Patents

Literature

74results about How to "Tough texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

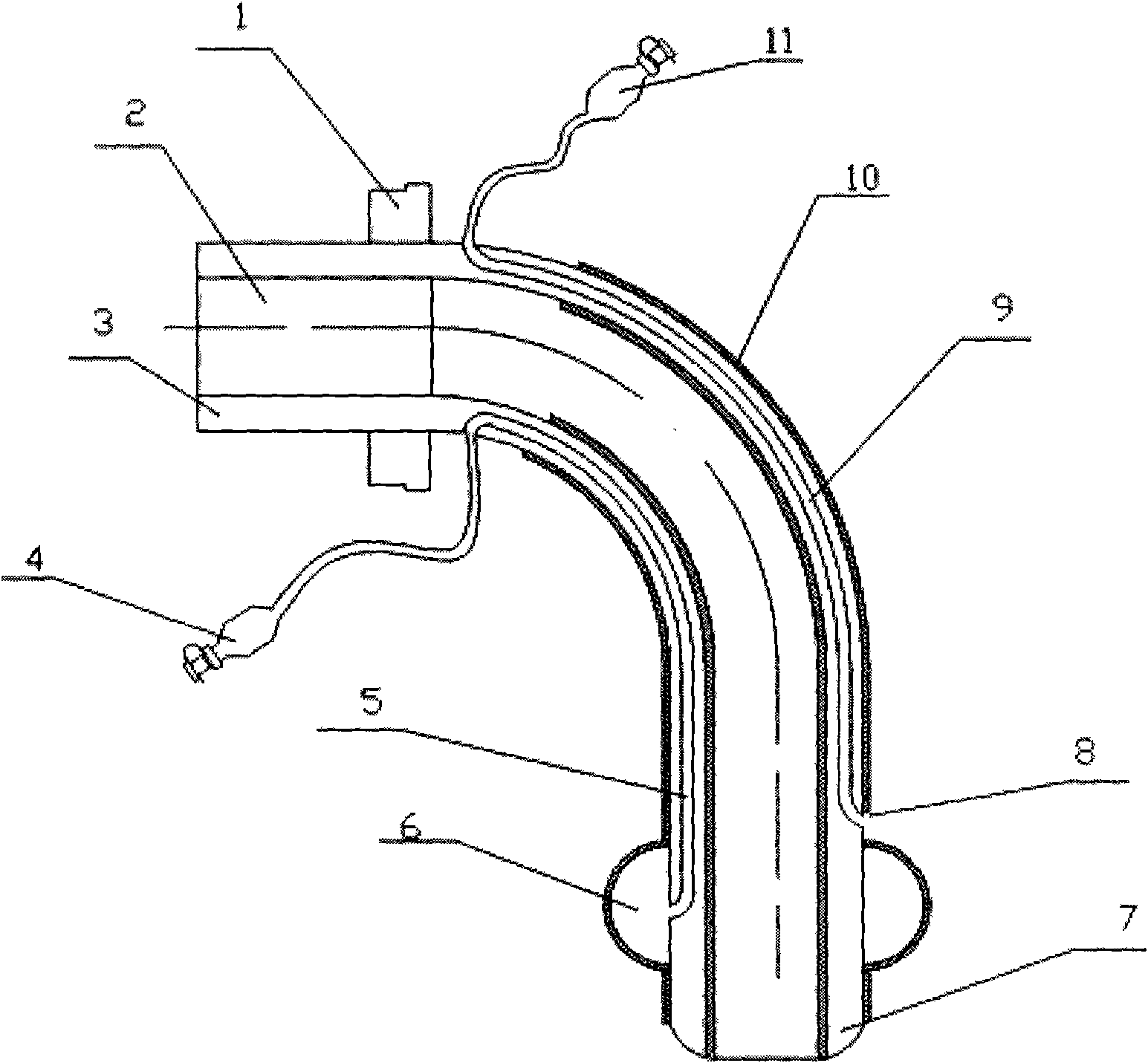

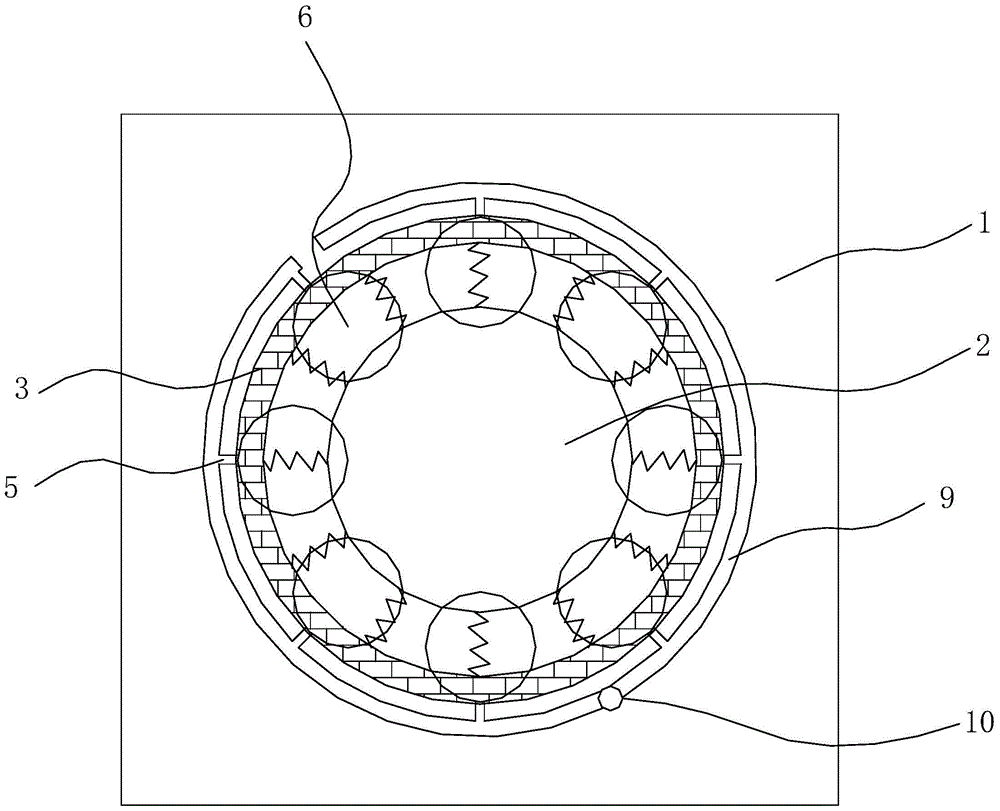

Manual tracheotomy tube with antibacterial nano material coating

InactiveCN101653635AAvoid enteringAchieve antibacterial effectTracheal tubesCatheterTracheotomyEngineering

The invention relates to the technical field of medical apparatus. The generation of ventilator-associated pneumonia is the result of the inspiration of secretion with pathogen, wherein the bacterialcontamination in a ventilator air tube is also a principal element for causing the ventilator-associated pneumonia. The invention aims to provide a manual tracheotomy tube with broad spectrum of antimicrobial activity and controllable slow-release medicaments, comprising a flexible tube body and a tampon system attached to the outside of the tube body, wherein the inner surface and the outer surface of the tracheotomy tube are combined with macromolecular polymer antimicrobial coatings in which medicaments with pharmacologic effect are loaded. The invention not only achieves the efficacy of providing air paths for a traditional tracheotomy tube and keeping the respiratory tract smooth, but also has excellent bacteriostatic effect and the slow release effect of the controllable medicaments,thereby providing a wide application prospect for clinical application of the manual tracheotomy tube.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

Sheet laminating preparation method for sisal fiber reinforced polypropylene composite material

The present invention adopts the sisal hemp fiber as fiber raw material, and uses the nonwoven fabric of thermoplastic resin PP, film, powder material and its fiber as resin base body, and adopts thefollowing steps: pretreating sisal hemp fiber and making it into fiber felt, hot-pressing and forming, selecting and using a certain number of fiber felts, delaminating and sand wiching pp nonwoven fabric or film, under the condition of a certain temp. and pressure hot-pressing and forming or mixing PP fiber (PP powder) directly with sisal hemp fibre, making them into fiber felt and then hot-pressing and forming so as to obtain the invented sisal hemp fiber reinforced polypropylene composite material.

Owner:SUN YAT SEN UNIV

Nano sterilizing anionic double-component aqueous wood paint

InactiveCN101880500ANo pollutionWon't hurtAntifouling/underwater paintsPaints with biocidesAcrylic resinLacquer

In order to solve the problem of environmental pollution of the conventional coating, the invention provides a novel nano sterilizing anionic double-component aqueous wood finishing paint and a preparation method thereof. The nano sterilizing anionic double-component aqueous wood finishing paint provided by the invention comprises a component A and a component B, wherein the component A comprises the following components in part by weight: 65 to 90 parts of acrylic resin, 0.2 to 0.4 part of antifoaming agent, 0.4 to 0.6 part of composite nano anionic powder, 0.1 to 0.3 part of dispersant, 0.5 to 1.5 parts of thickening agent and 15 to 25 parts of water; and the component B comprises the following component in part by weight: 40 to 60 parts of water-dispersed polyisocyanate, wherein the weight of the component A is 1.5 to 2.5 times that of the component B. The nano sterilizing anionic double-component aqueous wood finishing paint has the technical advantages of environmental protection, strong sterilization and mildew prevention, capability of constantly releasing anions and purification and indoor air.

