Patents

Literature

109results about How to "Improved UV protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet-proof nano-fiber yarn and preparation method thereof

InactiveCN105839253AGood mechanical tensile propertiesHigh mechanical tensile propertiesElectro-spinningYarnHeat resistanceElectrospinning

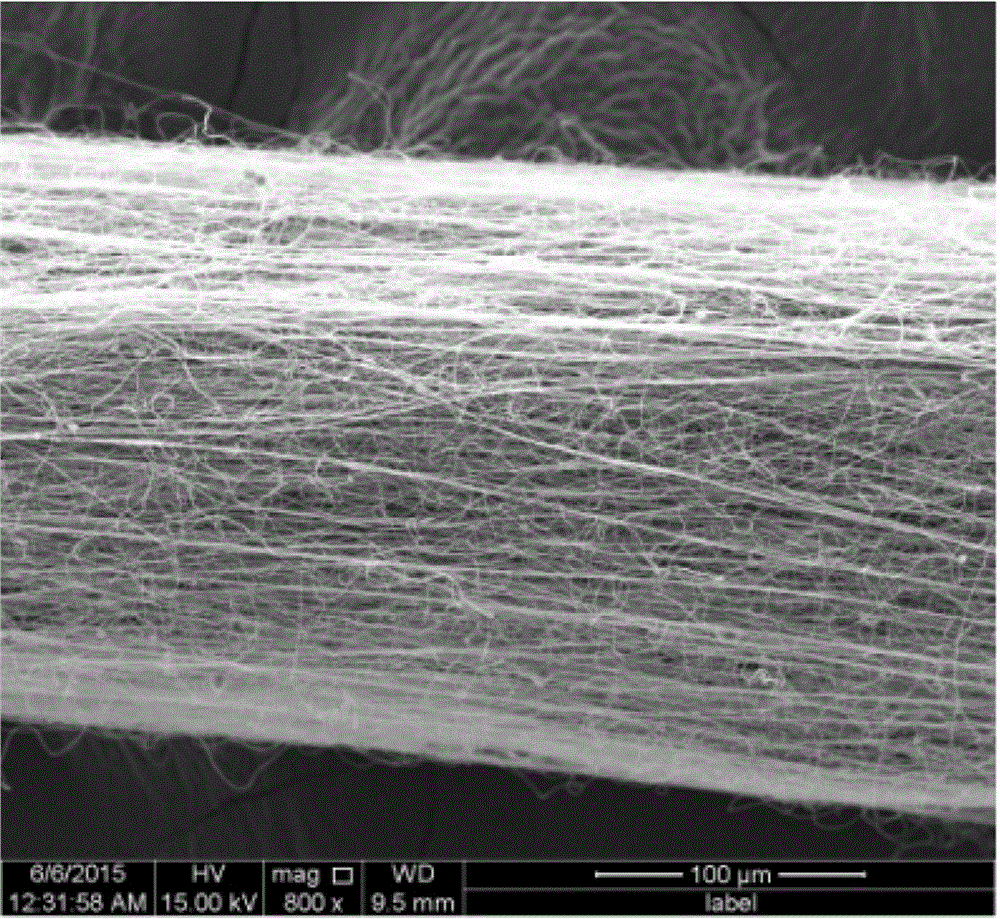

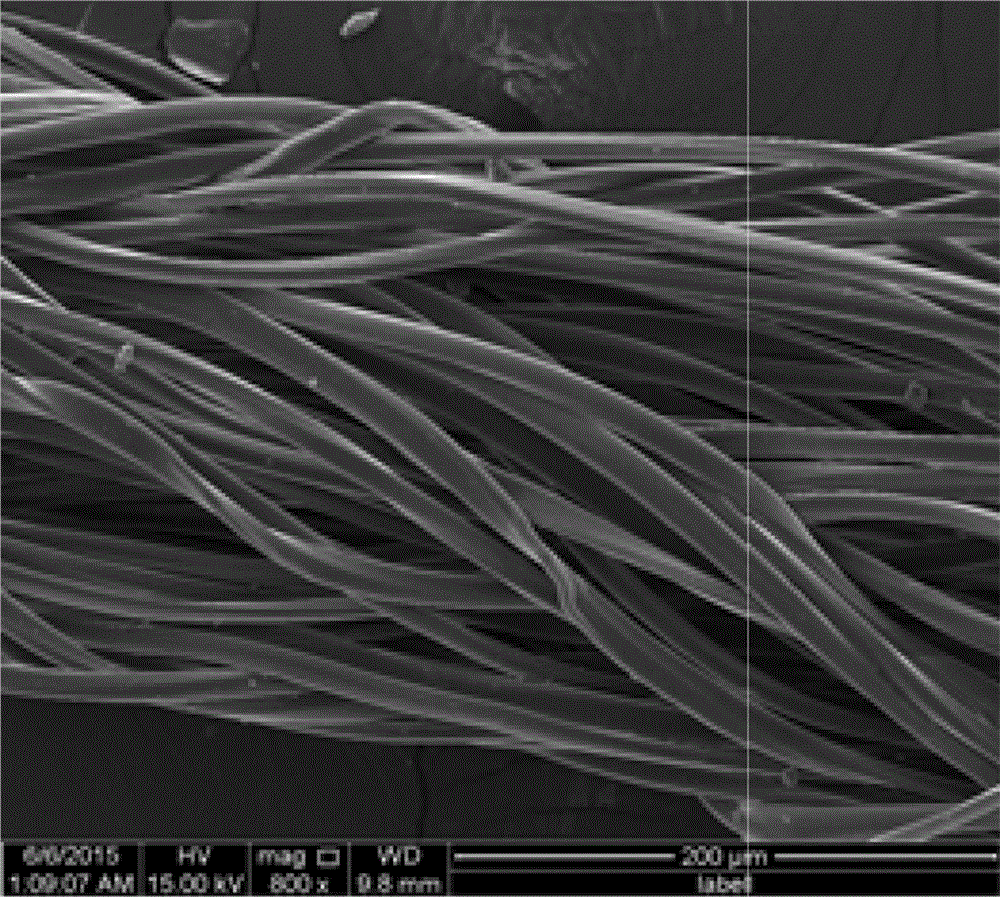

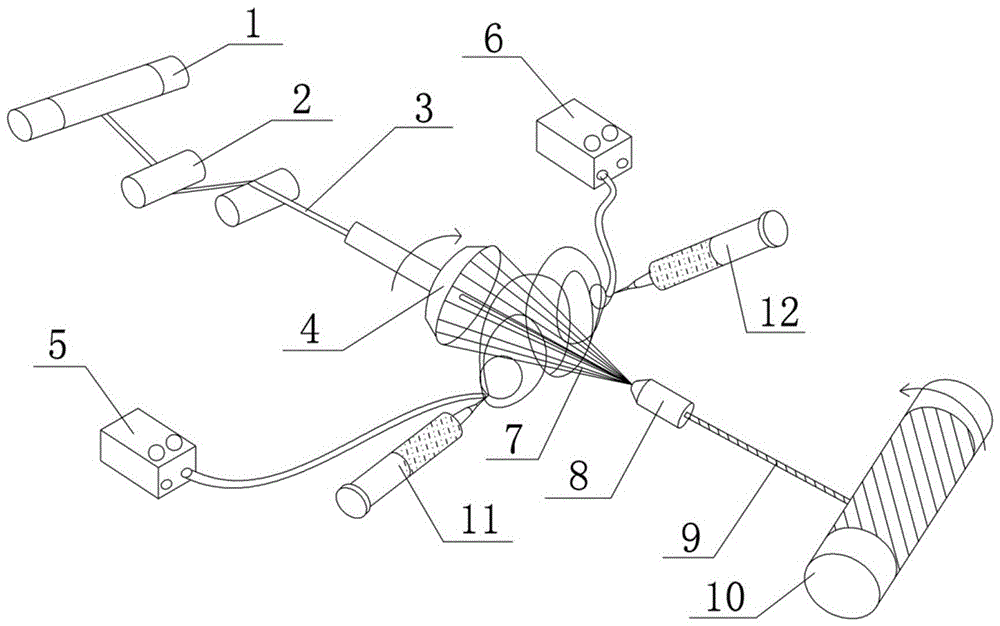

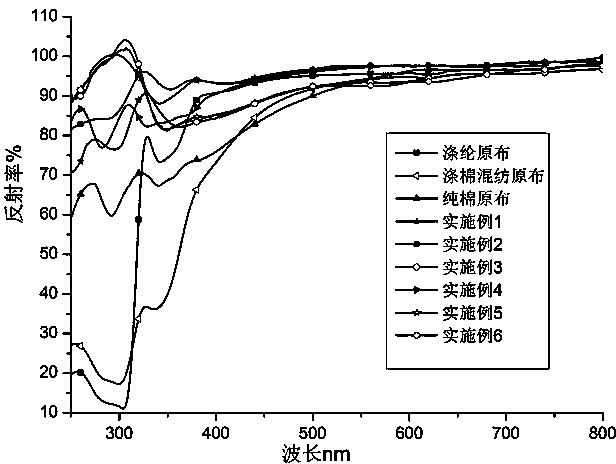

The invention discloses an anti-ultraviolet nanofiber yarn and a preparation method thereof. The anti-ultraviolet nanofiber yarn is a nanofiber-wrapped yarn structure, including a core and a skin layer completely and uniformly covering the outer surface of the core. The core is filament yarn or short fiber yarn, the cortex is electrospun nanofiber, and ultraviolet shielding agent or ultraviolet absorber is evenly distributed inside the electrospun nanofiber. The preparation method is a one-time forming method by electrospinning. During the electrostatic spinning, a nanofiber yarn machine is used for one-time forming production process. Under the coupling action of positive and negative electric fields, the surface of the yarn is directly coated with anti-ultraviolet nanofibers. The anti-ultraviolet nanofiber yarn of the present invention can achieve the comprehensive effect of anti-ultraviolet, antibacterial and antibacterial, and hydrophilic and comfortable, has good heat resistance and strong washability, and can be formed in one time during the production process, which can effectively save cost and energy.

Owner:HENAN INST OF ENG

White printing paste, preparation method and application of white printing paste

The invention discloses white printing paste, a preparation method and application of white printing paste. The white printing paste comprises the following components in parts by weight: 1 to 20 parts of white pigment, 2 to 5 parts of a thickening agent, 5 to 30 parts of an adhesive, 0.1 to 2 parts of a dispersing agent, and 43 to 91.9 parts of deionized water. The preparation method comprises the following steps: adding the dispersing agent and white pigment to deionized water under normal temperature; oscillating to uniformly disperse the pigment; then adding the thickening agent and the adhesive; agitating to obtain white printing paste; uniformly printing the white printing paste to a base fabric through a screen printing machine; preliminarily drying and then drying again; and then performing standard water washing to obtain snow pretending protective fabrics. According to the white printing paste and the preparation method, the printing technique is simple, the process is short; and the printed fabrics have snow pretending and ultrasonic proofing effects, and are also outstanding in wearability.

