Blade of window-shades and manufacturing method of blade

A technology of blinds and manufacturing methods, applied in the direction of textiles, papermaking, fiber processing, etc., can solve the problems that blinds cannot be applied, textiles do not have, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

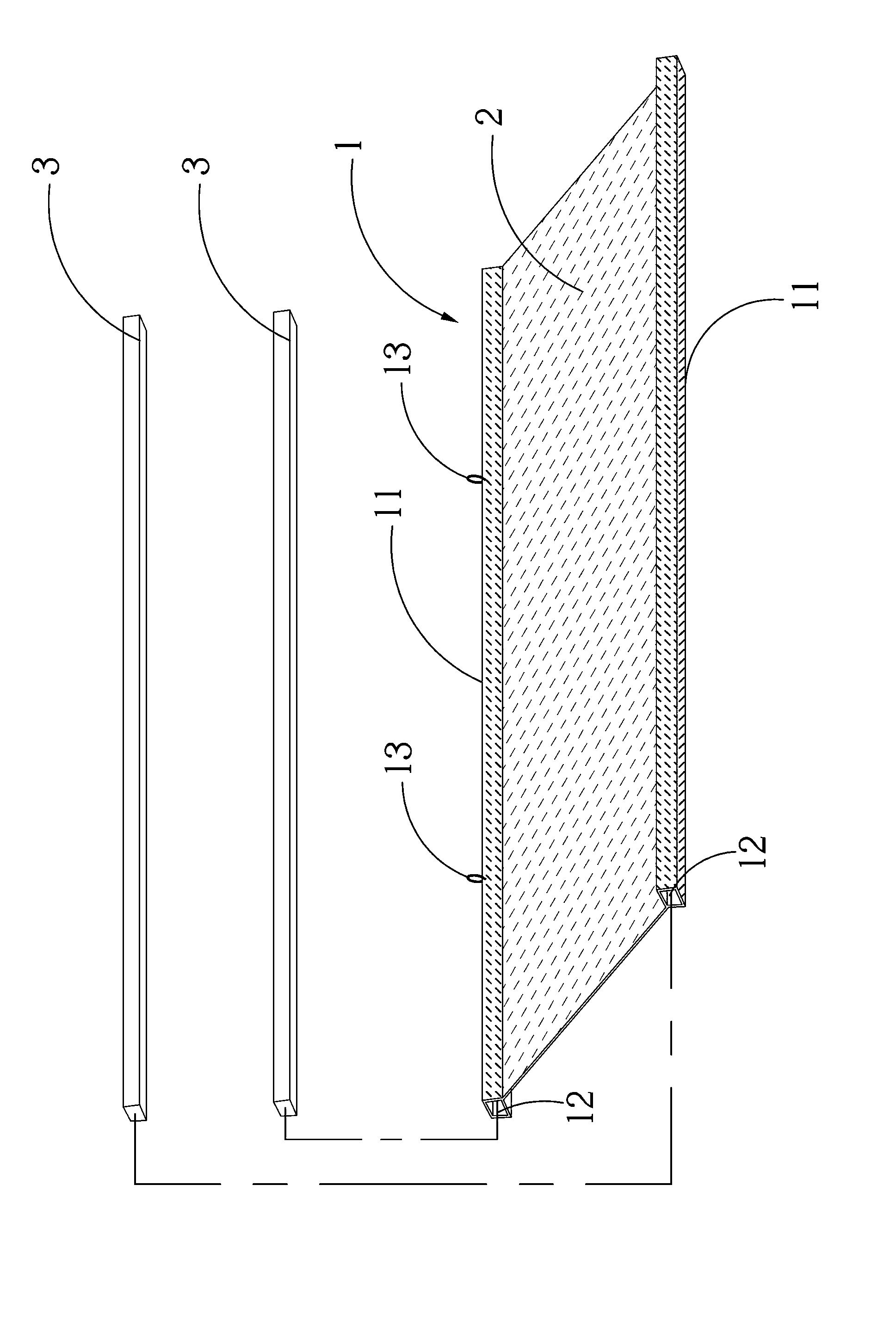

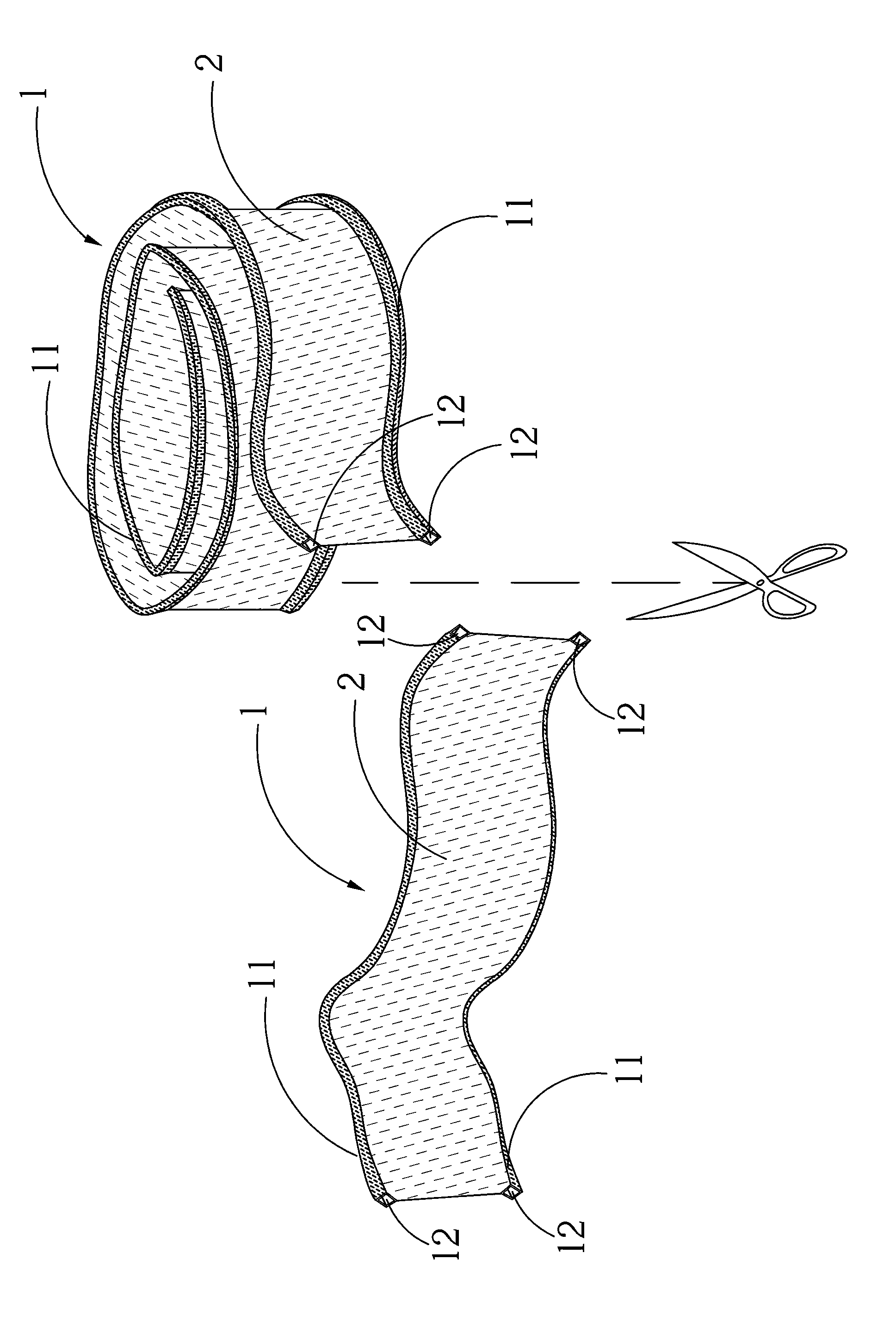

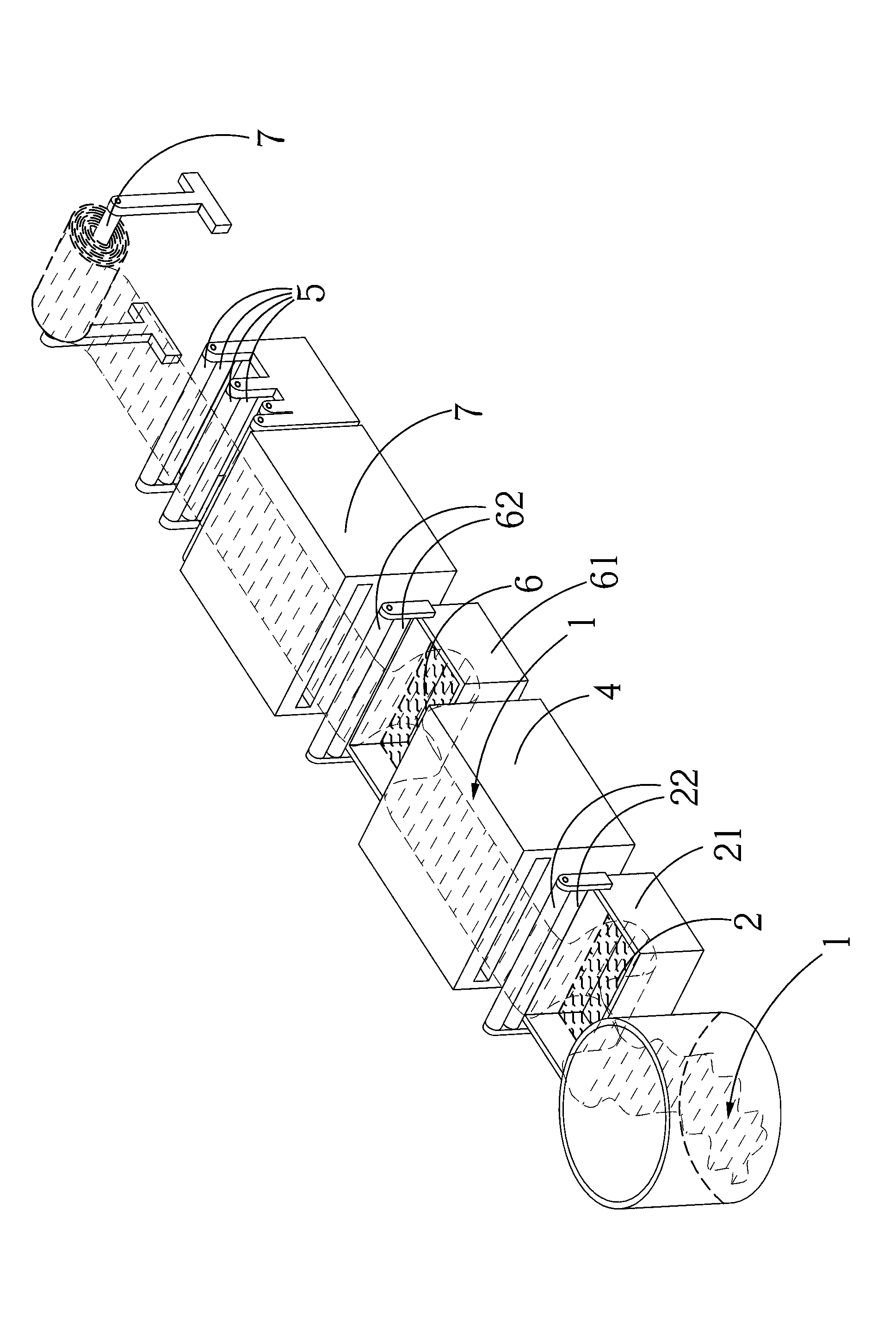

[0047] Please refer to figure 1 , The invention provides a blind blade made of textile, which overcomes the softness of general textiles. And it has advantages that the shutter blades made of general hard materials do not have. The shutter blade of the present invention comprises a strip-shaped shutter blade 1 made of textile, a stiffening agent 2 penetrating into the textile, and two strip-shaped hard rods 3 .

[0048] The two long edges 11 of the strip-shaped louver blade 1 are woven into double layers, forming a long inner space 12 inside, and the strip-shaped louver blade 1 is woven into a textile, and its textile material is polyester material. Including polyester filament yarn, polyester low stretch yarn, polyester high stretch yarn, or polyester network yarn. Its characteristics are high strength, anti-aging, not easy to absorb water, high temperature resistance (up to 180 degrees Celsius), and anti-mildew function. It is an ideal material for making blinds.

[0049]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com