Owner:QUANZHOU XINXIEZHI SPECIAL COATING

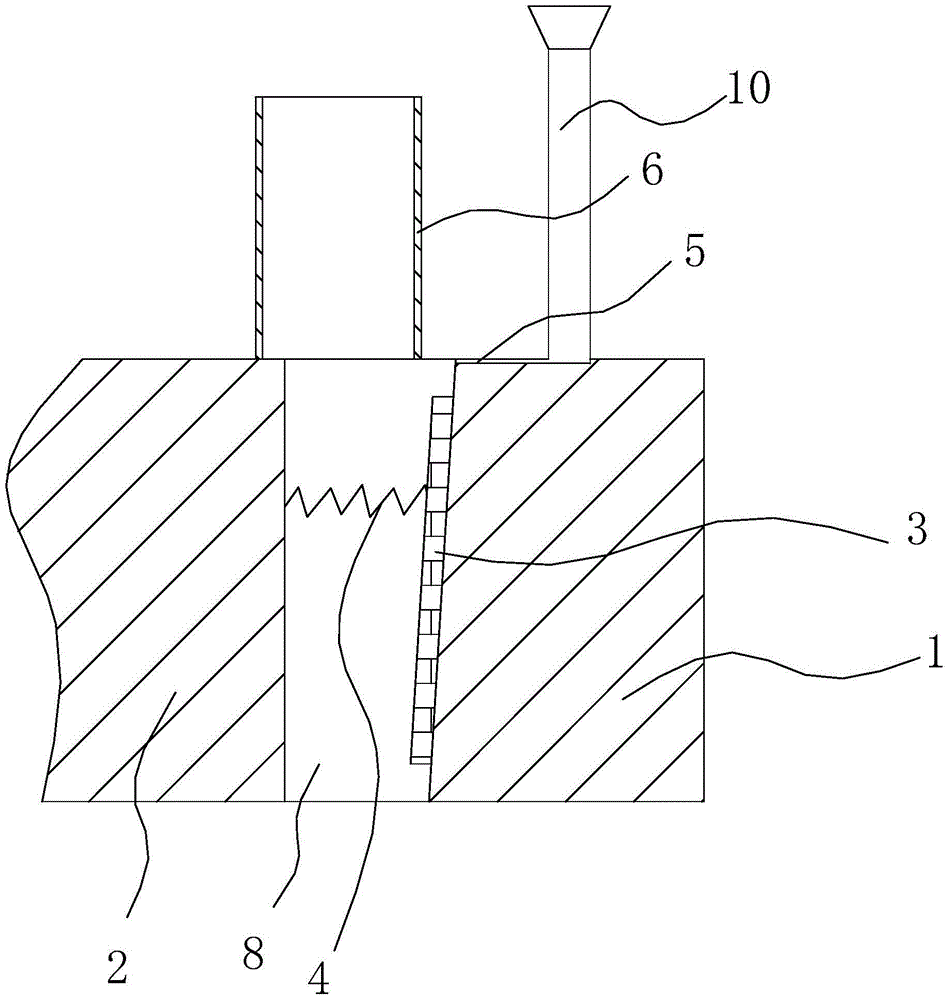

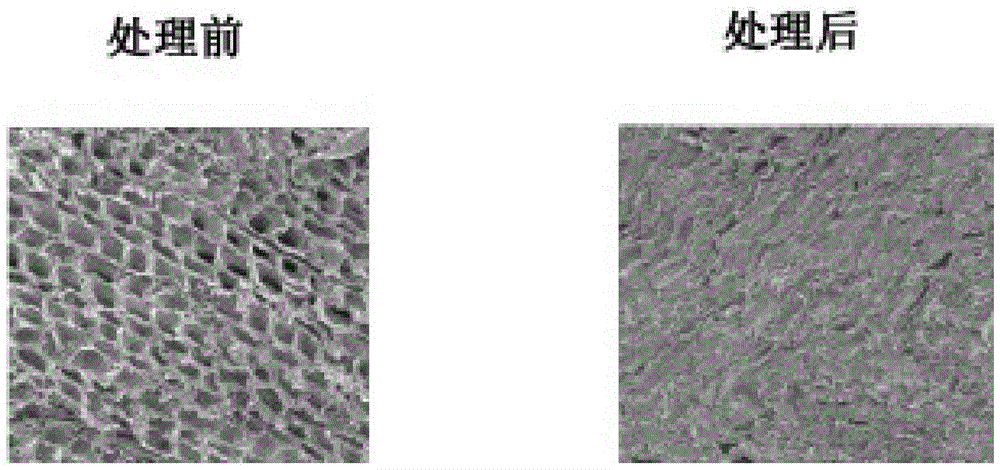

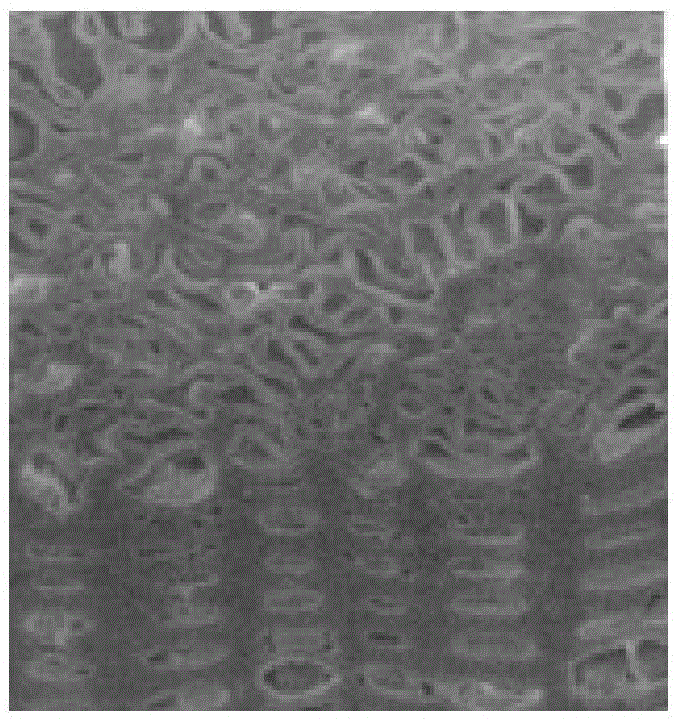

Preparation method for common casting iron-based ceramic composite vertical grinding roller

The invention discloses a preparation method of a vertical mill roller made of ordinary cast iron-based ceramic composite material. Provided is a method for preparing a vertical mill roller made of ordinary cast iron-based ceramic composite material, which is beneficial to the impregnation of high-chromium cast iron in molten iron, one-time pouring molding, simple process implementation, adjustable composite layer shape and thickness, and improved wear resistance. It includes the following steps: 1) Select 2-4mm fused zirconia corundum particles; 2) Prepare the arc-shaped honeycomb zirconia corundum ceramic particle preform from the above fused zirconia corundum particles, and cool it for use; 3) Arrange the prepared preforms side by side Place it on the arc surface of the sand mold cavity of the vertical mill roller, and fix it with the core support; 4) After closing the box, use a hot air blower to preheat the cavity, then cast it, and take it out of the box; 5) Put the above The obtained iron-based ceramic composite material vertical grinding roller is subjected to heat treatment. The invention has simple process; the composite grinding roller is formed by one-time pouring; the production process can realize mechanized operation, the production cost is low, and the production efficiency is high.

Owner:YANGZHOU ELECTRIC POWER EQUIP MFG FACTORY CO LTD

Brake gasket and its preparng metod

The preparation process of brake gasket includes the following steps: preparing sisal fiber via cutting sisal into 10-20 mm long segment, soaking in anhydrous alcohol plus benzene solution, washing with anhydrous alcohol and deionized water, boiling in NaOH solution, cooling to room temperature, washing with deionized water to neutrality and stoving in stove; mixing sisal fiber, phonetic resin, copper powder, graphite powder, MoS2, pre-polymer, metal oxide, butadiene-acrylonitrile rubber, non-metal compound and barium sulfate in a high speed mixer to form mixture material; making blank with the mixture material; hot pressing the blank to form; and heat treatment at 190-200 deg.c. The present invention makes asbestos-free brake gasket with sisal fiber as reinforcing material, and the brake gasket has stable friction coefficient, less heat degradation, low wear, no couple wear, smooth braking, low noise and no environmental pollution.

Owner:XI AN JIAOTONG UNIV +1

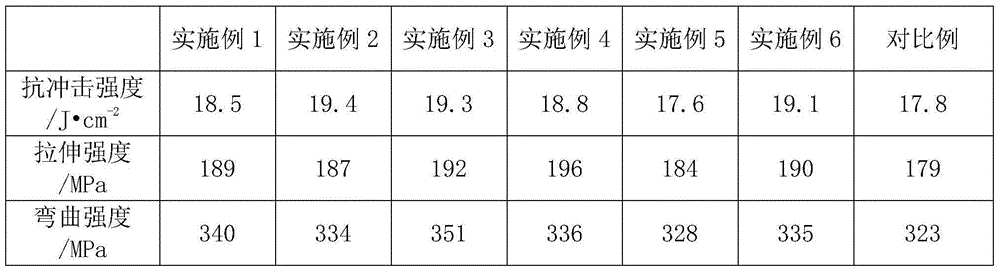

Preparation method for polyimide composite material for automobile

The invention provides a preparation method for a polyimide composite material for an automobile. The method comprises the following steps that 1, impurities in sisal fiber are removed, the sisal fiber is dried and added into a sodium hydroxide solution to be soaked, the sisal fiber is taken out to be washed to obtain alkalified sisal fiber, a silane coupling agent is dissolved into an acetic acid solution, the PH value is adjusted to be 7 through ammonium hydroxide, conditioning fluid is obtained after standing, and the alkalified sisal fiber is added into the conditioning fluid for ultrasonic dispersion and taken out for drying, taking, dispersion and smashing to obtain modified sisal fiber; 2, talcum powder is added into a mixing machine to be stirred, then a titanate coupling agent is added, and modified talcum powder is obtained after taking out and drying are performed; 3, polyimide, the modified sisal fiber and the modified talcum powder are added into a stirring machine for stirring and mixing and then taken out to be put into a mold for compression molding forming, and mold stripping is performed to obtain the polyimide composite material for the automobile. According to the preparation method, raw materials are cheap and easy to obtain, the production cost is saved, and the obtained composite material has the good mechanical performance, has the certain degradability and is environmentally friendly.

Owner:SUZHOU ZHENZHAN TECHCAL MATERIAL CO LTD

Nano anionic double-component aqueous wood paint

InactiveCN101880506ANo pollutionGood flexibilityPolyurea/polyurethane coatingsAcrylic resinMaterials science

In order to solve the problem of environmental pollution of the conventional coating, the invention provides a novel nano anionic double-component aqueous wood finishing paint and a preparation method thereof. The double-component aqueous wood finishing paint provided by the invention comprises a component A and a component B, wherein the component A comprises the following components in part by weight: 65 to 90 parts of acrylic resin, 0.2 to 0.4 part of antifoaming agent, 0.4 to 0.6 part of composite nano anionic powder, 0.1 to 0.3 part of dispersant, 0.5 to 1.5 parts of thickening agent and 15 to 25 parts of water; and the component B comprises the following component in part by weight: 40 to 60 parts of water-dispersed polyisocyanate, wherein the weight of the component A is 1.5 to 2.5 times that of the component B. The nano anionic double-component aqueous wood finishing paint has the technical advantages of environmental protection, capability of constantly releasing anions and purification and indoor air.

Owner:QUANZHOU XINXIEZHI SPECIAL COATING

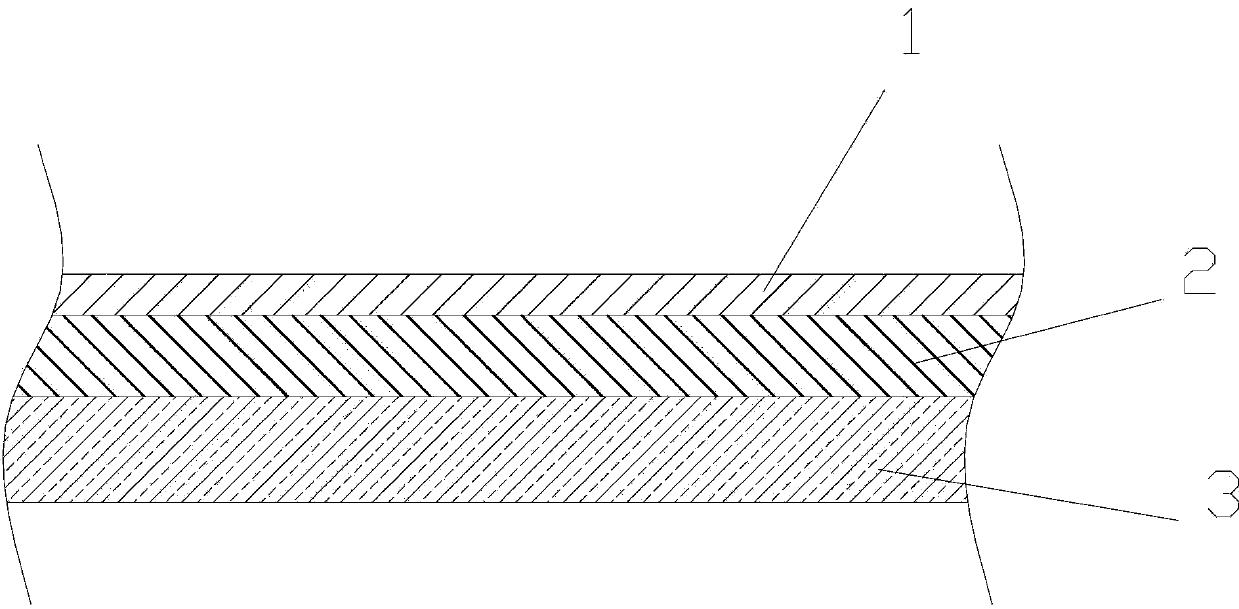

Sisal hemp car foot mat and production method thereof

InactiveCN104175932AWhite colorTough textureVehicle arrangementsRubber layered productsHemp fiberSISAL

The invention discloses a sisal hemp car foot mat which comprises a surface layer, a middle layer and a bottom layer, wherein the surface layer is arranged as a sisal hemp fiber cloth layer; a dacron punched felt is arranged on the middle layer; a rubber layer is arranged as the bottom layer. The sisal hemp car foot mat has the advantages that the sisal hemp fiber cloth layer is arranged on the surface and has the advantages of damp-poof property, anti-skidding property, anti-static property, wear resistance, easiness in cleaning, high cost performance, and the like; the dacron punched felt is arranged on the middle layer, the dacron punched felt is excellent in air permeability, strong in warm-keeping property, soft and low in cost, and the production cost of the car foot mat is reduced to a certain degree; the rubber layer is arranged as the bottom layer and is used for preventing skidding. The production method for the sisal hemp car foot mat provided by the invention has the advantages that the sisal hemp car foot mat which is unlikely to hide germs, stain, fade and deform and easy to clean can be produced, and meanwhile, the sisal hemp fiber cloth layer, the dacron punched felt and the rubber layer in the sisal hemp car foot mat are unlikely to fall off, and the surface of the rubber layer is smooth and odorless.

