Wedge bending-roller straightening deformation method for circularly solidifying waste titanium chips

A chip and roll straightening technology, which is applied in the high-efficiency and clean titanium chip remanufacturing technology, and the field of wedge bending-roll straight deformation of titanium waste chips cyclically solidified, to achieve strong controllability, high processing efficiency, and elimination of metallurgical defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

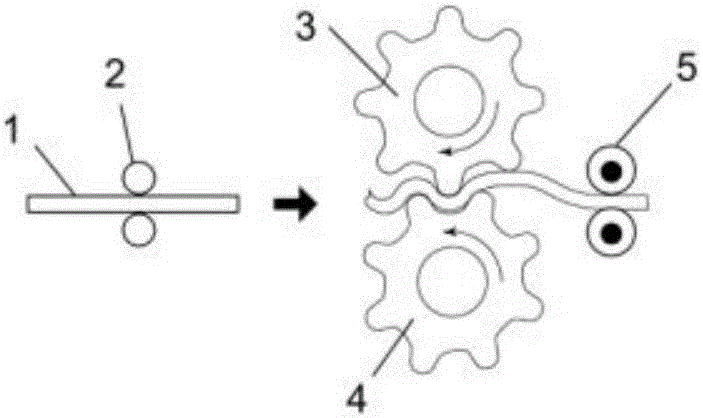

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

[0028] like figure 1 As shown, the specific steps of a wedge bending-roller straight deformation method for cyclic solidification of titanium chips proposed by the present invention include: Ti chip recycling pretreatment, Ti chip drying and degassing, wrapping and encapsulation of Ti chips, and wrapping and encapsulating Ti chips The room temperature cold rolling, wedge bending-roll straight deformation high temperature solidification processing and quenching process.

[0029] Step (1)-Ti chip recovery pretreatment: use the chips generated by end milling Ti 2 (ASTM Grade 2) as raw materials, collect the chips, and use Inductively coupled plasma atomic emission spectroscopy (ICP for short) -AES) to analyze its chemical composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com