Patents

Literature

86results about How to "There will be no unevenness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

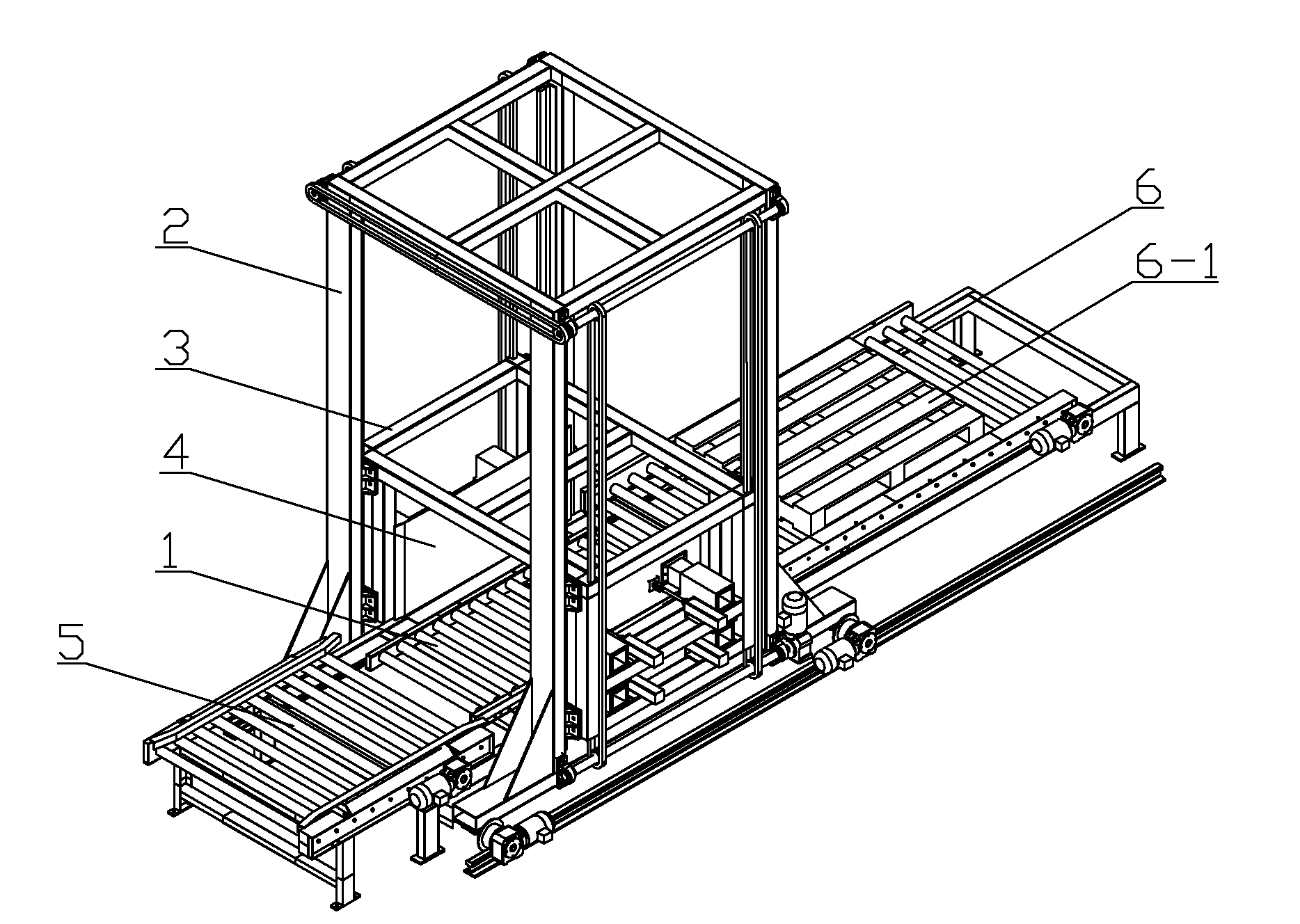

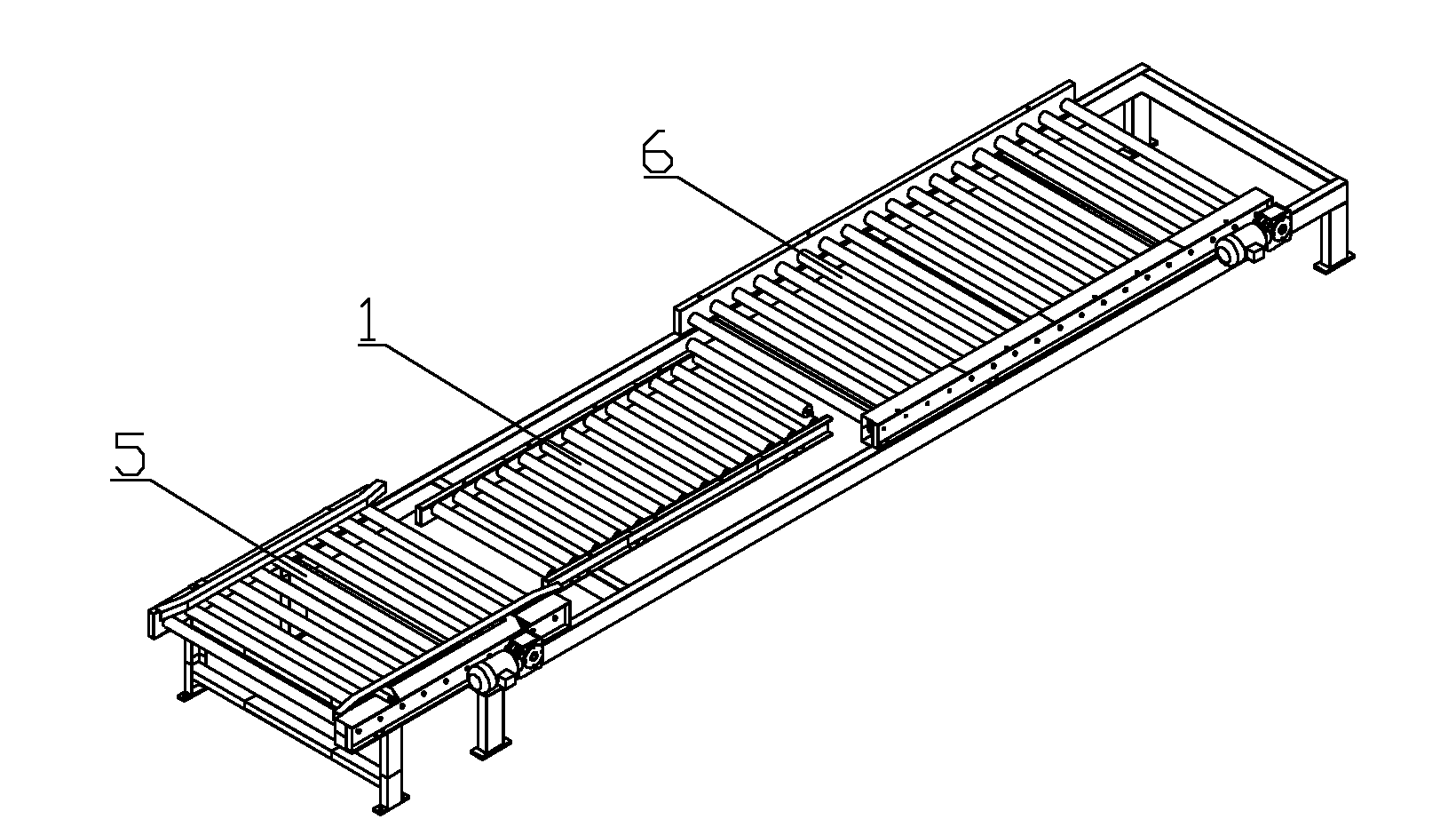

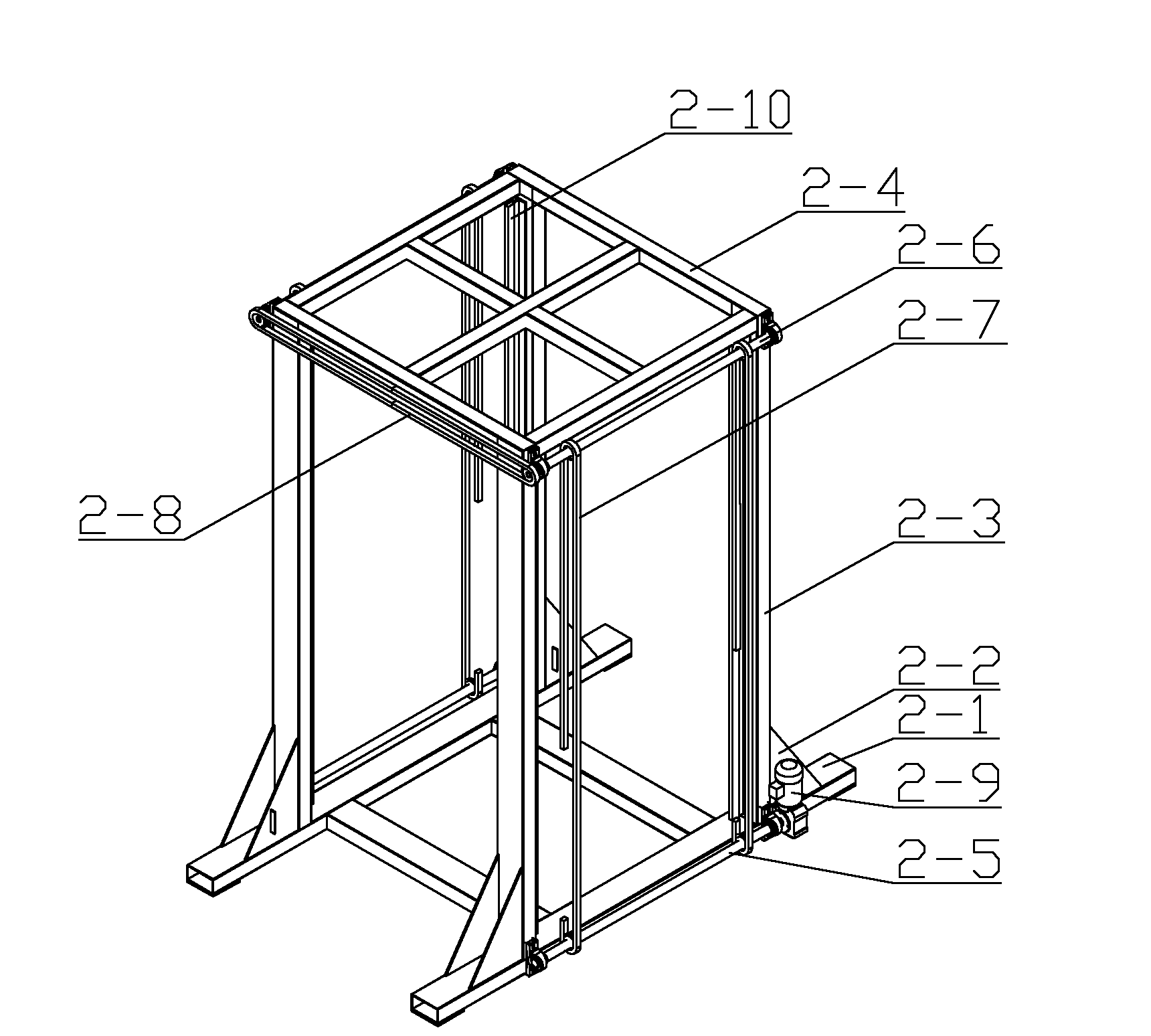

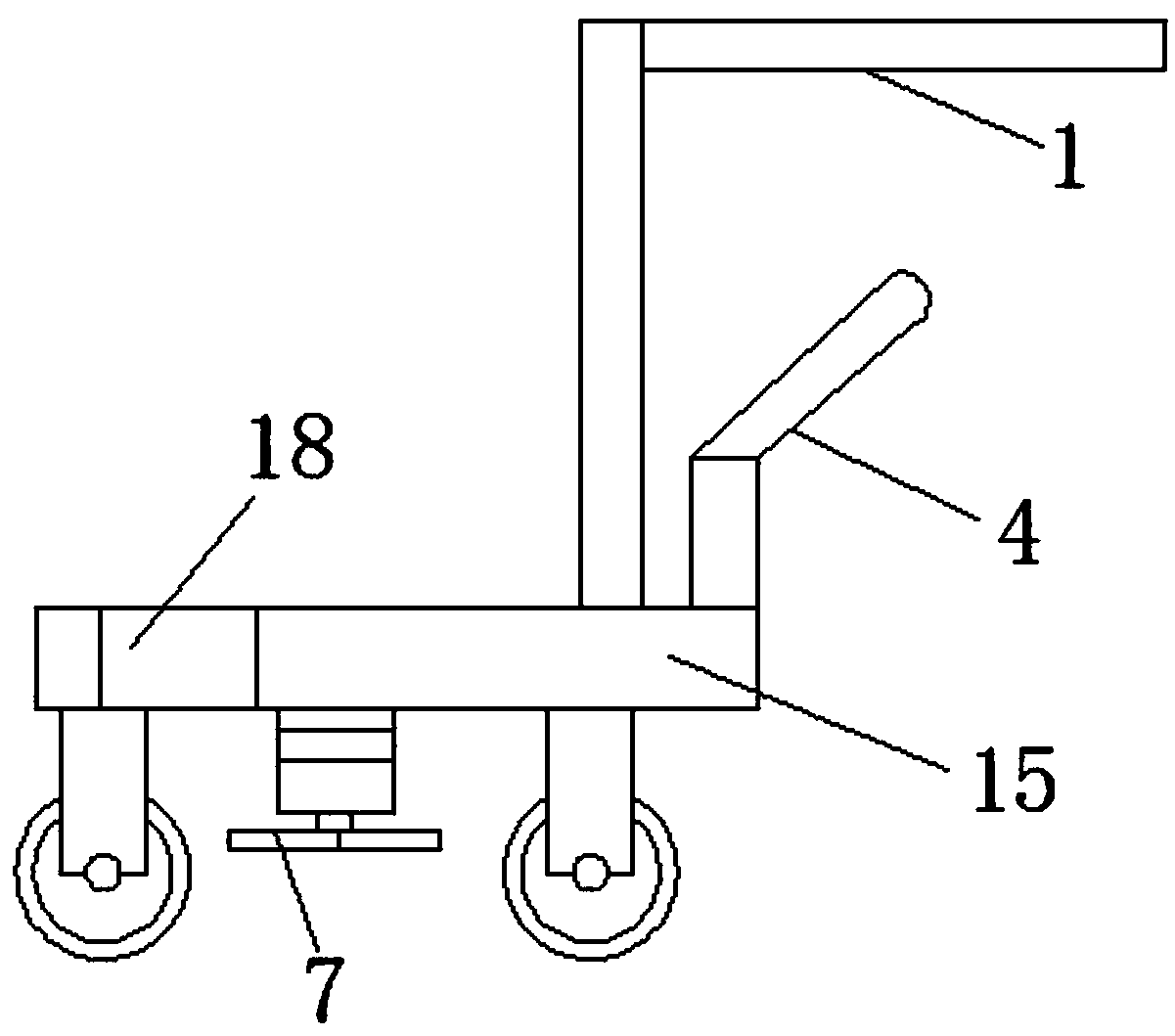

Smoke box stacker

The invention discloses a smoke box stacker. The smoke box stacker comprises a short roller way conveyer and an outer frame which can move along the length direction of the short roller way conveyer, wherein the outer frame is bridged above the short roller way conveyer; an inner frame which can move up and down is arranged inside the outer frame; smoke box clamping devices are arranged on the two sides of the inner frame; guide rails for supporting the outer frame are arranged on the two sides of the short roller way conveyer; the bottom of the outer frame is provided with a roller which is matched with the guide rails; and one end of a rotating shaft of the roller is provided with a traveling motor. Through the stacker, the completeness and the stacking stability of smoke boxes can be guaranteed during transferring and stacking.