Owner:JIANGSU HIMALAYA NATURAL FIBER PROD

Blended fibriia composite fabric

The invention discloses a blended fibriia composite fabric. The blended fibriia composite fabric comprises a hygroscopic and breathable layer which is a surface layer and an antibiotic and radiation-proof layer which is an internal layer, the hygroscopic and breathable layer is obtained through blending braiding of 15-22wt% of sisal fibers and 78-85wt% of pina fibers, and the antibiotic and radiation-proof layer is obtained through blending braiding of 45-51wt% of hemp fibers and 49-55wt% of kendir fibers. The blended fibriia composite fabric has a double-layer structure design, the hygroscopic and breathable layer which is the surface layer has the characteristics of tough texture, wear resistance, acid and alkali resistance, and good hygroscopic and breathable properties, and the hygroscopic and breathable layer which is the internal layer has the characteristics of antibiosis, deodorization, ultraviolet resistance and healthcare, so the fabric has the characteristics of cooling, comfortableness, unlikely damage, and maintenance of the cleanness and health of human bodies.

Owner:SUZHOU TANXI TEXTILE TECH CO LTD

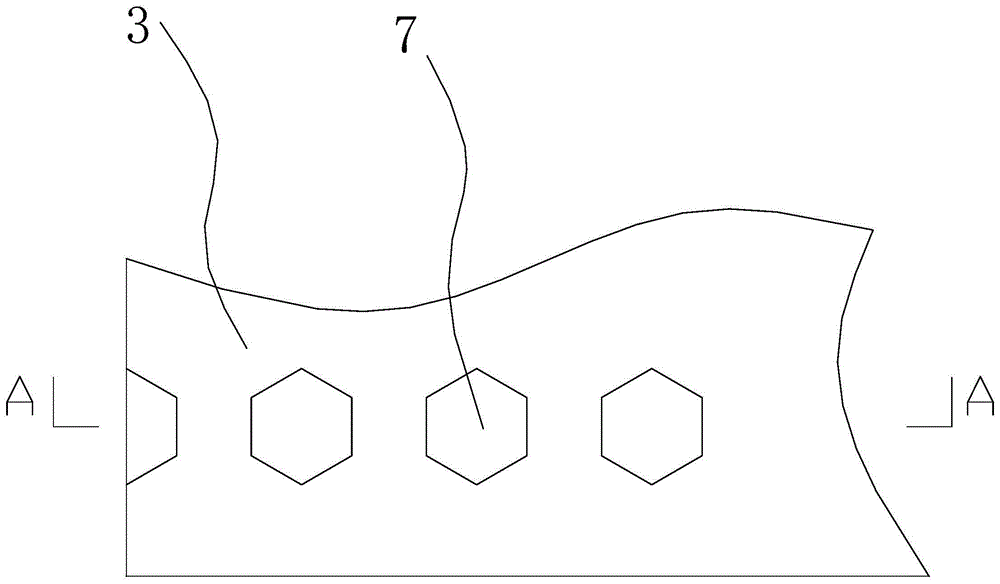

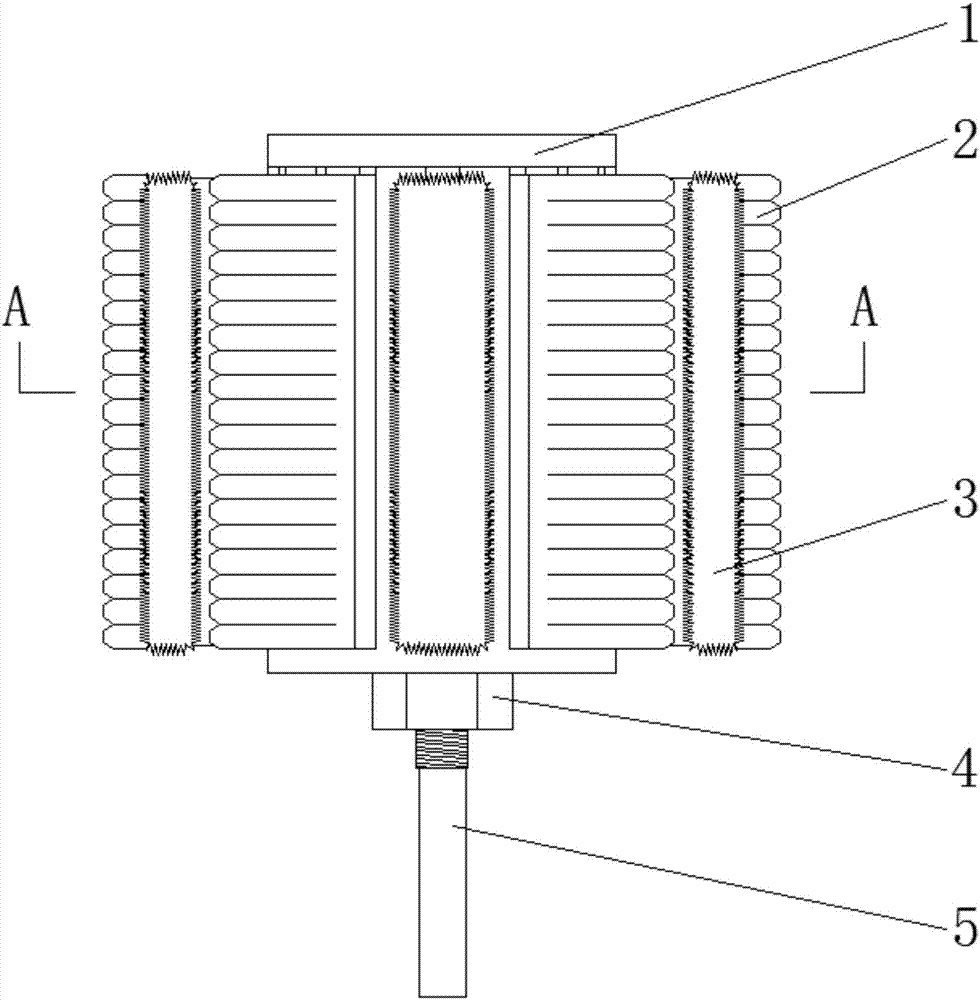

Polishing brush for curved surface board and plane board

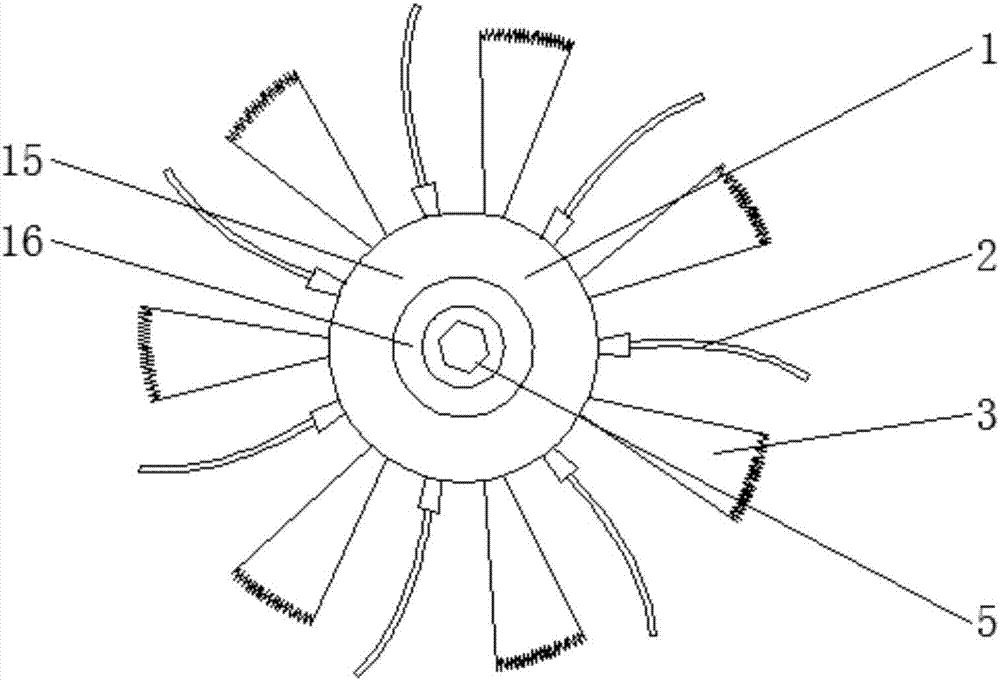

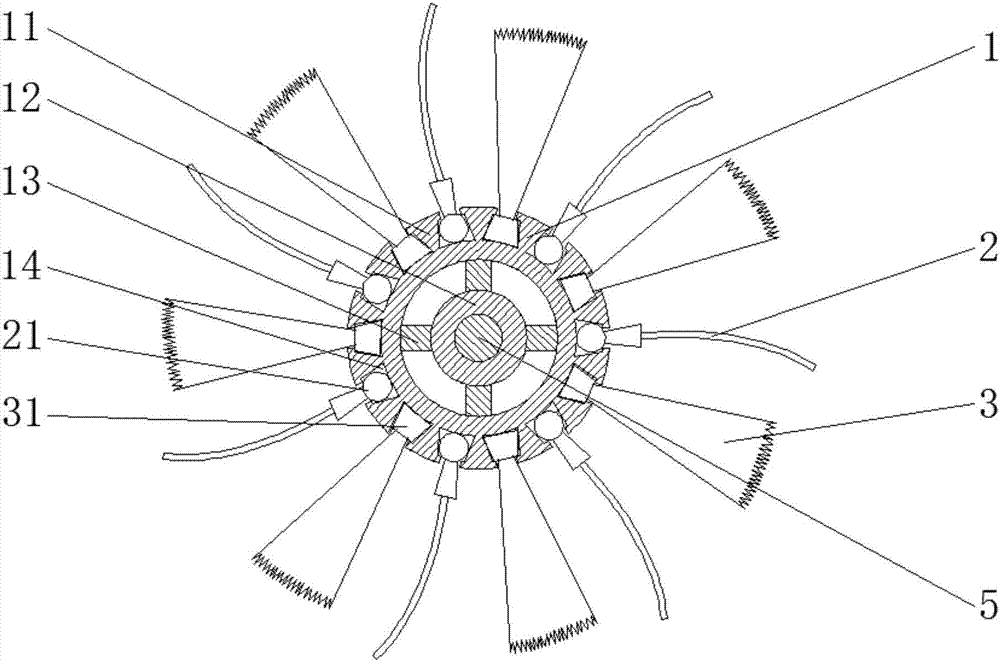

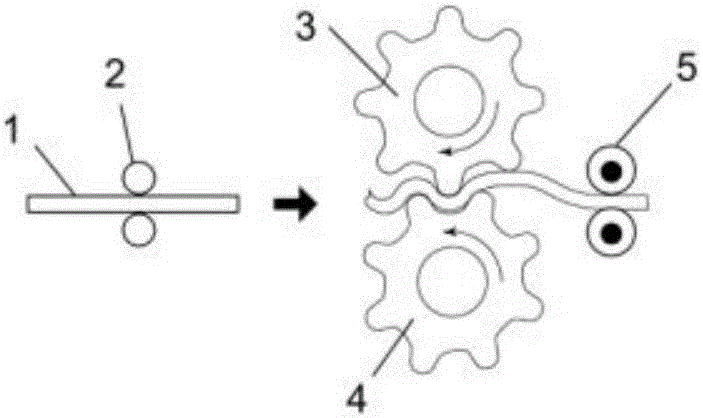

PendingCN107378808AEasy to transportAvoid excessive sandingFlexible-parts wheelsPolishingMaterials science

The invention discloses a polishing brush for a curved surface board and a plane board. The polishing brush comprises a rotary drum, polishing abrasive cloth, brush bars, a nut and a screw. One side edge of the polishing abrasive cloth is connected with the outer wall of the rotary drum, the connecting edges of the polishing abrasive cloth and the rotary drum are parallel to the axis of the rotary drum, and the bottom edges of the brush bars are connected with the outer wall of the rotary drum and are parallel to the axis of the rotary drum. The polishing abrasive cloth and the brush bars are alternately arranged. The screw penetrates through a center shaft of the rotary drum, the nut is mounted on the screw, and the rotary drum is tightly pressed between the nut and the head of the screw. The polishing brush can be used for polishing the curved surface board, a concave line groove and a convex line, the polishing effect is good, the polishing abrasive cloth is convenient to replace, the cost performance is high, economy and environment protection are realized, the boards can be protected, operation and transportation are convenient, and the working efficiency is high.

