Method for preparing nano TiO2 composite leather greasing agent with ultraviolet protecting function

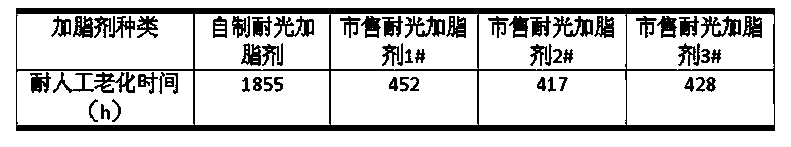

A leather fatliquor and nanotechnology are applied in the field of preparation of nano-TiO2 composite leather fatliquor to achieve the effects of strong covering power, good ultraviolet protection function and good anti-ultraviolet light performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] 1) Take 100mL of 2mol / L ammonia water and put it in a 500mL three-necked bottle, add the titanium sulfate solution (the molar ratio of titanium sulfate to ammonia water is 1:4) into the three-necked bottle at room temperature, and stir to obtain a white precipitate. Washed by centrifugation several times until SO-free 4 2- ions are detected. The precipitate was washed and dispersed in 4 mol / L nitric acid solution, refluxed at 70 °C for a period of time, centrifuged, washed, and dried to obtain rutile nano-TiO 2 .

[0012] 2) Mix 10g hydrogenated ricinoleic acid with 1g nano-TiO 2 After being fully dissolved with 20 mL of absolute ethanol, the reaction was ultrasonically heated at 80 °C for 3 h, and air-dried at 60 °C for 4 h. Nano-TiO modified by hydrogenated ricinoleic acid 2 .

[0013] 3) 10g of hydrogenated ricinoleic acid modified nano-TiO 2 React with 10g of maleic anhydride at 85°C for 4h, cool down to 75°C, add 35g of saturated sodium bisulfite solution d...

Embodiment 2

[0015] 1) Take 100mL of 2mol / L ammonia water and put it in a 500mL three-necked bottle, add the titanium sulfate solution (the molar ratio of titanium sulfate to ammonia water is 1:4) into the three-necked bottle at room temperature, and stir to obtain a white precipitate. Washed by centrifugation several times until SO-free 4 2- ions are detected. The precipitate was washed and dispersed in 4 mol / L nitric acid solution, refluxed at 70 °C for a period of time, centrifuged, washed, and dried to obtain rutile nano-TiO 2 .

[0016] 2) Mix 50g hydrogenated ricinoleic acid with 2g nano-TiO 2 After being fully dissolved with 50 mL of absolute ethanol, the reaction was ultrasonically heated at 80 °C for 3 h, and air-dried at 60 °C for 4 h. Nano-TiO modified by hydrogenated ricinoleic acid 2 .

[0017] 3) 20g of hydrogenated ricinoleic acid modified nano-TiO 2 React with 30g of maleic anhydride at 120°C for 5h, cool down to 75°C, add 100g of saturated sodium bisulfite solution...

Embodiment 3

[0019] 1) Take 100mL of 2mol / L ammonia water and put it in a 500mL three-necked bottle, add the titanium sulfate solution (the molar ratio of titanium sulfate to ammonia water is 1:4) into the three-necked bottle at room temperature, and stir to obtain a white precipitate. Washed by centrifugation several times until SO-free 4 2- ions are detected. The precipitate was washed and dispersed in 4 mol / L nitric acid solution, refluxed at 70 °C for a period of time, centrifuged, washed, and dried to obtain rutile nano-TiO 2 .

[0020] 2) Mix 30g hydrogenated ricinoleic acid with 4g nano-TiO 2 After being fully dissolved with 40 mL of absolute ethanol, the reaction was ultrasonically heated at 80 °C for 3 h, and air-dried at 60 °C for 4 h. Nano-TiO modified by hydrogenated ricinoleic acid 2 .

[0021] 3) 30g of hydrogenated ricinoleic acid modified nano-TiO 2 React with 60g of maleic anhydride at 85-150°C for 6h, cool down to 80°C, add 200g of saturated sodium bisulfite solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com