Owner:ZHEJIANG SCI-TECH UNIV +1

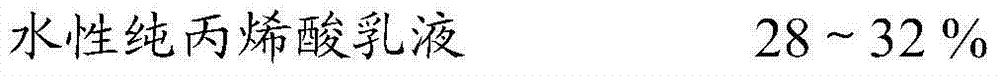

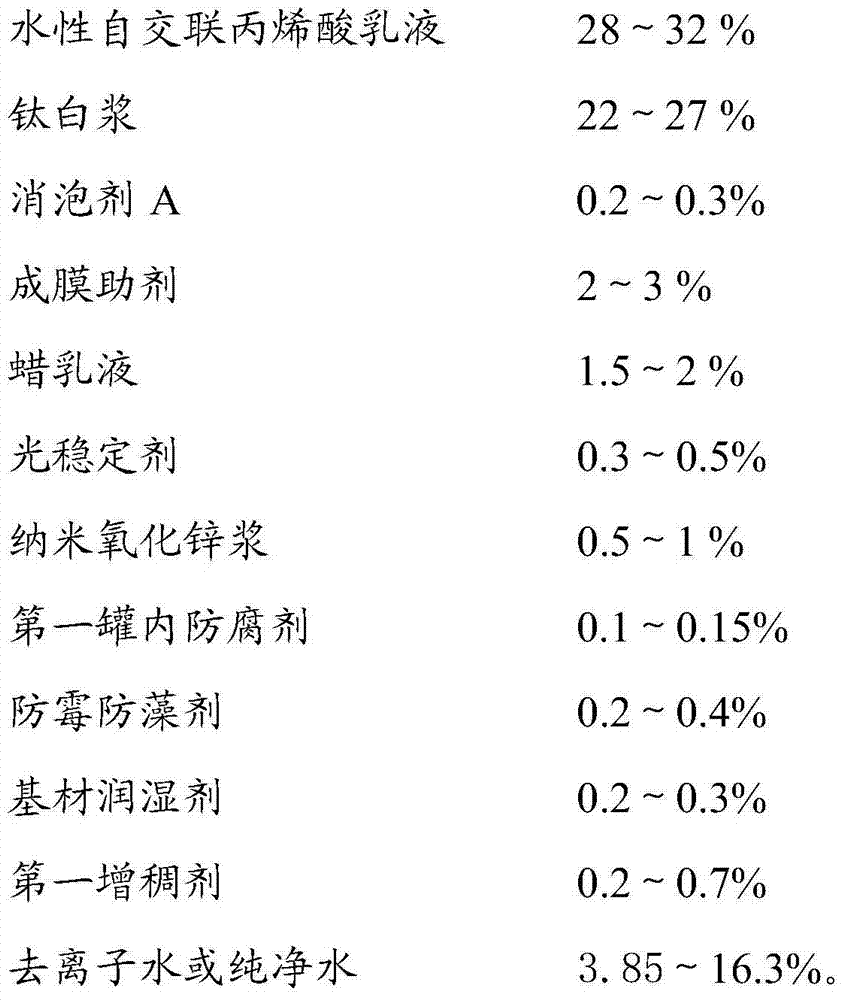

High-weather-resistance high-stain-resistance white paint for outdoor woodware and preparation method of paint

The invention discloses high-weather-resistance high-stain-resistance white paint for outdoor woodware and a preparation method of the paint. The high-weather-resistance high-stain-resistance white paint for the outdoor woodware comprises the following components in percentage by weight: 28-32% of water-based pure acrylic emulsion, 28-32% of water-based self-crosslinking acrylic emulsion, 22-27% of titanium dioxide pulp, 0.2-0.3% of a defoaming agent A, 2-3% of a film forming additive, 1.5-2% of wax emulsion, 0.3-0.5% of a light stabilizer, 0.5-1% of nanometer zinc oxide pulp, 0.1-0.15% of a first in-tank preservative, 0.2-0.4% of mildew-proof algaecide, 0.2-0.3% of a substrate wetting agent, 0.2-0.7% of a first thickening agent and 3.85-16.3% of deionized water or purified water. The high-weather-resistance high-stain-resistance white paint for the outdoor woodware is resistant to weather, stain and water, low in smell and VOC and excellent in environmental protection and safety comprehensive performances; the preparation method is simple in process and low in cost.

Owner:CHINA PAINT MFG CO SHENZHEN

Preparation method for sodium alginate-nano silicon dioxide compound film

The invention discloses a preparation method for a sodium alginate-nano silicon dioxide compound film. Through a series of technical means of performing in-situ compounding on sodium alginate and nano silicon dioxide, performing ultrasonic defoaming treatment before film casting, increasing the concentration of sodium alginate by step control in a preparation process, controlling addition time and speed of hydrochloric acid and the like, so that nano silicon dioxide is ideally dispersed in a reaction system, an agglomeration phenomenon is avoided, and the sodium alginate / nano silicon dioxide film which is compact in structure, colorless, transparent, airtight, high in quality, degradable, good in waterproof performance and strong in ultraviolet-proof capability, has comprehensive performance indexes and is suitable for food packaging is prepared. Compared with the prior art, the preparation method has the characteristics of simple and easily controlled process, low preparation cost and the like.

Owner:QINGDAO UNIV

Preparation method of nano zinc oxide modified polyester fiber

InactiveCN102345179AInhibit unstable factorsEvenlyFilament/thread formingMonocomponent polyesters artificial filamentNano zinc oxidePolyester

The invention relates to a preparation method of a nano zinc oxide modified polyester fiber, and the method comprises the following steps: preparing the slices of the nano zinc oxide modified polyester fiber; and spinning by virtue of a blended FDY (Fully Drawn Yarn) technology. The preparation method disclosed by the invention can be finished on the common spinning equipment, silk flock strips are dry and even, colors are evenly distributed, the fabric is flat, and the polyester fiber has soft gloss. The preparation method can be widely applied to the fields of clothes, decoration and industry.

Owner:JIANGSU YINGXIANG FIBER

Bedding fabric with antibacterial and cool functions and post-finishing process thereof

InactiveCN103132196AGood hygroscopicityRefreshingSolvent-treatmentBiochemical fibre treatmentPolymer scienceSpinning

The invention discloses bedding fabric with antibacterial and cool functions and a post-finishing process thereof. The bedding fabric is formed by weaving blended yarn with antibacterial and cool functions. The blended yarn with antibacterial and cool functions is formed by blending linen fiber, chitin fiber staple and polyester filament yarn according to sirofil spinning technology. In the blended yarn with antibacterial and cool functions, the linen fiber and the chitin fiber staple are both wrapped on the surface of the polyester filament yarn. The post-finishing process includes the following steps: desizing and scouring-singeing-bleaching repeatedly through chlorine oxygen-cellulase washing-dying-washing and gentle stretching-preshrinking-finished products. The fabric finished products has cool touch, excellent antibacterial performance and good crease resistance. Compared with pure linen fabric, the fabric is soft. Simultaneously compared with chitin fabric, the fabric has a certain body and is appropriate for bedding fabric in spring and summer.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

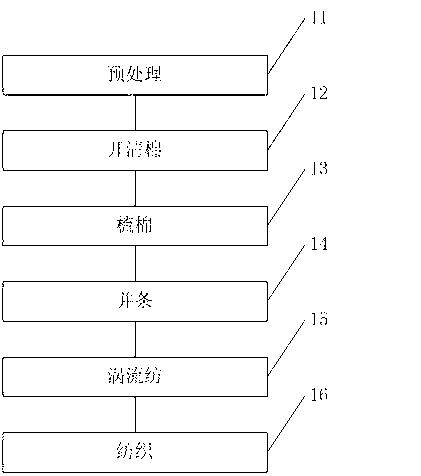

Ultraviolet-proof shell fabric and manufacturing method thereof

The invention discloses an ultraviolet-proof shell fabric and a manufacturing method thereof. The ultraviolet-proof shell fabric comprises the following raw materials in percentage by weight: 30%-70% of natural bamboo fibers and 30%-70% of polyester fibers. The manufacturing method comprises the steps of processing the natural bamboo fibers and the polyester fibers into core-spun yarns by a vortex spinning process, and then processing the core-spun yarns into the shell fabric with three-dimensional patterns by twisting and tattling. The shell fabric has a good ultraviolet-proof effect, is light, dry and breathable, overcomes the defects that the conventional clothes made from natural bamboo fibers is poor in abrasion resistance and easy to be damaged, and is applicable to manufacture of comfortable clothes worn in summer.

Owner:HANGZHOU CANSU GARMENT

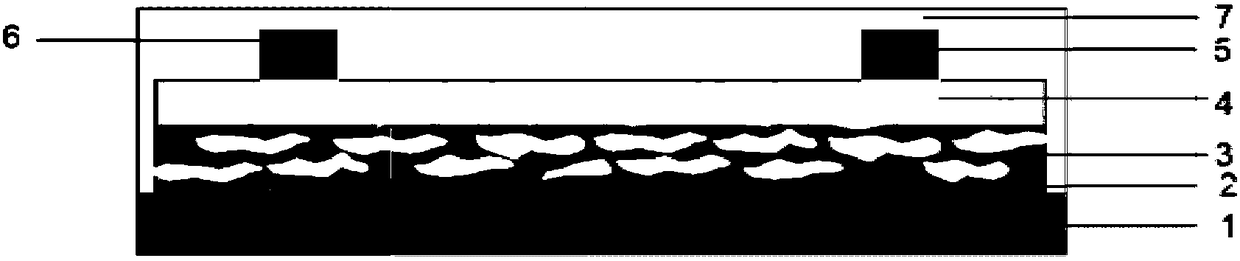

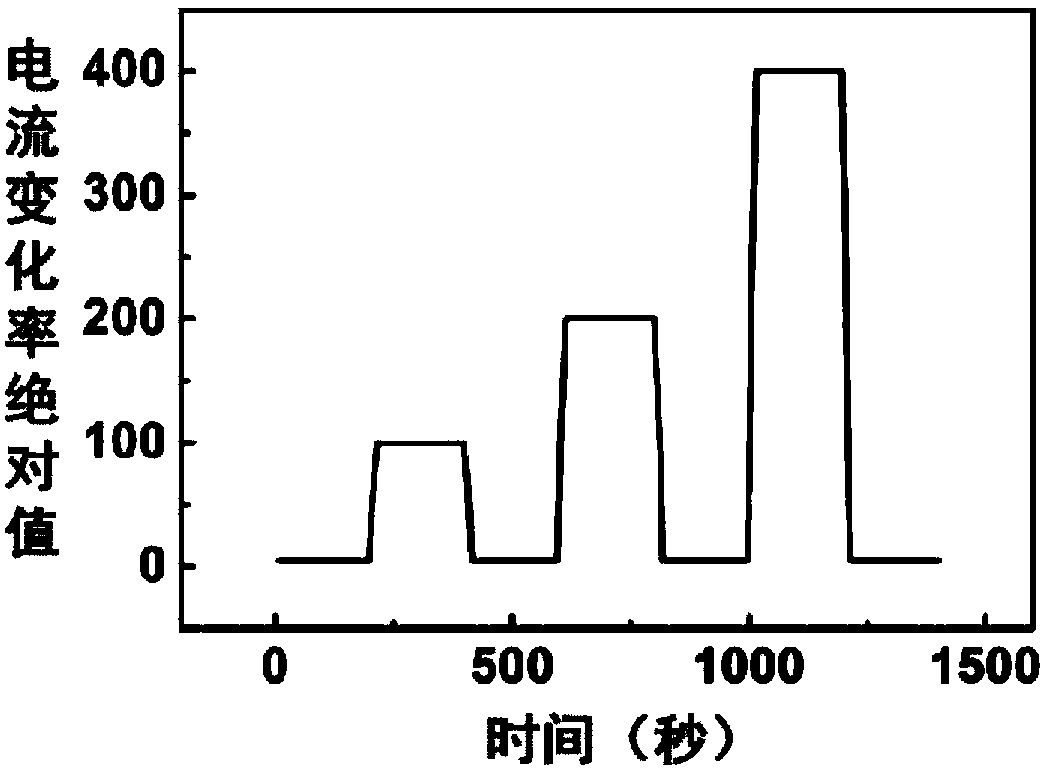

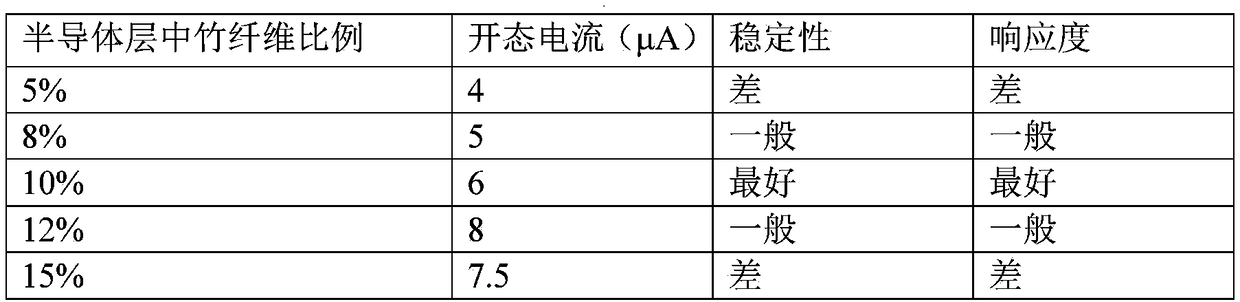

Pressure sensor based on organic field effect transistor and preparation method thereof