Owner:林建福

Nano antimicrobial water-based wood paint

InactiveCN103333601AEasy to transportTough textureAntifouling/underwater paintsPaints with biocidesWater basedSilicon dioxide

The invention relates to a simulated wood-grain nano water-based wood paint which comprises 10-20 parts of bisphenol A epoxy acrylate, 20-30 parts of brominated bisphenol A epoxy acrylate, 30-50 parts of aromatic polyurethane acrylate, 2-4 parts of nano zinc oxide, 1-3 parts of nano titanium oxide, 2-4 parts of nano silicon dioxide, 1-2 parts of diphenyl ketone and 3-7 parts of nano silver antimicrobial agent. The nano silver antimicrobial agent is a nano metal silver dispersion solution. The particle size of the nano silver antimicrobial agent is 30-40nm. The simulated wood-grain nano water-based wood paint provided by the invention is environment-friendly, safe, efficient, beautiful and firm.

Owner:FORTUNE WOODEN PROD

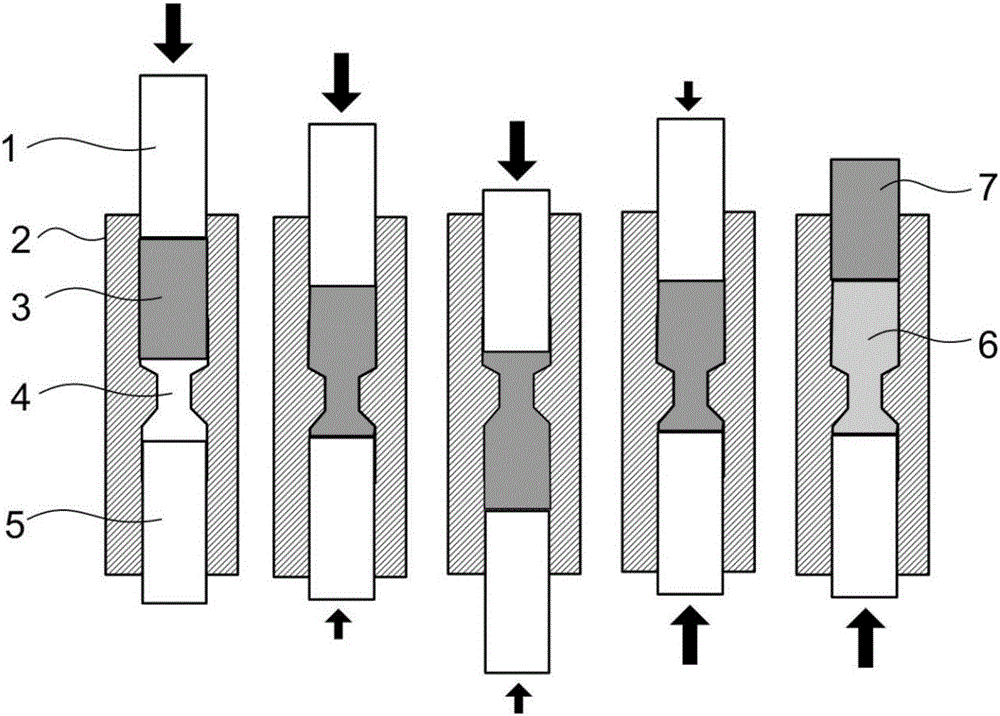

Wedge bending-roller straightening deformation method for circularly solidifying waste titanium chips

InactiveCN106583411AEasy to oxidizeReduced mechanical propertiesSolid waste disposalRoom temperatureTitanium

The invention provides a wedge bending-roller straightening deformation method for circularly solidifying waste titanium chips. The method comprises the following steps: (1) recovering and pretreating Ti chips, namely, cleaning the titanium chips to remove oil stains and impurities; (2) drying and deairing the Ti chips, namely, drying and deairing the pre-treated Ti chips; (3) sleeving and sealing Ti chips, namely, filling the dried Ti chips obtained in step (2) into a copper barrel cavity, and then primarily compacting the chips through a manual press; (4) performing cold rolling on the sleeved Ti chips under room temperature, namely, performing cold rolling on the sleeved and sealed Ti chips obtained in step (3) among rollers so as to obtain a cold-rolled pure Ti board; (5) performing wedge bending-roller straightening deformation high-temperature solidifying processing; and (6) quenching, namely, quenching to cool the Ti material subjected to high-temperature solidifying processing in step (5) to reach the room temperature in a water cooling manner.

Owner:SHANGHAI DIANJI UNIV

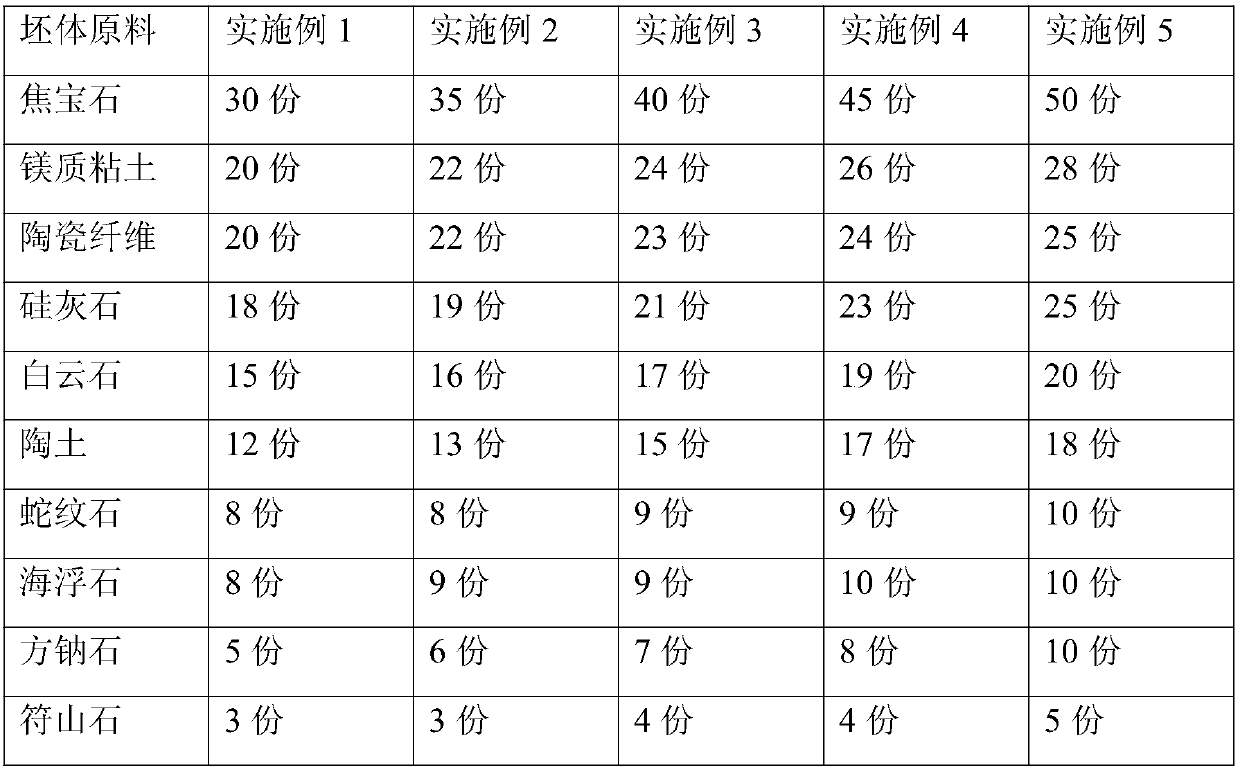

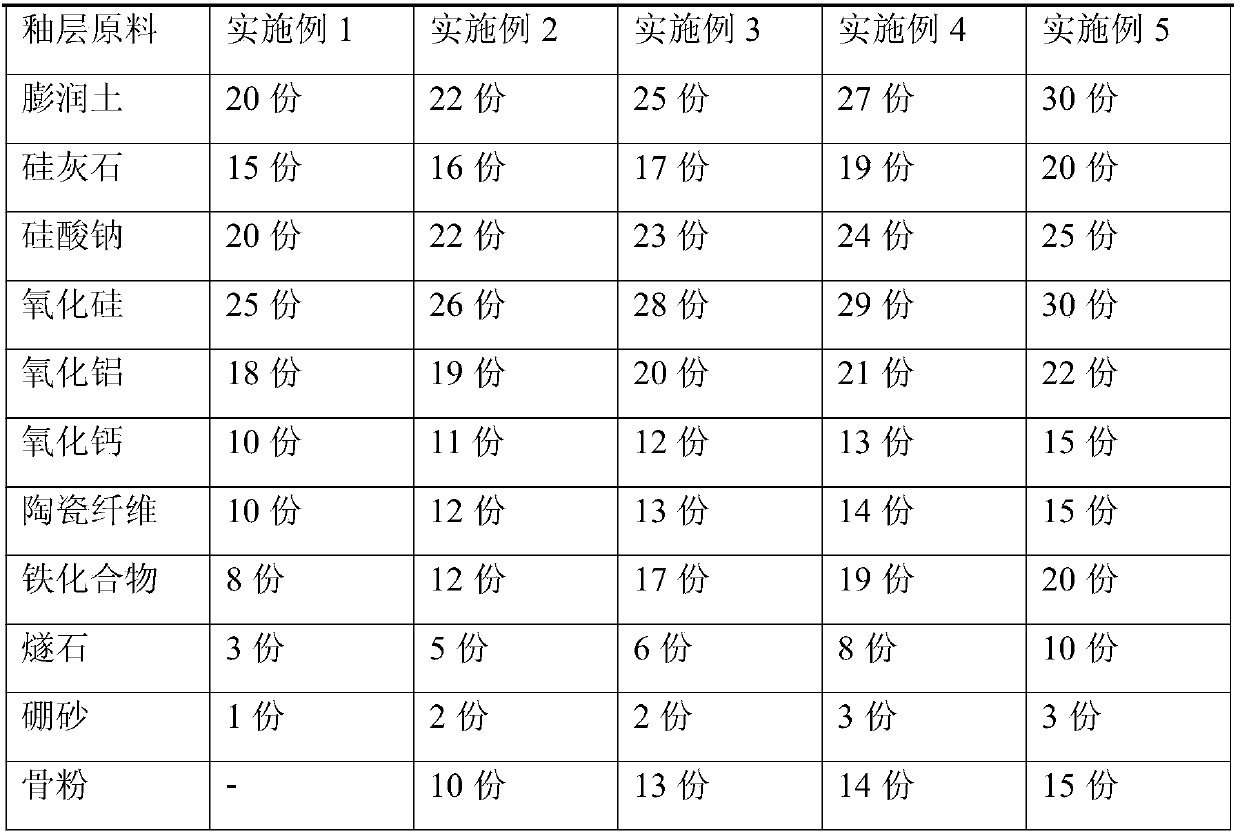

Quick burnt iron series crystal ceramic tableware and preparation technology thereof

The invention provides a quick burnt iron series crystal ceramic tableware which comprises a blank body and an enamel coating applied to the tank body; the blank body is prepared from the following raw materials: flint clay, magnesium clay, ceramic fiber, wollastonite, dolomite, pottery clay, serpentine, bryozoatum, sodalite and idocrase; the enamel coating is prepared from the following raw materials: bentonite, wollastonite, sodium silicate, silicon oxide, aluminum oxide, calcium oxide, ceramic fiber, iron compound, flint and borax. The quick burnt iron series crystal ceramic tableware provided by the invention has the advantages of smooth and bright appearance, mold and smooth hand feel, tough texture, high strength, high water resistance, excellent weather resistance, slow heat conduction and being durable in use.

