Sisal hemp car foot mat and production method thereof

A technology for automobile floor mats and production methods, which is applied to chemical instruments and methods, layered products, vehicle parts, etc., can solve the problems of plastic floor mats such as easy deformation, easy accumulation of dust layer, non-slip price, etc., to achieve easy cleaning, The effect of good air permeability and soft price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

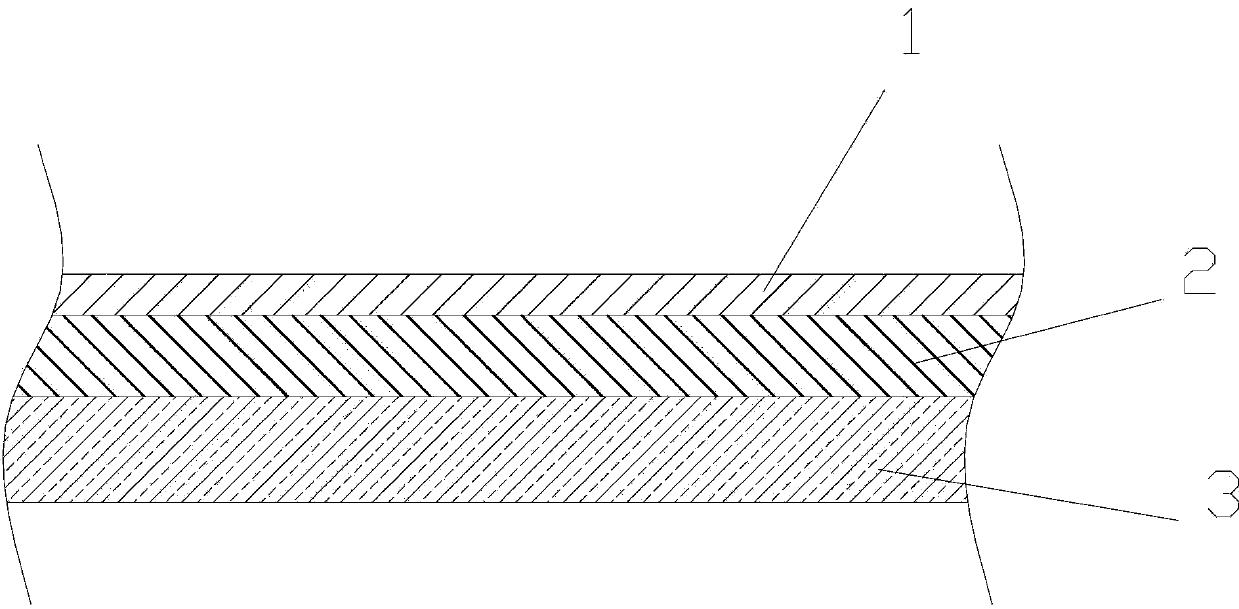

[0025] Such as figure 1 As shown, the sisal car floor mat described in this embodiment includes a surface layer 1, an intermediate layer 2 and a bottom layer 3, the surface layer 1 is a sisal fiber cloth layer, and the intermediate layer 2 is a polyester needle felt. The bottom layer 3 is a rubber layer, and the surface density of the polyester needle felt is 350g / m 2 , the thickness of the rubber layer is 2mm.

[0026] The sisal car floor mat described in the present embodiment, the surface layer 1 is a sisal fiber cloth layer, and the sisal fiber is extracted from the leaves of the agave plant of 5 to 7 years, and has easy weaving, pure white color and texture. Tough, strong, acid and alkali resistance, corrosion resistance, not easy to slip and so on. The sisal fiber cloth layer spun from sisal fiber is an all-natural product, which contains moisture and can absorb or release moisture as the environment changes to adjust the environment and air temperature. It also has t...

Embodiment 2

[0029] The production method of the sisal car mat described in the present embodiment comprises the steps:

[0030] a. Weave sisal fiber cloth with sisal fiber yarn according to certain ups and downs on the loom;

[0031] b. The polyester staple fiber is opened, carded, and laid into a polyester fiber web, and then the polyester fiber web is passed through a cross-lapper to form a multi-layer fiber web, and then passed through a pre-acupuncture machine, a barb machine, and a main machine. The puncture machine repeatedly punctures the polyester fiber net, and the hook belt fiber is reinforced to form a polyester needle felt;

[0032] c. Lay a layer of hot melt adhesive evenly on the surface of the polyester needle felt, heat it in the gelling furnace, the temperature is controlled at 100°C, and then melt it while it is hot to tightly compound the sisal fiber cloth on it.

[0033] d. Natural cooling;

[0034] e. Evenly coat the carpet glue on the bottom surface of the polyeste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com