Patents

Literature

224results about How to "Good product quality and stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

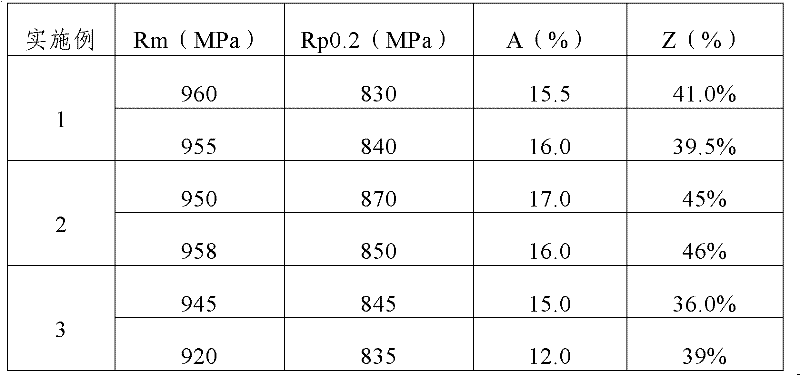

Processing method for TC4 titanium alloy large-sized bar

The invention discloses a processing method for a TC4 titanium alloy large-sized bar. The method comprises the following steps of: cogging and forging TC4 titanium alloy ingots for 2 to 3 heating times to obtain forging billets; 2, upsetting the forging billets repeatedly and performing drawing-out forging for 2 to 3 heating times; 3, upsetting the forging billets subjected to forging repeatedly and performing drawing-out forging for 3 to 5 heating times; and 4, performing chamfering round forging on the forging billets subjected to forging for 2 heating times to obtain the TC4 titanium alloy large-sized bar with the diameter of 200 to 400 mm and length of not less than 2,500 mm. The TC4 titanium alloy bar processed by the method has uniform and fine grains, few internal defects and high safety and accords with the domestic advanced level of the like products. In the processed TC4 titanium alloy bar, the room-temperature tensile strength is 920 to 960 MPa; the yield strength is 830 to 870 MPa; the elongation percentage is not less than 12 percent; the contraction ratio of the cross section is not less than 36 percent; flaw detection clutter reflects small signals; and the flaw detection level is high.

Owner:WESTERN TITANIUM TECH

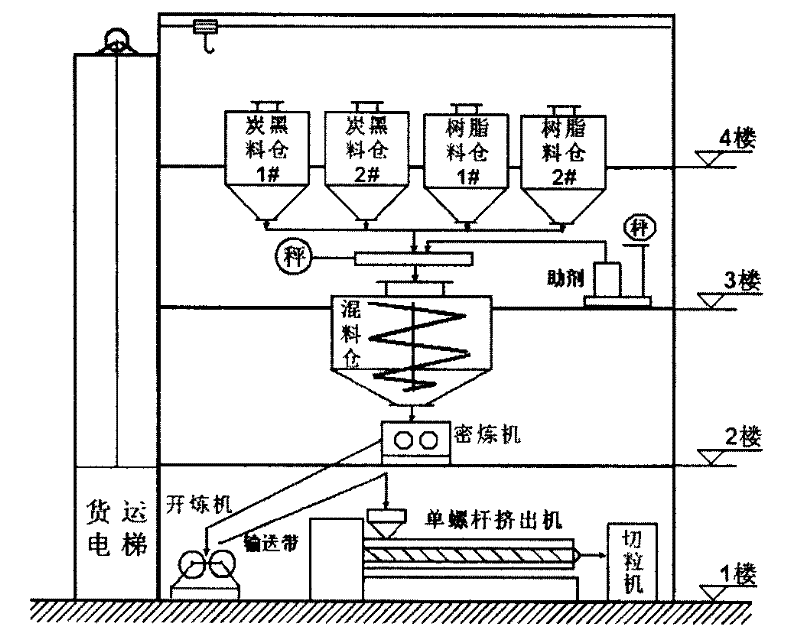

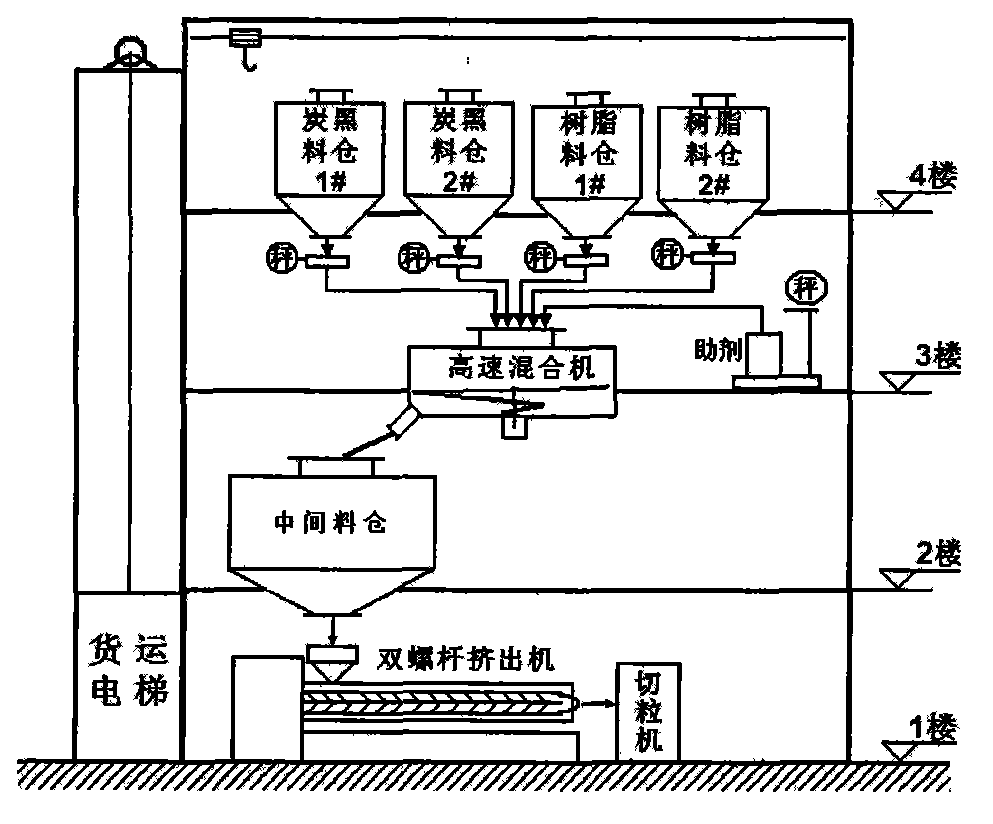

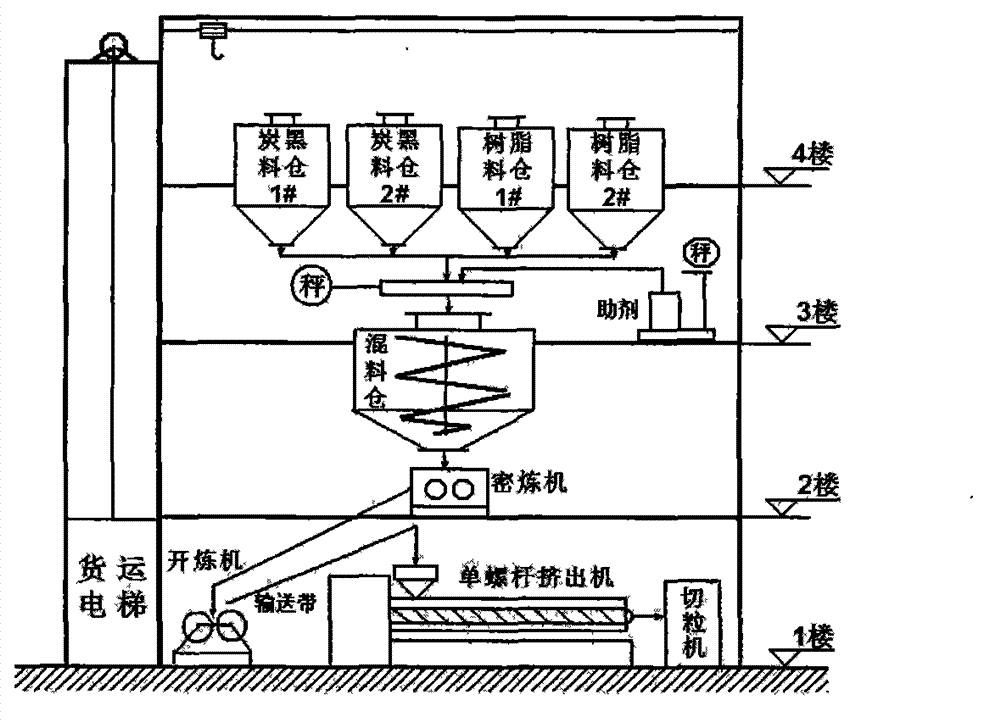

Black masterbatch with high performance, preparation system device and its preparation method

The invention discloses a black masterbatch with high performance, a preparation system device and its preparation method. The masterbatch can be taken as an ultraviolet shielding agent and a black coloring agent, which is widely applied to a polyolefin gas pipeline, a purified water delivering pipeline, conductive plastics, films and cable materials and the like. The characteristics of short production process, raw material negative pressure conveying, sealed type for formulating and feeding, continuously smelting and granulating system enable the raw materials to convey and produce in a sealed system without leakage and fly phenomenon of the carbon black, thereby the good production environment can be guaranteed. According to the invention, the black masterbatch with high performance isprepared by the following raw materials in weight proportion: 20 to 80 parts of polyolefin carrier resin, 20 to 55 parts of carbon black, 0.2 to 2 parts of dispersant, 0.1 to 0.5 parts of processing auxiliary agent and 0.1 to 1.0 parts of anti-oxidant.

Owner:NANJING UNIV OF TECH +1

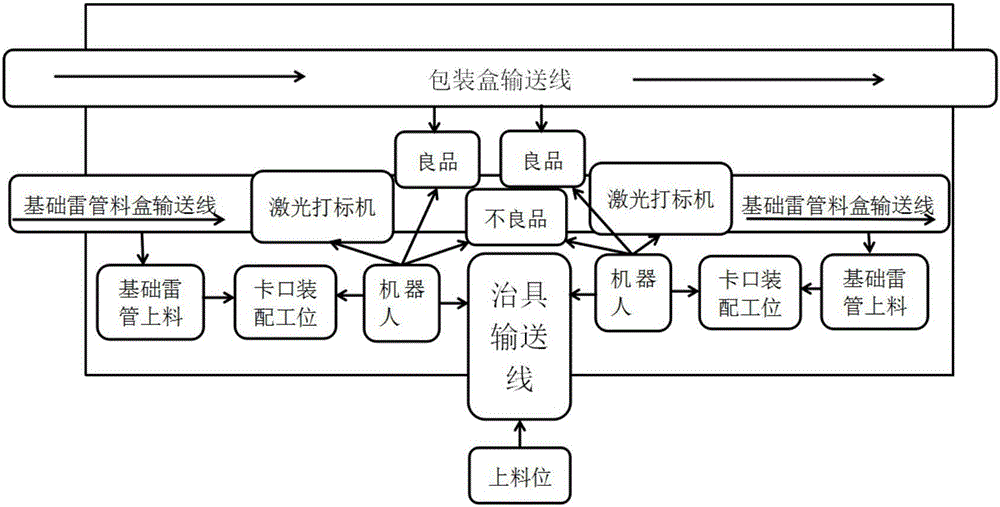

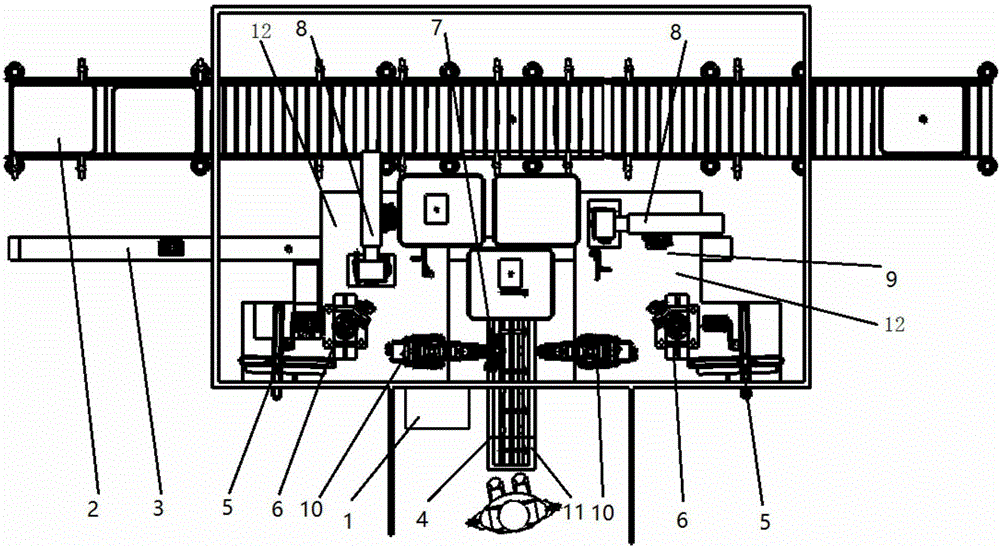

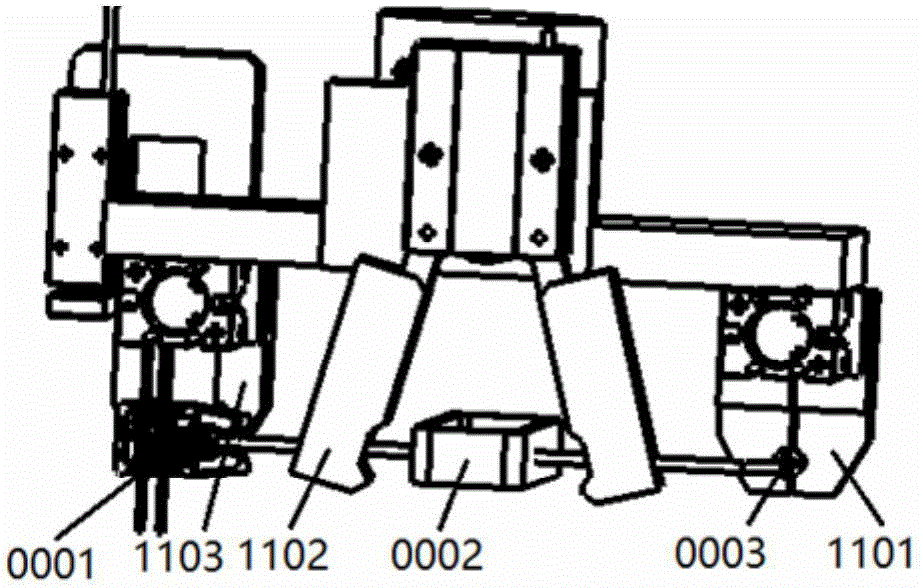

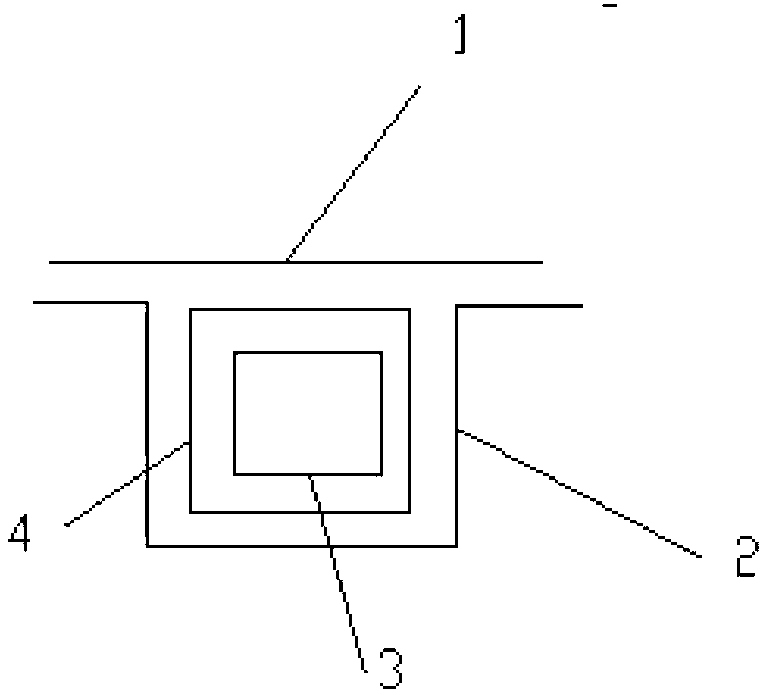

Automatic assembly, detection and marking method and system for electronic detonator

The invention provides an automatic assembly, detection and marking method and system for an electronic detonator. The automation degree can be significantly improved by the method and the system; multi-station parallel production can be achieved through cooperation with a packaging box transport mechanism; the production efficiency is high; the quality and stability of a product are good; man-machine isolation operation of dangerous procedures of feeding, closing, detecting and laser marking of the most dangerous basic detonator in detonator production is completely achieved; the security is extremely high; the new function requirement of binding of a novel electronic detonator password, a UID code and a detonator body laser code can be achieved; and therefore, the automatic assembly, detection and marking method and system for the electronic detonator have extremely high popularization values and application prospects.