Owner:FUJIAN DEHUA FIVE CONTINENTS CERAMIC MFG CO LTD

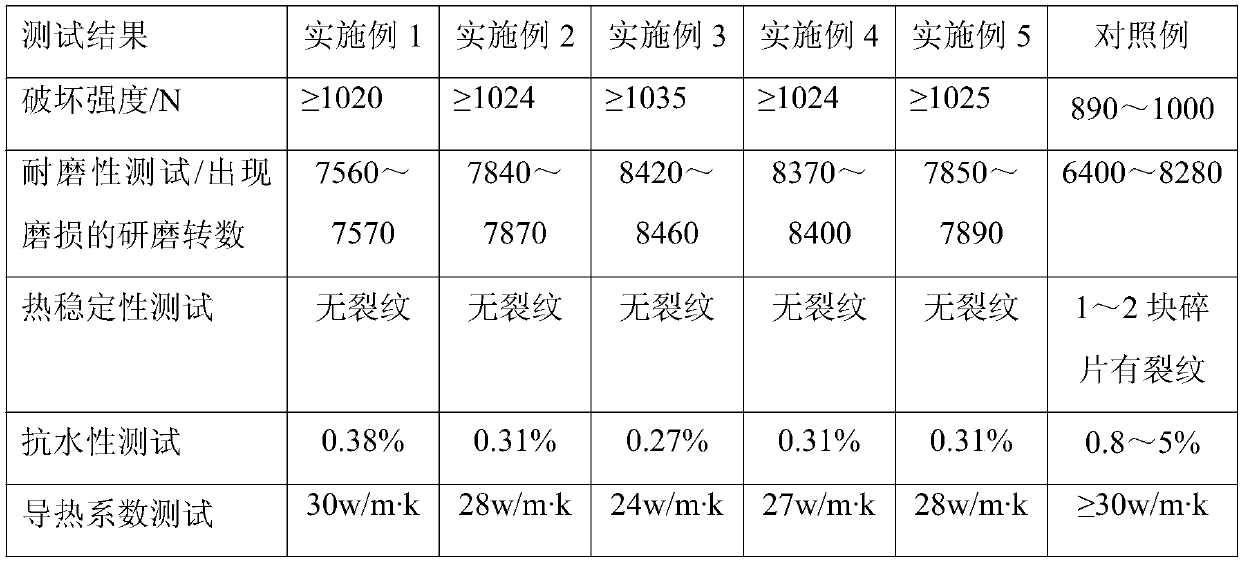

Glass conveyor

InactiveCN105173725ASimple structureEasy to manufactureCharge manipulationConveyor partsEngineeringPulley

The invention relates to a glass conveying device, in particular to a glass conveyor. The glass conveyor comprises a bottom board, sliding wheels and a handle, wherein the sliding wheels and the handle are arranged on the bottom board. The handle is located at one end of the bottom board. The handle is provided with an elastic net cover used for binding glass. The net cover is provided with clamping pieces. Buckles in which the clamping pieces are inserted are arranged at the other end, away from the handle, of the bottom board. The handle is further provided with suction cups and air bags capable of being manually squeezed. Air pipes for communication are arranged between the air bags and the suction cups. The suction cups are provided with squeezing blocks used for closing the air pipes and exhausting air. The bottom board is detachably connected with a clamping groove where glass is clamped and located. The glass conveyor can be used for conveying glass of various sizes.

Owner:深圳市光华中空玻璃工程有限公司

Organic modified reinforcement and strengthening road surface material and preparation method thereof

The invention provides an organic modified reinforcement and strengthening road surface material and a preparation method thereof. The organic modified reinforcement and strengthening road surface material is prepared by the following raw materials: sand, a mineral powder mixture, a composited alkaline exciting agent, an organic mixture, a fiber mixture, a composited dispersing agent and water. According to the organic modified reinforcement and strengthening road surface material prepared by the preparation method, the fiber mixture is added to the mineral powder mixture, used fibers are all natural, and environment-friendly and harmless; a palm fiber and a jute fiber have texture toughness, high elasticity and corrosion resistance and are decomposed into monofilaments under an alkaline condition, through mixing, the fibers are overlapped mutually to form a reticular three-dimensional structure to be evenly dispersed, and by using excellent bonding performance of the organic mixture, elastic nodes are formed, and a sheeted elastic material consisting of a plurality of plant fiber ''springs'' are formed in the organic modified reinforcement and strengthening road surface material. The organic modified reinforcement and strengthening road surface material is of great help in reducing road surface cracks, and can improve the crack resistance of a road surface.

Owner:CHANGAN UNIV

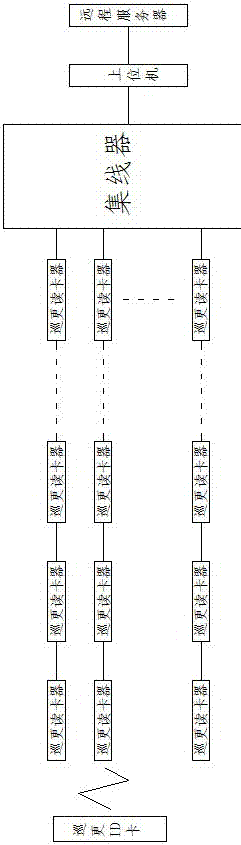

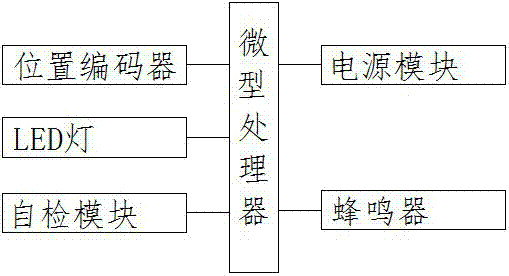

Online electronic patrol system

InactiveCN106898056ATough textureDurable textureChecking time patrolsCard readerRemote data transmission

The invention relates to an online electronic patrol system. The system comprises a patrol ID card, a plurality of patrol card readers, an upper computer and a remote server, wherein microprocessors are arranged in the patrol card readers; the microprocessors are connected with a position coder used for coding address information, a power module, a self-inspection module, a buzzer and a RGB (red, green and blue) three-color LED (Light-emitting Diode); the microprocessors perform data transmission and power management by adopting a high-performance low-power-consumption ARM chip STM32 in company ST; RJ45 interfaces are arranged in the patrol card readers; the plurality of patrol card readers are connected in series through the RJ45 interfaces; the tail-end patrol card reader is connected to a concentrator through a signal line; the concentrator is connected with the upper computer; and the upper computer is connected with a remote server. The online electronic patrol system disclosed by the invention has the advantages that remote data transmission can be realized, and online conditions of devices, whether patrol exists, whether patrol is on time, who performs patrol, whether missing patrol exists and whether patrol is performed according to a specified sequence can be checked in real time.

Owner:HENAN DANFENG TECH

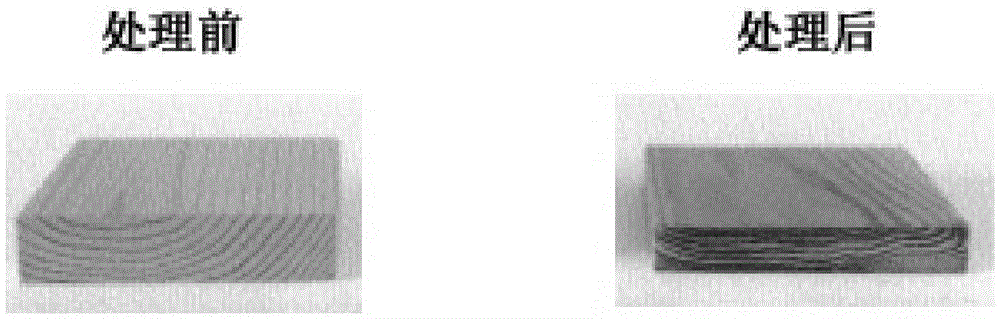

New hardwood based on compaction technology

The present invention relates to a new type of hardwood made on the basis of compaction techniques; the hardness of the new type of hardwood is 5H-9H, and the surface of the hardwood is glossy or matte; the hardwood is obtained by way of the compaction techniques: softwood pretreatment, high-temperature high-pressure treatment, continued pressure treatment, high-temperature reduced-pressure treatment, and temperature-reduction constant-pressure treatment; the hardwood prepared in the present invention is resistant to high temperatures and boiling; it is hard and resistant to wear, and its surface has good glossiness; when manufacturing wood products, no spray painting or lacquering processes are needed; the product is green and environmentally friendly.

Owner:香河凯王压密木科技有限公司

Double-ironing cyclic extrusion solidification method for remanufacturing titanium abandoned cuttings

InactiveCN106734063AEasy to oxidizeGrain weakeningSolid waste disposalProcess efficiency improvementQuenchingStain

The invention provides a double-ironing cyclic extrusion solidification method for remanufacturing titanium abandoned cuttings. The method includes the following steps of (1), recycling and pretreatment of the Ti cuttings, specifically, the Ti cuttings are cleaned for removing oil stains and impurities; (2), BM treatment of the Ti cuttings, specifically, the Ti cuttings pretreated in step (1) are subjected to ball milling; (3), sleeving and packaging of the BM-Ti cuttings, specifically, the BM-Ti cuttings are loaded into a copper barrel cavity, and then the cuttings are compressed preliminarily by a manual pressing machine; (4), room temperature cold squeezing of the sleeved and packaged BM-Ti cuttings; (5), double-ironing cyclic extrusion high-temperature solidification machining; (6), ejection and demoulding of a Ti material sample, specifically, an upper punch pin is removed, a pure-aluminum pseudo sample is placed in a die lower cavity, and a lower punch pin provides extension force to push the remanufactured Ti material obtained in step (5) for demoulding; (7), quenching, specifically, a block Ti material obtained in the ejection step (6) is quenched in a water cooling manner and cooled to the room temperature.