ActiveCN108225621AHigh dielectric constantRealize high sensitivity and high response detectionPiezoelectric/electrostrictive device manufacture/assemblySolid-state devicesCelluloseFiber

The invention discloses a pressure sensor based on an organic field effect transistor and a preparation method thereof. The pressure sensor based on the organic field effect transistor comprises a substrate arranged at the lowest layer, wherein a gate electrode is arranged on the surface of the substrate, a dielectric layer is arranged on the upper surface of the substrate and the gate electrode,a semiconductor layer is arranged on the upper surface of the dielectric layer, a source electrode and a drain electrode are arranged on the semiconductor layer respectively, and an encapsulation layer is also arranged on the substrate and wraps the gate electrode, the dielectric layer, the semiconductor layer, the source electrode and the drain electrode inside, wherein the dielectric layer is made from a mixed material of bamboo cellulose and a biological dielectric material, content of bamboo cellulose is 50-75%, the semiconductor layer is made from a mixed material of bamboo fibers and a soluble biological semiconductor material, and cellulose content is 5-15%. The pressure sensor disclosed by the invention has the advantages that the bamboo cellulose can detect pressure with high sensitivity and high response, the dielectric layer doped with the bamboo cellulose and an organic semiconductor layer enable device stability to be higher and the pressure sensor device to be more environment-friendly, the preparation method and technology are easy to realize, a biological material functional layer can be well compatible, and environmental pollution in a preparation process is reduced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

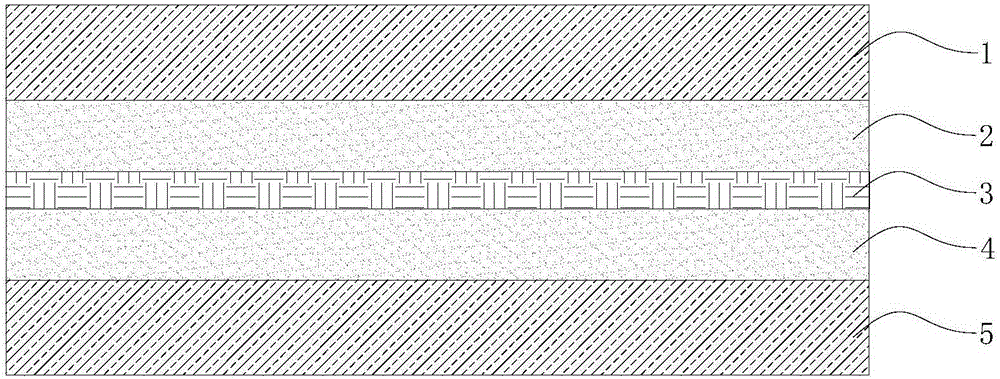

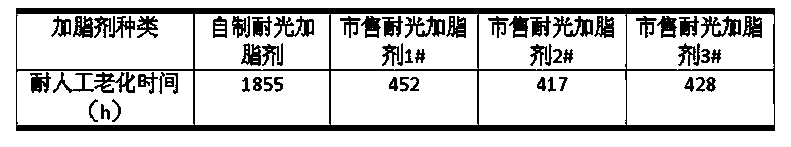

Melt-blown composite nano-antibacterial super-soft non-woven material and preparation method thereof

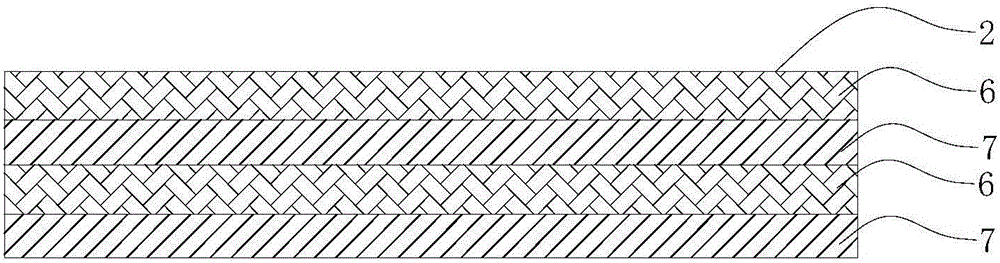

ActiveCN105882075AImprove hydrophilicityImprove antibacterial propertiesSynthetic resin layered productsFiberNanofiber

The invention discloses a melt-blown composite nano-antibacterial super-soft non-woven material and a preparation method thereof. The melt-blown composite nano-antibacterial super-soft non-woven material comprises a first flexible met-blown layer, a first nano fiber antibacterial layer, a nano fiber hydrophilic layer, a second nano fiber antibacterial layer and a second flexible melt-blown layer, all of which are sequentially arranged from top to bottom. The first nano fiber antibacterial layer and the second nano fiber antibacterial layer are both formed by alternately laminating nanometer titania material layers and nano fiber antibacterial material layers. The melt-blown composite nano-antibacterial super-soft non-woven material achieves good softness, good hand feeling and high comfort through the first flexible met-blown layer and the second flexible met-blown layer. The nano fiber antibacterial material layers and the nanometer titania material layers are alternately laminated to form a continuous antibacterial body, so that the non-woven material has a lasting antibacterial effect. The nanometer titania layers have a good ultraviolet-proof function. Then non-woven material has a good hydrophilic property through the nano fiber hydrophilic layer.

Owner:JIANGSU SHENGFANG NANO MATERIAL TECH CO LTD

Weaving method of carbon fiber electromagnetic shielding fabric with antibacterial, anti-odor and anti-ultraviolet function

InactiveCN102465394AImprove shielding effectImprove breathabilityHeating/cooling textile fabricsShieldingFiberCarbon fibers

The invention discloses a weaving method of carbon fiber electromagnetic shielding fabric with antibacterial, anti-odor and anti-ultraviolet function, referring to the weaving method field of the electromagnetic shielding fabric, wherein in the weaving method, the electromagnetic shielding fabric is woven by spinning, weaving, pre-oxidizing, carbonizing and weaving bamboo fibers and carbon fibers. The electromagnetic shielding fabric woven by the invention can shield electromagnetic wave well and reduce damage of the electromagnetic wave for body; because of the bamboo fibers, the fabric has good ventilation performance and with antibacterial, anti-odor and anti-ultraviolet function.

Owner:XIAOJIAN TECH DALIAN

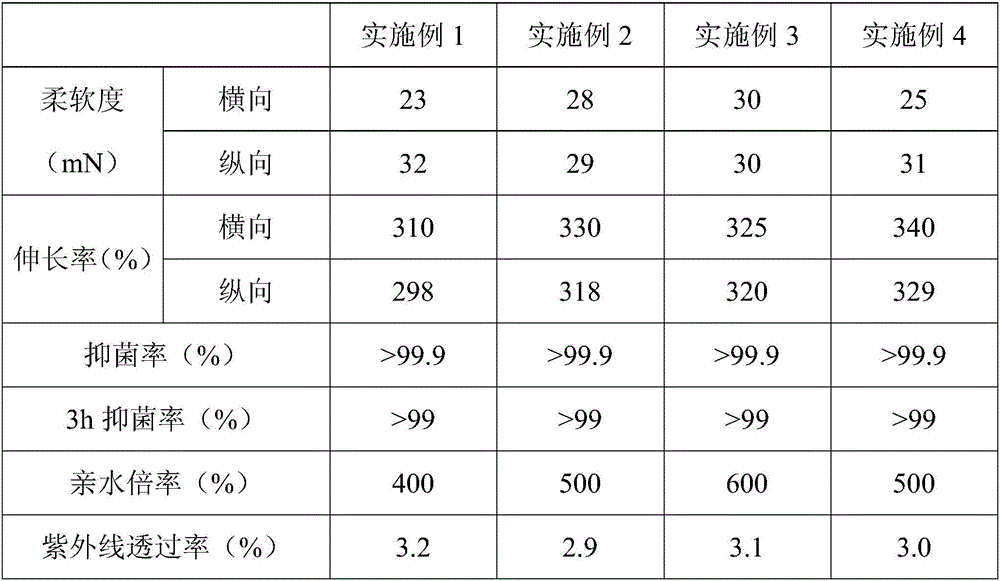

Method for preparing nano TiO2 composite leather greasing agent with ultraviolet protecting function

The invention discloses a method for preparing a nano TiO2 composite leather greasing agent with an ultraviolet protecting function. At present, the research on the application of nano TiO2 and hydrogenated ricinoleic acids to the leather greasing agent has been rarely reported at home. Rutile nano TiO2 with an excellent anti-ultraviolet capability is prepared by adopting a chemical precipitation method, and is modified with the hydrogenated ricinoleic acids, and modified rutile nano TiO2 and maleic anhydride react to obtain the TiO2 composite leather greasing agent with the ultraviolet protecting function. The ultraviolet protecting performance is realized by the hydrogenated ricinoleic acids and rutile nano TiO2. The hydrogenated ricinoleic acids are ricinus oil derivates, and the greasing agent manufactured in such a way that double bonds in molecules of the hydrogenated ricinoleic acids are subjected to hydrotreating is excellent in ultraviolet protecting performance. An electron hole formed in the surface of the rutile nano TiO2 has the advantages of relatively high recombination speed and relatively high UV-shielding capability, and the leather is provided with the ultraviolet protecting function.

Owner:SHAANXI UNIV OF SCI & TECH

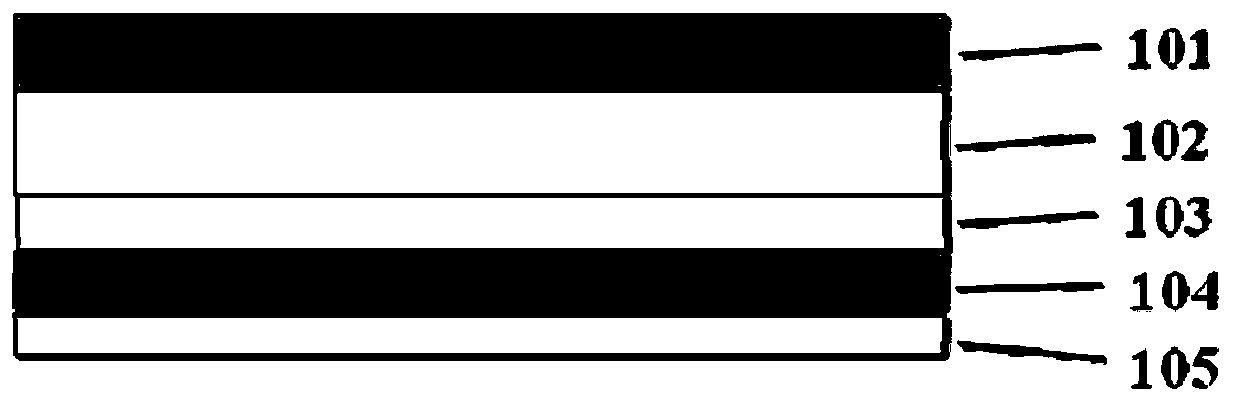

Transparent lacquer protective film and application thereof

ActiveCN109837028AHigh light transmittanceImprove self-healing performancePolyurea/polyurethane coatingsPressure sensitive film/foil adhesivesPressure sensitiveTransmittance

The invention relates to the field of functional films, in particular to a transparent lacquer protective film and application thereof. In order to solve the problem that the current lacquer protective film has poor impact resistance and large water contact angle, the invention provides a transparent lacquer protective film and application thereof. The transparent lacquer protective film providedby the invention comprises a self-healing layer, a substrate layer and a pressure-sensitive adhesive layer. The raw materials of the self-healing layer are composed of the following materials (by weight): 55-80 parts of polyol resin, 3-18 parts of a crosslinking agent, 5-32 parts of inorganic nanoparticles, 0.2-3 parts of a catalyst, and 0.5-3 parts of an ultraviolet light absorber. The prepared lacquer protective film not only has high light transmittance and self-repairing property, but also has excellent performances such as high impact performance and low water contact angle. The lacquer protective film provided by the invention has simple preparation process, is easy to operate, and is convenient for industrial production.