Owner:BEIJING QAML OF SCI & TECH CO LTD

Forming method of composite material part with variable cross-section closed cavity

InactiveCN103213285AGood product quality and stabilityStrong manufacturability and implementabilityForming processesMaterials science

The invention belongs to a forming technology of a composite material and relates to a forming method applicable to a composite material part with a variable cross-section closed cavity. The forming method adopts a composite material forming process combining with various pressurizing modes and can be used for realizing a curing forming method of the composite material part which simultaneously provided with the variable cross-section closed cavity and a tubular beam structure. The forming method adopts internal and external pressurizing modes for pressurization in the curing process of a product, respectively adopts different pressurizing modes for forming according to different structure regions of the product, finally the product is cured by adopting a mixed pressurizing mode, and the stability of the product quality is good. For the products with relatively complex structures, the forming method is strong in manufacturability and feasibility, and can be used for realizing the integrated forming of the composite material products with various structure modes.

Owner:HARBIN

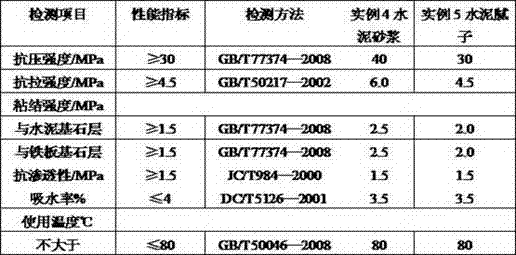

High-performance silicone-acrylate-modified water-based epoxy emulsion and production method thereof

InactiveCN102336874AImprove adhesionExcellent closed shielding performanceAnti-corrosive paintsFilling pastesWater basedChemical industry

The invention discloses a high-performance silicone-acrylate-modified water-based epoxy emulsion and a production method thereof, relating to the technical field of production of coatings used in the chemical industry field. The emulsion is prepared with a core-shell mechanism process; in a core layer, a grafted polymer consists of low molecular bisphenol A epoxy resin, epoxy group siloxane and acrylic ester; a shell body consists of hydroxyl-containing siloxane and acrylic ester; and the shell body and the core layer are subjected to interpenetration graft polymerization. In the invention, epoxy resin is modified with an organic silicon acrylic acid monomer, so that a dense crosslinked netlike structure with a special interpenetration network and excellent enclosed shielding performance is obtained. Multiple series of anti-corrosive paints can be prepared on the basis of the high-performance silicone-acrylate-modified water-based epoxy emulsion provided by the invention by taking mixed modified amine as a curing agent. The emulsion has the advantages of easy and convenient production process, saving in energy, environmental friendliness, easiness for coating construction, low sensitivity to water vapor and temperature, extremely high substrate adhesion, high corrosion resistance, high chemical stability and wide formula adjusting range.

Owner:IANGSU JINLING SPECIAL PAINT CO LTD

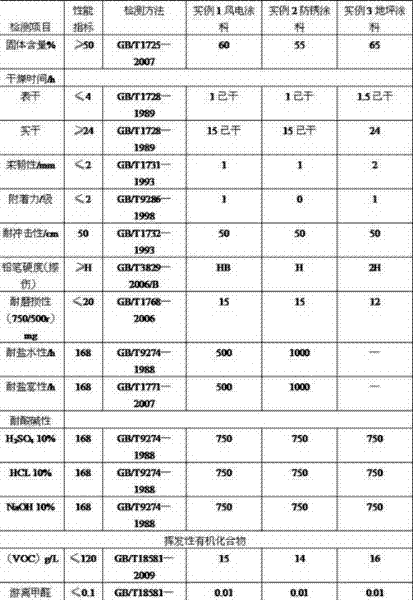

Lansoprazole intestine solution capsule and its preparation method

ActiveCN101156852AHigh dissolution rateSolve easy aggregationOrganic active ingredientsDigestive systemIntestinal structureVegetable oil

The invention discloses a lansoprazole enteric liquid capsule which has a simple manufacturing process, avoids water from being led in during the manufacturing process, and has good storage stability and a manufacturing method. The lansoprazole enteric liquid capsule consists of lansoprazole, dispersant, edible vegetable oil, magnesium oxide or magnesium carbonate, an emulsifier, poloxamer, animal and vegetable glue, and sodium citrate. After being mixed uniformly, raw materials enter into a colloid mill, and then the raw materials are infused into a hollow capsule, and polyacrylic resin ethanol solution is used as the sealing material to sleeve and seal the infused capsule. The invention suspends the lansoprazole into hydrophobic excipient oil, forms a protective film around the lansoprazole powder, does not lead in water during the manufacturing process, avoids the degradation of the lansoprazole, does not need to wrap an isolation layer and an enteric coating, and has short production cycle, simple production process, low cost, and good product quality and stability.

Owner:INCREASEPHARM TIANJIN INST CO LTD

Preparation process of composite copper powder catalyst

ActiveCN102941102AReduce lossesPrecise control of ingredientsMetal/metal-oxides/metal-hydroxide catalystsElectrolysisZinc alloys

The invention provides a preparation process of a composite copper powder catalyst, comprising the steps of cutting an electroplating copper plate into a copper block and machining into copper scales; grinding the copper scales into sheet-shaped copper powder; obtaining sheet pure copper powder through a magnetic selection and air flow grading technology; smelting and atomizing a copper-tin-zinc alloy to prepare needed copper-tin-zinc alloy powder; drying and screening, and grinding to obtain scale-shaped copper-tin-zinc alloy powder; magnetically selecting and screening to obtain the needed copper-tin-zinc alloy powder; and mixing the sheet pure copper powder with the copper-tin-zinc alloy powder according to a ratio to obtain the needed composite copper powder catalyst. According to the preparation process of the composite copper powder catalyst, elements which are harmful to an environment are not introduced in a whole process, the quality stability of a product is good, concave-convex defects of the surface of powder grains are more and the specific surface is large; the catalysis property of the composite copper powder catalyst is obviously better than that of common composite copper powder so that the effect of an organic silicon monomer synthesized metal catalyzing system is improved, the time-space yield of an organic silicon monomer synthesized fluidized bed is increased, a synthesis reaction period is prolonged, the selectivity is improved, the cost is reduced and good economic benefits are created.

Owner:湖南省天心博力科技有限公司

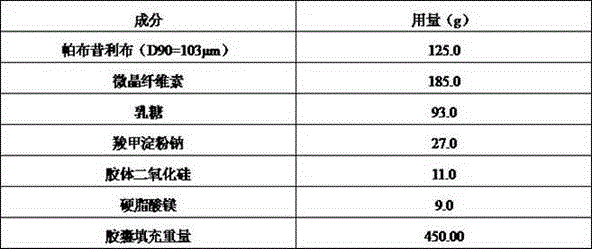

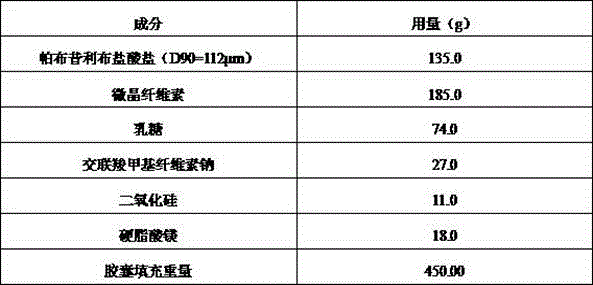

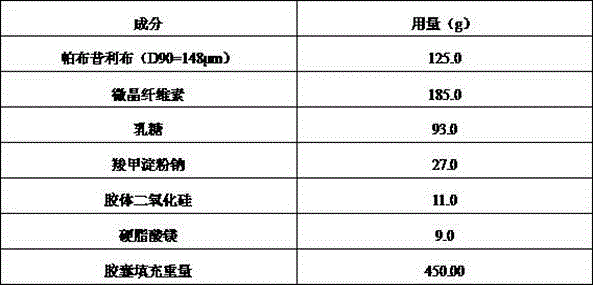

Palbociclib pharmaceutical composition and preparation method thereof

ActiveCN105748435AShorten absorption timeGuaranteed validityOrganic active ingredientsCapsule deliveryMedicineBiological availability

The invention discloses a palbociclib pharmaceutical composition, comprising palbociclib or its medicinal salt and a pharmaceutically acceptable auxiliary material, wherein the palbociclib or its medicinal salt is 50-150 Mum, and the medicinal salt includes isethionates, hydrochlorides, sulfates or benzene sulfonates.Direct mixing and capsuling process of raw and auxiliary materials is used for the pharmaceutical composition provided herein, the biological availability is high, product quality stability is good, the technical process is easy to control, inter-batch reproducibility is good, and the composition is easy to industrialize.

Owner:河北泽运生物医药科技有限公司

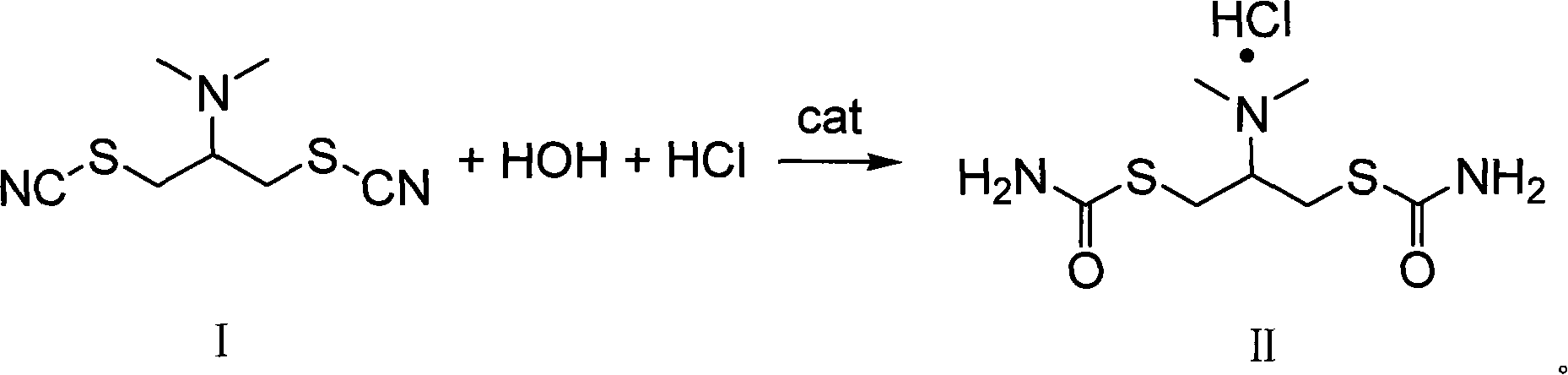

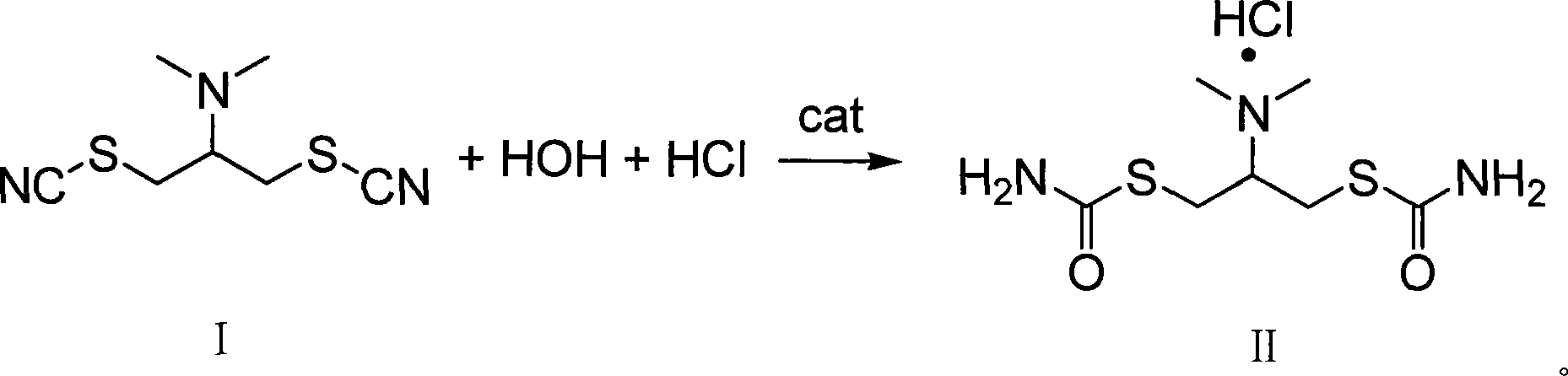

Cartap environment-friendly type preparing method

InactiveCN101103725ATaking into account the costTaking toxicity into accountBiocideOrganic chemistryAlcoholWastewater

The invention discloses an environmental protection preparation method for cartap hydrochloride; rhodanide solution, water and catalyst are arranged inside a reactor, and chlorine hydride gas is input in the reactor for hydrolysis reaction for 15 to 24 hours under -18 to 25 DEG C, so that the cartap hydrochloride can be produced. The hydrolysis processing technique of the invention firstly adopts a hydrolyst method instead of a methyl alcohol alcoholysis for solving the problems of the exhaust gas and waste water from the prior processing technique, furthermore, the hydrolysis rate can reach 95 percent, the quality stability of the cartap hydrochloride product is good, and the processing to the recovery solvent and the mother liquor has unparalleled advantages than the prior art, which fully embodies the call of nation on energy saving and pollutants discharge reduction, thereby the invention has a great social and economic efficiency.

Owner:JIANGSU TIANRONG GROUP

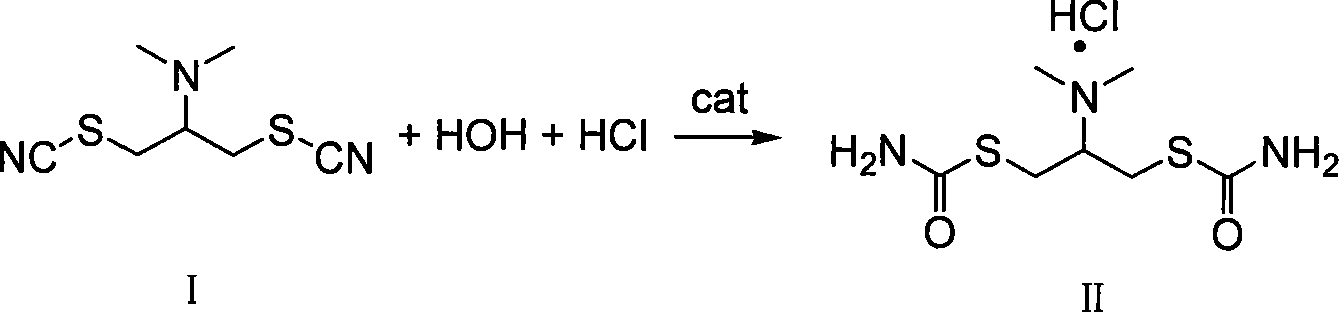

BIM (building information modeling) combined utility tunnel intersection prefabricated component optimization method

ActiveCN106844938ASimple construction processWork lessGeometric CADDesign optimisation/simulationNODALDynamic monitoring

The invention relates to a BIM (building information modeling) combined utility tunnel intersection prefabricated component optimization method. The method includes steps: (1) adopting a BIM technique for modeling of a tunnel body and each functional node; (2) implementing dynamic monitoring on pipelines entering a tunnel according to modeling information, calculating structural dimensions required by communication of upper and lower chamber pipelines of main and branch utility tunnel intersections on the basis of information of the pipelines entering the tunnel, and analyzing and demonstrating calculated dimension information; (3) analyzing and demonstrating the calculated dimension information, and performing special secondary design of medium plate prefabricated components on the basis of the demonstrated dimension information; (4) prefabricating, namely manufacturing utility tunnel intersection prefabricated components according to secondary design results, and designing an integral utility tunnel intersection layout. The method has advantages of flexibility in mounting timeliness, convenience and quickness in component demounting and replacement and high integrating degree in long-term pipeline planning and capacity increasing.

