New hardwood based on compaction technology

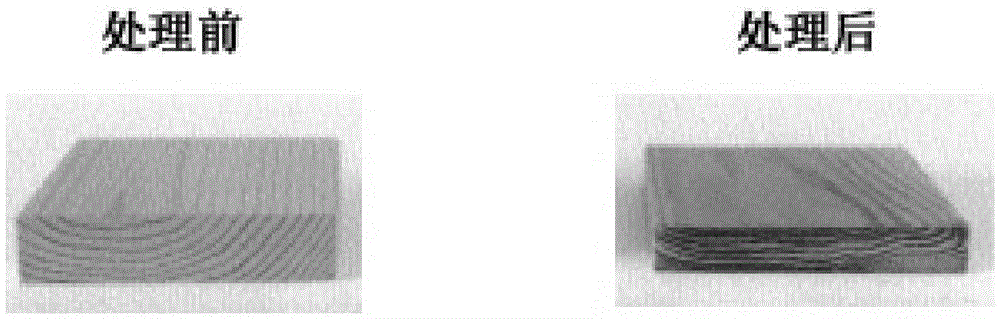

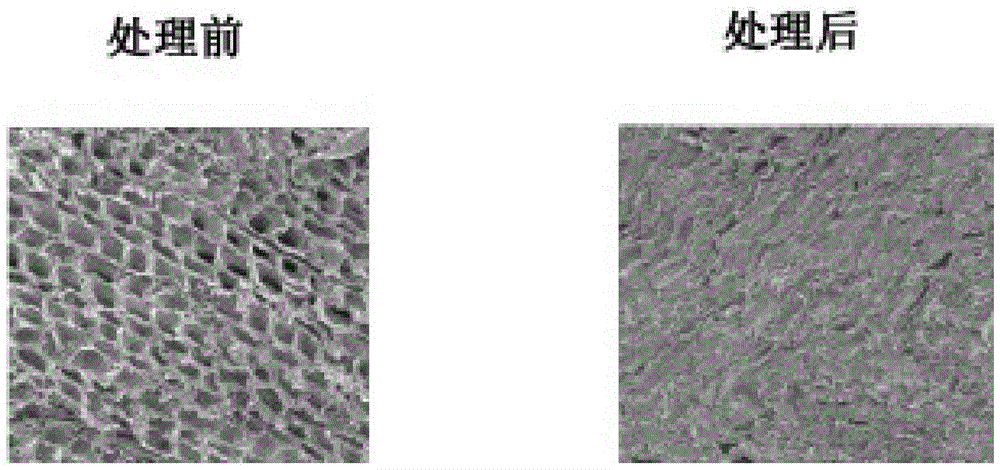

A technology of hardwood and technology, applied in the field of new hardwood, can solve the problems of poor economic benefits, low utilization value, fade out of consumers, etc., and achieve the effect of good surface gloss, large specific gravity and good texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1 Novel hardwood made based on compaction technology

[0057] The hardness of described hardwood is 7H, and the surface of described hardwood is a mirror surface; Described compaction technique comprises the steps:

[0058] a. Cork pretreatment: process the cork into boards, dry them, control the moisture content of the boards, and perform positioning sanding on the dried boards;

[0059] b. High temperature and high pressure treatment: apply a certain pressure to the pretreated cork at a certain temperature, and perform high temperature and high pressure treatment in a closed space;

[0060] c. Continued pressure treatment: apply a certain pressure to the cork after high temperature and high pressure treatment at a certain temperature, and carry out continuous pressure treatment in a closed space;

[0061] d. High temperature and decompression treatment: the cork after the continuous pressure treatment is subjected to decompression treatment in a closed spa...

Embodiment 2

[0063] Embodiment 2 Novel hardwood made based on compaction technology

[0064] The hardness of described hardwood is 5H, and the surface of described hardwood is frosted surface; Described compaction technique comprises the steps:

[0065] 1) Cork pretreatment: process the cork into boards, dry them, control the moisture content of the boards, and perform positioning sanding on the dried boards;

[0066] 2) Steam preheating and pressure treatment: steam for a certain time and temperature is passed into the space where the pretreated cork is located;

[0067] 3) High-temperature and high-pressure treatment: Apply a certain pressure to the cork after steam preheating and pressure treatment at a certain temperature, and perform high-temperature and high-pressure treatment under the condition of intermittent or continuous steaming, and the time of steaming is not longer than The time of high temperature and high pressure treatment;

[0068] 4) Continued pressure treatment: Appl...

Embodiment 3

[0071] Embodiment 3 Novel hardwood made based on compaction technology

[0072] The hardness of the hardwood is 9H, the surface of the hardwood is a mirror surface, and the specific gravity of the hardwood is 850kg / m 3 , the internal resin content of the hardwood is 0.05%, the content of tannin compound is 0.1%, the moisture content of the hardwood is 7%, the shrinkage rate of the hardwood is 16%, and the transverse swelling rate of the hardwood is 0, the longitudinal wet expansion rate is 0.2%; the compaction technique comprises the following steps:

[0073] a) Cork pretreatment: process the cork into boards, dry them, control the moisture content of the boards to 5%, and carry out positioning sanding treatment on the dried boards;

[0074] b) High temperature and high pressure treatment: apply 25kg / cm2 to the pretreated cork at 120°C 2 The pressure is high temperature and high pressure treatment in a closed space, and the time for high temperature and high pressure treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com