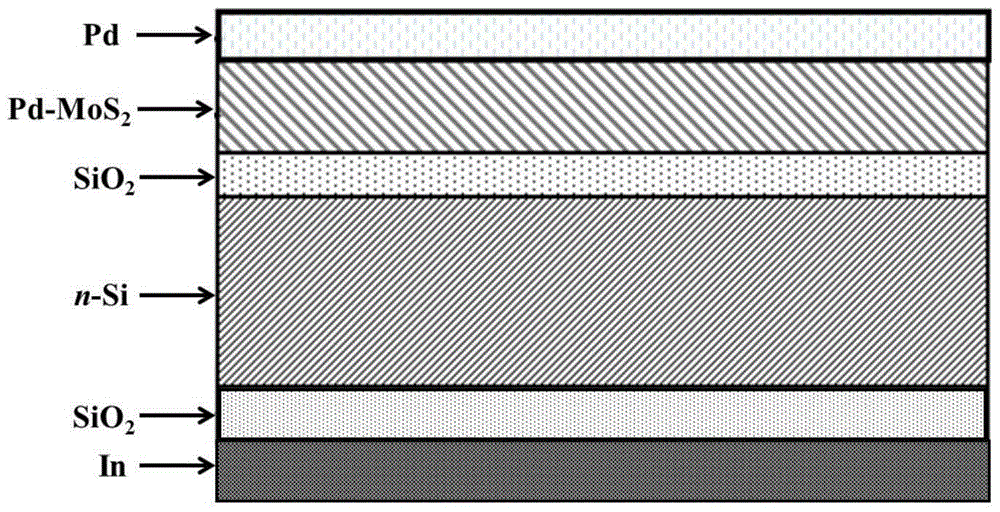

Pd-MoS2 heterojunction photovoltaic solar cell device and preparation method thereof

A solar cell, pd-mos2 technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of improving the axial conductivity of MoS2, not taking effective technical methods, low short-circuit current density, etc., and achieving good thermal stability. performance and chemical stability, improved photoconversion efficiency, and reduced defect density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The preparation method is as follows:

[0063] The first step, Pd-MoS 2 Target preparation steps

[0064] Take 1 part of Pd metal particles with a purity of 99.99% or more and MoS with a purity of 99.9% or more according to the mole fractions 2 99 parts of particles, blended and pulverized into a ball mill to a particle size of 500-800 mesh powder;

[0065] Put the powder obtained by grinding into a tablet press mold and place it on the tablet press. The pressure of the press is 20-25MPa, the pressing time is 1 hour, and it is pressed into a cylindrical target with a thickness of 3-5mm and a diameter of 60mm. material;

[0066] The second step is the passivation step of the silicon substrate surface

[0067] Select an n-type Si single crystal substrate with a resistivity of 1-10Ω·cm and a crystal plane orientation of (100) planes, and ultrasonically clean them in alcohol, acetone and deionized water for 180s in sequence;

[0068] Take it out and place it in a hydrofluoric acid so...

Embodiment 2

[0081] (Note: This example is a comparative example, the target material used is pure MoS 2 Target. That is, in the preparation process of the target, Pb metal is not used to MoS 2 Doping treatment)

[0082] The first step, pure MoS 2 Target preparation steps

[0083] Take MoS with purity above 99.9% 2 The particles are pulverized into a ball mill to a particle size of 500-800 mesh powder;

[0084] Put the powder obtained by grinding into a tablet press mold and place it on the tablet press. The pressure of the press is 20-25MPa, the pressing time is 1 hour, and it is pressed into a cylindrical target with a thickness of 3-5mm and a diameter of 60mm. material;

[0085] The rest are the same as in Example 1.

[0086] Product performance test results:

[0087] After testing, at 30mWcm -2 Under the white light conditions, the prepared MoS 2 The light excitation current density of the heterojunction photovoltaic solar cell device is 3.5mAcm -2 , The open circuit voltage is 0.23V, and the c...

Embodiment 3

[0089] The first step, Pd-MoS 2 Target preparation steps

[0090] Take 0.5 parts of Pd metal particles with a purity of 99.99% or more and MoS with a purity of 99.9% or more according to the mole fractions 2 99.5 parts of particles, blended and pulverized into a ball mill to a particle size of 500-800 mesh powder;

[0091] Put the powder obtained by grinding into a tablet press mold and place it on the tablet press. The pressure of the press is 20-25MPa, the pressing time is 1 hour, and it is pressed into a cylindrical target with a thickness of 3-5mm and a diameter of 60mm. material;

[0092] The rest are the same as in Example 1.

[0093] Product performance test results:

[0094] After testing, at 30mWcm -2 Under the white light conditions, the Pd-MoS prepared 2 The light excitation current density of the heterojunction photovoltaic solar cell device is 5.2mAcm -2 , The open circuit voltage is 0.33V, and the conversion efficiency is 2.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com