Owner:XIDI (SUZHOU) SURVEY & DESIGN CONSULTING CO LTD

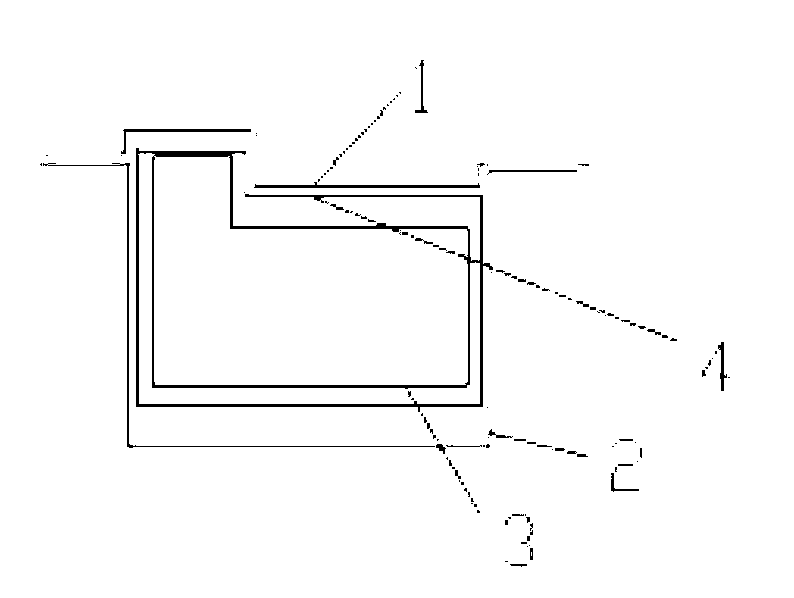

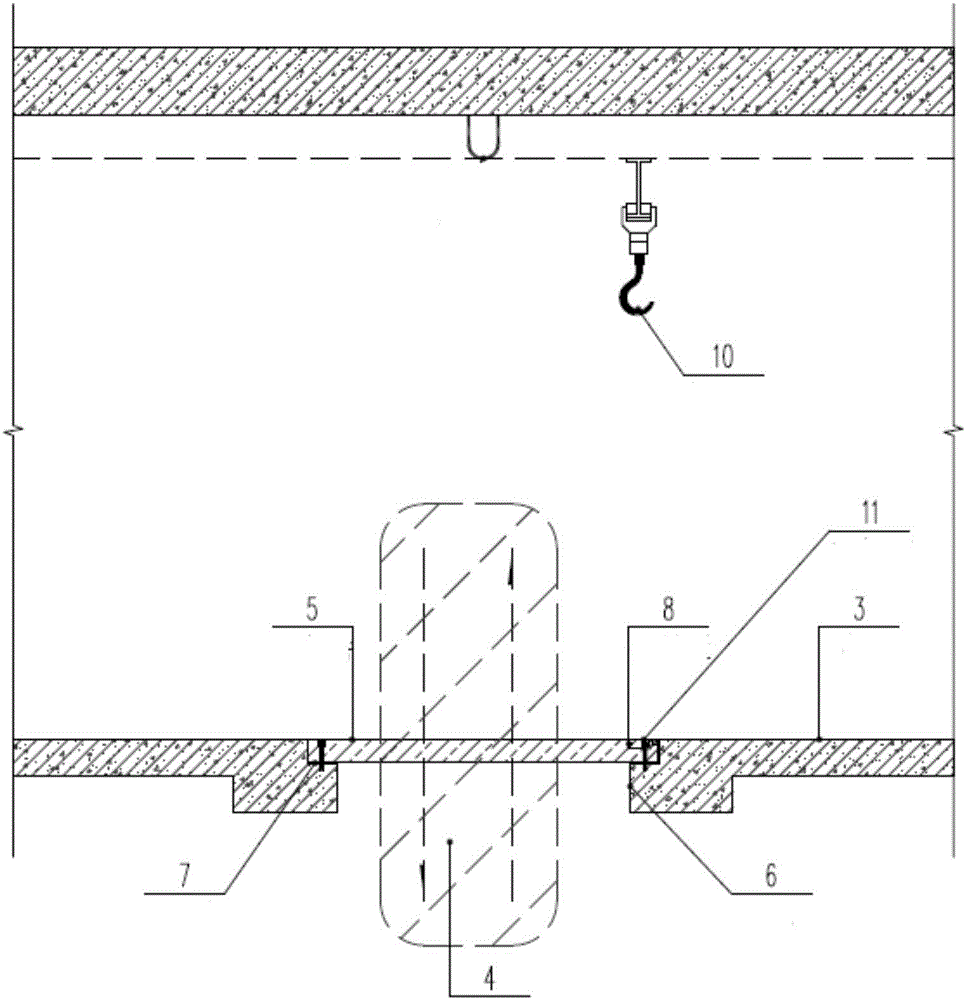

Automatic chamfering machine

ActiveCN103737443AQuality improvementThere will be no unevennessEdge grinding machinesGrinding carriagesTime segmentEngineering

