Hydrophobic and oleophobic sand wall like coating and preparation method thereof

A sand wall-like coating and formulation technology, applied in the field of sand wall-like coating and its preparation, can solve the problems of increasing labor, material cost, inconsistent side light of paint film, affecting decorative effect, etc. The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

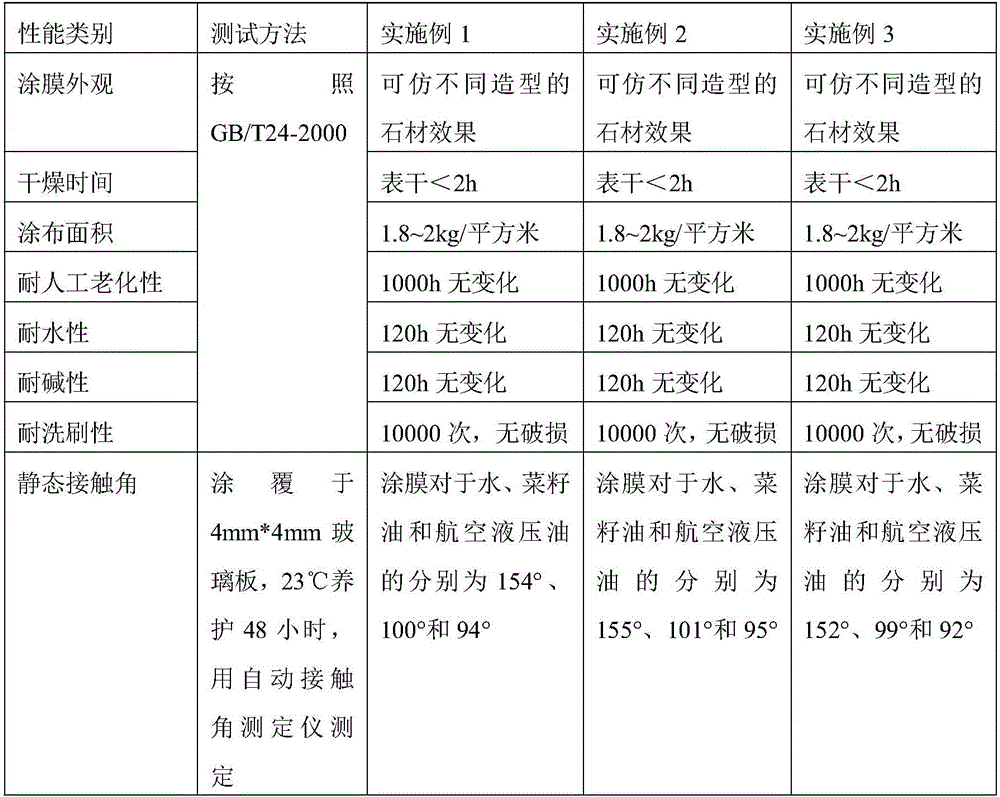

Examples

Embodiment 1

[0027] In the present embodiment, the amphoteric sand wall paint comprises the following raw materials in parts by weight:

[0028] 28 parts of base paint, 4 parts of smoothing agent, 4 parts of 325 mesh quartz powder, 35 parts of 40 mesh quartz sand, 28 parts of 80 mesh quartz sand, 2.5 parts of coupling agent, and 0.3 parts of thickener.

[0029] Wherein, the base paint comprises the following components in parts by weight: 18.9 parts of deionized water, 0.5 parts of dispersant, 0.1 part of wetting agent, 0.4 part of defoamer, 1 part of ethylene glycol, and 4 parts of coalescent , 1 part of titanium dioxide, 0.15 part of cellulose, 0.1 part of pH regulator, 68 parts of emulsion, 4 parts of thickener, and 0.15 part of fungicide.

[0030] The slippery agent comprises the following components in parts by weight: 90 parts of deionized water and 12 parts of bentonite.

[0031] The preparation method of loose sand wall-shaped coating in the present embodiment may further comprise...

Embodiment 2

[0039] In the present embodiment, the amphoteric sand wall paint comprises the following raw materials in parts by weight:

[0040] 25 parts of base paint, 3 parts of slip agent, 2 parts of 325 mesh quartz powder, 30 parts of 40 mesh quartz sand, 25 parts of 80 mesh quartz sand, 2 parts of coupling agent, and 0.2 parts of thickener.

[0041] Wherein, the base paint comprises the following components in parts by weight: 18 parts of deionized water, 0.3 parts of dispersant, 0.1 part of wetting agent, 0.4 part of defoamer, 1 part of ethylene glycol, and 3 parts of coalescent , 1 part of titanium dioxide, 0.1 part of cellulose, 0.1 part of pH regulator, 60 parts of emulsion, 2 parts of thickener, and 0.1 part of bactericide.

[0042] The slippery agent comprises the following components in parts by weight: 85 parts of deionized water and 10 parts of bentonite.

[0043] The raw materials used in the preparation method of the sand-thinning wall coating in this embodiment are as abo...

Embodiment 3

[0045] In the present embodiment, the amphoteric sand wall paint comprises the following raw materials in parts by weight:

[0046] 30 parts of base paint, 5 parts of slip agent, 5 parts of 325 mesh quartz powder, 40 parts of 40 mesh quartz sand, 30 parts of 80 mesh quartz sand, 3 parts of coupling agent, and 0.4 parts of thickening.

[0047] Wherein, the base paint comprises the following components in parts by weight: 21 parts of deionized water, 0.8 parts of dispersant, 0.2 part of wetting agent, 0.5 part of defoamer, 2 parts of ethylene glycol, and 4 parts of coalescent , 2 parts of titanium dioxide, 0.2 part of cellulose, 0.15 part of pH regulator, 80 parts of emulsion, 6 parts of thickener, and 0.2 part of fungicide.

[0048] The slippery agent comprises the following components in parts by weight: 90 parts of deionized water and 15 parts of bentonite.

[0049] The raw materials used in the preparation method of the sand-thinning wall coating in this embodiment are as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com