Owner:SHANGHAI DIANJI UNIV

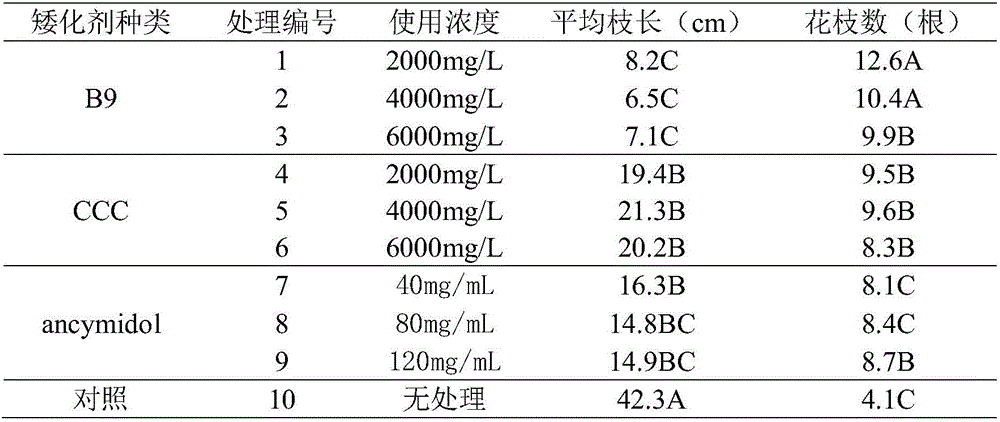

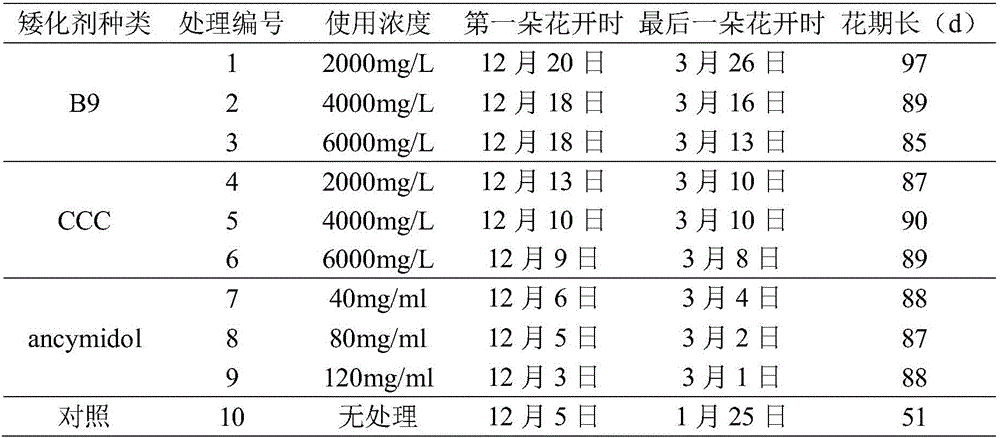

Branch control and blossom promotion method for Belgian azalea

InactiveCN106105746AIncrease the number ofTough texturePlant cultivationCultivating equipmentsCuckooPetal

The invention discloses a branch control and blossom promotion method for Belgian azalea. The method comprises the following steps: (1) selection of Belgian azalea seedlings; (2) pinching treatment; (3) treatment with a dwarfing agent after pinching treatment. According to the method, a growth regulator at a certain concentration and in a certain volume is applied to control the lengths of plant branches and promote increase of the number of flowering branches, so that the number of blossoms is increased; when the method is used for effectively, conveniently and rapidly controlling the lengths of the branches and promoting increase of the number of the blossoms, the average branch length can be reduced by over 50 percent compared with that of Belgian azalea cultivated by an ordinary method, and the number of the flowering branches can be increased by over 98 percent compared with that of the Belgian azalea cultivated by the ordinary method; with increase of the number of the flowering branches, the total number of the blossoms is increased, so that the ornamental value is effectively improved; in addition, by the method, the textures of petals are stronger, the petals are thicker, and the flowering time is longer.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

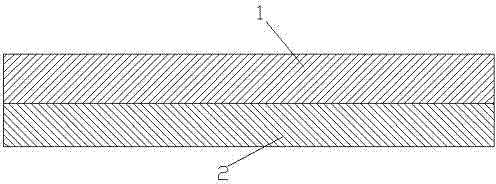

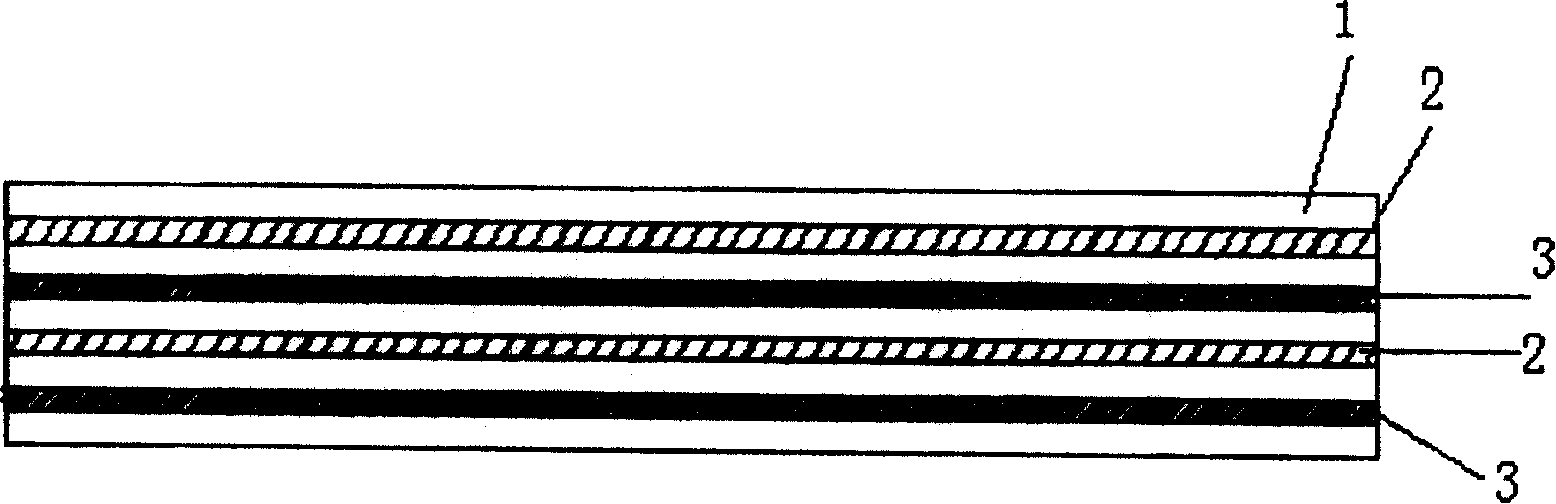

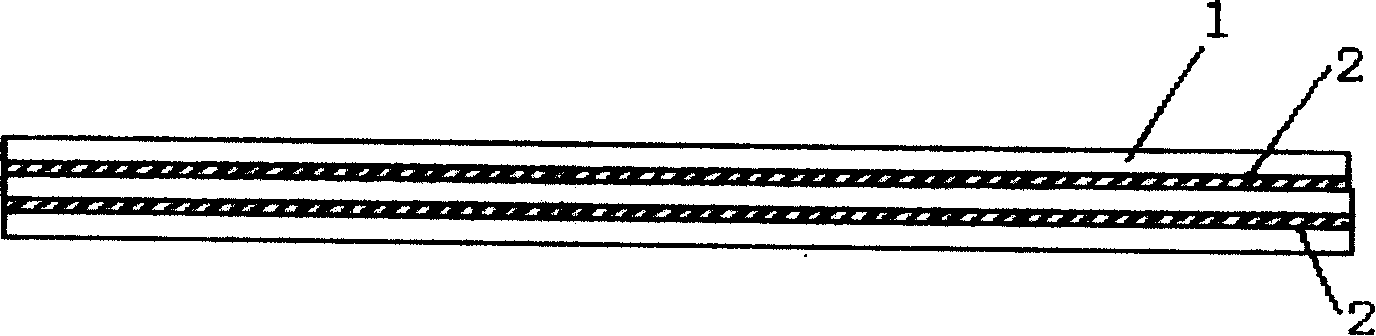

Regenerated plastic base sisal hemp fiber reinforced construction mould plate and its processing method

InactiveCN100383080CImprove waterproof performanceImprove corrosion resistanceSolid waste managementSisal fiberCorrosion

The present invention relates to sisal fiber reinforced regenerated plastic building shuttering and its making process. The sisal fiber reinforced regenerated plastic building shuttering consists of laminated plastic base and sisal fabric-dry sisal leaf layer, and through hot pressing to form integral. The building shuttering is made through sorting, cleaning and pelletizing waste plastic; banburing together with stuffing to form sheet in certain size; laminating the plastic sheets and sisal fabric-dry sisal leaf layers and hot pressing. The building shuttering has high strength, high corrosion resistance, high rain water resistance, smooth surface, convenient construction and environment friendship.