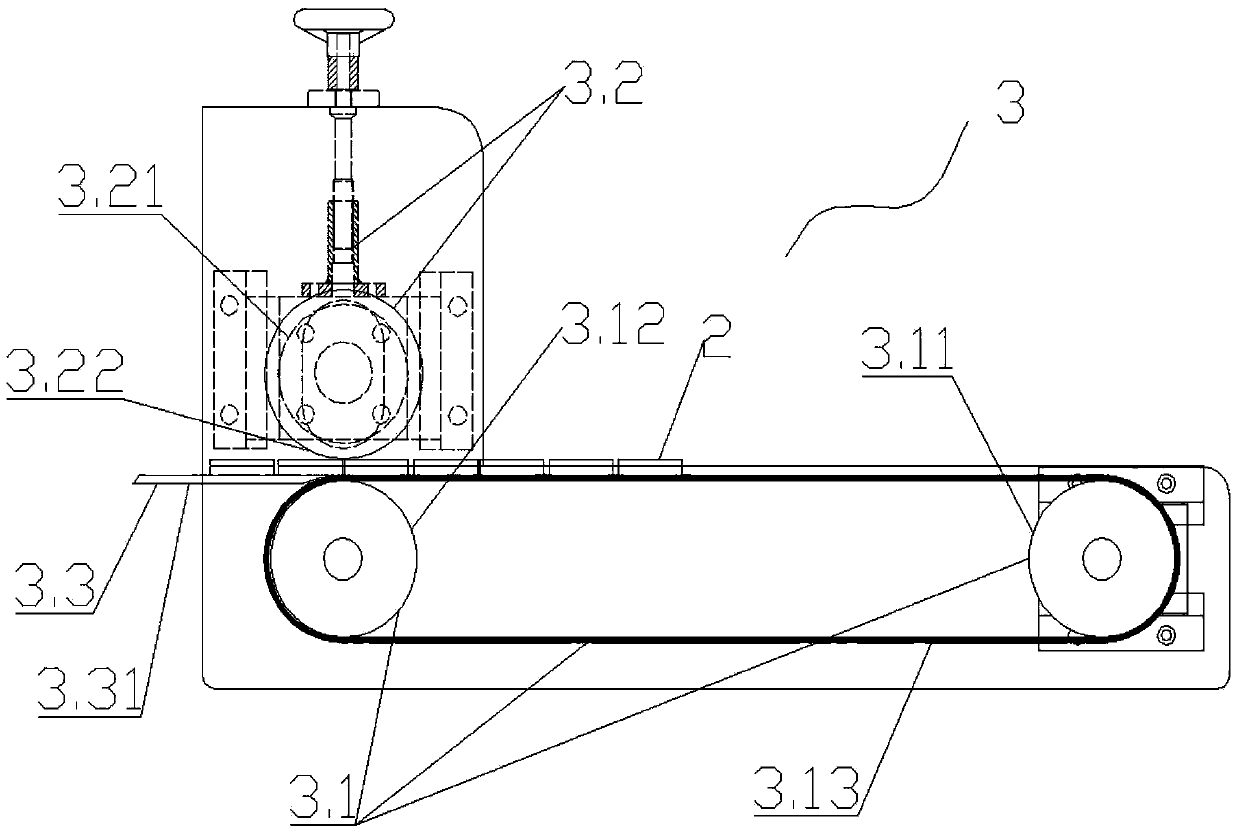

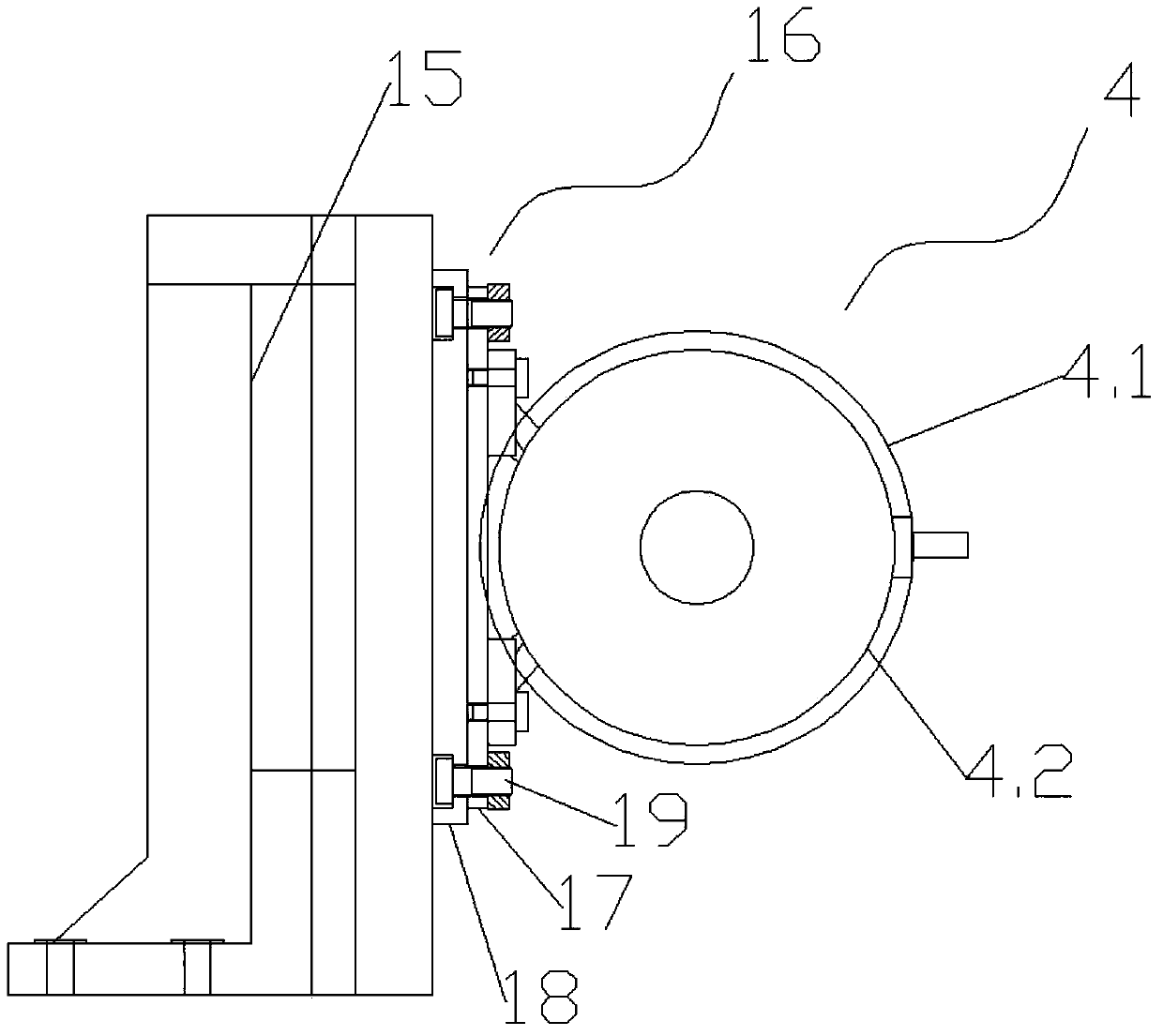

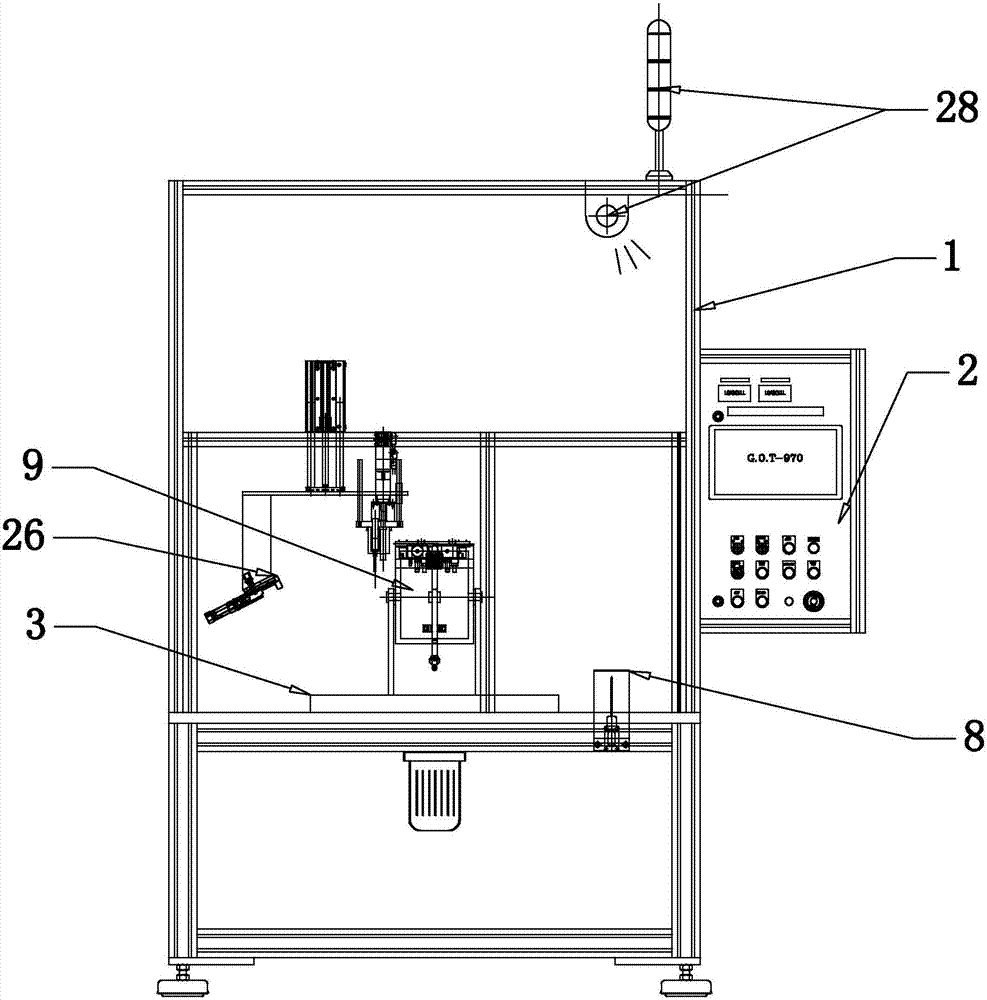

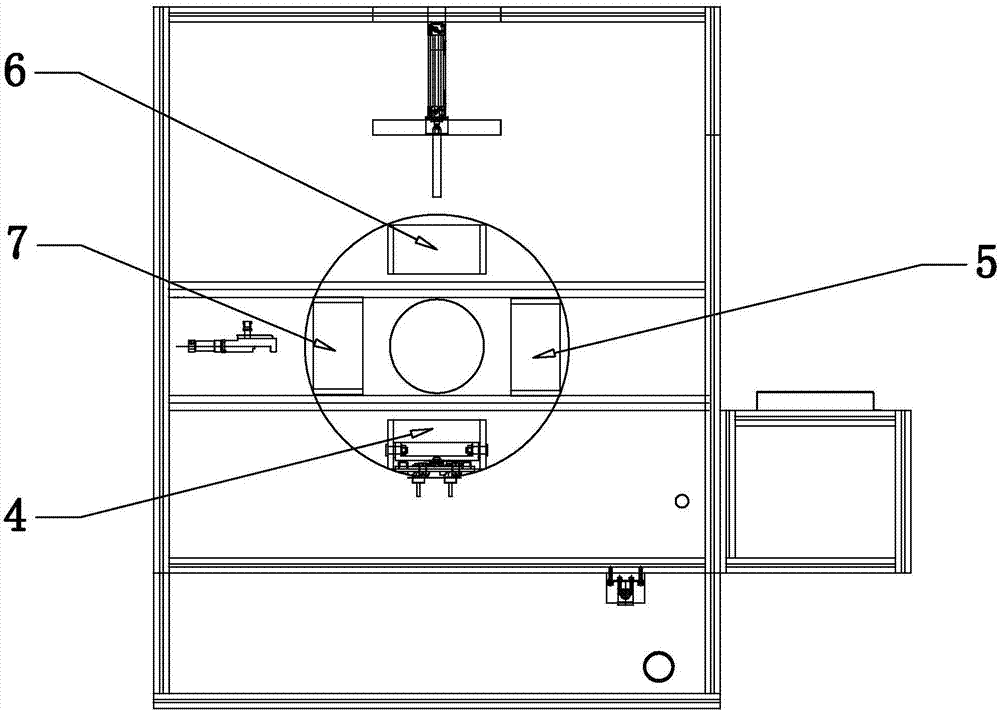

The invention discloses an automatic chamfering machine. The chamfering machine comprises an engine base (1), a conveying mechanism (3), four sand wheel chamfering mechanisms (4) and a guide rail clamping mechanism (5), wherein the conveying mechanism (3) is arranged at one end of the engine base (1) and is used for conveying a work-piece (2), the four sand wheel chamfering mechanisms (4) are arranged on the engine base (1) and simultaneously chamfer the two groups of long opposite sides (2.1) of the workpiece (1), and the guide rail clamping mechanism (5) is used for clamping and smoothly moving the clamped work-piece (2) and is arranged on the working table (1.1) of the engine base (1); two of the sand wheel chamfering mechanisms (4) are respectively located at one group of long opposite sides (2.1) used for processing the work-piece (2) at the two sides of the guide rail clamping mechanism (5) in parallel, and the other two sand wheel chamfering mechanisms (4) are respectively located at the other group of long opposite sides (2.1) used for processing the work-piece (2) at the two sides of the guide rail clamping mechanism (5) in parallel. The automatic chamfering machine is not manually operated, can simultaneously chamfer the two groups of long opposite sides of the work-piece, and can continuously work for a long time segment, and has the advantages of good chamfering quality and high efficiency.

Owner:宁波市鄞州启威机械科技有限公司

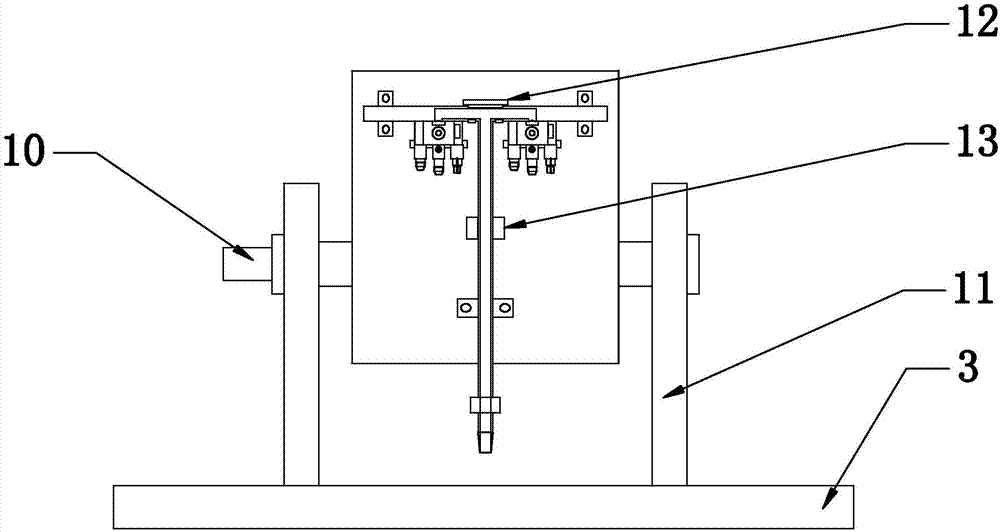

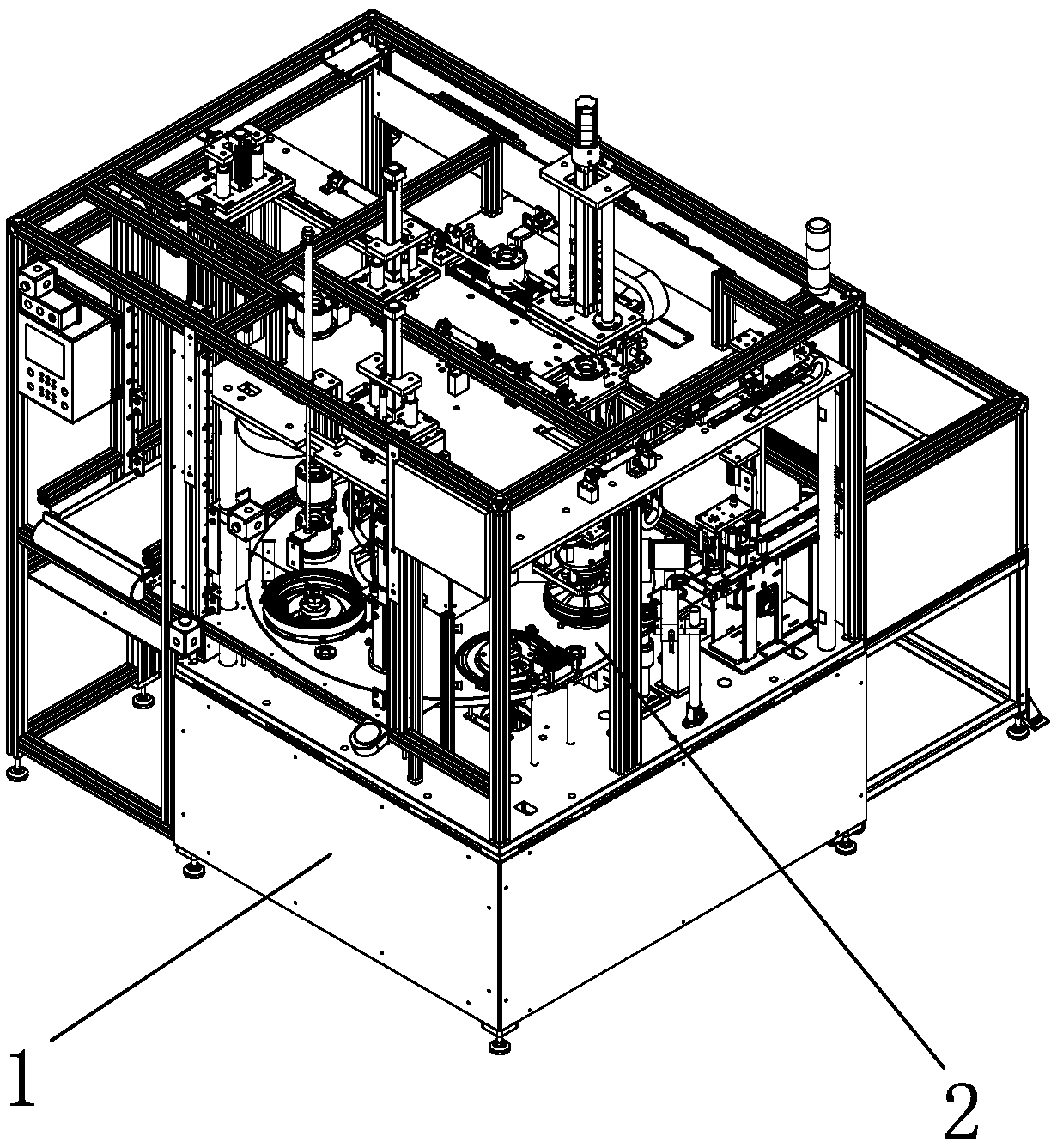

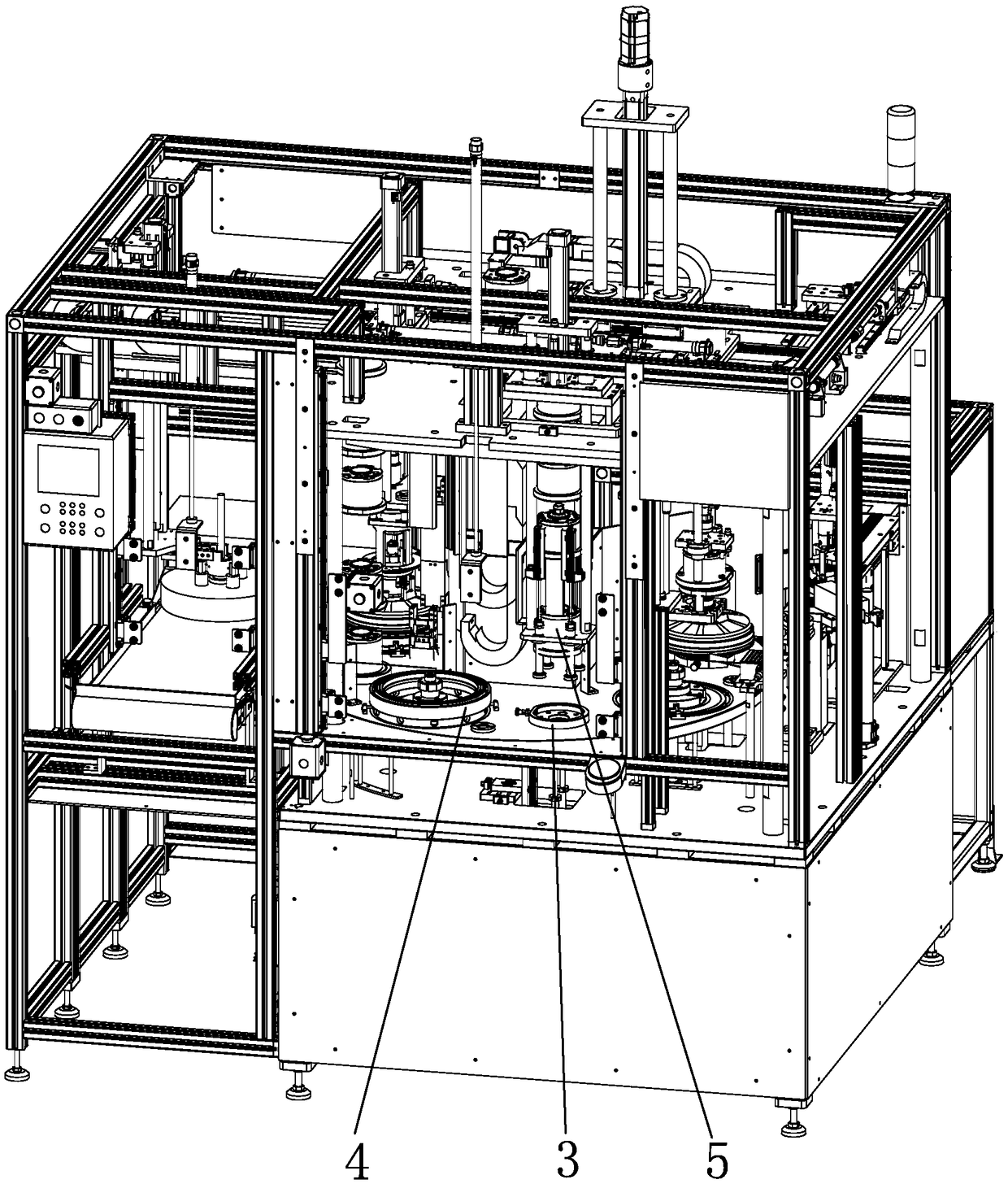

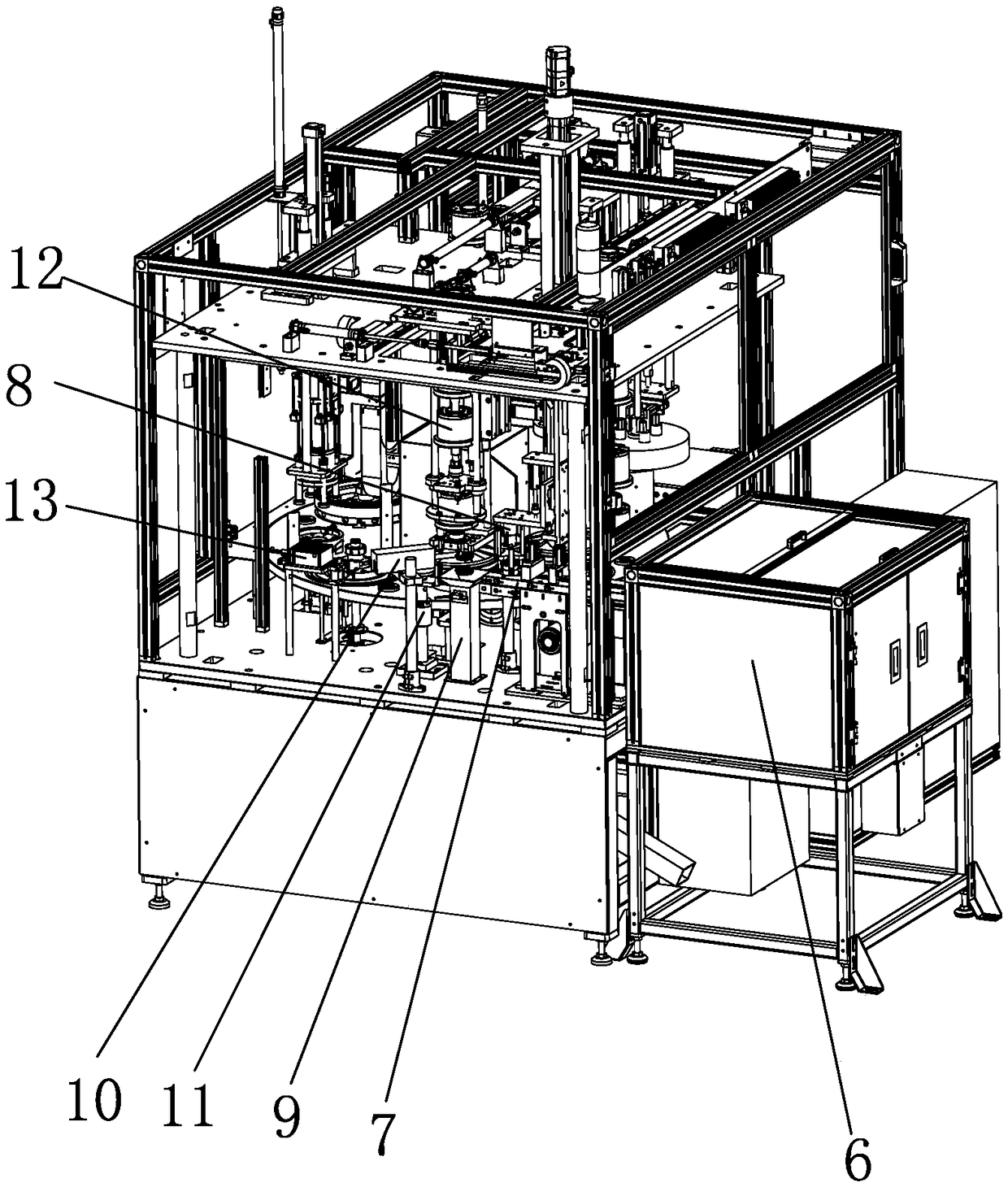

Automatic assembly machine of gas stove ignition device, and control method thereof