Owner:NINGBO EXCITON TECH

Soybean protein fiber graphene fiber blended knitted fabric

The invention discloses a soybean protein fiber graphene fiber blended knitted fabric, which comprises the following components in parts by weight: 30-60 parts of graphene viscose composite fiber, 30-50 parts of soybean protein fiber, 10-30 parts of organic cotton and 3-10 parts of spandex; according to the fabric, the graphene, the soybean protein, the organic cotton and the spandex are matched and blended according to a proper ratio, so that the fabric is soft and comfortable, good in skin affinity, good in wrinkle resistance and smoothness, and good in elasticity and shaping effect. The fabric has the functions of ultra-strong far infrared, sterilization and bacteriostasis, moisture absorption and perspiration, and ultraviolet-proof and antistatic function, the function of the fabric isnot weakened due to wearing time, the material used by the fabric is green and environment-friendly, and the fabric is a green and environment-friendly inner heating material with a health-care function.

Owner:FOSHAN YUANCHENGSHUN ECOLOGICAL TEXTILE SCI & TECH CO LTD

Nano-ZnO (zinc oxide) modified polyester pre-oriented yarn

InactiveCN102251313AGood UV protectionImproved UV protectionMonocomponent polyesters artificial filamentArtifical filament manufactureCopolyesterNano zinc oxide

The invention relates to a method for preparing a nano-ZnO (zinc oxide) modified polyester pre-oriented yarn. The method comprises preparation of modified polyester melt and preparation of direct-spun polyester pre-oriented yarn (POY); and in the process of preparing a modified polyester melt, a pure terephthalic acid (PTA) and an ethylene glycol (EG) monomer are taken as raw materials, and a nano modifier is added so as to prepare a modified copolyester melt, then the polyester melt is directly conveyed by a melt, and through carrying out metering, spinning assembly extrusion, air blast cooling, oil applying, channel passing, and winding on the polyester melt, a nano-ZnO modified polyester pre-oriented yarn is obtained. A fiber prepared by using the method provided by the invention has a good ultraviolet-resistant function, and the ultraviolet reflection capacity of the fiber is as high as 50-60%.

Owner:JIANGSU YINGXIANG FIBER

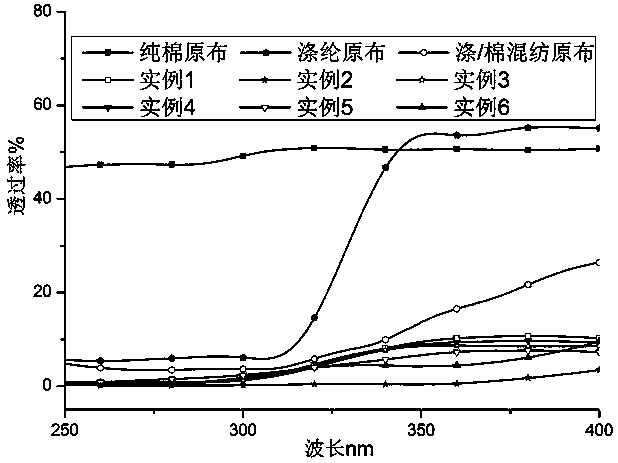

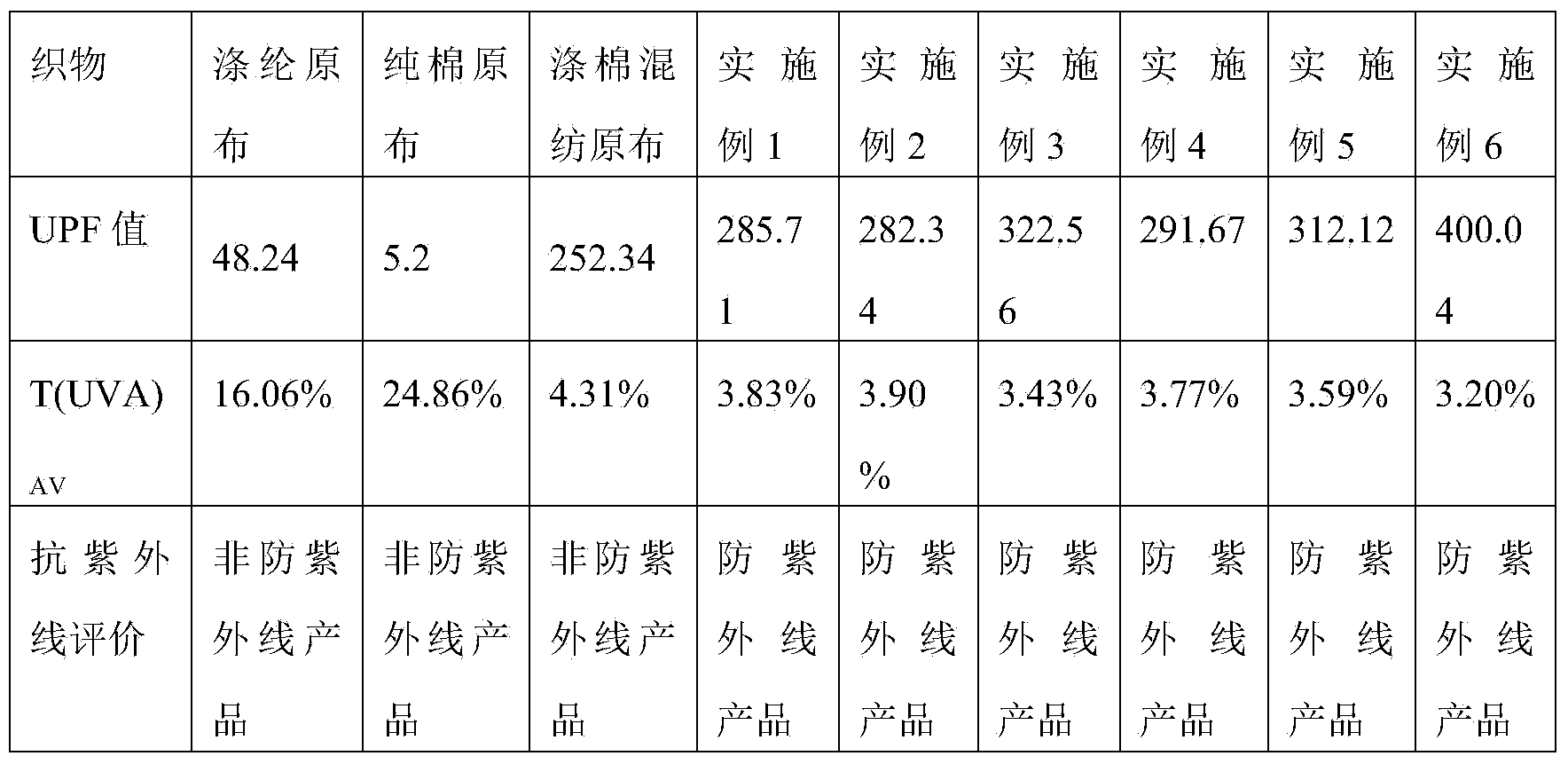

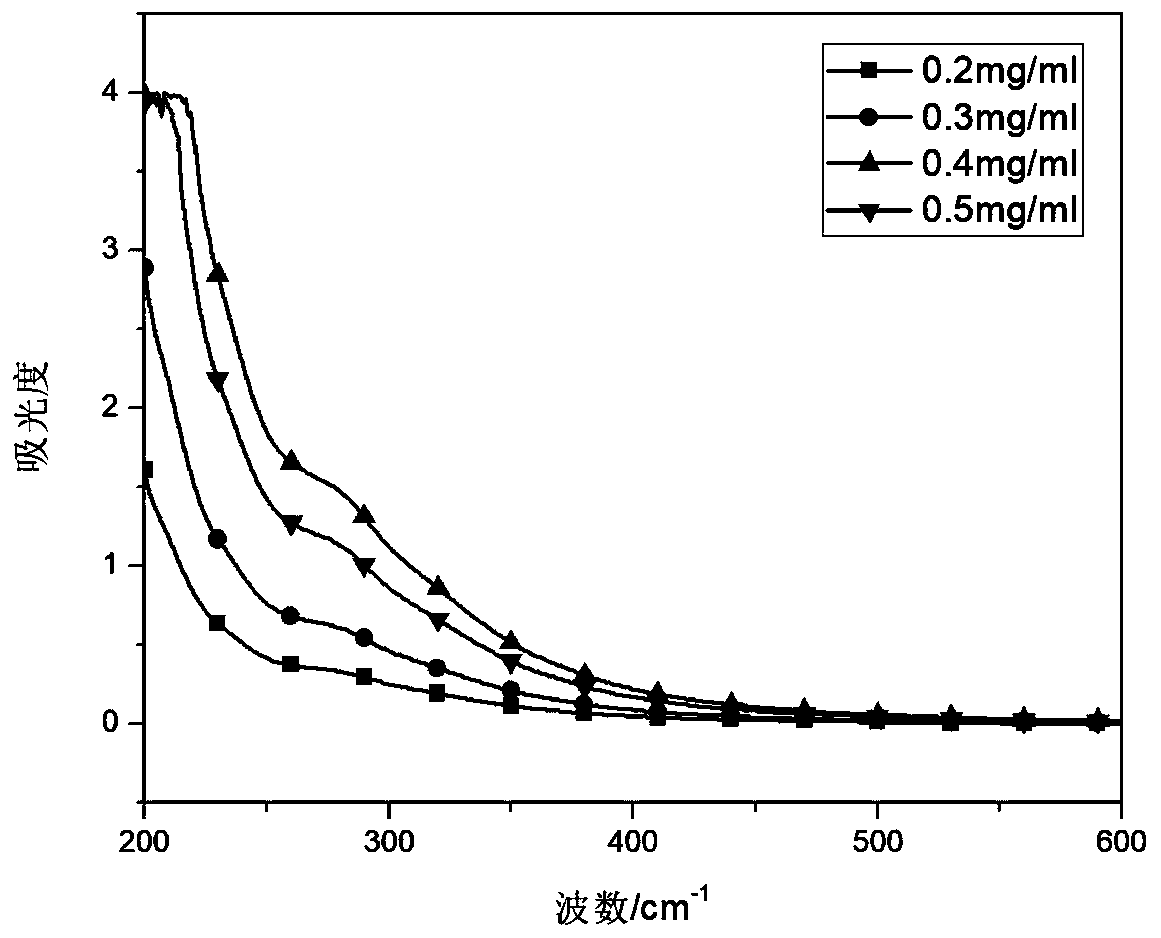

Preparation method and application of textile ultraviolet-proof finishing agent

ActiveCN106592244AImproved UV protectionImprove washing fastnessLight resistant fibresVegetal fibresViscous liquidPolymer science

