Anti-ultraviolet fabric and manufacturing method thereof

An anti-ultraviolet and anti-ultraviolet technology, used in textiles and papermaking, textiles, light-resistant fibers, etc., can solve problems such as adding special coatings, reduce transmittance, improve washability, and enhance the effect of anti-ultraviolet function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

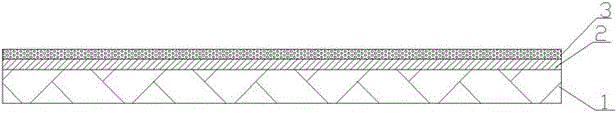

[0029] see figure 1 As shown, an anti-ultraviolet fabric, the fabric body includes a gray cloth layer 1 treated with anti-ultraviolet and water-repellent treatment, the inner surface of the gray cloth layer is covered with an anti-ultraviolet layer 2, and the surface of the anti-ultraviolet layer is covered with a filling layer 3 , the thickness of the anti-ultraviolet layer is 0.005mm, and the thickness of the filling layer is 0.03mm;

[0030] The grammage of the gray cloth layer is 75g / ㎡, its warp tightness is 43.3%, its weft tightness is 28.9%, the total tightness is not less than 59.69%, the single fiber fineness of the warp is less than 2.2dtex, and the single fiber of the weft is fine The degree is less than 2.2dtex.

[0031] In this embodiment, nylon fibers are used for the gray cloth layer, and UV-resistant fibers or filaments can also be used, or one or more of other functional and non-functional cellulose fibers and protein fibers can be selected.

[0032] The gray...

Embodiment 2

[0047] Example 2: The gray cloth layer is made of polyester-cotton blended anti-ultraviolet functional fibers, the warp tightness is 59.3%, the weft tightness is 42.1%, and the total tightness is 76.43%. The single fiber fineness of the warp yarn is 0.93dtex, and the single fiber fineness of the weft yarn is 0.74dtex. The fiber adopts sizing and non-twisting process, and is woven through ordinary looms, and finally obtains twill weave fabric.

[0048] The desizing process is adopted, dyeing is carried out with reactive dyes and chemicals at a normal temperature of 100°C, the setting temperature of clear water is 170°C, and the vehicle speed is 60 m / min. Using UV additives, the brand is American Angolao Mountain C, at a speed of 60 m / min and a temperature of 160 °C, the ratio of at least 100:1 is used for treatment. Secondly, conventional waterproof treatment was done with Japanese waterproofing agent, the vehicle speed was 60 m / min, and the temperature was 150°C. Then use Ja...

Embodiment 3

[0050] Example 3: The gray cloth layer is made of conventional nylon fiber, with a grammage of 75g / ㎡, a warp tightness of 43.3%, a weft tightness of 28.9%, and a total tightness of 59.69%. The single fiber fineness of the warp yarn is 2.2dtex, and the single fiber fineness of the weft yarn is 2.2dtex.

[0051] The desizing process is adopted, dyeing is carried out with reactive dyes and chemicals at a normal temperature of 100°C, the setting temperature of clear water is 170°C, and the vehicle speed is 60 m / min. Using UV additives, the brand is Huntsman UV-SUN (Uvey Sun) CEL LIQ, at a speed of 60 m / min and a temperature of 160 °C, the ratio of 100:3 is used for treatment. Secondly, a waterproof treatment was done with a conventional waterproofing agent, the vehicle speed was 60 m / min, and the temperature was 150°C. Then use BASF (Ciba) CHIMASSORB81 UV powder and glue to mix at a ratio of 3:100, at a temperature of 160°C, at a speed of 50 m / min, carry out 30g of coating treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com