InactiveCN106964970AImprove efficiencyGood product quality and stabilityMetal working apparatusEngineeringVia device

An automatic assembly machine of a gas stove ignition device comprises a rack and a control unit. The rack is provided with a working platform of which the center is provided with a rotary device, and four sides of the rotary device are provided with feeding and blanking stations, tightening stations, flow adjusting stations and airtightness detecting stations in order respectively; the rack is provided with a start switch, the control unit and a power system, and the rotary device, the feeding and blanking stations, the tightening stations, the flow adjusting stations and the airtightness detecting stations are all connected to the power system and the control unit; and the start switch is connected to the control unit. In the invention, automatic assembly and detection of an ignition device are achieved, without manual assembly required, and the assembly efficiency is improved; quality inspection is performed through equipment, so that the product quality stability is improved.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

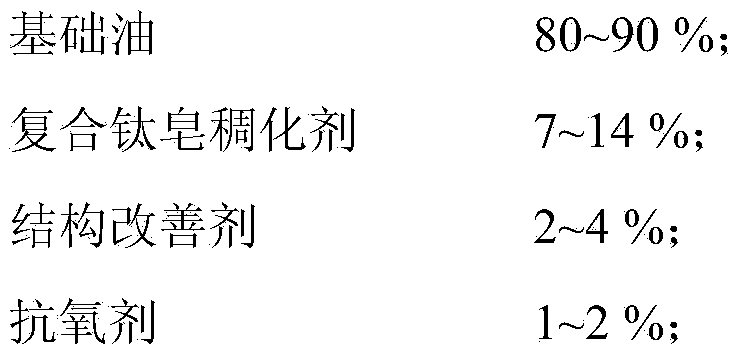

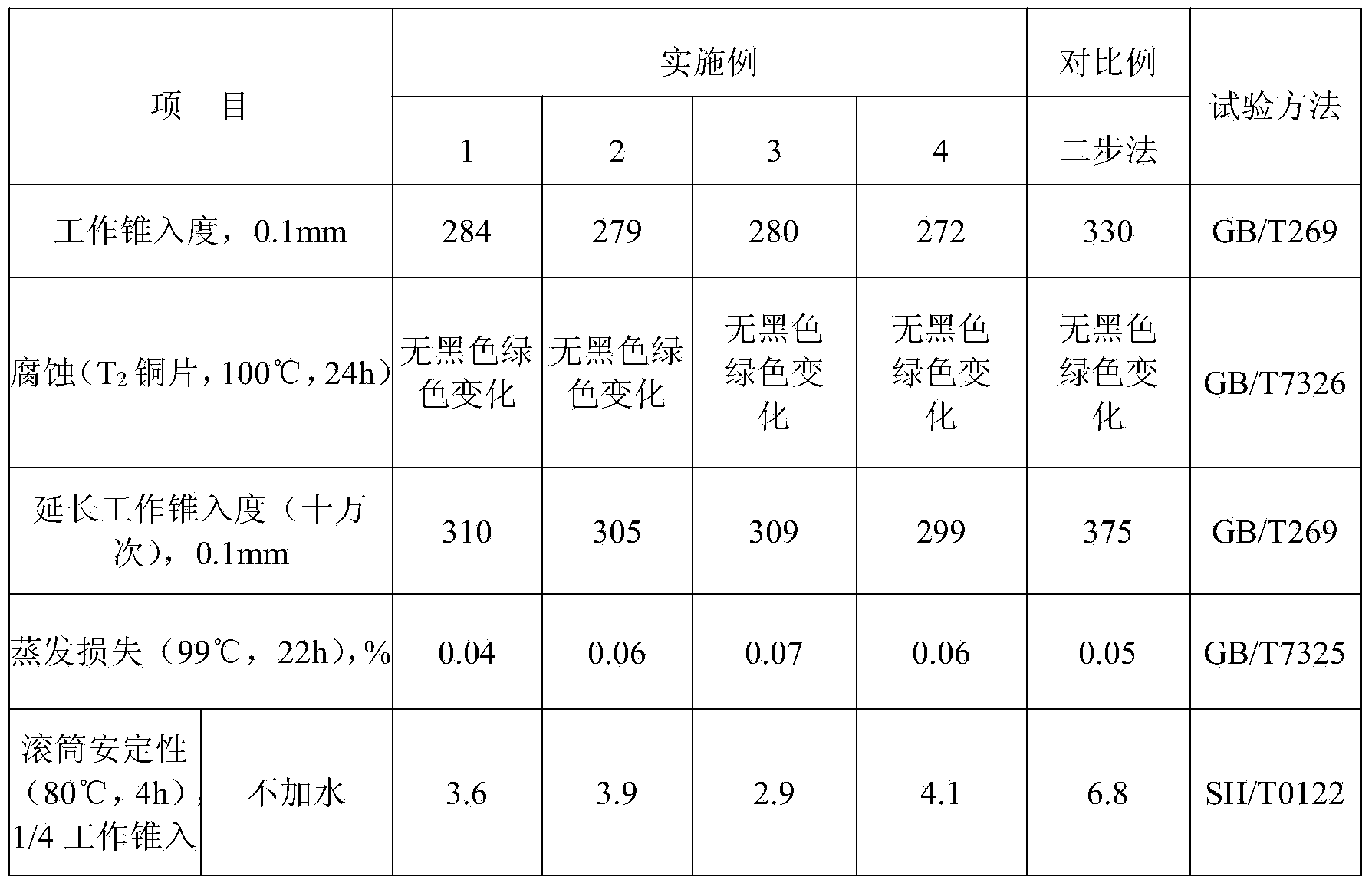

Compound titanium-based lubricant and preparation method thereof

ActiveCN104342243AStrong thickening abilityGood reproducibilityLubricant compositionAntioxidantMechanical stability

The invention relates to a compound titanium-based lubricant and a preparation method thereof. The compound titanium-based lubricant comprises the following formula components in percentage by mass: 80-90% of base oil, 7-14% of compound titanium soap thickening agent, 2-4% of structure modifier, and 1-2% of antioxidant. According to the preparation method, and through the introduction of a solvent and the base oil, the reaction interface can be increased, the reaction speed and reaction degree can be improved, the preparation time can be greatly shortened, the thickening capability of a compound titanium soap can be improved, the production cost can be lowered, the one-step reaction system is simple to operate, the reproducibility is high, and the quality stability of products is good. The compound titanium-based lubricant is good excellent mechanical stability and oxidization stability, and especially good in water resistance property.

Owner:苏州山河星程材料科技有限公司

Seal ring assembling device for brake booster

PendingCN109290768AReasonable structureEasy to operateVehicle componentsMetal working apparatusMechanical engineering

The invention discloses a seal ring assembling device for a brake booster. The seal ring assembling device for the brake booster comprises a machine platform, a machine frame, a rotating disk, a firststation, a second station, a third station and a fourth station, wherein the first station, the second station, the third station and the fourth station are sequentially arranged around the rotatingdisk. The first station is provided with a feeding window used for feeding of a valve body assembly and a shell and used for detecting a bolt on the shell. The second station is used for detecting, oiling and installing the seal ring and detecting the valve body assembly. The third station is used for installing the shell on the valve body assembly. The fourth station is used for discharging the well assembled brake booster. The seal ring assembling device for the brake booster is reasonable in structure, easy to operate, small in volume, small in occupied space, capable of automatically achieving the process of installing the seal ring of the brake booster and assembling the brake booster, high in operation efficiency, low in production cost and good in product quality stability.

Owner:苏州鲁巴斯特机械科技有限公司

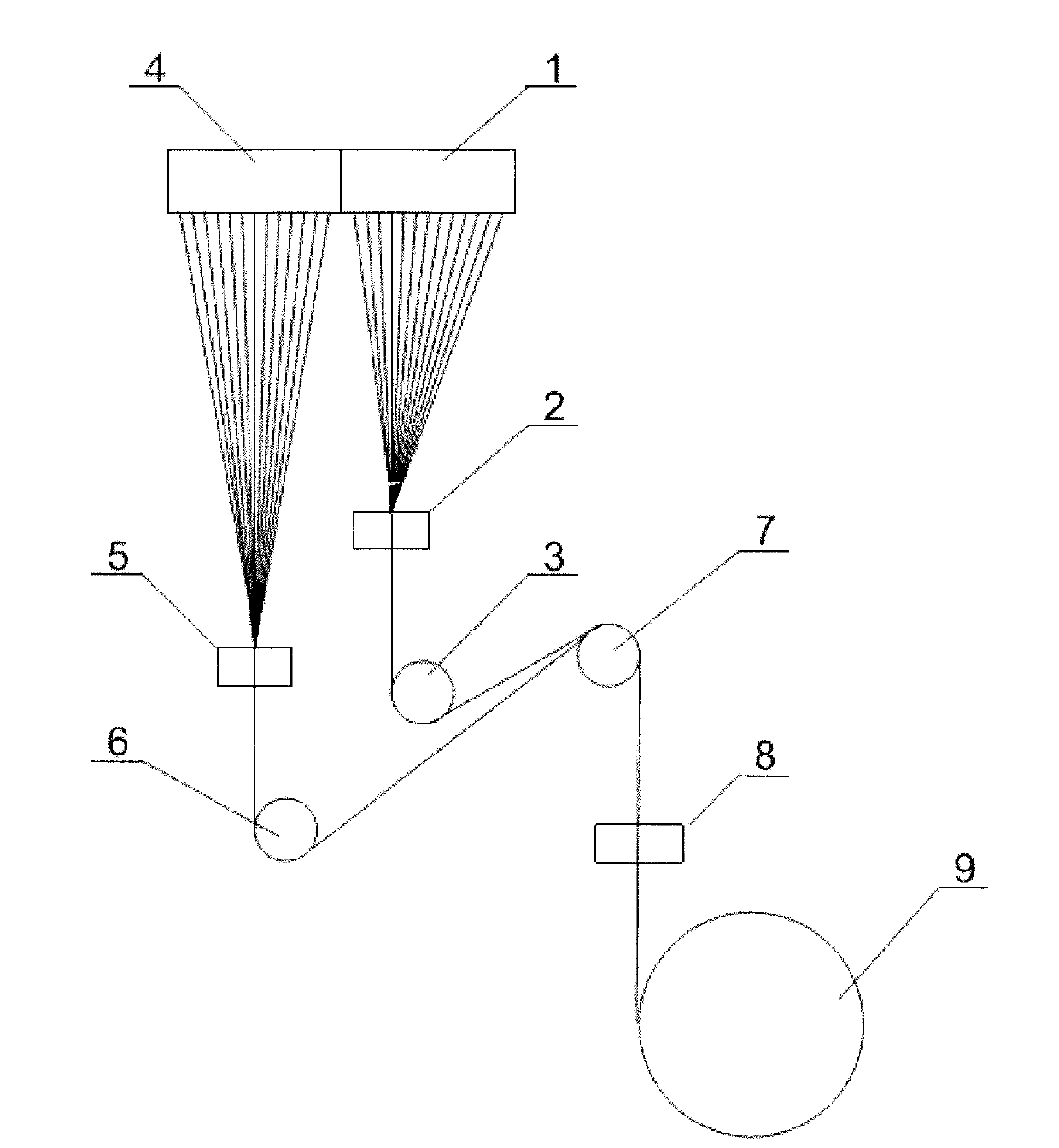

One-step preparation method of POY/POY combined yarn and device

InactiveCN103276457ASoft touchAbundant raw materialsArtificial thread manufacturing machinesMelt spinning methodsYarnEngineering

The invention discloses a one-step preparation method of POY / POY combined yarns and device. The method includes the steps: spinning is carried out with a first spinning assembly using first spinning liquid; spinning is carried out with a second spinning assembly using second spinning liquid; yarns spun through the first spinning assembly and the second spinning assembly pass through lower yarn guide plates of yarn paths respectively, then are combined on an upper yarn guide plate, and then sequentially pass a wire stitching machine and a winding roller to obtain the POY / POY combined yarns. Improvement is made on the basis of an existing production device preparing combined yarns of pre-oriented yarns and fully drawn yarns in a one-step method, the improvement is easy and convenient, compared with the conventional combined yarns of the pre-oriented yarns and the fully drawn yarns, the POY / POY combined yarns prepared in the one-step method are soft in handfeel, materials are various, spinning is flexible, production efficiency is high, the technological process is short, energy consumption and material consumption are low, fixed length and fixed weight are achieved, product quality stability is good, and the POY / POY combined yarns prepared in the one-step method can be directly used for weaving, the combined yarns with different sections, different fineness and different constituents can be prepared, and the combined yarns can be used for simulation fabric or functional products.

Owner:DONGHUA UNIV +1

Preparation method of polyisobutene with low molecular weight and high activity

ActiveCN102603950AMolecular weight is easy to control and stableActivity is easy to control and stableDouble bondHigh activity

The invention discloses a preparation method of polyisobutene with low molecular weight and high activity. The method comprises the following steps of: continuously adding a raw material with isobutylene content of 40-90wt% into a polymer reactor, and simultaneously adding a catalyst A and a catalyst B from the two inlets of the polymer reactor to perform polymerization reaction; terminating the obtained polymer material by a terminator; performing tertiary countercurrent washing and then removing the unreacted C4 component by a climbing-film evaporator; further removing the unreacted C4 component in a falling-film evaporator; and finally removing low polymer through vacuum distillation to obtain high-activity polyisobutene with number-average molecular weight of 500-5,000, wherein the content of alpha-terminal double bonds is greater than or equal to 80% by mole, the maximum isobutylene conversion rate can reach 85%, and the molecular weight distribution is narrow. The method disclosed by the invention is simple and reasonable in polymerization technology; and due to the mode of continuously adding catalysts at different positions, the reaction conditions are relatively mild, the polymerization occurrence possibility is low, the reaction conditions are easy to control, and the quality stability is good.

Owner:SHANDONG HONGRUI NEW MATERIAL TECH

Concrete construction method combining BIM

InactiveCN108396858AShorten the design cycleShorten the manufacturing cycleCeramic shaping apparatusForming/stuttering elementsProcess efficiencyShop drawing

The invention provides a concrete construction method combining BIM. The concrete construction method comprises the following steps that (1) modeling is conducted through a BIM technology, and a shaped template construction drawing is designed; (2) according to the construction drawing in the step (1), templates are processed and assembled; (3) steel bars are bound, a steel bar frame is obtained,and the steel bar frame is arranged in the assembled templates; (4) concrete is configured and prepared, and the concrete is poured into a mold; and (5) curing is conducted, and then mold removal is conducted. According to the concrete construction method, a construction technology is simple and convenient, the product quality stability is good, the concrete construction method greatly improves both the construction process efficiency and stability, and the service life of a poured piece is prolonged.

