, high strength, low toxicity, long preservation time, simplicity and convenience for use and the like.

Owner:NINGBO DINGCHENG ADHESIVE

Flame retardant adhesive composition, and adhesive sheet, coverlay film and flexible copper-clad laminate using same

InactiveUS7524394B2Excellent flame retardancy and electrical characteristicExcellent characteristicsNon-macromolecular adhesive additivesAdhesive articlesCopper foilSynthetic rubber

Provided is a flame retardant adhesive composition including (A) a halogen-free epoxy resin, (B) a thermoplastic resin and / or a synthetic rubber, (C) a curing agent, (D) a nitrogen-containing polyphosphate compound, and (E) a curing accelerator. Also provided are an adhesive sheet having a layer including the above composition, and a protective layer for covering the layer including the composition; a coverlay film having an electrically insulating film, and a layer including the above composition provided on top of the film; a flexible copper-clad laminate having an electrically insulating film, a layer including the above composition provided on top of the film, and copper foil; and a method of bonding two substrates, including the steps of sandwiching the above adhesive sheet between two substrates, and curing the adhesive sheet. Further provided are a process for producing the adhesive sheet, a process for producing the coverlay film, and a process for producing the flexible copper-clad laminate. The halogen-free adhesive composition yields a cured product, on curing, that exhibits excellent flame retardancy and anti-migration properties. The composition can be used for producing an adhesive sheet, a coverlay film, and a flexible copper-clad laminate. The adhesive sheet can be used for a method of bonding two substrates.

Owner:SHIN ETSU CHEM CO LTD

Pressure-sensitive adhesive product and substrate for pressure-sensitive adhesive product

InactiveUS20060154056A1Improve heat resistanceImprove rigidityLayered productsFilm/foil adhesivesAcrylic rubberAcrylonitrile

The pressure-sensitive adhesive product has a constitution wherein a pressure-sensitive adhesive layer is formed on at least one surface of a substrate, the substrate being formed from a resin composition containing an acrylonitrile-styrene copolymer and an acrylonitrile-styrene-acrylic rubber copolymer as main components and the weight ratio of the acrylonitrile-styrene copolymer to the acrylonitrile-styrene-acrylic rubber copolymer being 90 / 10 to 20 / 80. The above resin composition preferably has a form where the acrylonitrile-styrene-acrylic rubber copolymer is dispersed in the acrylonitrile-styrene copolymer.

Owner:NITTO DENKO CORP

Wear-resistant resin adhesive

InactiveCN104710955ANo bubblesFlat surfaceNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesWear resistantMoisture resistance

The invention discloses a wear-resistant resin adhesive, which comprises the following components, by mass, 50-80 parts of an epoxy resin pouring sealant, 100-120 parts of a bisphenol A epoxy resin, 120-150 parts of a phenolic resin, 100-150 parts of a non-saturated resin, 150-200 parts of an ABS resin, 100-150 parts of a polyester resin, 120-180 parts of a polyamide resin, 100-120 parts of a rosin resin, 20-30 parts of polytetrafluoroethylene micro powder, 30-35 parts of a polysiloxane compound wear-resistant agent, 15-20 parts of a calcium oxide lubricant, 10-15 parts of a dispersant, and 10-15 parts of a brightener. The cured wear-resistant resin adhesive has no bubble, is flat in surface, good in glossiness, high in hardness, and excellent in leakproofness, has good properties of high temperature resistance, acid and alkali resistance, water resistance, wear resistance, oil resistance, moisture resistance, water resistance, oil resistance, dirt resistance, humidity and heat resistance, and atmospheric ageing resistance, and has excellent electrical and physical characteristics such as electrical insulation, thermal conductivity, flame resistance, stress resistance, and high bonding strength.

Owner:张国华

Polyvinylbutyral compositions and blends having enhanced surface properties and articles made therefrom

The present invention provides a polymer blended compositions toughened with polyvinylbutyral having enhanced adhesive surface properties, including enhanced surface adhesion and low surface gloss, are disclosed. Also disclosed are articles of manufacture comprising the compositions described herein.

Owner:EI DU PONT DE NEMOURS & CO

Two-component acrylate structure adhesive with high strength and excellent stability and preparation method of two-component acrylate structure adhesive

PendingCN110218547AImprove stabilityExtended shelf lifeNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAviationEpoxy

The invention discloses a two-component acrylate structure adhesive with high strength and excellent stability and a preparation method of the two-component acrylate structure adhesive. The two-component acrylate structure adhesive is composed of a component A and a component B, and the volume ratio of the component A to the component B is 10:1. The component A comprises the following raw materials in percentage by weight: 30-70% of an acrylate monomer, 10-40% of a flexibilizer, 0.1-5% of a stabilizer, 0.1-5% of an accelerant and 0.1-5% of a reducing agent; and the component B comprises the following raw materials in percentage by weight: 10-40% of an epoxy resin, 0.1-10% of a graphene derivative, 10-50% of a plasticizer, 5-40% of an oxidizing agent, 0.1-2% of a polymerization inhibitor and 0.1-2% of a compound coupling agent. The acrylate structure adhesive disclosed by the invention has the advantages of capacity of being rapidly and completely cured at a normal temperature, excellent manufacturability, excellent stability, high strength and the like, and is applicable to the fields of machinery, sport equipment, automobiles, electronics and electrical appliances, military industry, solar photovoltaic, space flight and aviation and the like.

