Isotropic conductive adhesive and adhesive film using the same

一种各向异性、导电性的技术,应用在导电性粘接剂领域,能够解决电极间隔缩小、易发生剥离、短路等问题,达到防止短路现象、长期可靠性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

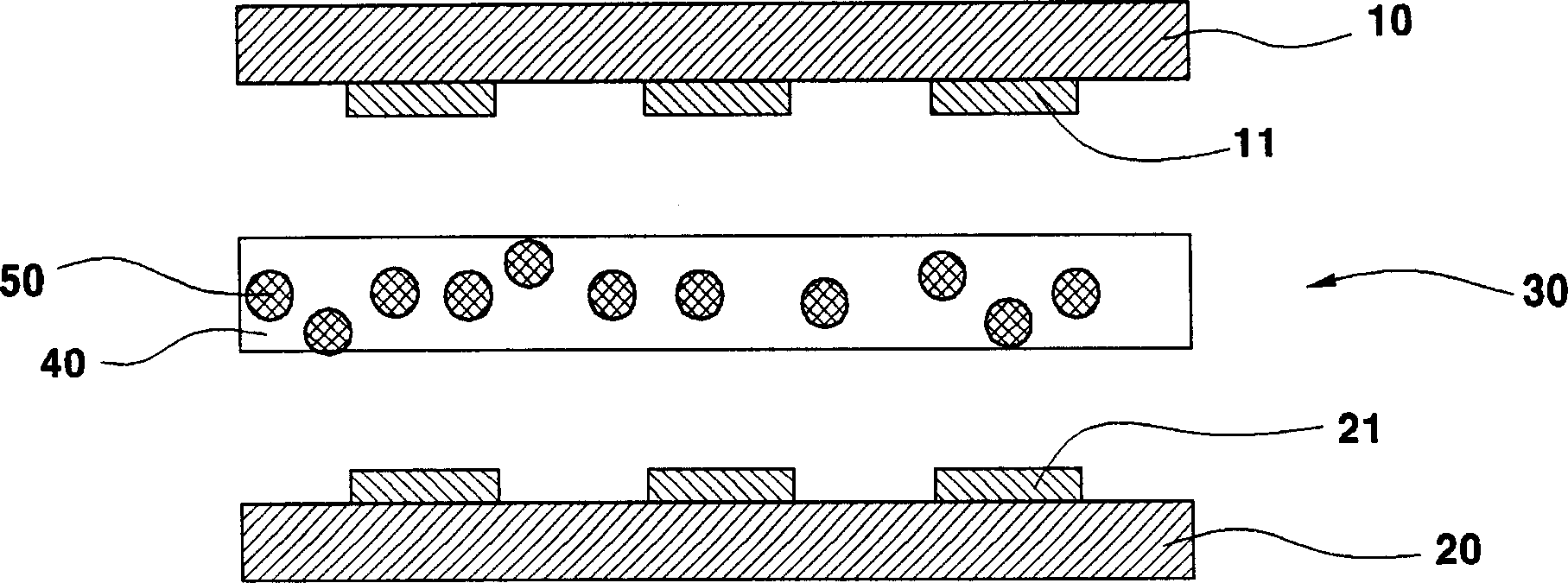

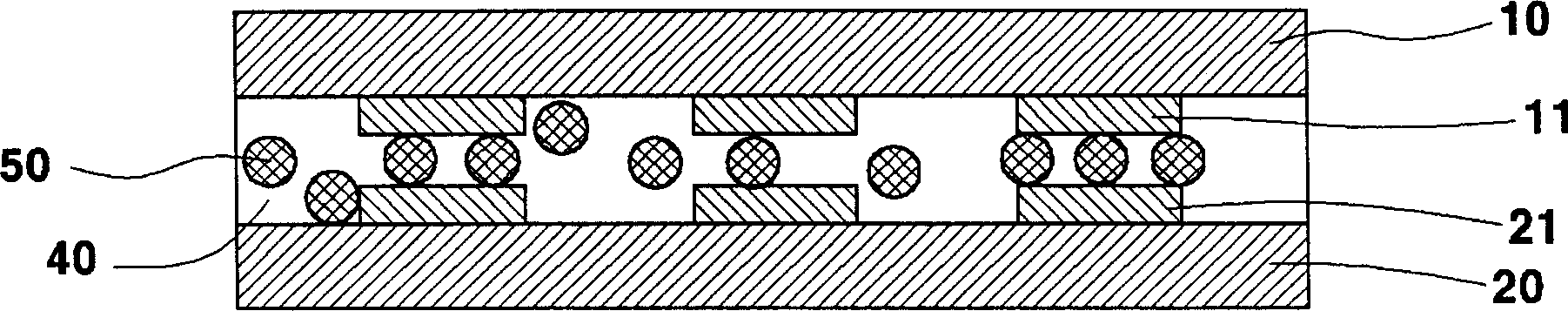

Method used

Image

Examples

Embodiment 1

[0036] 50 grams of phenoxy resin (Inchem Inc., trade name PKHC, average molecular weight 45000) was dissolved in toluene (boiling point 110.6°C, SP value 8.90) / acetone (boiling point 56.1°C, SP value 10.0) at a weight ratio of 50 / 50 In the mixed solvent, a solution with a solid content of 40% was obtained. Next, add radical polymerizable resin, 25 grams of ethylene glycol modified bisphenol A diacrylate (Donga Synthesis Co., trade name M-210); polymerization initiator, 5 grams of tert-hexylperoxy-2-ethyl Caproic acid ester (Nipponushi Inc., trade name パ一キュア HO); cross-linkable rubber resin, 7 grams of EPDM (Kumhopolychem Co., trade name Vistalon 503K) with a Mooney viscosity of ML1+4@100°C: 34 At this time, in an amount of 3% by volume of the adhesive component, conductive particles composed of metal-coated resin particles (Jeoksoo Chemical Co., trade name Micropearl AU205, 5.0 μm) were added thereto, and then dispersed uniformly , Preparation of anisotropic conductive adhesive. A...

Embodiment 2

[0038] Except that the added crosslinkable rubber resin is 7 grams of EPDM (Kumhopolychem Co., trade name KEP-330, Mooney viscosity is ML1+4@125°C: 28), the same method as in Example 1 is used to produce Anisotropic conductive adhesive film.

Embodiment 3

[0040] Except that the added crosslinkable rubber resin is 7 grams of butyl rubber resin (InterService, trade name BK-1675N, Mooney viscosity is ML1+8@125°C: 47-54), the same as in Example 1 is adopted. The method to produce anisotropic conductive adhesive film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com