Owner:HONGXIN LIMITED COOPERATION OF LANDSCAPE ARCHITECTURE OF ZHEJIANG

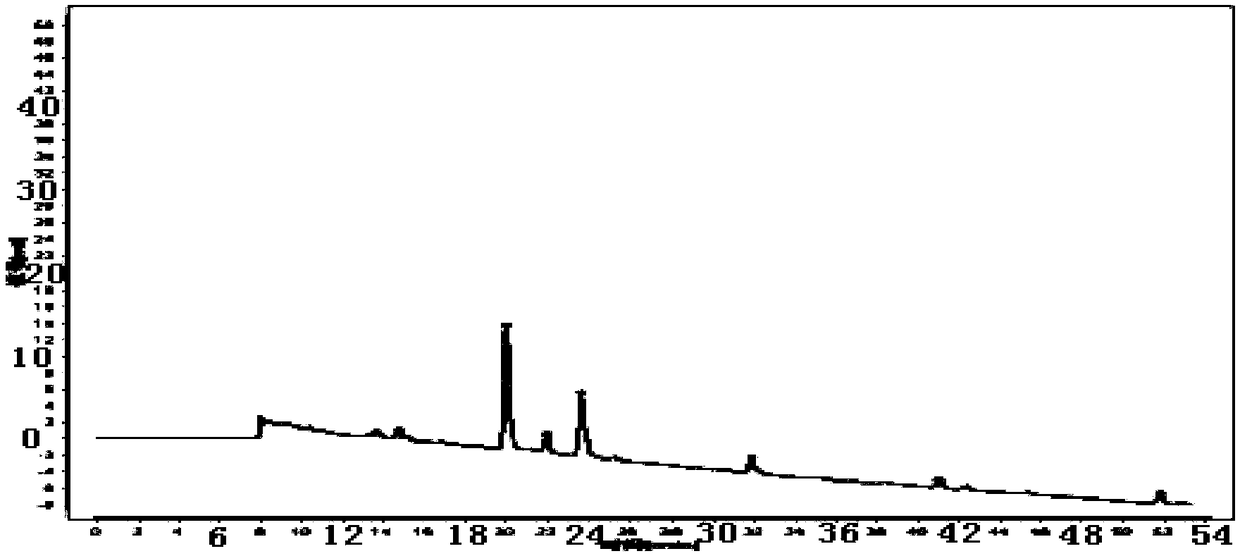

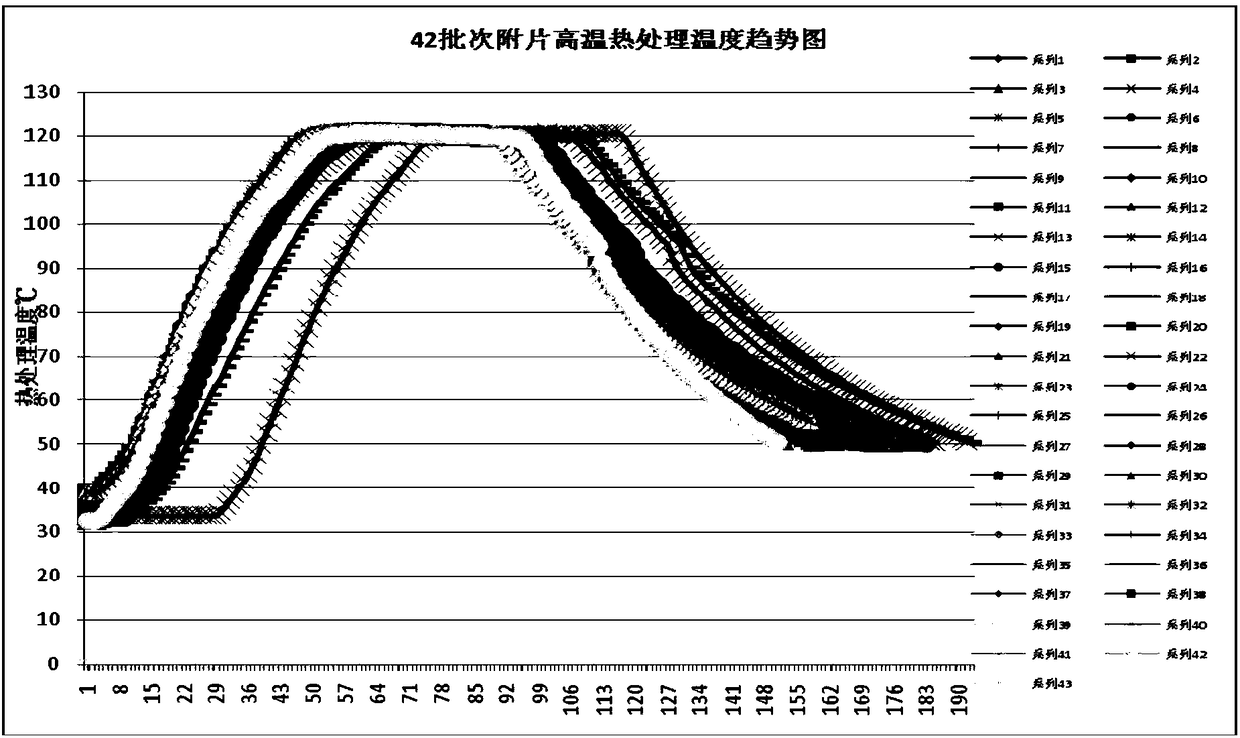

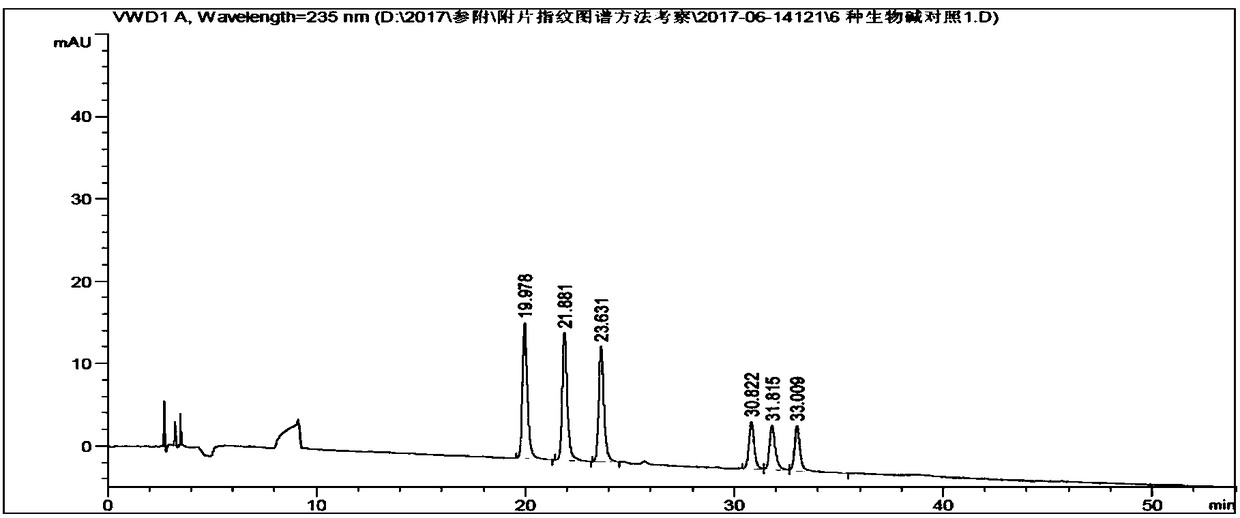

Black prepared lateral root of aconite extracting solution and shenfu injection obtained by adopting real-time release method in automatic black prepared lateral root of aconite extracting process

ActiveCN108459096AImprove batch-to-batch stabilityGood product quality and stabilityComponent separationPharmaceutical delivery mechanismAdditive ingredientUltrafiltration

The invention discloses a black prepared lateral root of aconite extracting solution and shenfu injection obtained by adopting a real-time release method in the automatic black prepared lateral root of aconite extracting process, and relates to the field of traditional Chinese medicine injection production testing. The real-time release method in the automatic black prepared lateral root of aconite extracting process comprises the steps of collecting and detecting the alkaloid content and a chromatographic fingerprint spectrum of a black prepared lateral root of aconite raw material sample; preparing acid volume extraction according to the alkaloid content of black prepared lateral root of aconite raw materials, and adopting an ultrafiltration membrane for removing impurities to obtain theblack prepared lateral root of aconite extracting solution; performing online collecting and detecting on the alkaloid content and the chromatographic fingerprint spectrum of the black prepared lateral root of aconite extracting solution sample; according to the alkaloid content of the black prepared lateral root of aconite extracting solution, black prepared lateral root of aconite extracting technological parameters are adjusted. Due to the fact that different raw materials correspond to different technological parameters, the stable effective ingredient is obtained, the batched stability and safety for reducing toxicity and increasing effect of the black prepared lateral root of aconite are improved, meanwhile, application of a poisonous and harmful reagents is lowered, the product quality stability of the obtained black prepared lateral root of aconite extracting solution and shenfu injection is good, and the clinic pharmaceutical safety and effectiveness are high.

Owner:YAAN THREE NINE PHARMA

Epoxy plastic

The invention discloses an epoxy plastic which is prepared from the following raw materials in parts by weight: 40-45 parts of glycidyl ether epoxy resin, 30-35 parts of bisphenol A epoxy resin, 5-10 parts of polyamide resin, 1-3 parts of dibutyl phthalate, 2-4 parts of stearic acid, 5-8 parts of carbon fiber, 3-5 parts of glass fiber, 2-4 parts of aluminum oxide, 1-5 parts of talcum powder, 2-5 parts of plasticizer, 2-5 parts of antioxidant, 1-3 parts of coupling agent and 1-3 parts of flame retardant. The epoxy plastic has the advantages of excellent alkali resistance, excellent acid resistance, excellent solvent resistance, low production cost and high quality stability of the product.

Owner:QINGDAO DAFANG WISDOM NETWORK TECH CO LTD

Method for producing multicolor section color yarn and drawing frame device

ActiveCN103866441AEasy to operateGood product quality and stabilityTextiles and paperYarnMaterial resources

The invention discloses a method for producing multicolor section color yarn. Main color rough yarn and secondary color rough yarn are adopted to be spun on a three-roller ring spinning section color yarn spinning frame, so that the multicolor section color yarn is obtained. The main color rough yarn is continuously fed in from a middle-roller horn mouth, the secondary color rough yarn is continuously fed in from a rear-roller horn mouth, pre-drawing strips with two or more colors are adopted for the secondary color rough yarn and fed into a cotton-feed roller of a drawing frame in parallel when the drawing procedure is carried out for combination, pre-drawing strips of the same color are concentrated and fed into the cotton-feed roller of the drawing frame in parallel, then the yarn roughing procedure is carried out on the pre-drawing strips, and accordingly the single multicolor secondary color rough yarn is formed. A traditional three-roller ring spinning section color yarn spinning frame is adopted in the method, multicolor section color yarn products with different effects can be produced without the need of improving spinning equipment any more, industrialization and mass production of the multicolor section color yarn products can be achieved through the production method, and cost of manpower and material resources is saved.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

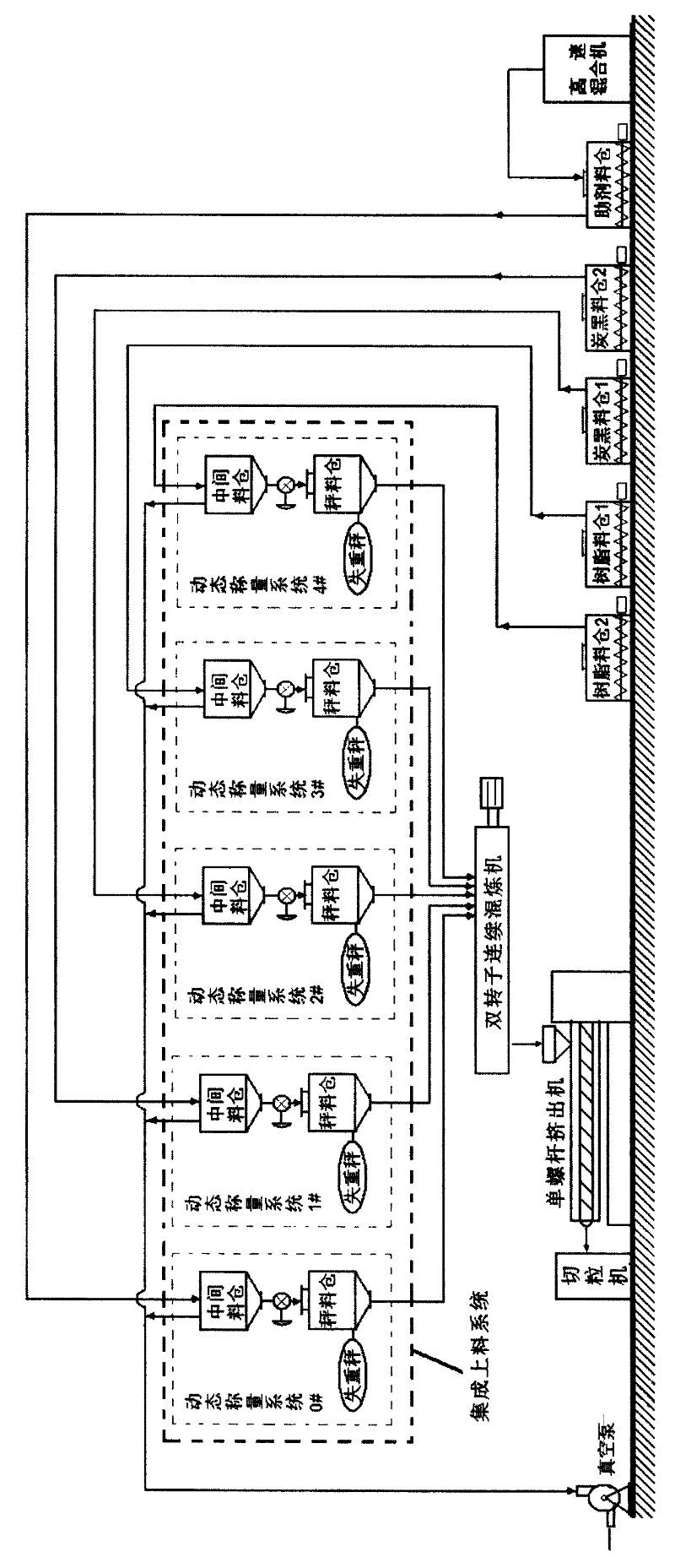

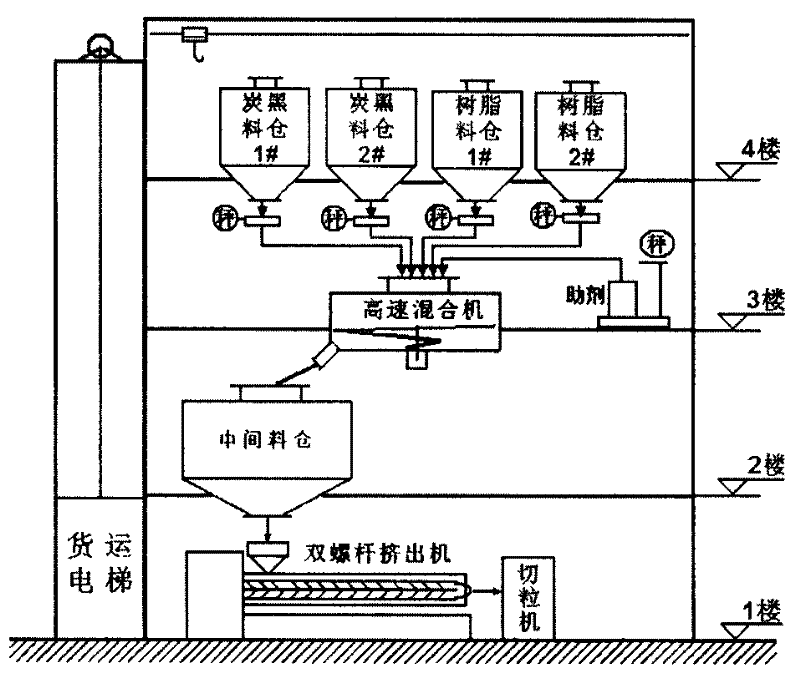

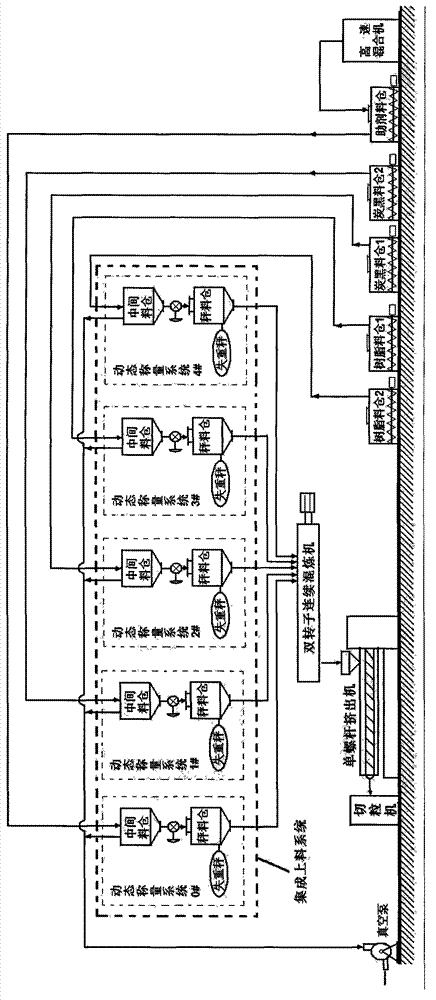

Preparation system device and preparation method for high-performance black master-batches

The invention discloses a preparation system device and a preparation method for high-performance black master-batches. The preparation system device comprises a raw material bin, an integrated feeding system, a dual-rotor continuous mixing mill, a single-screw extruder and a granulator, wherein the integrated feeding system consists of n dynamic weighing systems; each dynamic weighing system consists of a middle bin, a weighing bin and a weight loss scale; the top of the middle bin is connected with the corresponding raw material bin through a sealed conveying pipeline; the middle bin is further connected with a vacuum pump through the sealed pipeline; the bottom of the middle bin is connected with the weighing bin through the sealed pipeline; a switching valve is arranged between the middle bin and the weighing bin; the weighing bin is provided with the weight loss scale for weighing raw materials; the bottom of each weighing bin is connected with the dual-rotor continuous mixing mill through the sealed pipeline; and n is less than or equal to number of used raw materials in the formula. The preparation system device realizes continuous and automatic production, high production efficiency and high stability of product quality.