Owner:蚌埠市环球机电设备有限公司

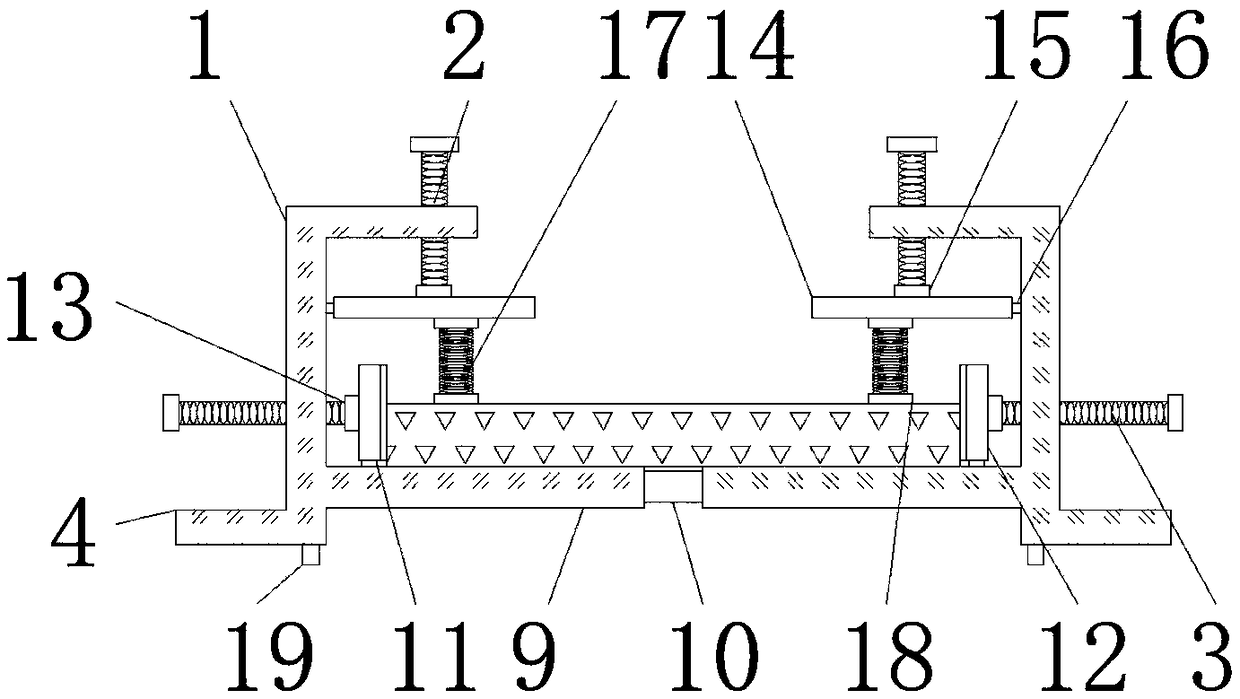

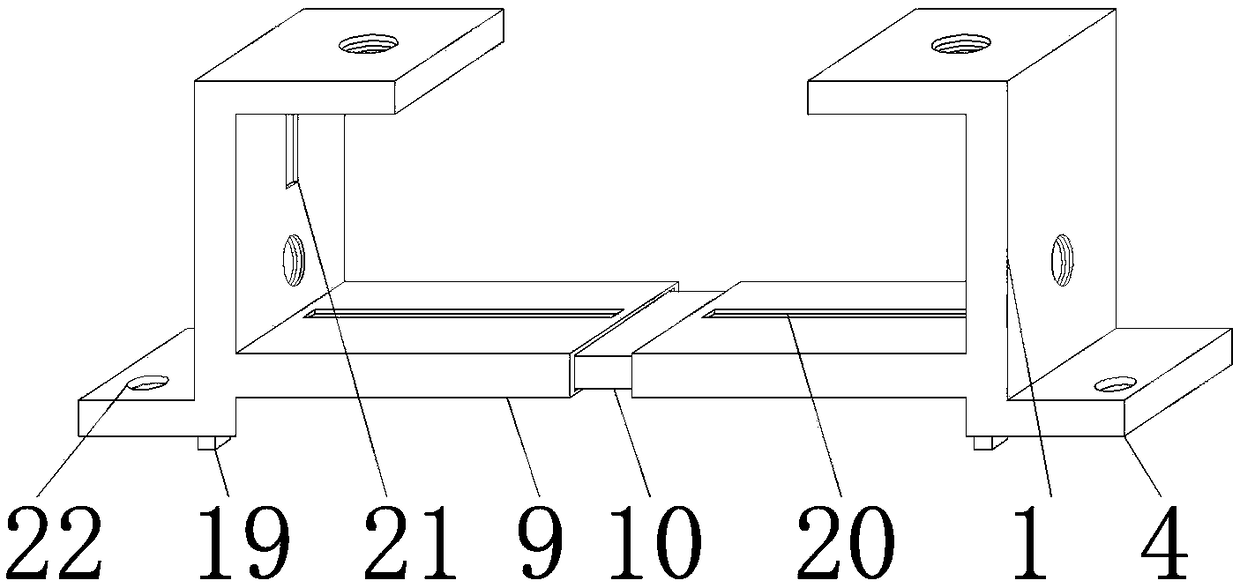

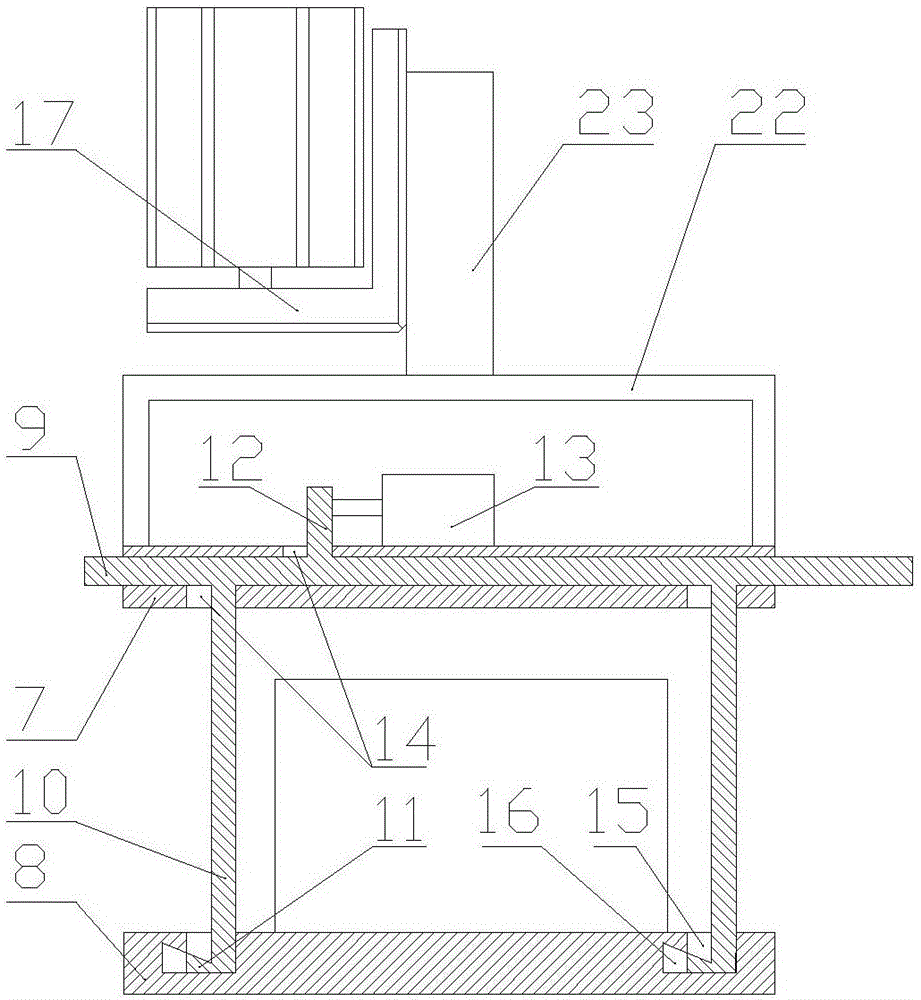