Owner:WUHAN TEXTILE UNIV

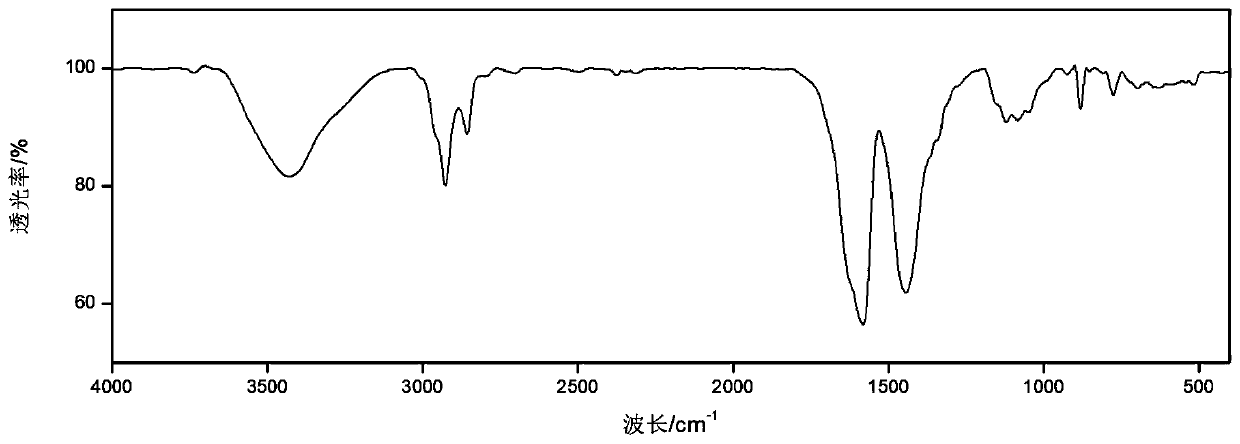

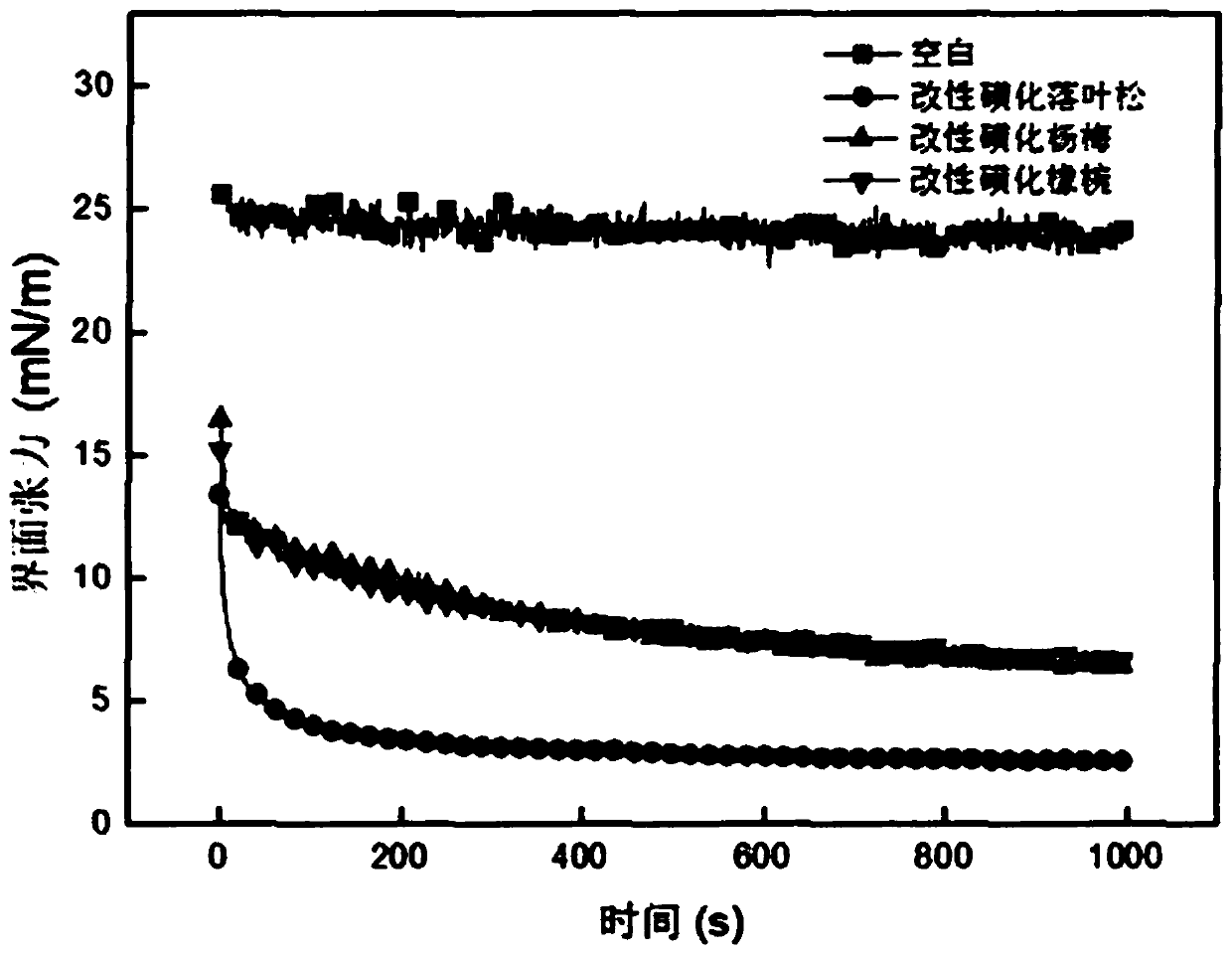

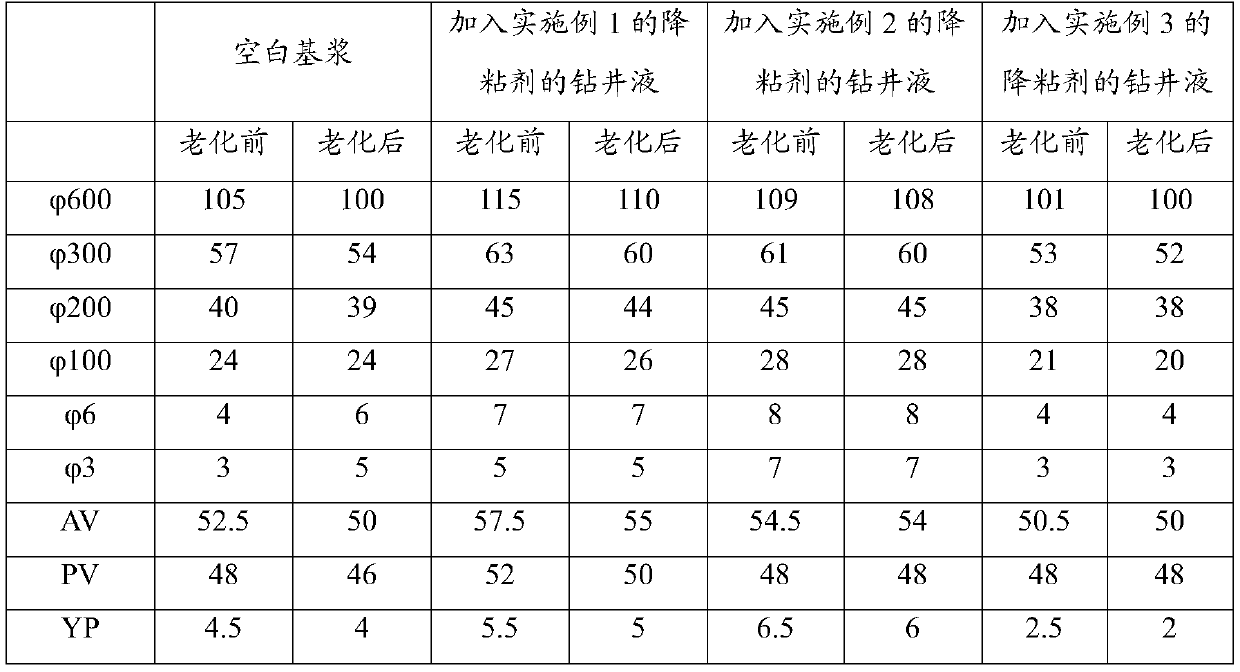

High-temperature-resistant and high-pressure-resistant viscosity reducer for oil-based drilling fluid and preparation method of viscosity reducer

ActiveCN111205834AGood dilution viscosity reduction effectStable performance of dilution viscosity reductionDrilling compositionNatural resin chemical modificationPolyphenolHydrolysis

The invention discloses a high-temperature-resistant and high-pressure-resistant viscosity reducer for oil-based drilling fluid and a preparation method of the viscosity reducer. The preparation method comprises the step of carrying out ammonolysis modification on a hydrolysable plant extraction polyphenol by adopting a partially amidated active amine to obtain the viscosity reducer. The preparation method is simple in process, the raw materials are easy to obtain, the prepared viscosity reducer has good dilution and viscosity reduction effects, the dilution and viscosity reduction performanceis stable under the high-temperature and high-pressure conditions, and certain filtrate loss reduction performance is achieved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

A manufacturing process of peach wood hollow screen

ActiveCN107199614BMoisture-proof and anti-corrosionImprove densification performanceScreensDecorative surface effectsManufacturing technologyDistillation

The invention discloses a manufacturing technology of a hollowed-out peach wood screen. The technology is characterized by comprising the steps as follows: (1) material selection is performed as follows: a peach tree with the tree age being 20 years or above is selected as a machining material; (2) board sawing is performed as follows: a peach wood board is 1.8-2 cm thick; (3) heating and boiling in saline water are performed as follows: the board is immersed in water with the sodium chloride concentration ranging from 0.7% to 1% for heating and boiling; (4) high-pressure fumigation is performed as follows: the board is vertically placed on a distillation layer of a pressure cooker, a preservative is added, and high-temperature fumigation is performed; (5) softening in an acid and a base is performed as follows: the board is immersed in a sodium hydroxide solution and a hydrochloric acid solution respectively for soaking treatment; (6) drying is performed as follows: the board is vertically placed in a drying box, and a drying technology is performed; (7) hollowing-out engraving is performed as follows: the hollowed-out screen is engraved; (8) waxing is performed as follows: the screen is coated with wood wax by the aid of a soft brush and is coated repeatedly for 3-4 times. With the technology, the content of moisture in the peach wood board can be reduced, the anti-corrosion and moisture-proof performance can be improved, and the engraving performance and the smoothness of the peach wood board can be improved.

Owner:FUNAN TENGBO ARTS & CRAFTS CO LTD

Watermelon fresh-keeping method

The invention relates to a watermelon fresh-keeping method, and belongs to the field of watermelon fresh keeping. In the prior art, the storage time of the watermelon is relatively short, the general watermelon fresh keeping method can only provide the 1-3 month fresh keeping time, and the user inconveniently eat the watermelon. A purpose of the present invention is to effectively solve the problems in the prior art. According to the present invention, watermelon is adopted as an object, 10-20 g of chitosan is weighed and is dissolved with glacial acetic acid, water is added to swell, glycerol is added, water is supplemented to achieve a volume of 1 L so as to obtain a chitosan film liquid with a concentration of 1-2%, the watermelon with characteristics of late ripeness, thick peel, tough texture, compact peel-flesh organization, healthy growth on the living vine and no pest is selected, the chitosan film liquid is sprayed 10 days before harvesting, the harvested watermelon is placed into a shady shed and solarization is avoided, 10 cm of the watermelon pedicel is retained during the harvesting, hay is padded during the watermelon transportation, the obtained watermelon is placed into a warehouse with a temperature of 2-8 DEG C. observation is performed every 7 days, the relatively-stable temperature and the relatively-stable humidity in the warehouse are maintained during the storage, doors and windows are closed during the day and are opened at night, and the ventilation state is maintained.

Owner:王园园

Novel hardwood manufactured based on compaction technology

The invention relates to novel hardwood manufactured based on a compaction technology. The hardness of the novel hardwood is 5-9H, the surface of the hardwood is a mirror surface or a frosted surface, and the hardwood is manufactured by the compaction technology including softwood pretreatment, high-temperature high-pressure treatment, pressure continuing treatment, high-temperature treatment under reduced pressure, and constant-pressure maintaining treatment at reduced temperature. The manufactured hardwood is resistant to high temperature and boiling, is hard and wearable, has good surface glossiness, is not required to be painted, paint-sprayed or treated with other processes when used for manufacturing a wood product, and is an environment-friendly product.

Owner:香河凯王压密木科技有限公司

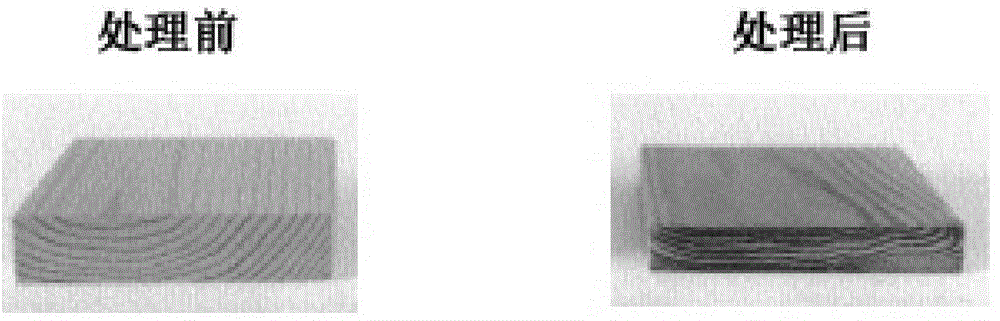

Machining process method for plywood

InactiveCN105382888AEasy to operateEasy to produceLaminationLamination apparatusProduction rateWood machining

The invention provides a machining process method for plywood, and relates to the field of wood machining. Machining operation of the plywood is carried out through four steps including log machining, drying, glue passing processing and pressing plate molding. The compressive strength and the toughness of the plywood are sufficiently improved, the toughness can be improved to a certain degree through the structure of the plywood, cracking is reduced, the production rate of inferior-quality products is reduced, the overall technological process is novel, and further application and popularization can be carried out.