Owner:NANJING UNIV OF TECH +1

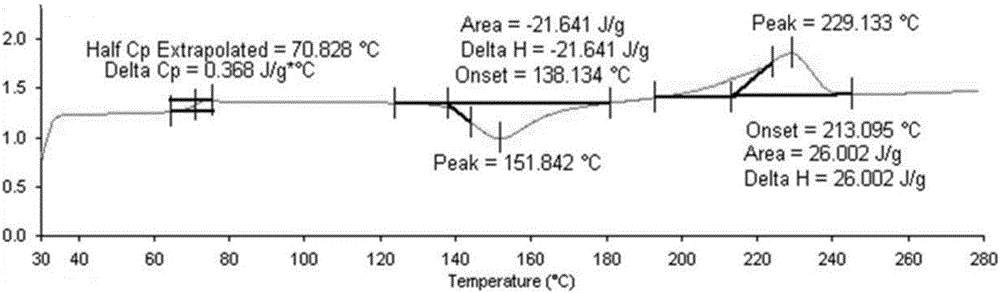

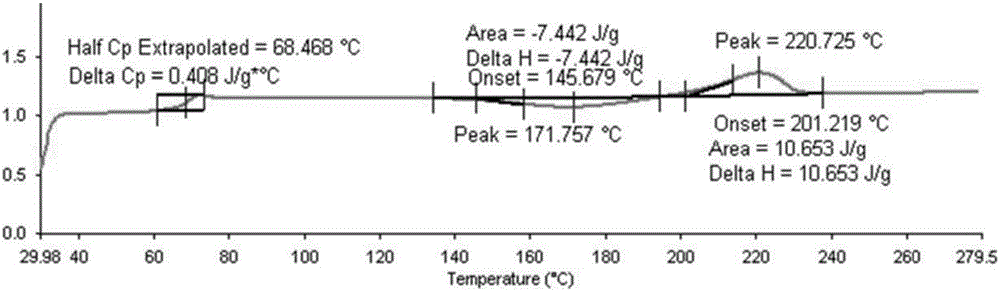

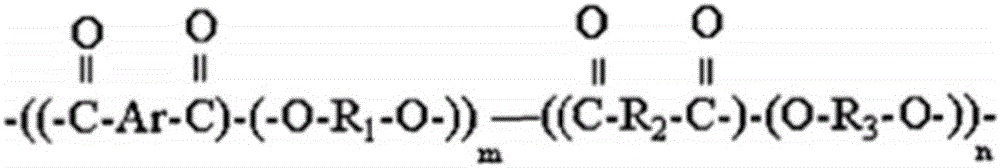

Aromatic polyester-aliphatic polyester block copolyester and preparing method thereof

ActiveCN106589330ALower glass transition temperatureImprove flexibilityMonocomponent copolyesters artificial filamentDyeing processDisperse dyePolyethylene terephthalate glycol

The invention discloses an aromatic polyester-aliphatic polyester block copolyester and a preparing method thereof. The copolyester is formed by polyethylene terephthalate oligomer and aliphatic polydiol diester polyhydric alcohol through condensation polymerization, the randomness degree of the copolyester is smaller than or equal to 0.05 and is larger than or equal to 0.95, the intrinsic viscosity is 0.5-1.2 dL / g, the melting point is 160-250 DEG C, the glass transition temperature is 40-77 DEG C, the hue B value is 1-8, and the content of diglycol is smaller than or equal to 1.5%. The aromatic polyester-aliphatic polyester block copolyester is excellent in hue, and spun fiber has excellent disperse dye constant-pressure dyeing performance and size stability. The preparing method is low in energy consumption, high in production efficiency, high in quality stability and easy to achieve large-scale industrial production.

Owner:CHINA TEXTILE ACADEMYTIANJINSCI & TECH DEV CO LTD +1

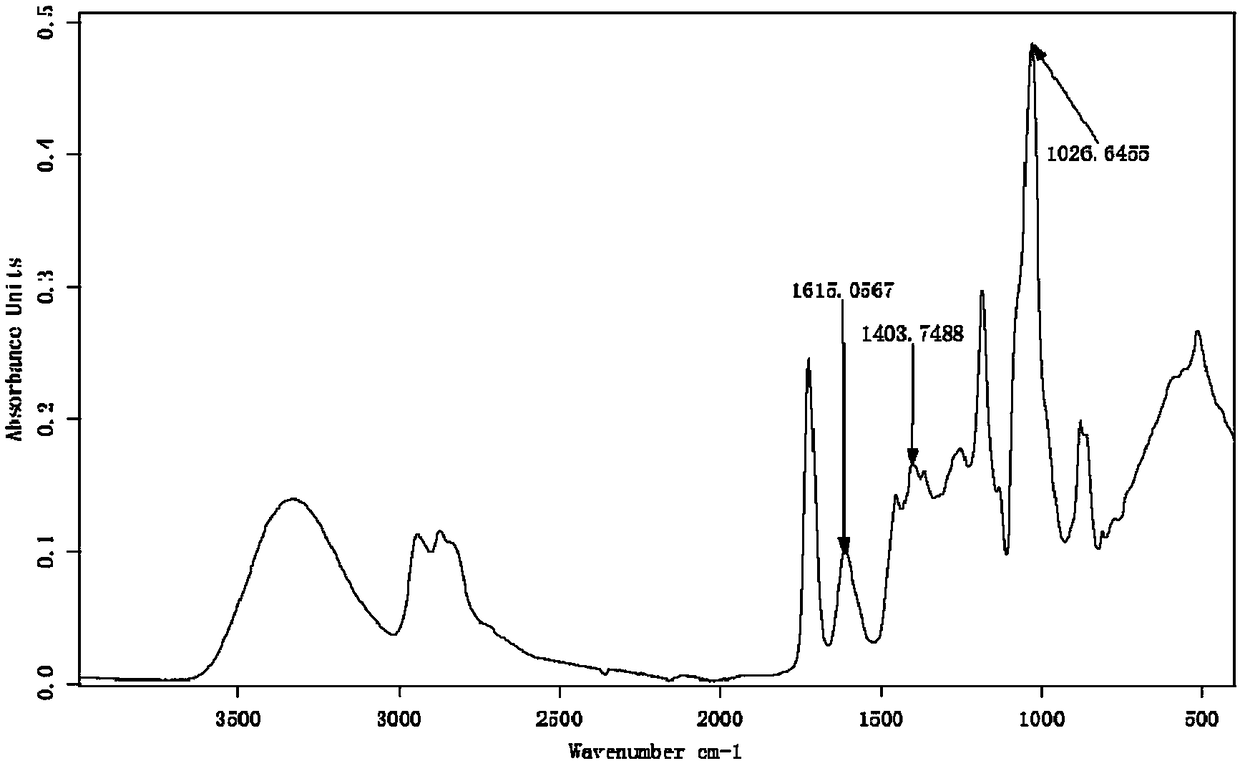

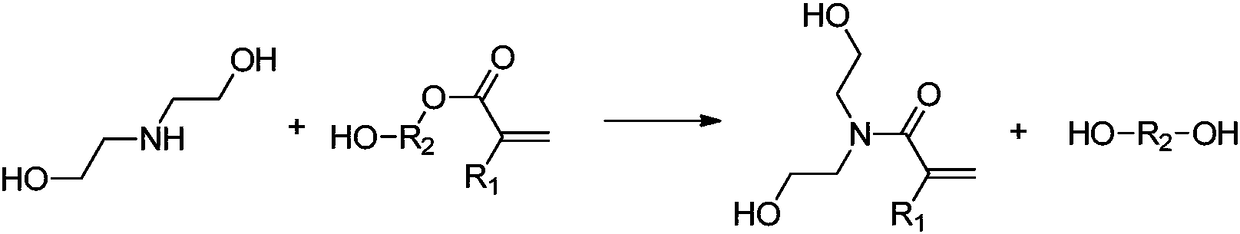

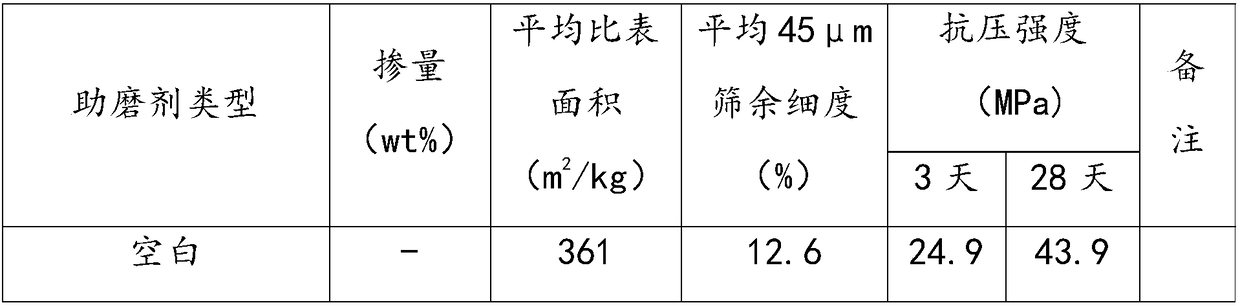

Cement grinding aid and preparation method thereof

The invention relates to the technical field of cement additives, in particular to a cement grinding aid and a preparation method thereof. The cement grinding aid comprises an amide compound and a polyol compound. The preparation method includes: mixing and stirring diethanol amine and acrylate derivatives to perform ester aminolysis reaction so as to obtain the cement grinding aid. The cement grinding aid is capable of satisfying the standard requirements of the cement grinding aids, excellent in grinding aiding effect and quality stability, capable of increasing compressive strength and capable of being used along with an existing cement grinding aid to improve the quality stability of the existing cement grinding aid and increase the grinding aiding effect.

Owner:北京金隅节能科技有限公司 +1

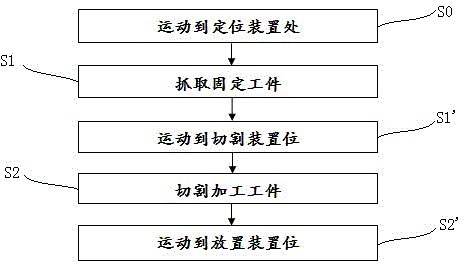

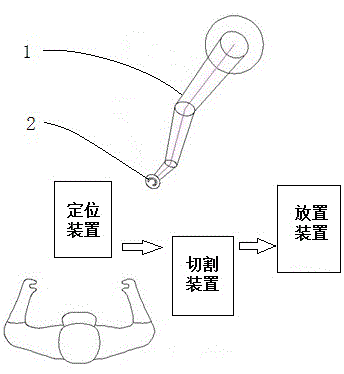

Unartificial process for processing tooth socket

InactiveCN104546157AImprove processing efficiencyGood product quality and stabilityOthrodonticsMechanical equipmentProcessing cost

The invention discloses an unartificial process for processing a tooth socket. The process sequentially comprises the following steps: S1 grasping a fixed workpiece, namely clamping the workpiece by mechanical equipment, firmly adsorbing and clamping the workpiece by negative pressure, simultaneously, accurately positioning the clamping position of the tooth socket through a positioning device; and S2 cutting the workpiece, namely processing workpiece data by the mechanical equipment to obtain cutting trajectory data to achieve flexible cutting on the workpiece. According to the process, artificial processing in the prior art is replaced by mechanical equipment processing; the mechanical equipment preferably is a robot or a mechanical arm; the action of grasping the fixed workpiece is carried out by the robot or the mechanical arm according to an instruction sent out by a controller; and the cutting equipment at a cutting device position is used for identifying the workpiece and executing the cutting action. The artificial operation in a processing workshop is replaced by the process disclosed by the invention; the processing efficiency is improved; and the quality stability of a product is good, so that the processing cost is reduced.

Owner:浙江正雅齿科股份有限公司

Method for high temperature quick synthesizing blender or compound titanate ceramic powder

The present invention provides high temperature synthesizing process of blended or compound titanate ceramic powder. The method includes fully mixing titanate synthesized in advance and blended elements, grinding and tabletting, fast reaction of the mixture in argon atmosphere inside vacuum arc furnace, and grinding the reacted solid into the blended titanate ceramic powder. The present invention has simple technological process, easy operation, short reaction period, low cost, and high quality and performance of prepared blended titanate ceramic powder.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Water-based ink covering emulsion and preparation method thereof

The invention relates to the technical field of covering emulsion, and in particular, relates to a water-based ink covering emulsion and a preparation method thereof. Raw materials adopted by the water-based ink covering emulsion are all conventional low-cost raw materials, so the produced water-based ink covering emulsion has low cost; the water-based ink covering emulsion contains no toxic solvent, has low VOV content, contains no free TDI and various heavy metals, and is environmentally friendly and safe; the water-based ink covering emulsion has the advantages of good covering power and good color developing effect, and an obtained printing layer has high surface glossiness; the preparation method has the advantages of simple process and high operability, can be promoted and used on large scale, and cooperates with a water-based ink covering emulsion formula for use; the produced water-based ink covering emulsion has the advantages of good covering power and good color developing effect, and the obtained printing layer has high surface glossiness.