The invention discloses a preparation method and application of textile ultraviolet-proof finishing agent. The ultraviolet-proof finishing agent on the current market has the problems such as non-ideal ultraviolet-proof effect, bad fastness-to-washing and the like. The preparation method of the textile ultraviolet-proof finishing agent comprises the steps of making low polymer polyhydric alcohol, diisocyanate, hydrophilic chain extender, catalyst and solvent react at the temperature of 70-100 DEG C for 4-8 hours, when mass percentage of isocyanato reduces to 0.5% or below, stopping the reaction to acquire a prepolymer, cooling the prepolymer to 30-60 DEG C, adding a neutralizing agent, stirring the mixture for 15-30 minutes, adding an ultraviolet absorbing agent into the system, continuing to stir until the mixture is uniformly mixed to acquire transparent viscous liquid, adding deionized water into the transparent viscous liquid for emulsification, and finally acquiring stable light yellow nano-emulsion. The clothes treated with the textile ultraviolet-proof finishing agent not only have an excellent ultraviolet-proof function, but also have excellent washing fastness.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +1

Manufacturing method of aluminum alloy coated plates

InactiveCN103790317AHigh transparencyHigh glossCovering/liningsLamination ancillary operationsAcoustic absorptionThermal insulation

The invention relates to a manufacturing method of building plates, in particular to a manufacturing method of aluminum alloy coated plates. The building plates are resistant to corrosion and weather proof, prevent dew dropping, and have certain insulation performance. The manufacturing method includes the steps of selecting materials, preprocessing surfaces of plates, drying, coating with glue, laminating, drying, hot-pressing, and checking for storage. The product manufactured by the method has good fire resistance; detections show that the product is approved by the level B-1 of fire rating for national building materials, is fully environment friendly and pollution free, also passes environmental certification, and has the advantages of long service life, environment friendliness, fire proofing, dew prevention, corrosion resistance, acoustic absorption, light absorption, thermal insulation, high transparency, high glossiness, low haze, excellent UV barrier property, laser security, and bright decoration.

Owner:WUXI XINDAZHONG STEEL SHEET

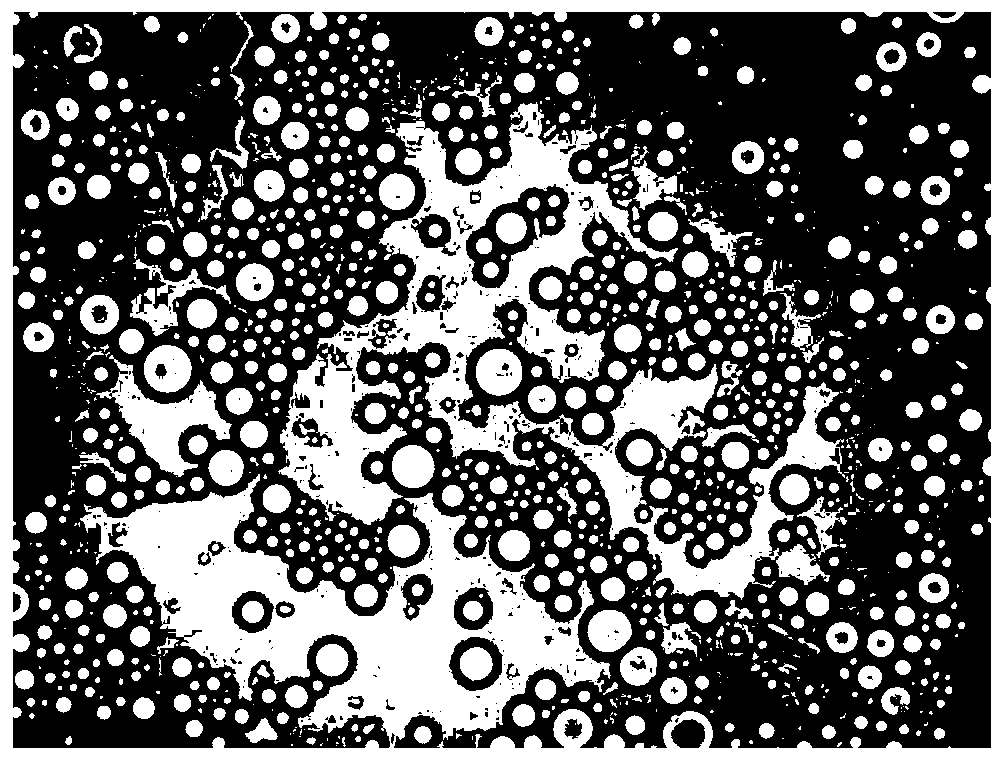

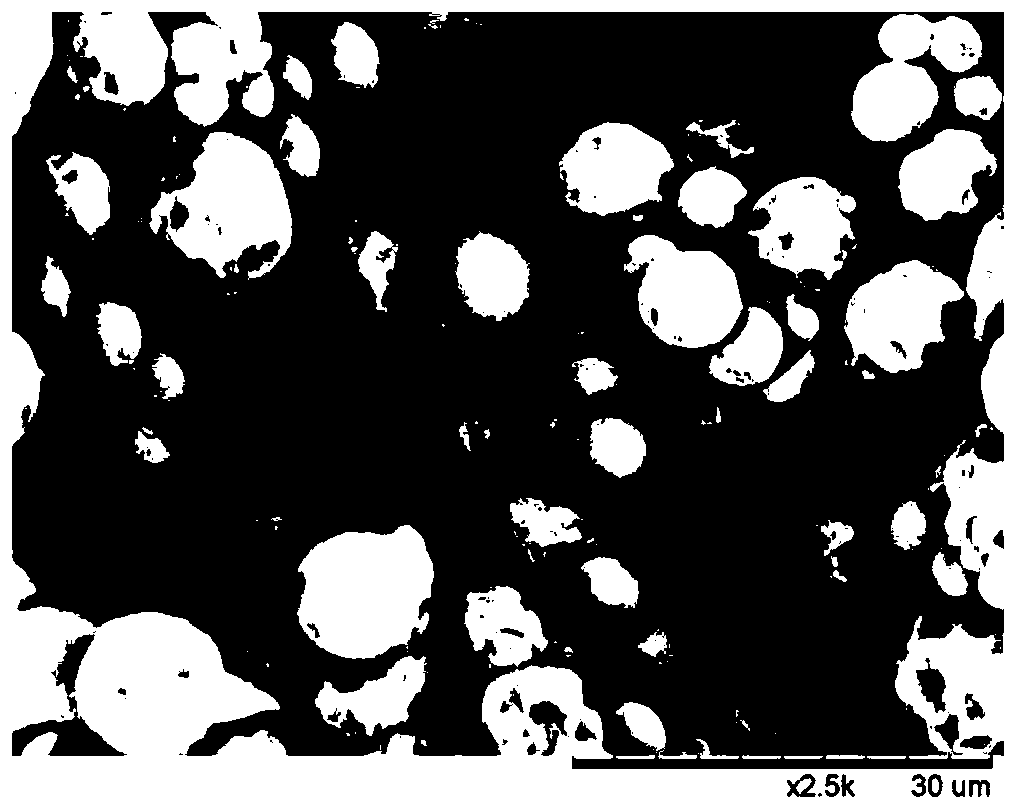

Mosquito-repelling and sun-proof composite functional microcapsule and preparation method thereof

ActiveCN110144734ASolve problems with relatively single functionalityImproved UV protectionBiochemical fibre treatmentLight resistant fibresUltraviolet absorptionComposite function

The invention relates to a mosquito-repelling and sun-proof composite functional microcapsule and a preparation method thereof. The composite functional microcapsule comprises a capsule wall supporting an ultraviolet absorption material and a capsule core wrapped in the capsule wall, wherein the ultraviolet absorption material is acidified lignin, and the capsule core is a mixture of a plant-basedmosquito repellent and an ultraviolet absorbent. The synergistic interaction between the lignin and the ultraviolet absorbent can be effectively utilized, and an excellent ultraviolet protection function can be realized on the basis of lasting mosquito repelling. The composite functional microcapsule has important application value in the fields of summer clothes, daily cosmetics and the like.

Owner:上海驰纺材料科技有限公司

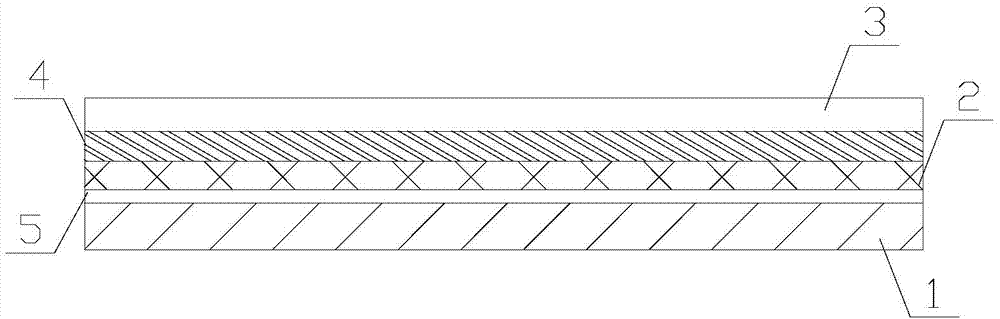

Anti-ultraviolet fabric and manufacturing method thereof

ActiveCN106567258AReduce transmittanceGuaranteed breathable and moisture permeable functionLight resistant fibresWoven fabricsYarnGram

The invention discloses an anti-ultraviolet fabric. A fabric body comprises a grey layer undergoing ultraviolet resistance and water repellency treatment, the inner side of the grey layer is adhered with an anti-ultraviolet layer, the surface of the anti-ultraviolet layer is adhered with a filling layer, the thickness of the anti-ultraviolet layer is 0.005 mm, and the thickness of the filling layer is 0.03 mm; and the gram weight of the grey layer is 75 g / m<2>, the warp tightness is 43.3%, the weft tightness is 28.9%, the total tightness is not less than 59.69%, the fineness of a single warp yarn fiber is less than 2.2 dtex, and the fineness of a single weft yarn fiber is less than 2.2 dtex. The anti-ultraviolet fabric has anti-ultraviolet function, ventilation and moisture permeation functions, and improved washability.

