Seal ring assembling device for brake booster

A technology for assembling equipment and sealing rings, applied in metal processing equipment, vehicle parts, transportation and packaging, etc., can solve the problems affecting the industrialized production process of brake boosters, poor product quality stability, high labor intensity, etc., to achieve stable product quality. The effect of good performance, low production cost and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

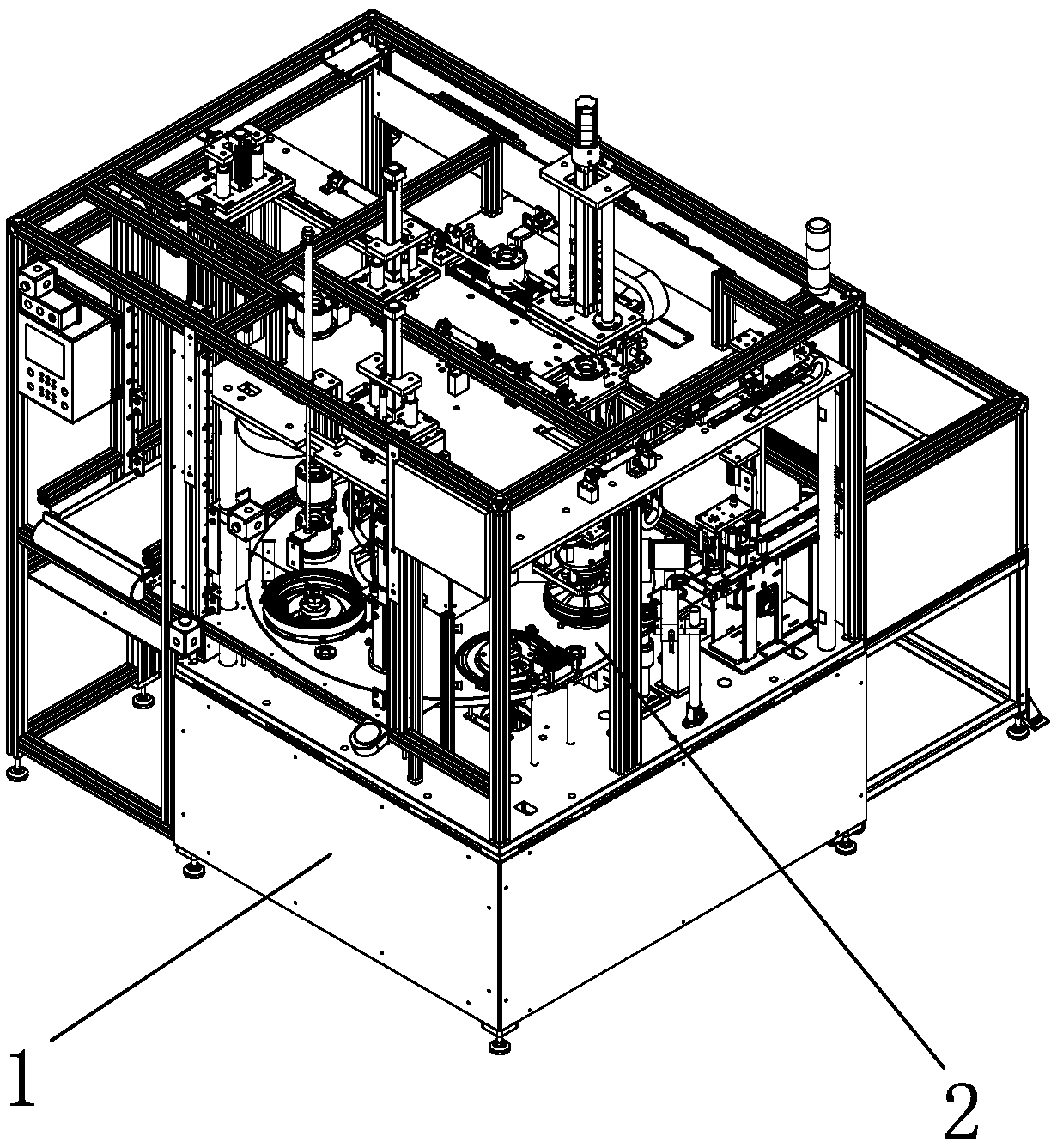

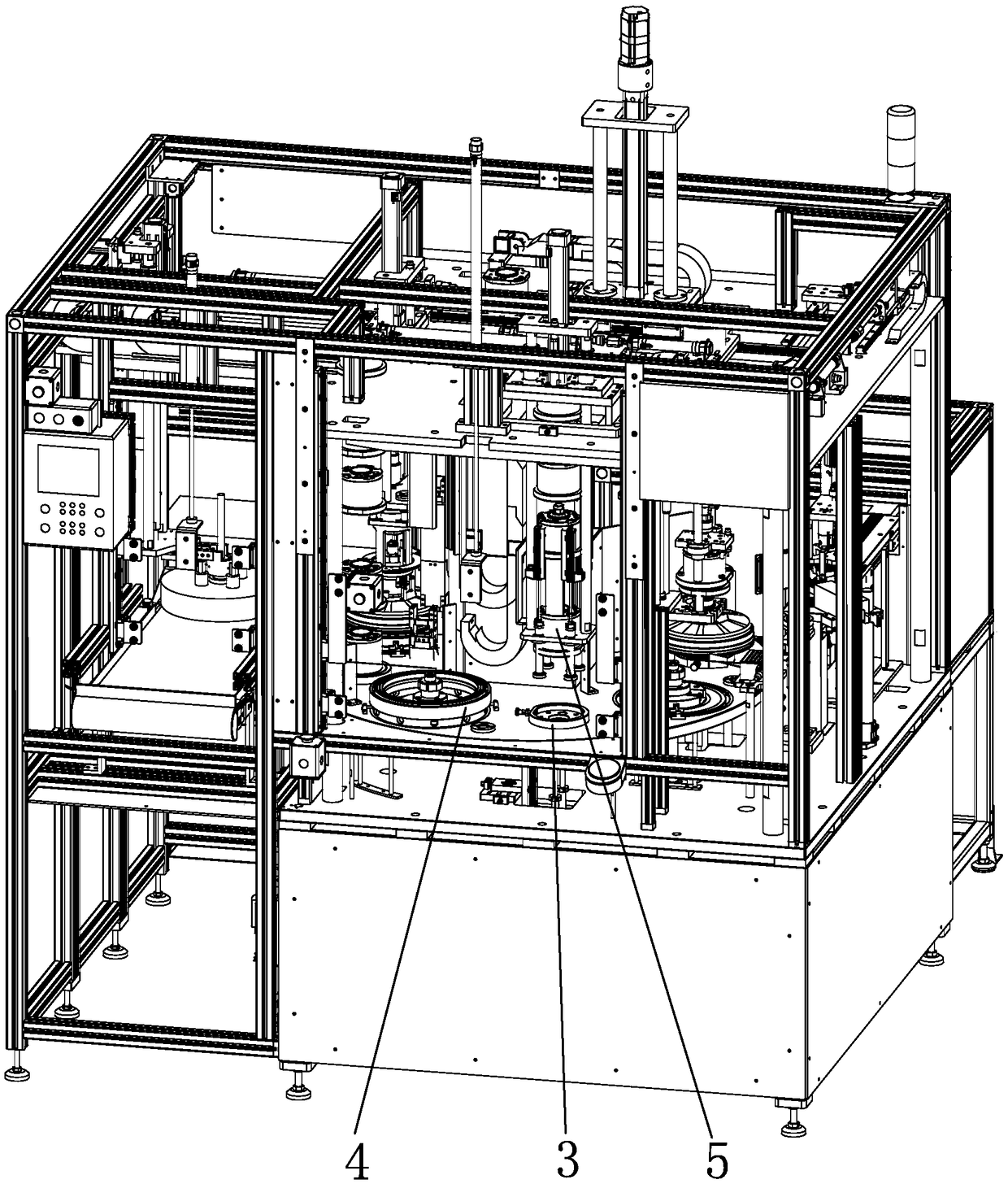