Owner:杨康营 +1

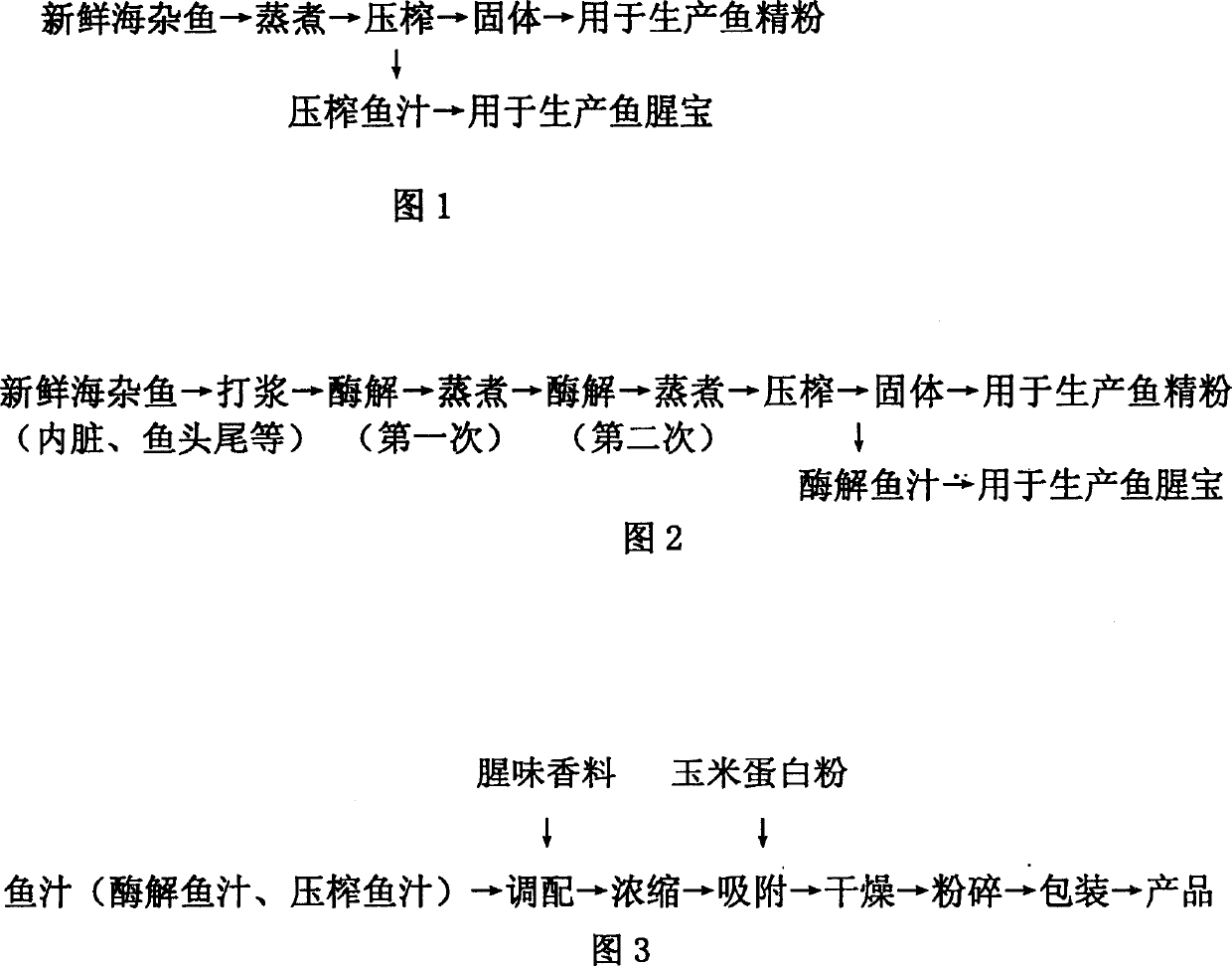

Fodder phagostimulant compounded with fish extract and preparing method use thereof

InactiveCN1488277ASolve the way outCover up the smellAnimal feeding stuffAccessory food factorsFlavorFish extract

The invention is a kind of feed bait prepared by fish extract, making method and application, referring to synthetic use of offal. It adds fishy flavor to fish extracts í«pressed fish juiceí» and í«enzymolysis fish juiceí» for preparation and concentration, adds in corn protein powder for absorption, then dries, crushes and packs to get it, providing the wide breeding users with a high-quality feed additive.

Owner:JIANGNAN UNIV

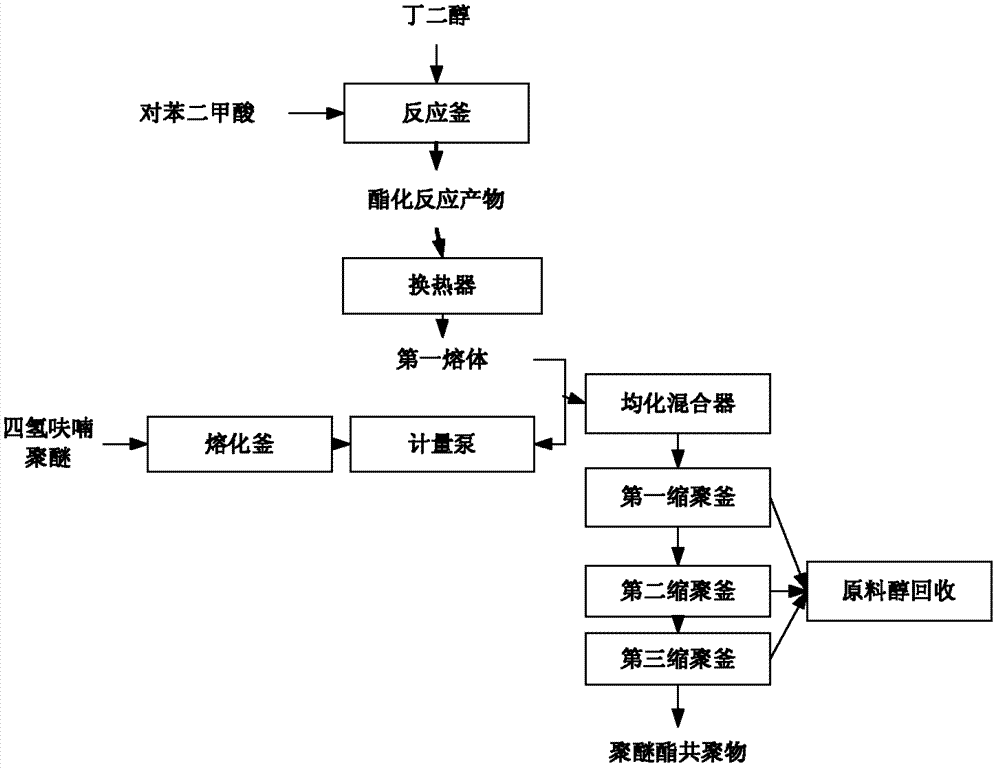

Continuous polymerization method for polyether ester copolymer

The invention discloses a continuous polymerization method for polyether ester copolymer. The method comprises the steps of adding terephthalic acid and butanediol into a reaction kettle for carrying out esterification reaction, thus obtaining esterification reaction product; carrying out heat exchange between the esterification reaction product with a heat exchanger connected with the reaction kettle to obtain a first fondant at temperature of 225-235 DEG C, wherein the first fondant enters a homogenizing mixer; leading the tetrahydrofuran homopolymerize ether with the molecular weight 800-2000 to sequentially pass through a fusion kettle and a metering pump and enter the homogenizing mixer, evenly mixing the tetrahydrofuran homopolymerize ether and the first fondant to obtain a second fondant; and leading the second fondant to enter a polycondensation kettle and generate a polycondensation reaction, wherein the polycondensation kettle is of a multistage polycondensation kettle. The technical scheme is applied to prepare the polyether ester copolymer, and the continuous polymerization is adopted, thus having the advantages of low energy consumption, large yield, easiness for large-scale production and good quality and stability of products.

Owner:CHINESE TEXTILE ACAD

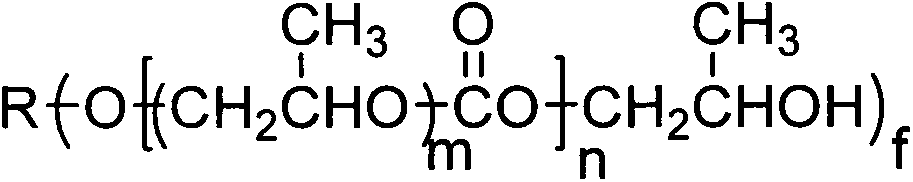

Preparation method for block oligomeric dihydric alcohol with controllable structure

The invention relates to block oligomeric dihydric alcohol with a controllable structure and a preparation method thereof. The main chain of the block oligomeric dihydric alcohol is a controllable block structure and is obtained by performing propoxylation or ethoxylation / propoxylation on polycarbonate, the terminal group is hydroxyl, the number-average molecular weight is 500-10000, and the molecular weight of carbonate chains and oxidized propylene / ethylene chains is adjustable. The preparation method of the block oligomeric dihydric alcohol comprises the following steps: firstly adding polycarbonate diol and a double-metal cyanide complex catalyst into a reaction kettle, heating to a certain temperature, and performing vacuum dewatering; then adding a part of an epoxide under the condition of 100-180 DEG C to perform an induction reaction, and after the induction reaction is finished, dropwise adding the residual epoxide; and after the reaction is finished, removing the unreacted epoxide to obtain oligomeric dihydric alcohol. The oligomeric dihydric alcohol is mainly applied to synthesis a polyurethane material.

Owner:WANHUA CHEM GRP CO LTD +1

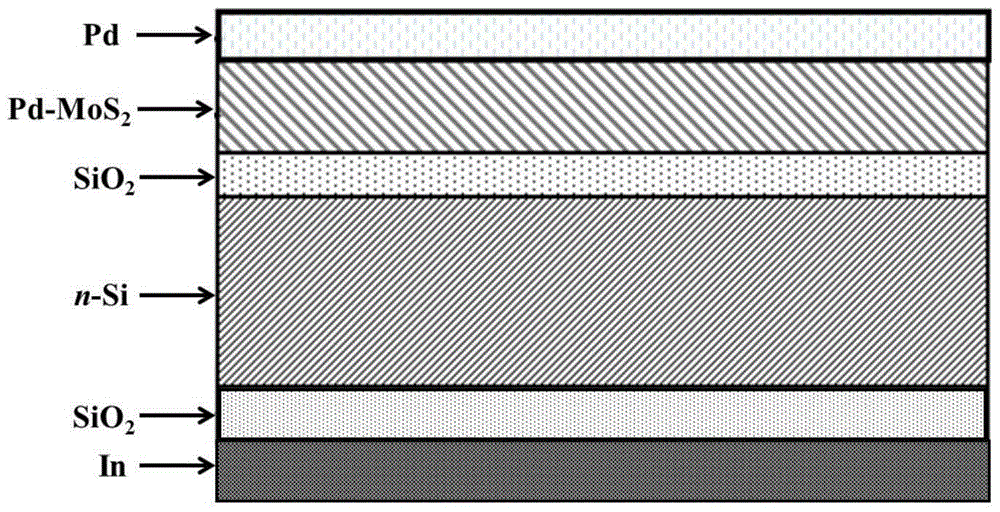

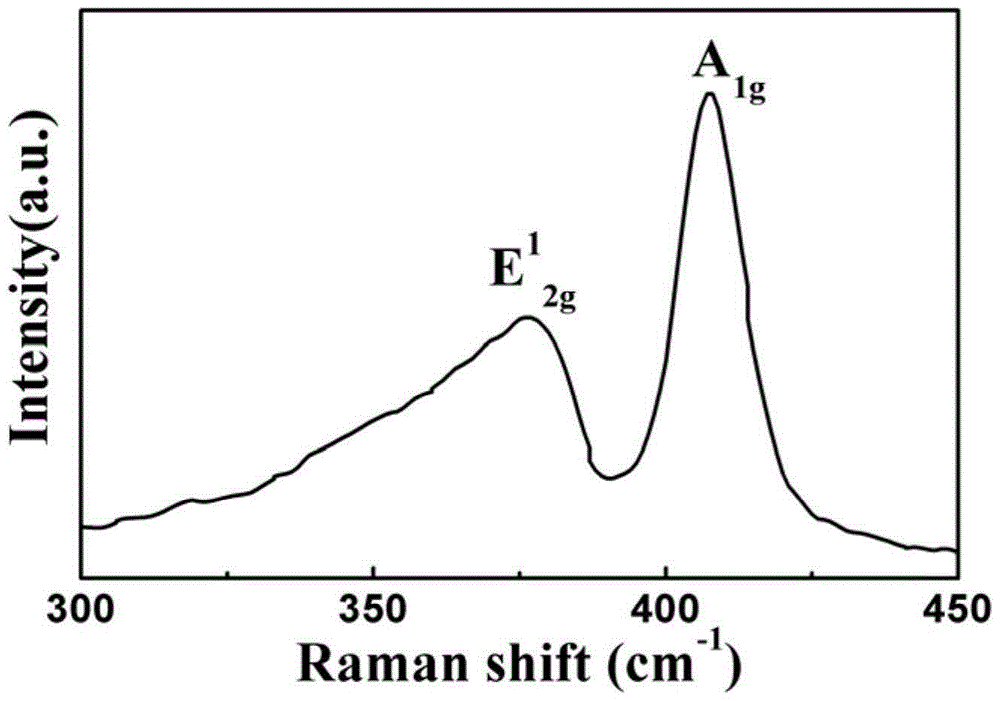

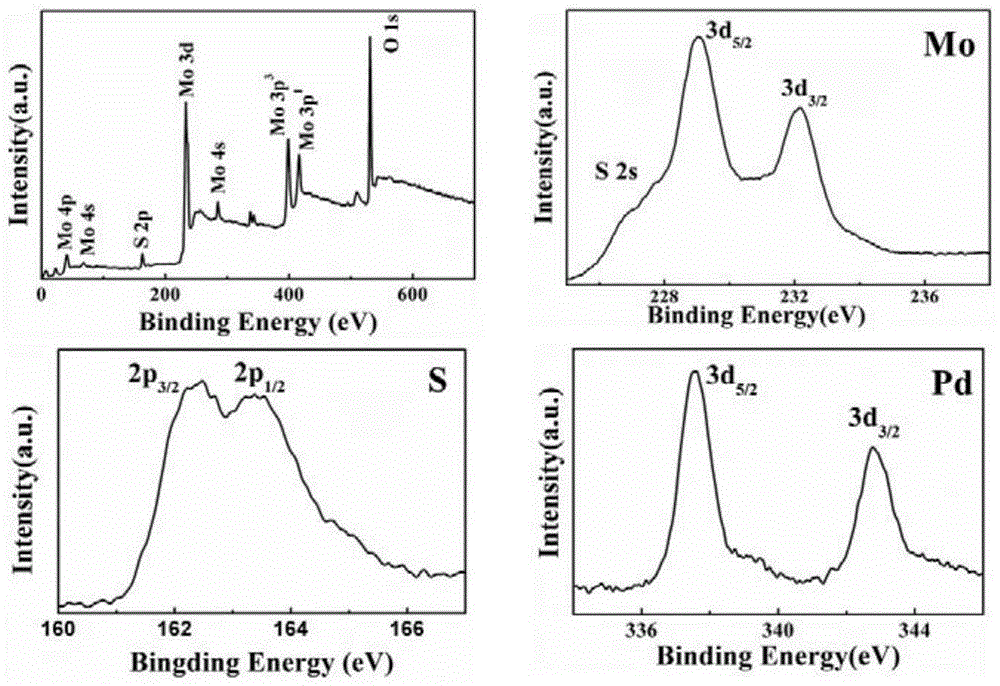

Pd-MoS2 heterojunction photovoltaic solar cell device and preparation method thereof

InactiveCN105226125AImproved PV performance parametersSimple processFinal product manufacturePhotovoltaic energy generationHeterojunctionHigh energy

The invention discloses a Pd-MoS2 heterojunction photovoltaic solar cell device. The Pd-MoS2 heterojunction photovoltaic solar cell device is of a layered structure and sequentially comprises a Pd metal front electrode, a Pd-MoS2 thin film layer, a first SiO2 insulation buffer layer, a Si monocrystal substrate, a second SiO insulation buffer layer and a metal In back electrode from top to bottom. The preparation method mainly adopts a DC magnetron sputtering technique and comprises the following steps of: bombarding the surface of a Pd-MoS2 target with high-energy electrons so that a large amount of ions are sputtered; depositing a thin film on the surface of the Si monocrystal substrate subjected to passivation treatment; and preparing front electrode and back electrode layers and completing. The open-circuit voltage, the short-circuit current density and the light conversion efficiency of the Pd-MoS2 heterojunction photovoltaic solar cell device disclosed by the invention are respectively improved by over 60%, 160% and 300% compared with the similar products in the prior art. The Pd-MoS2 heterojunction photovoltaic solar cell device disclosed by the invention has the advantages of simplicity in process, greenness and environment protection on the production process and a product, high finished product rate and low manufacturing cost, and is suitable for industrial production at a large scale.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com