Owner:姚璇

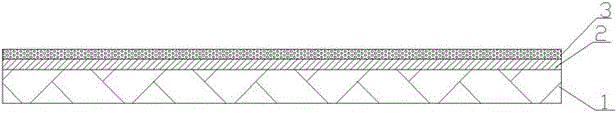

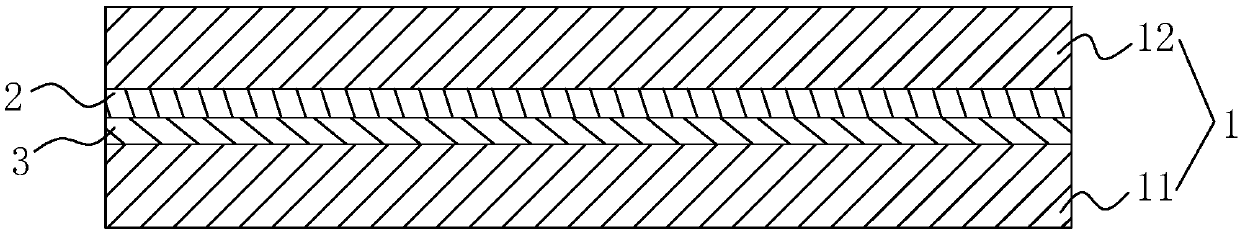

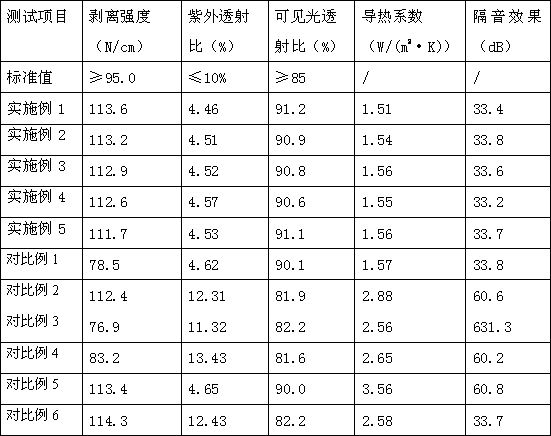

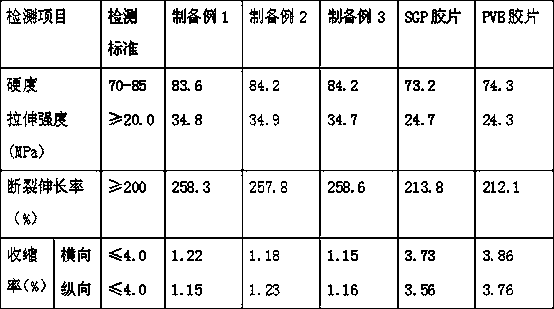

Gradient laminated glass and preparation technology thereof

ActiveCN109648954AGood shading effectImprove barrier propertiesNon-macromolecular adhesive additivesSynthetic resin layered productsUltravioletGlass sheet

The invention discloses a gradient laminated glass and a preparation technology thereof. The gradient laminated glass comprises a glass sheet, a soundproof film and a gradient film, the glass sheet comprises a first glass sheet and a second glass sheet, the soundproof film and the gradient film are located between the first glass sheet and the second glass sheet, and the soundproof film is in contact with the second glass sheet; and the soundproof film comprises PVB resin, trans-polyisoprene rubber, a plasticizer, hollow glass beads, ABS resin, a maleic anhydride-grafted ethylene-vinyl acetatecopolymer, a borax crosslinker, modified diatomite, bentonite, glass fibers, rosin, a heat insulating material and an ultraviolet absorber. The preparation technology of the gradient laminated glasscomprises the following steps: S1, cleaning the glass sheet; S2, sheet combination; S3, hot press molding. The gradient laminated glass of the invention has the advantages of good soundproof effect and high carrying capacity.

Owner:江苏儒耀装饰设计道具有限公司

Processing method of anti-ultraviolet thermal-insulation clothing

InactiveCN104975503ASimple production processEasy to operateVegetal fibresMonocomponent polyesters artificial filamentFiberPolyester

The invention discloses a processing method of an anti-ultraviolet thermal-insulation clothing. The processing method comprises following steps: 1) modified polyester fiber with high hygroscopicity is taken as meridional fiber, bamboo fiber is taken as latitudinal fiber for weaving so as to obtain a garment fabric; 2) the garment fabric is immersed in an anti-ultraviolet solution, after full infiltration, the garment fabric is collected, is subjected to pre-drying at 65DEG C for 5 to 8min, and is subjected to baking at 120 to 130DEG C for 2 to 4min; 3) the garment fabric processed via step 2) is immersed into an antibacterial solution at 38 to 45DEG C for 20 to 25min, is collected, and is delivered into a drying plant; and 4) the garment fabric obtained via step 3) is subjected to rolling and dyeing, and is made into clothes of different specifications so as to obtain the anti-ultraviolet thermal-insulation clothing. Production technology of the processing method is simple, is convenient for operation, and is high in yield; ultraviolet transmittance (UVA) of the anti-ultraviolet thermal-insulation clothing is 5% or less; ultraviolet protect coefficient (UPF) is 30 or higher; surface specific resistance is 105 omega / m2 or less; electromagnetic shielding coefficient can be as high as 20dB; the anti-ultraviolet thermal-insulation clothing possesses excellent ultraviolet resistance.

Owner:安徽东锦高科新材料有限公司

Outdoor ultraviolet-proof advertisement board

InactiveCN104742418ASimple structureImproved UV protectionSynthetic resin layered productsBoardsHoneycomb structureEngineering

The invention relates to an outdoor ultraviolet-proof advertisement board. The outdoor ultraviolet-proof advertisement board comprises a paper base plate layer, wherein an ink layer is arranged on the upper surface of the paper base plate layer, a waterproof PVC film layer and an ultraviolet-proof layer are sequentially formed on the upper surface of the ink layer from top to bottom, the ultraviolet-proof layer is a transparent film layer coated with a reflective ultraviolet material, the thickness of the ultraviolet-proof layer is 0.5-6mm, the ink layer is fixed on the paper base plate layer by a bonding layer, the bonding layer is formed by a polymer binder, a magic tape or the like, the paper base plate layer comprises an upper surface layer, a lower surface layer and a filling layer arranged between the upper surface layer and the lower surface layer, and the filling layer is of a honeycomb structure or a latticed structure. The outdoor ultraviolet-proof advertisement board has a simple structure and a good ultraviolet-proof function, and the contents of an advertisement cannot fade easily when the outdoor ultraviolet-proof advertisement board is used outside, so that the outdoor ultraviolet-proof advertisement board has long service life; and besides, the outdoor ultraviolet-proof advertisement board has good waterproof property and good tensile performance.

Owner:崔国锐

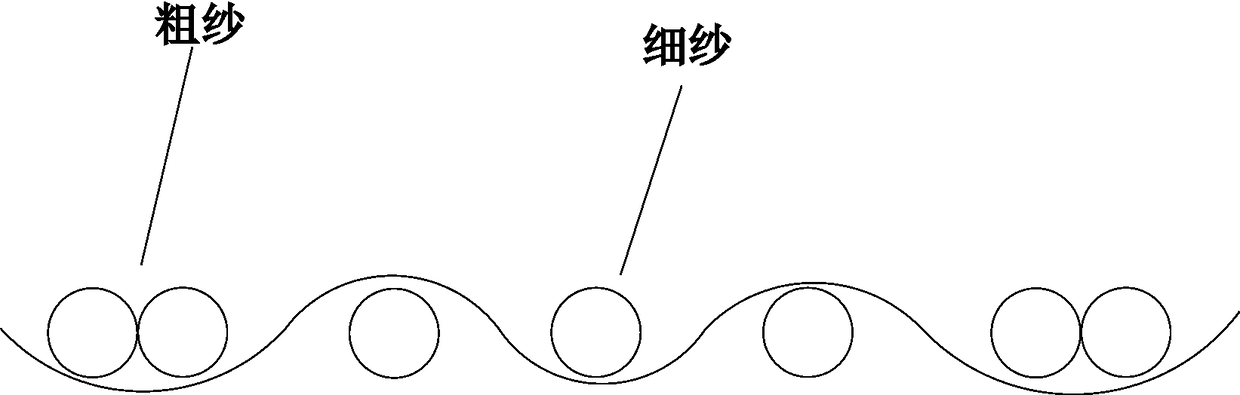

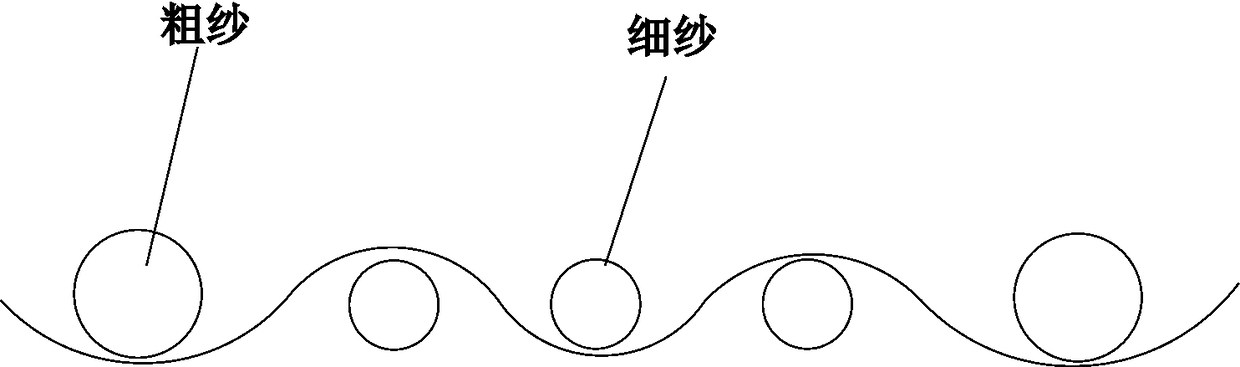

Breathable cool ultraviolet ray proof woven fabric

The invention discloses a breathable cool ultraviolet ray proof woven fabric, and relates to a woven fabric. The fabric is formed by interlacing warp yarns and weft yarns, at least one of the warp yarns or the weft yarns has a structure in which roving and spun yarns are uniformly mixed and arranged, the warp yarns and the weft yarns are interlaced to form a uniformly distributed and convex line structure or mesh structure on the fabric surface, the cross sections of fibers in the warp yarns and the weft yarns are polygons with a plurality of lobes, and the adjacent fibers conform to each other. Compared with the prior art, special weaving is conducted on the yarns with special structures, so that the fabric is provided with a concave-convex structure, does not fully fit a human body, canmaintain the ventilation between the fabric and the human body, and has the effect of quick sweat absorption and perspiration, the special structures of the yarns also keep the tightness between the yarns, and prevent ultraviolet rays from irradiating, and the fabric has the effect of isolating the ultraviolet rays.

Owner:MAXWIN CHINA CO LTD

Modified polyester fully drawn yarn with ultraviolet resistance

InactiveCN102330182AGood UV protectionImproved UV protectionMonocomponent polyesters artificial filamentArtifical filament manufactureDyeingGlycol synthesis

The invention relates to a method for preparing a modified polyester fully drawn yarn with ultraviolet resistance, which comprises the preparation step of condensing and polymerizing modified polyester melt and the preparation process of directly spinning the polyester fully drawn yarn (FDY). In the preparation process of condensing and polymerizing modified polyester melt, the modified co-polyester melt is prepared from pure terephthalic acid (PTA) and ethylene glycol (EG) monomers as raw materials by adding nano zinc oxide. The polyester melt is directly transported through a melt, extruded through metering and spinning assemblies, cooled by blowing air, oiled and wound by a channel, a first yarn guide roller and a second yarn guide roller to prepare the modified polyester fully drawn yarn. The prepared fiber has good ultraviolet resistance, and the reflecting ability to ultraviolet rays reaches as high as 50-60%. The prepared fiber has stable contraction rate, uniform dyeing and excellent spinning performance.

