Cartap environment-friendly type preparing method

An environmentally friendly technology of cartap, applied in the field of preparation of nereistin derivatives biomimetic insecticides, can solve the problems of increased difficulty and cost of wastewater treatment, complex process operation, serious environmental pollution, etc., and achieve product quality stability Good, simple process operation, and the effect of meeting a large number of requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

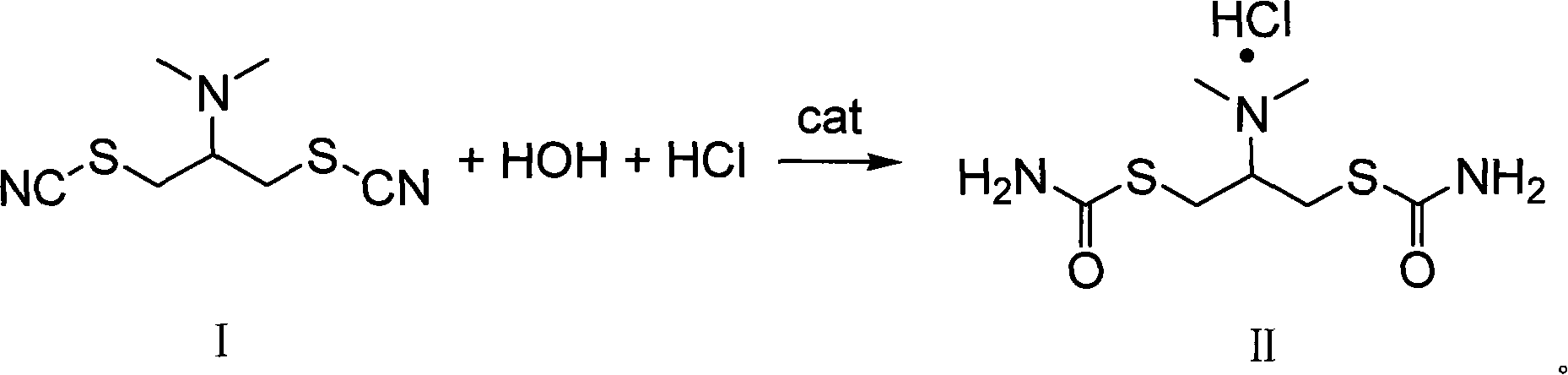

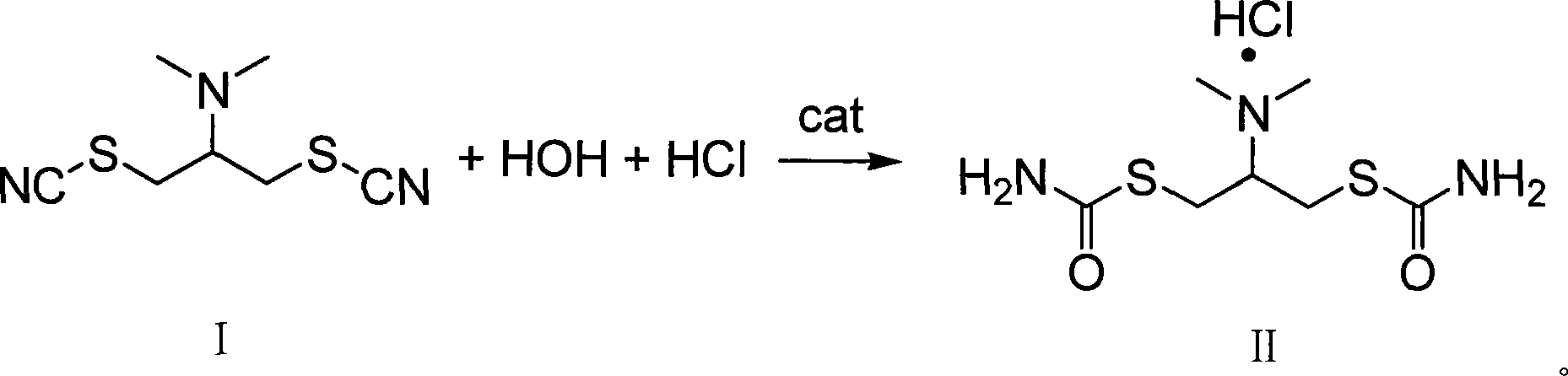

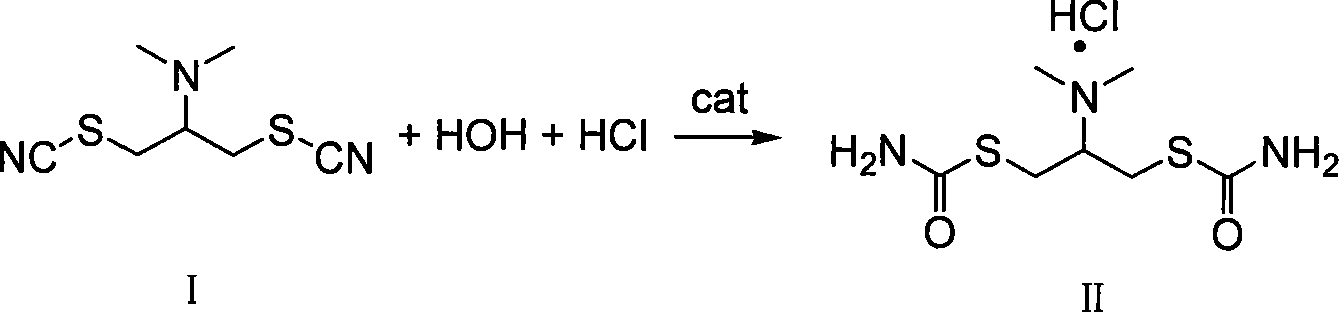

[0024] The ethylene dichloride solution (mass content is 25%) of the thiocyanide of 0.2mol and the water of 2.8mol, 0.5g benzyl trioctyl ammonium chloride catalyst are placed in reactor together, pass into hydrogen chloride gas then, The feed rate is 0.35mol, the reaction temperature is controlled at 20°C, and the hydrolysis reaction is carried out for 20 hours, and the reaction formula is

[0025]

[0026] Finally, the obtained crude cartap was recrystallized with water to obtain 0.19 mol of cartap product.

Embodiment 2

[0028] The toluene solution (mass content is 30%) of the thiocyanide of 0.2mol and the water of 2.2mol, 0.5g butyl trioctyl ammonium bromide catalyst are placed in reactor together, then pass into hydrogen chloride gas, pass into amount The reaction temperature is controlled at -10°C for 0.5 mol, and the hydrolysis reaction is carried out for 15 hours. Finally, the crude cartap obtained is recrystallized with water to obtain 0.186 mol of cartap product.

Embodiment 3

[0030] The carbon tetrachloride solution (mass content is 20%) of the thiocyanide of 0.2mol and the water of 2.5mol, 0.4g benzyltributylammonium chloride catalyst are placed in the reactor together, then pass into hydrogen chloride gas, The feeding amount is 0.4 mol, the reaction temperature is controlled at 10° C., and the hydrolysis reaction is carried out for 24 hours. Finally, the obtained cartap crude product is recrystallized with water to obtain about 0.188 mol of cartap product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com