Owner:广州正琪新材料科技有限公司

TPV thermoplastic elastomer with excellent adhesive property and preparation method thereof

InactiveCN109370482ANo pollutionConvenient sourceMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesRecreationThermoplastic elastomer

The invention relates to a TPV thermoplastic elastomer with an excellent adhesive property and a preparation method thereof. The TPV thermoplastic elastomer comprises the following raw materials in parts by weight: 15-30 parts of EPDM, 10-20 parts of PP, 10-20 parts of SEBS, 1-5 parts of EVA, 1-5 parts of TPU, 1-5 parts of C5 petroleum resin, 1-5 parts of terpene resin, 10-30 parts of softening oil, 15-20 parts of ABS resin, 1-3 parts of MBS resin, 1-3 parts of PA, 3-5 parts of a vulcanizing agent, 1-2 parts of antioxidant and 1-2 parts of an anti-aging agent. The TPV thermoplastic elastomer provided by the invention is prepared in the manner of twice extruding pelletizing through a twin screw parallel mixing type extruder; the invention mainly solves the problem of poor adhesive propertyof the TPV thermoplastic elastomer with other materials; processing property and abrasion resistance of the TPV thermoplastic elastomer are both greatly promoted, so that the TPV thermoplastic elastomer can be applied to the fields of home appliances, automobiles, recreation and sports, medical treatment, and the like, and especially can be applied to automotive trim leather.

Owner:湖北恒标塑胶股份有限公司

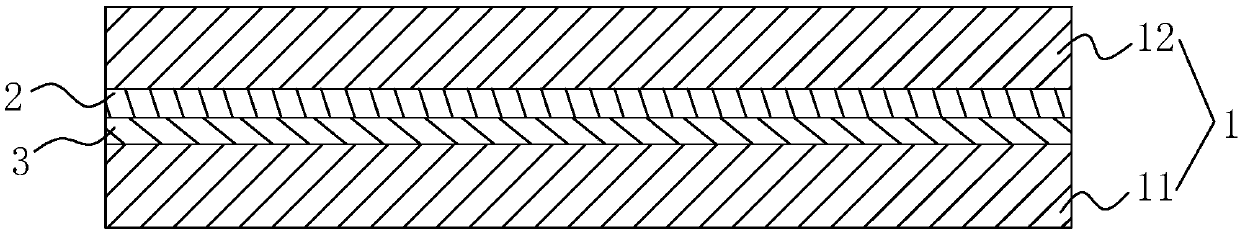

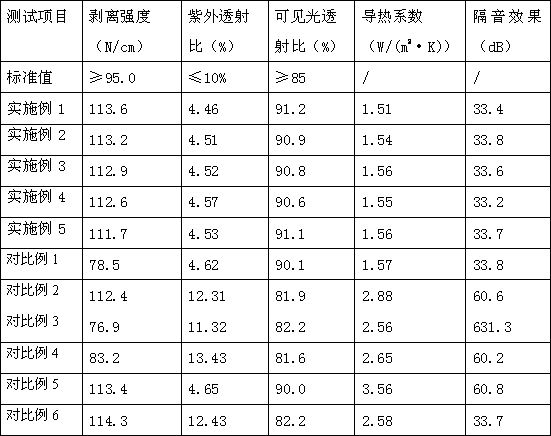

Gradient laminated glass and preparation technology thereof

ActiveCN109648954AGood shading effectImprove barrier propertiesNon-macromolecular adhesive additivesSynthetic resin layered productsUltravioletGlass sheet

The invention discloses a gradient laminated glass and a preparation technology thereof. The gradient laminated glass comprises a glass sheet, a soundproof film and a gradient film, the glass sheet comprises a first glass sheet and a second glass sheet, the soundproof film and the gradient film are located between the first glass sheet and the second glass sheet, and the soundproof film is in contact with the second glass sheet; and the soundproof film comprises PVB resin, trans-polyisoprene rubber, a plasticizer, hollow glass beads, ABS resin, a maleic anhydride-grafted ethylene-vinyl acetatecopolymer, a borax crosslinker, modified diatomite, bentonite, glass fibers, rosin, a heat insulating material and an ultraviolet absorber. The preparation technology of the gradient laminated glasscomprises the following steps: S1, cleaning the glass sheet; S2, sheet combination; S3, hot press molding. The gradient laminated glass of the invention has the advantages of good soundproof effect and high carrying capacity.

Owner:江苏儒耀装饰设计道具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com