Owner:JIANGSU YINGXIANG FIBER

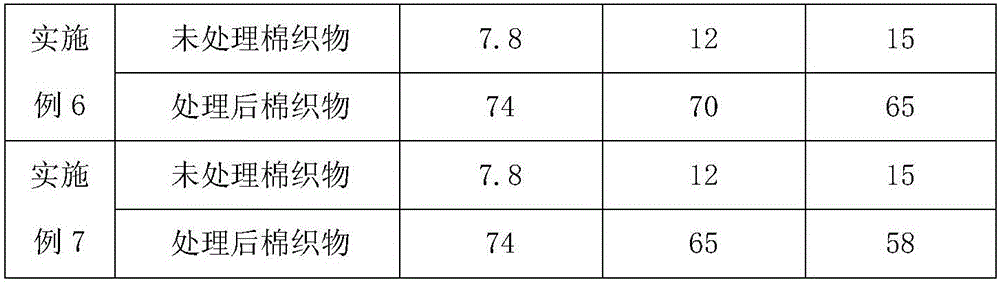

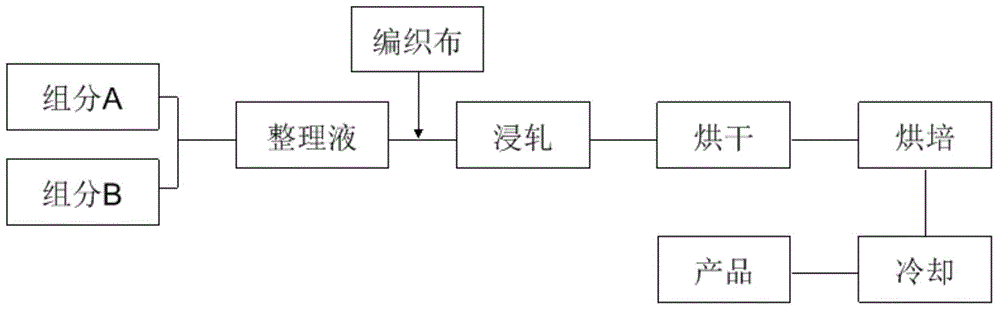

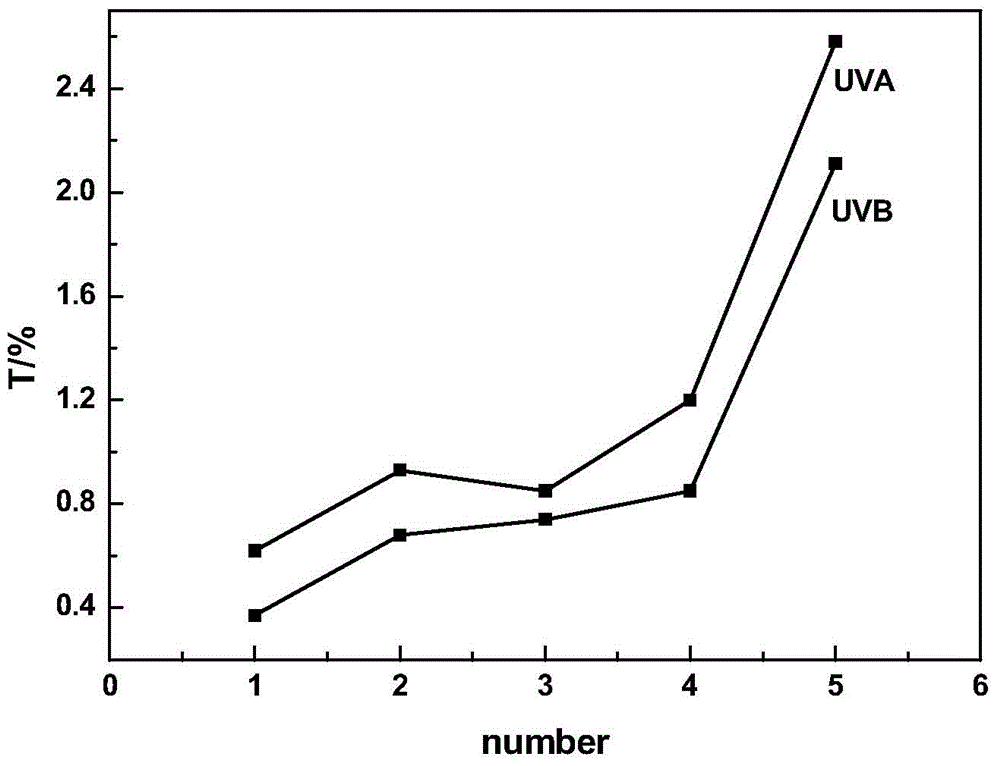

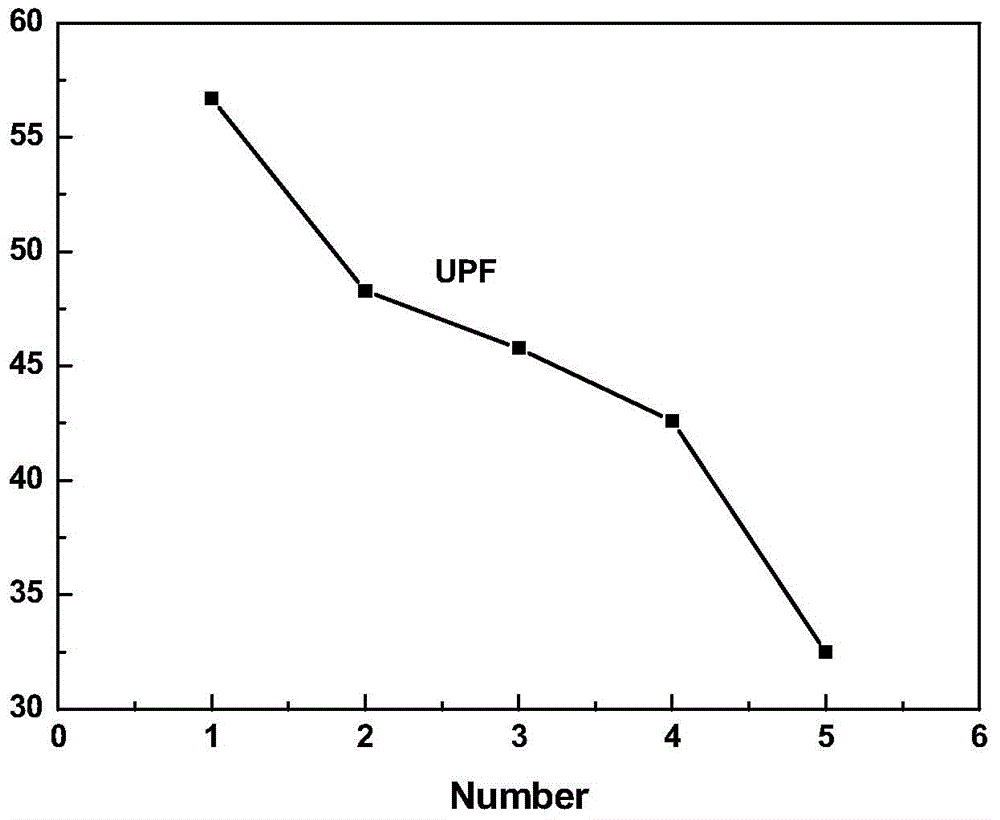

Composite ultraviolet-proof finishing liquid and preparation method and application thereof

The invention relates to composite ultraviolet-proof finishing liquid. The composite ultraviolet-proof finishing liquid comprises 25-30 g / L of nanometer oxide, 15-30 g / L of metallo chelate, 20-30 g / L of synergist, 15-20 g / L of ethyl alcohol, 10-15 g / L of methyl alcohol, 10-15 g / L of urea, 2-4 g / L of glycerinum, 0.5-1 g / L of polyoxyethylene ether, 0.5-1 g / L of azodiisobutyronitrile, 0.3-1 g / L of flatting agent, 0.2-1 g / L of antifoaming agent, and 1-2 g / L of curing agent, water serves as the solvent, the nanometer oxide is the powder mixture of ZnO, TiO2 and SiO2. Woven cloth treated through the finishing liquid has the excellent ultraviolet-proof function, the shading coefficient reaches to over 70%, the ultraviolet light shielding rate reaches to over 98%, and the ultraviolet protection factor (UPF) is higher than 40.

Owner:NINGBO SANDO KNITTING

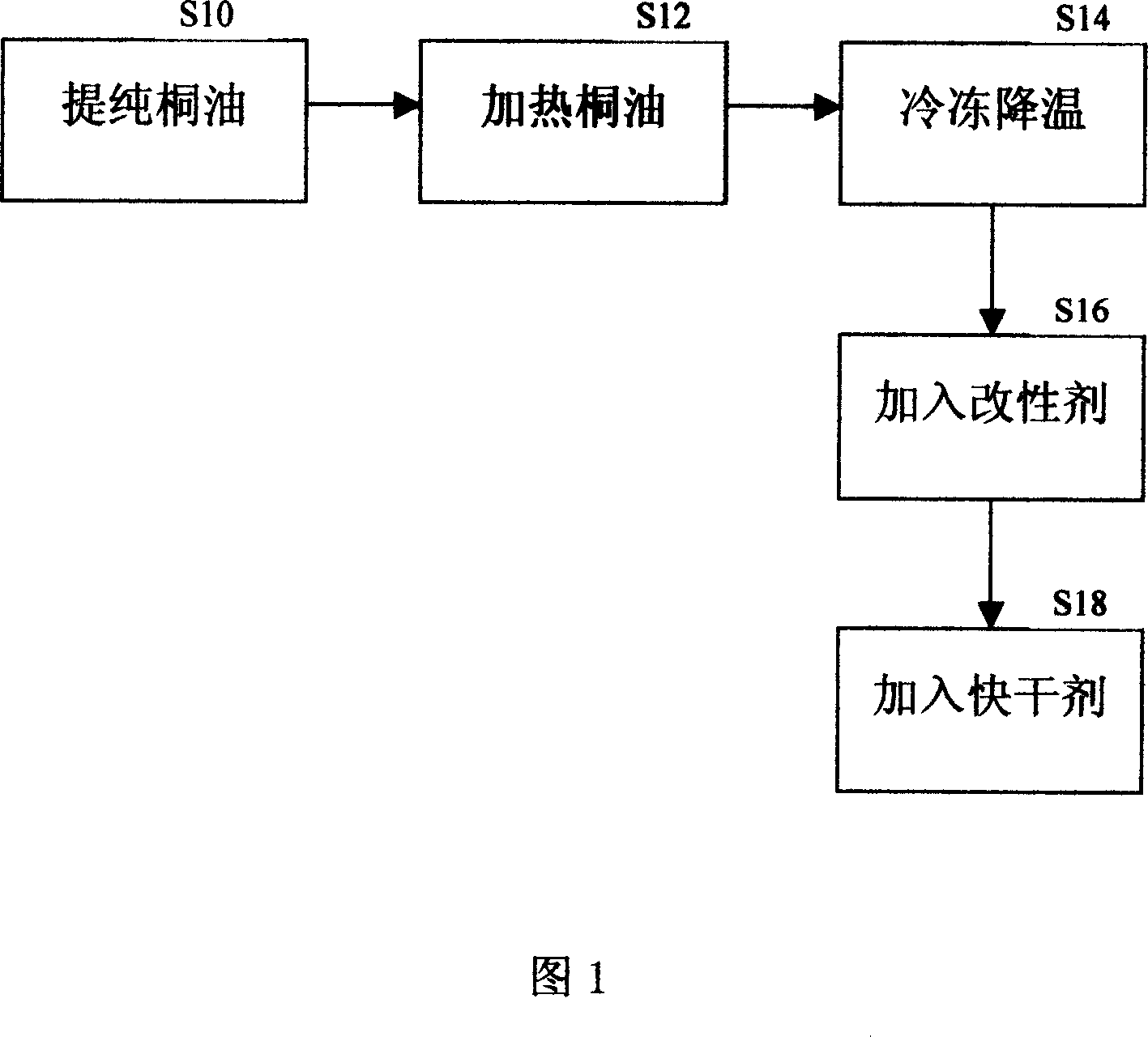

Whether-resisting wood oil and preparation method thereof

InactiveCN101121862ALight aromatic smellDry fastLiquid surface applicatorsCoatingsAntibiotic effectMoisture

The present invention discloses a weatherproof wood oil, including tung oil as well as modifier. The tung oil covers 47.5 to 77.5wt percent, modifier 17.5 to 47.5wt percent; the total weight percent of the tung oil and the modifier is not less than 95 percent, and the total percent of water and foreign substances is not bigger than 5 percent. The wood oil becomes dry rapidly after painting, and has better moisture-proofing, fungi-proofing, sun-screening and antibiotic effects, sound desquamation-proofing and ultraviolet-proofing functions. The weatherproof wood oil prepared by the method is characterized by light fragrance and environment-friendly features.