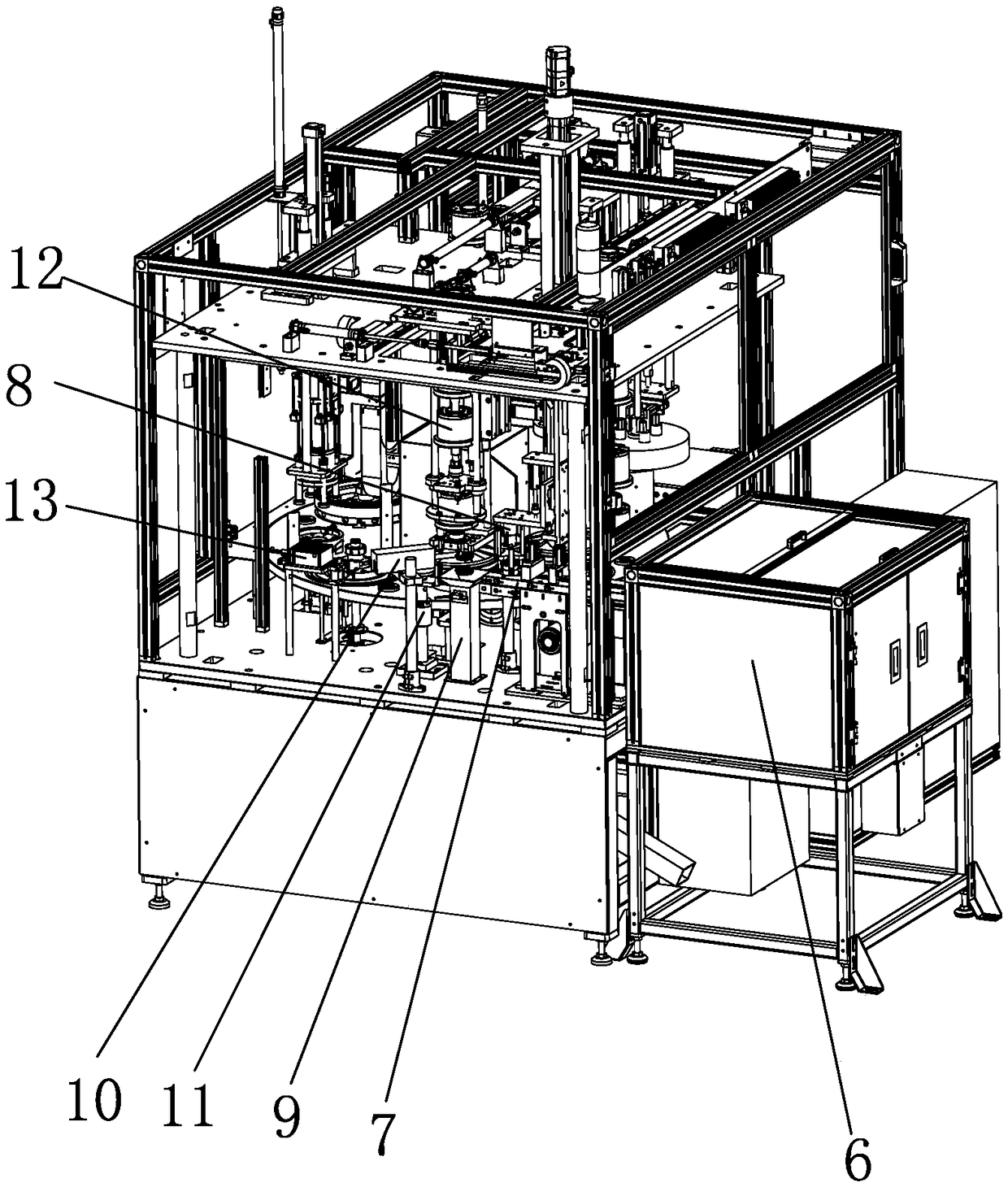

[0037] combine figure 1, the invention discloses a brake booster sealing ring assembly equipment, comprising a machine 1, a frame installed on the machine 1, a turntable 2 movably arranged on the machine 1, and surrounding the turntable 2 and arranged in sequence The first station, the second station, the third station and the fourth station. The turntable 2 is movably installed on the machine platform 1 and rotates relative to the machine platform 1 . Specifically, the turntable 2 is installed on the machine platform 1 through the rotating main shaft, the rotating main shaft is arranged vertically, and the turntable 2 is installed horizontally on the top of the rotating main shaft; a driving motor is arranged on the machine platform 1; The main shaft is meshed, and the main shaft is driven to rotate, so that the turntable 2 rotates. On the turntable 2, a station seat is installed. One group of station seats includes a valve body station seat 4 and a housing station seat 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com