Owner:GUANGDE CHANGFENG BAMBOO IND PROD CO LTD

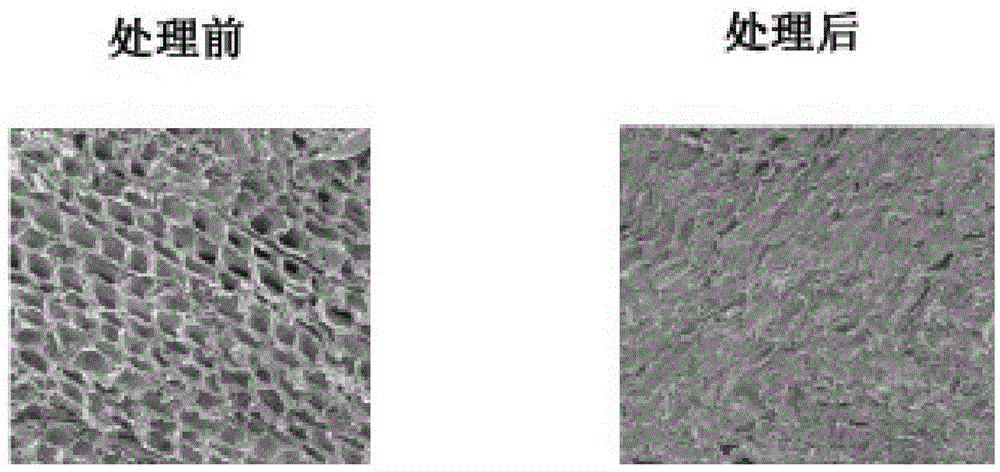

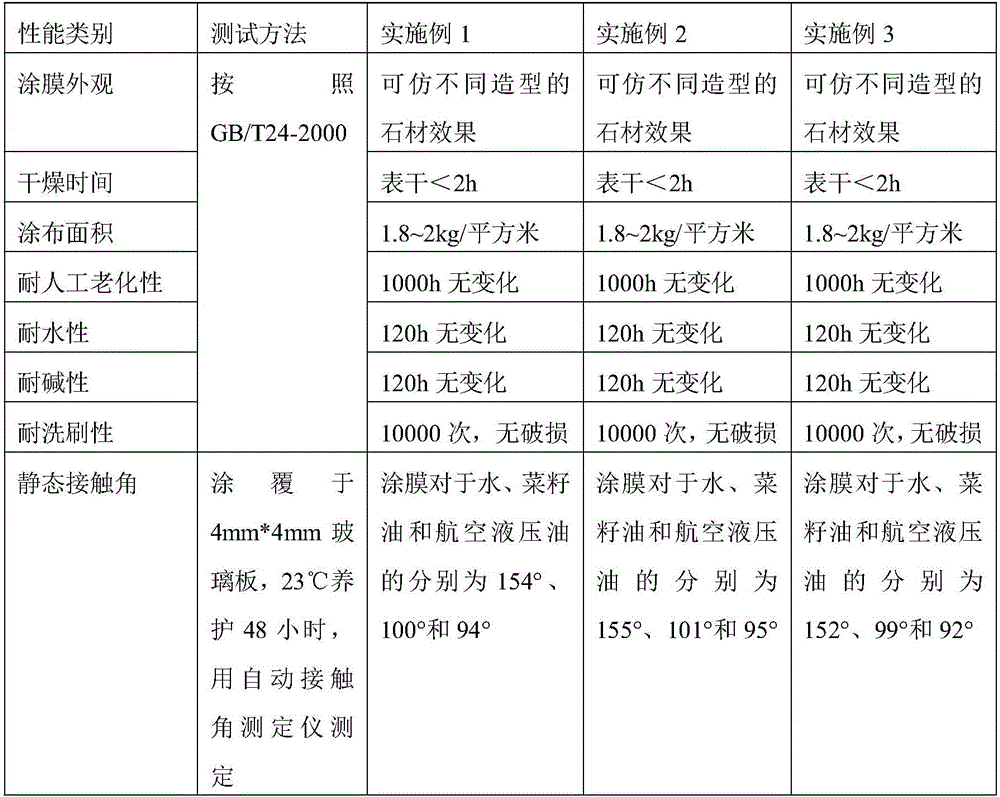

Hydrophobic and oleophobic sand wall like coating and preparation method thereof

The invention discloses a hydrophobic and oleophobic sand wall like coating. The hydrophobic and oleophobic sand wall like coating is prepared from, by weight, 25-30 parts of basis paint, 3-5 parts of a slipping agent, 2-5 parts of 325-mesh quartz powder, 30-40 parts of 40-mesh quartz sand, 25-30 parts of quartz sand, 2-3 parts of a coupling agent and 0.2-0.4 part of a thickening agent. The invention further discloses a preparation method of the hydrophobic and oleophobic sand wall like coating. The hydrophobic and oleophobic sand wall like coating has the advantages that good hydrophobic and oleophobic effects are achieved, a coating layer is transparent in texture, strong but pliable in texture, high in third dimension and flexible in luster, and the coating is good in quality, long in service life, elastic, free of cracking, resistant to weather and alkaline, colorfast and capable of preventing water permeability. According to the preparation method of the hydrophobic and oleophobic sand wall like coating, operation is easy, and large-scale production is easy.

Owner:WUXI HUHUANG PAINT

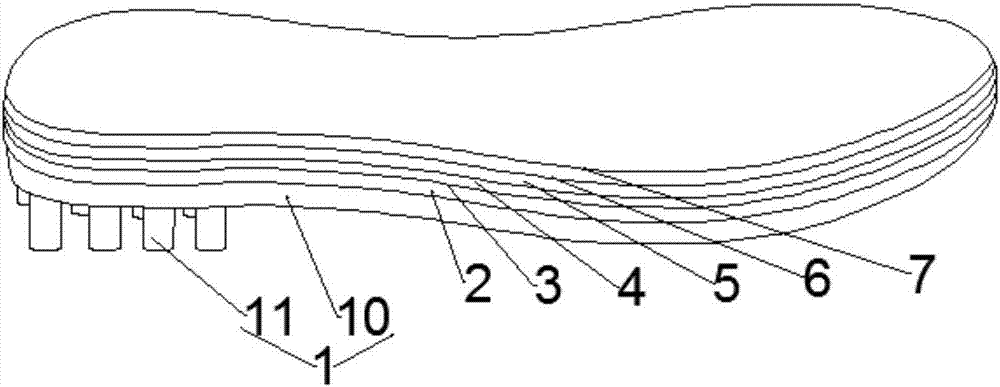

Durable and environment-friendly sisal hemp shoe sole

The invention discloses a durable and environment-friendly sisal hemp shoe sole. The durable and environment-friendly sisal hemp shoe sole is characterized by comprising a base layer, a first fabric layer, a second aluminum foil layer, a sisal hemp leaf layer, a loofah sponge layer, a second aluminum foil layer, a second fabric layer and a third fabric layer which are sequentially bonded and fixed from bottom to top, wherein the first fabric layer, the second fabric layer and the third fabric layer are formed by sewing and stacking 2-4 layers of fabrics from bottom to top, the fabrics of the first fabric layer and the second fabric layer are formed by spinning sisal hemp fiber subjected to modification treatment, the fabrics of the third fabric layer is made by blending the sisal hemp fiber and cashmere fiber according to the mass ratio of 2 to 1, and the sisal hemp fiber is subjected to modification treatment. The shoe sole mainly uses the sisal hemp fiber as a raw material, the sisal hemp fiber is subjected to different modification treatments, the third fabric layer is made by blending the sisal hemp fiber and the cashmere fiber, their advantages of the fibers are utilized to improve the practicability and durability of the shoe sole, and abrasion resistance of the shoe sole can be improved and enhanced by arranging a base layer flat base and a supporting pad.

Owner:GUANGXI TEACHERS EDUCATION UNIV

Production method of fan pedestal material

InactiveCN102434447ATough qualityTough texturePositive displacement pump componentsLiquid fuel engine componentsChemistryMagnesium

The invention discloses a production method of a fan pedestal material, which has tough quality, is smooth, artistic and durable, and has water-proof, moisture-proof, fire-proof, freeze-proof, corrosion-resisting, inflaming-retarding, heat-insulation and sound-proof special functions and good heat isolation effect, is environmentally-friendly in production mode and is cheap and fine. The method comprises the following steps: water accounting for 10 percent of total weight is used for melting magnesium chloride accounting for 5 percent of total weight to obtain the mixed solution, and then 30 percent of magnesium chloride (wt %), 5 percent of oxalic acid, 5 percent of colloidal particles, 5 percent of short fibers, 10 percent of gaiting light, 5 percent of wood shavings, 5 percent of talcum powder, 10 percent of nanometer pint and 5 percent of colloidal particle nails are mixed into the mixed solution to form paste under stirring, the pasty mixing material is fed into a mould at 60-85 DEG C for 5-10 hours, and finally, the molded material is placed into a ventilation environment for 3-10 days. The production method is mainly used for the fan pedestal.

Owner:何庆伟

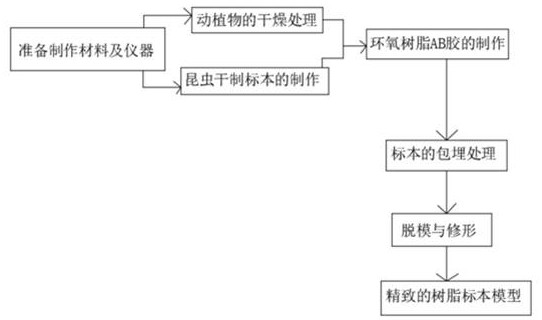

Resin polymer material and silica gel simulation animal and plant model

InactiveCN114467912AIncrease success rateReasonably preparedDead plant preservationDead animal preservationEpoxyToxic material

The invention discloses a manufacturing method of a resin high polymer material and silica gel simulation animal and plant model, which comprises the following steps: (1) preparing manufacturing materials and instruments, the materials including various animals and plants and insects, epoxy resin AB glue and a drying agent (aluminum oxide); the insect collection materials comprise a collection net, a poison bottle, a plastic bag, long tweezers, gloves and a triangular paper bag; the insect dried specimen model is manufactured through tweezers, pins, insect needles, wing spreading plates, a three-stage table, parchment paper, label paper and a specimen box. According to the manufacturing method of the resin high polymer material and the silica gel simulation animal and plant model, a delicate resin specimen model is finally obtained, meanwhile, the steps in the method are more specific and perfect, the success rate of specimens is high, and the specimens manufactured according to the method are easy and convenient to operate, excellent in transparency, tough in texture, not prone to being damaged, non-toxic, free of environment pollution and suitable for popularization and application. And no toxic substance or pollutant is used in the method, so that the method is more environment-friendly.

Owner:河南有道展览科技有限公司

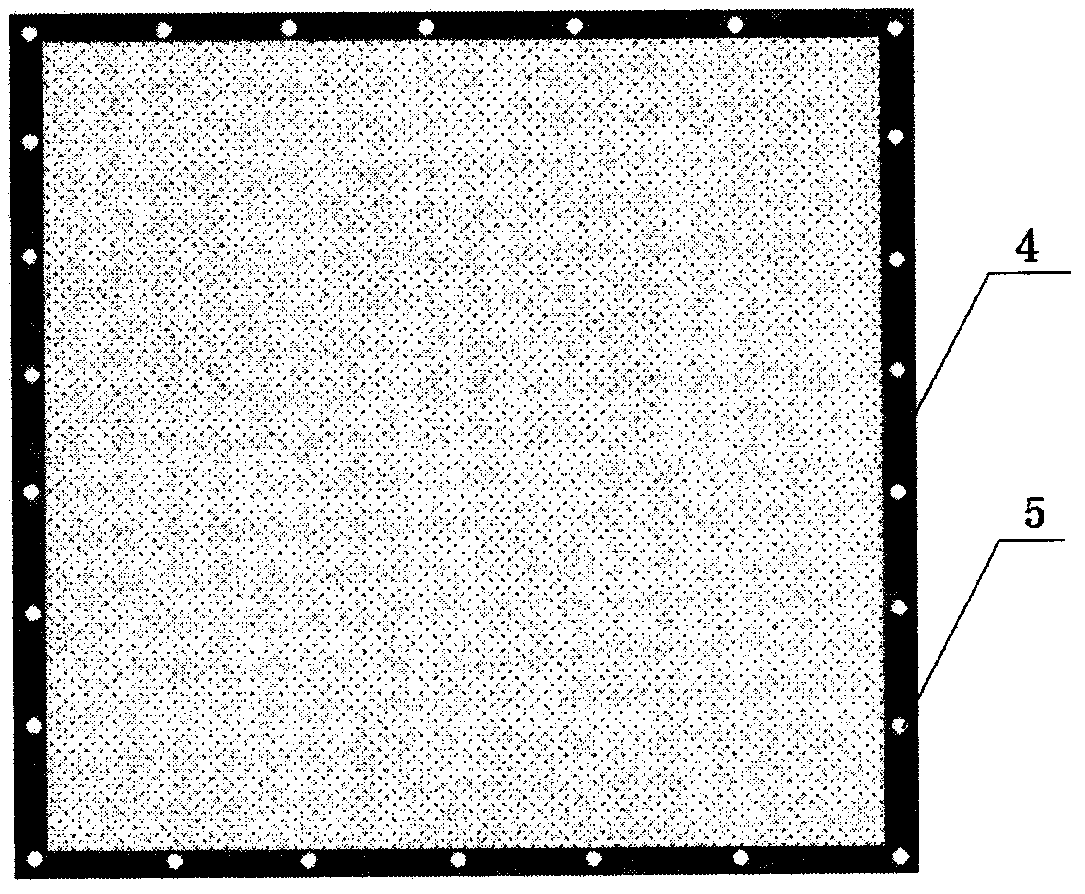

High-definition screen

PendingCN109960101AChange viewing angleChange surface oxidation resistanceProjectorsDiffusionComposite film

The invention discloses a high-definition screen which comprises a flexible film, a metal film and a scattering diffusion composite film. The flexible film acts as the substrate to be arranged on thelowest layer. The metal film is is plated on the surface of the flexible film by a vacuum plating mode. The scattering diffusion composite film covers the metal film. The high-definition screen also comprises sound-transmitting holes, a frame and fixing holes. The sound-transmitting holes are uniformly and densely distributed on the screen and penetrate through the screen. The frame tightly stretches around the screen for the fastening effect. The frame is provided with the fixing holes for installation. The high-definition screen has the gain value and the high-definition degree that the conventional metal screen cannot reach, and the color restoring effect of the picture is good so that the problem that the conventional metal screen is liable to oxidize can be thoroughly changed, the service life of the screen can be greatly prolonged, and the high-definition screen is worth of popularization and use.

Owner:冯超

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com