Continuous polymerization method for polyether ester copolymer

A technology of copolymer and polyether ester, which is applied in the field of continuous polymerization of polyether ester copolymer, can solve the problems of low production efficiency and unstable product quality, and achieve large output, good product quality stability, and easy large-scale production The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Polyether ester is prepared by the method for continuous polymerization of polyether ester copolymer provided by the invention

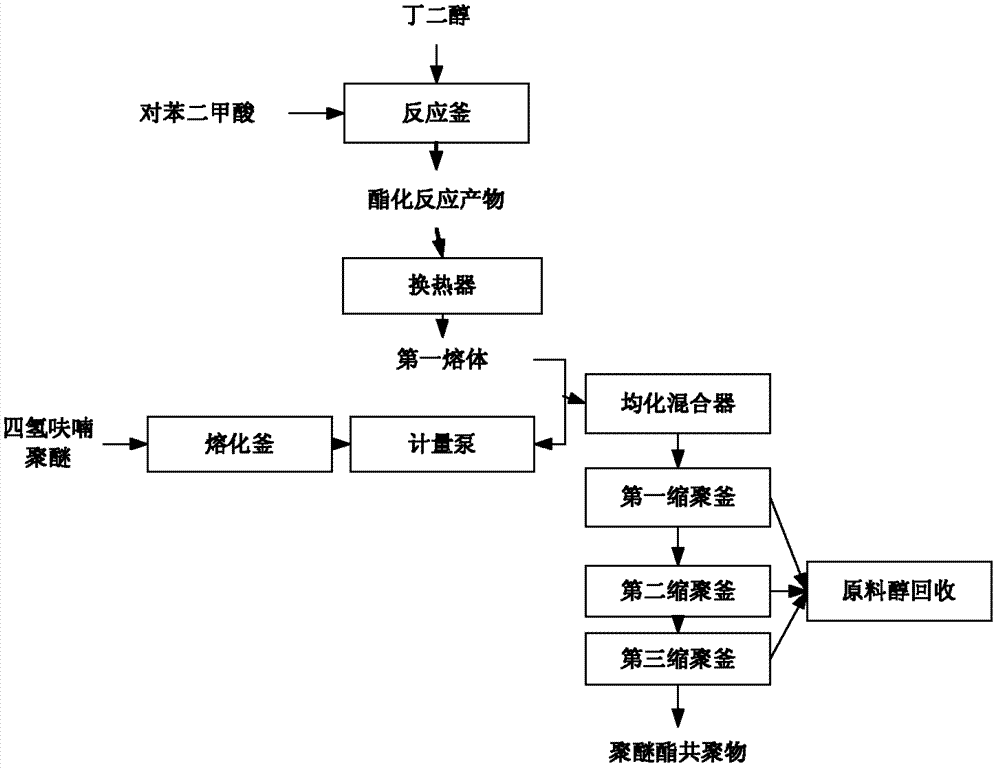

[0035]With the 3 tons of small-scale low-temperature short-process continuous polyester polycondensation production equipment produced by Shanghai Petrochemical Company as equipment, terephthalic acid (PTA), butanediol (BG) and tetrahydrofuran homopolyether with a molecular weight of 800-2000 are used as raw materials. Using tetrabutyl titanate as a catalyst to continuously produce co-condensed polyether ester. Add terephthalic acid and butanediol to the reaction kettle at a ratio of 1:2.2 to carry out esterification reaction. The temperature of the esterification reaction is 250-260° C., and the reaction time is 20 minutes to obtain the esterification reaction product BHBT: heat exchange the esterification reaction product through a heat exchanger connected to the reactor to obtain the first melt with a temperature of 228-232°C, and then the ...

Embodiment 2

[0049] With the 3 tons of small-scale low-temperature short-process continuous polyester polycondensation production equipment produced by Shanghai Petrochemical Company as equipment, terephthalic acid (PTA), butanediol (BG) and tetrahydrofuran homopolyether with a molecular weight of 800-2000 are used as raw materials. Using tetrabutyl titanate as a catalyst to continuously produce co-condensed polyether ester. Add terephthalic acid and butanediol to the reaction kettle at a ratio of 1:2.2 to carry out esterification reaction. The temperature of the esterification reaction is 250-260° C., and the reaction time is 20 minutes to obtain the esterification reaction product BHBT; heat exchange the esterification reaction product through a heat exchanger connected to the reactor to obtain the first melt with a temperature of 225-235°C, and then the first melt enters the homogenizer; wherein, the heat exchanger passes through The heat medium circulates the hot oil, and the hot oil e...

Embodiment 3

[0055] With the 3 tons of small-scale low-temperature short-process continuous polyester polycondensation production equipment produced by Shanghai Petrochemical Company as equipment, terephthalic acid (PTA), butanediol (BG) and tetrahydrofuran homopolyether with a molecular weight of 800-2000 are used as raw materials. Using tetrabutyl titanate as a catalyst to continuously produce co-condensed polyether ester. Add terephthalic acid and butanediol to the reaction kettle at a material ratio of 1:2.1 for esterification reaction, the temperature of the esterification reaction is 250-260°C, and the reaction time is 60 minutes to obtain the esterification reaction product BHBT; heat exchange the esterification reaction product through a heat exchanger connected to the reactor to obtain the first melt with a temperature of 225-235°C, and then the first melt enters the homogenizer; wherein, the heat exchanger passes through The heat medium circulates the hot oil, and the hot oil ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com