Owner:伍共华

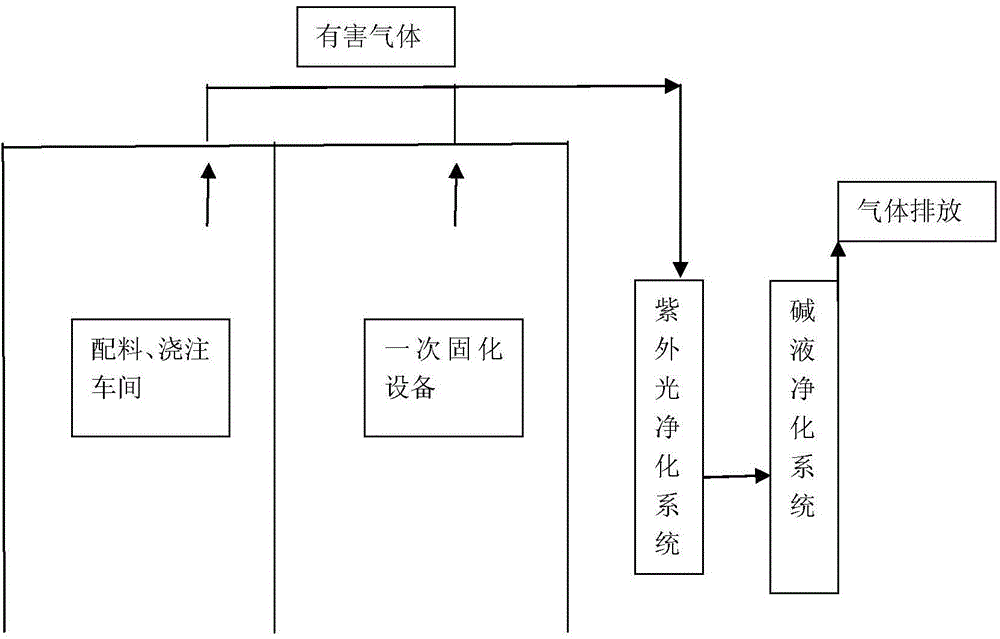

Manufacturing technology for resin lens with high refraction index and high abbe number

ActiveCN104802430AHigh refractive indexImproved UV protectionOptical articlesManufacturing technologyUltraviolet lights

The invention relates to a manufacturing technology for a resin lens with high refraction index and high abbe number. The manufacturing technology is implemented through the following steps: cleaning a mould, and then assembling the mould; adding a component B, a component C and an ultraviolet light absorbent into a mixing barrel, and uniformly mixing; adding a catalyst, a release agent, a blue organic pigment and a red organic pigment, uniformly mixing, adding a component A, and uniformly mixing; filtering, then, injecting raw materials into the assembled mould, and sealing the mould; performing primary solidification on the filled mould, prying the solidified mould, and separating out the mould and molded lenses; trimming the lenses; performing multi-grooved ultrasonic cleaning and secondary solidification on the trimmed lenses; inspecting the lenses subjected to the secondary solidification, and selecting a qualified lens; coating the qualified lens with a film, then, performing hardening solidification on the lens coated with the film; evaporating an antireflection film on the hardened lens. The refraction index of the lens manufactured by adopting the manufacturing technology is 1.693-1.701, and the abbe number of the lens is 34-37.

Owner:JIANGSU MINGYUE PHOTOELECTRICS TECH

Manufacturing method of hot-dip galvanized coated plates

InactiveCN103790309AExtended service lifeEnvironmentally friendlyLamination ancillary operationsCovering/liningsAcoustic absorptionThermal insulation

The invention relates to a manufacturing method of building plates, in particular to a manufacturing method of hot-dip galvanized coated plates. The building plates are resistant to corrosion and weather, prevent dropping of dews, and have certain thermal insulating property. The manufacturing method includes the steps of selecting materials, preprocessing the surfaces, drying, coating with glue, laminating, drying, hot-pressing, and checking for storage. Products manufactured by method are well fireproof; detections show that the products are approved by the level B-1 of national building materials fire rating, are fully environment friendly and free of pollution, also pass environmental certification, and have the effects of long service life, environment friendliness, fire proofing, dew prevention, corrosion resistance, acoustic absorption, light absorption, thermal insulation, high transparency, high glossiness, low haze, excellent UV barrier property, laser security, and bright decoration.

Owner:WUXI XINDAZHONG STEEL SHEET

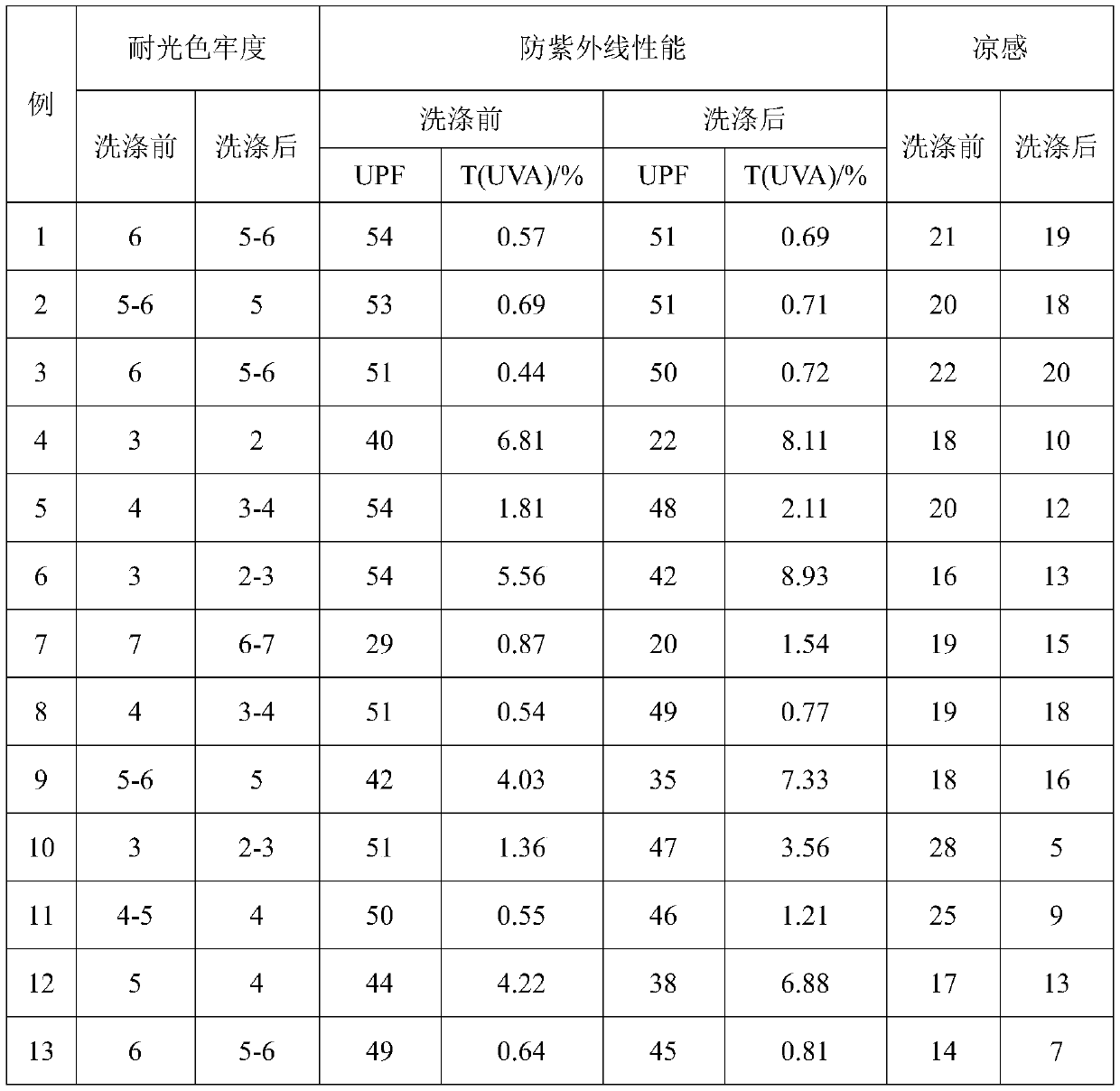

Ultraviolet-proof fabric

ActiveCN111118882AImprove light fastnessImproved UV protectionLight resistant fibresVegetal fibresCyclodextrinUltraviolet resistance

The invention discloses an ultraviolet-proof fabric. The ultraviolet-proof fabric is finished by an ultraviolet-proof finishing agent, wherein the ultraviolet-proof finishing agent comprises the following raw materials in parts by weight: component A: 45-55 parts of nano titanium dioxide, 1-3 parts of a silane coupling agent and 190-210 parts of water; and (B) component: 3-5 parts of cyclodextrin,2-4 parts of plant extract and 45-55 parts of water; and (3) component C: 1-2 parts of a thickening agent. Under the optimal condition, the fabric prepared by the invention shows good light fastnessbefore and after washing through a light fastness test; the ultraviolet resistance tests show that after 50 times of washing, the detergent still far meets the national standard of ultraviolet resistance products; and the cool feeling performance test shows that the mild and moderate cool feeling is displayed before washing and after 50 times of washing. The fabric prepared by the invention has excellent ultraviolet-proof function, good color fastness to light, long-acting cooling experience in the using process, simple preparation process and extremely high practical application value.

Owner:JIANGSU DAMAONIU NEW MATERIAL TECH CO LTD

Heat-accumulating and heat-preserving plastic fiber master batch and plus material thereof

ActiveCN102627839BWidely producedNice appearanceMonocomponent polyesters artificial filamentYarnEngineering

The invention discloses a heat-accumulating and heat-preserving plastic fiber master batch, which is prepared by pelletizing PET (Polyethyleneglycol Terephthalate) plastic slices and MoO3 nano-powder of which the average particle diameter is less than or equal to 40 nanometers through a plastic pelletizer, wherein the using amount of the MoO3 nano-powder is 8-12 percent by weight. The invention further discloses a heat-accumulating and heat-preserving plus material, which is prepared by performing wire drawing, yarn spinning, cloth spinning and cloth weaving on the heat-accumulating and heat-preserving plastic fiber master batch and the PET plastic slices, wherein the using amount of the heat-accumulating and heat-preserving plastic fiber master batch is 3-7 percent by weight. The heat-accumulating and heat-preserving plastic fiber master batch has very high social and economic values when used for making various cold-proof underwear, cold-proof shoe soles, cold-proof waist supports and knee pads, winter outdoor clothes, cold-proof bedding articles, cold-proof window curtains and the like.

Owner:上海沪正实业有限公司

Anti-ultraviolet moisture-absorbing breathable cloth and preparation method thereof

InactiveCN107675291AImproved UV protectionImprove toughnessConjugated cellulose/protein artificial filamentsArtifical filament manufactureUltravioletUltimate tensile strength

The invention relates to the field of cloth production, in particular to anti-ultraviolet moisture-absorbing breathable cloth and a preparation method thereof. The cloth is formed by blending of bamboo charcoal fiber, sugarcane fiber, wood fiber, combed cotton fiber and Longxiang taro fiber. Made cloth fibers have an excellent anti-ultraviolet function, are non-toxic and harmless to the human body, have good fiber toughness and high strength, are not subjected to ageing easily, and do not fade easily due to strong capability of adsorption to coloring agents.

Owner:JIANGSU AOYANG SHIJIA CLOTHING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com