Gradient laminated glass and preparation technology thereof

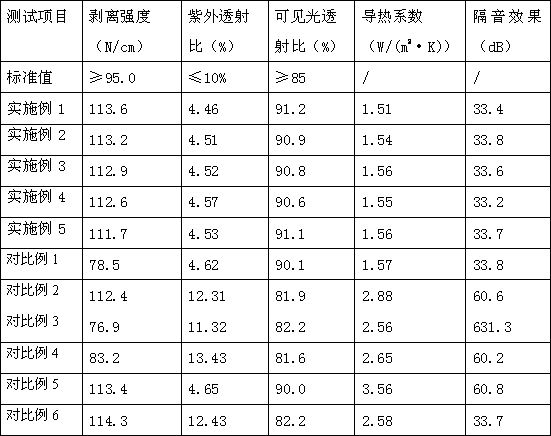

A technology of laminated glass and glass, applied in glass/slag layered products, adhesives, acrylonitrile butadiene styrene polymer adhesives, etc., can solve the problem of reduced bearing capacity of laminated glass and poor sound wave blocking effect , small shear modulus, etc., to achieve the effect of good UV protection, good sound insulation, and improved bonding tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

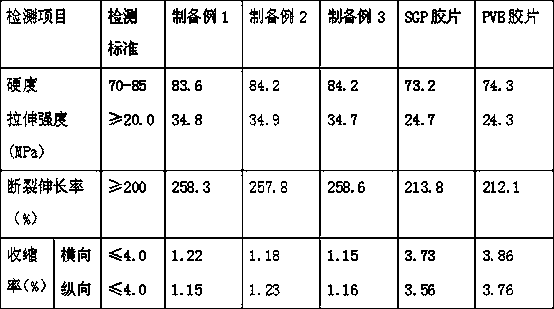

preparation example 1-3

[0043] The maleic anhydride grafted vinyl acetate copolymer is selected from the model EVA-G-MAH type maleic anhydride grafted vinyl acetate copolymer sold by Nanjing Deba Polymer Material Co., Ltd., and the trans polyisoprene rubber is selected from the above The model sold by Haishucan Industrial Co., Ltd. is yc-8742 trans-polyisoprene rubber. The PVB resin is selected from SD-5 PVB resin sold by Qingdao Haocheng Industrial Co., Ltd., and the ABS resin is selected from Suzhou Qiaoshun Plastic Chemical Co., Ltd. The PA-717C ABS resin sold by the company, the borax crosslinking agent is selected from the DS-PS pentahydrate borax of Guangzhou Desheng Chemical Co., Ltd., and the bentonite is selected from the QGF bentonite sold by Lingshou County Jingkun Mineral Products Processing Factory , the silica airgel powder is selected from the silica airgel powder powder of Hongda Technology (Beijing) Co., Ltd. with a particle size of 5-10 μm.

preparation example 1

[0044] Preparation Example 1: (1) According to the ratio in Table 1, stir 0.3kg of trans polyisoprene rubber at 70°C for 10 minutes, add 40kg of PVB resin heated to 60°C into trans polyisoprene rubber In, after mixing evenly, add 1kg of plasticizer, mix evenly, the plasticizer is tributyl citrate;

[0045] (2) Heat 15kg of rosin to 135°C, then mix and grind 10kg of modified diatomite, 5kg of bentonite, 1kg of heat insulating material, 5kg of ultraviolet absorber and 1kg of glass fiber until the particle size is 2μm. The final powder is added to the rosin and mixed evenly;

[0046] Among them, the modified diatomite is prepared by the following method: mix 10kg of diatomite with 40kg of sulfuric acid solution with a mass fraction of 10%, heat to 40°C, stir for 20min, cool and stand still, wash until the pH is 6.8, and then It is dried at 100° C. for 30 min;

[0047] The heat insulation material is a mixture of ferric oxide, indium tin oxide and silica airgel powder with a mas...

preparation example 2

[0051] Preparation Example 2: (1) According to the ratio in Table 1, stir 0.5kg of trans polyisoprene rubber at 75°C for 15 minutes, add 50kg of PVB resin heated to 65°C into trans polyisoprene rubber In, after mixing evenly, add 3kg plasticizer, mix evenly, plasticizer is epoxy soybean oil;

[0052] (2) Heat 18kg of rosin to 145°C, then mix and grind 13kg of modified diatomite, 8kg of bentonite, 3kg of heat insulating material, 8kg of ultraviolet absorber and 3kg of glass fiber until the particle size is 4μm. The final powder is added to the rosin and mixed evenly;

[0053] Among them, the modified diatomite is prepared by the following method: mix 13kg of diatomite with 50kg of sulfuric acid solution with a mass fraction of 15%, heat to 50°C, stir for 25min, cool and stand still, wash until the pH is 7.0, and then It is dried at 103° C. for 40 min;

[0054] The heat insulation material is a mixture of ferric oxide, indium tin oxide and silica airgel powder with a mass rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com