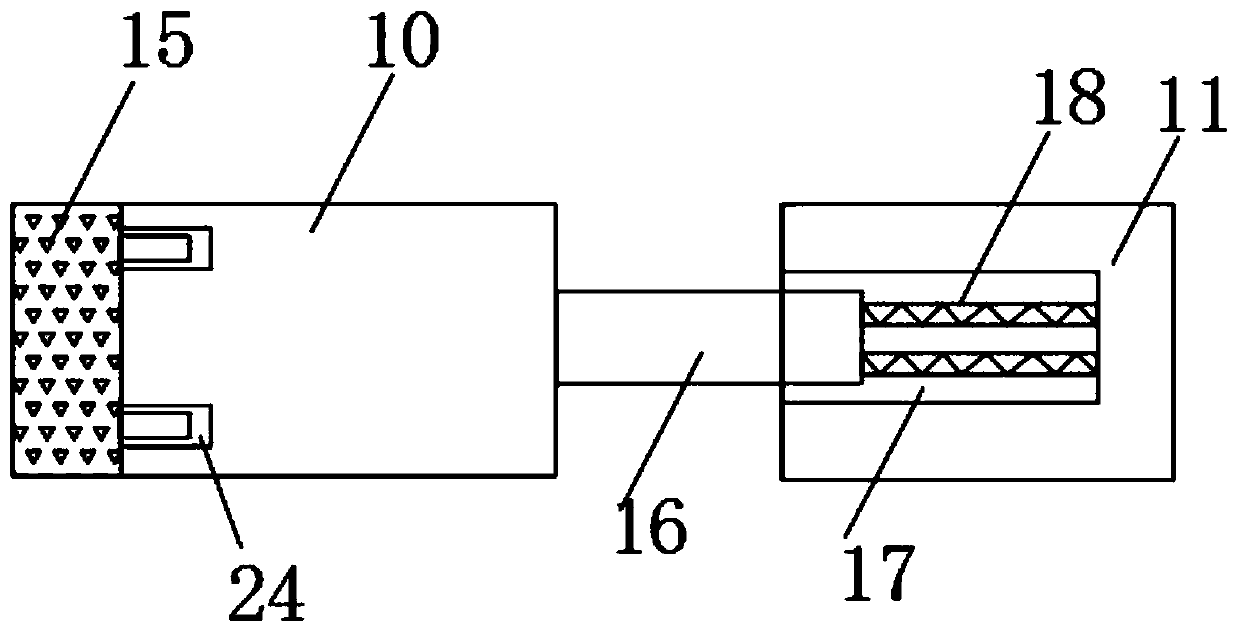

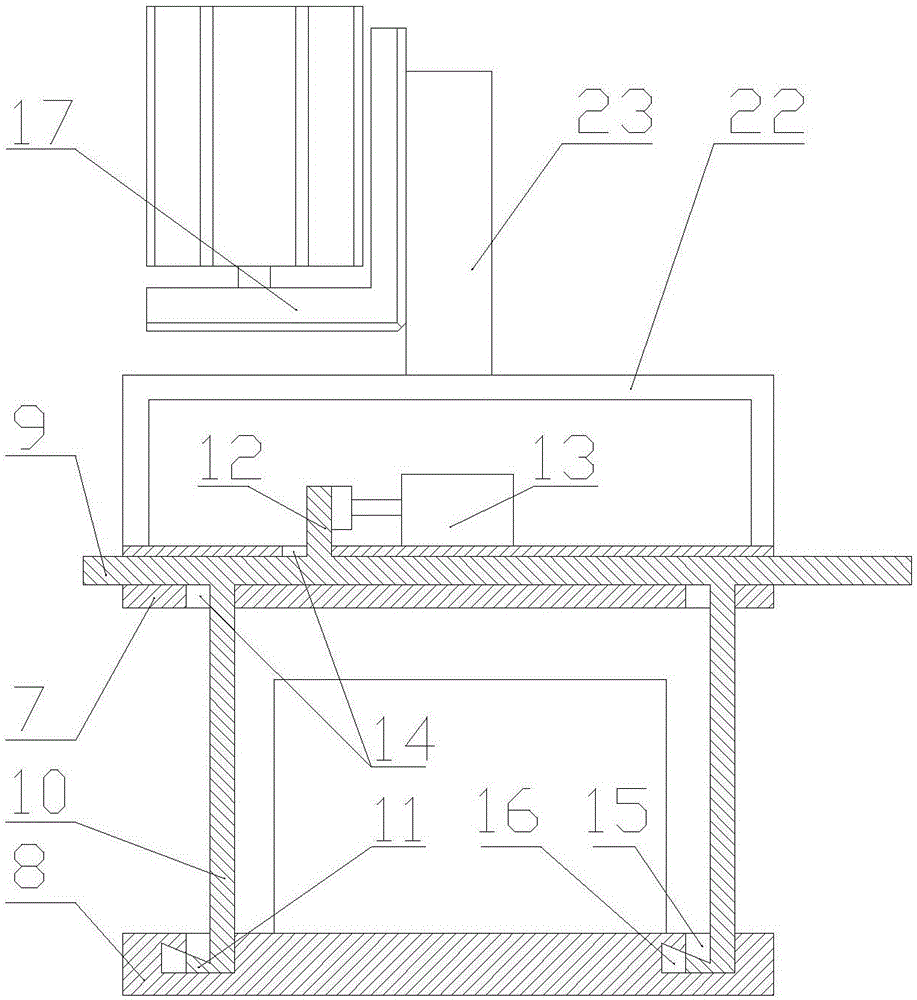

Panel welding clamping device convenient to adjust

InactiveCN108637565APrecision weldingEasy to adjustWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

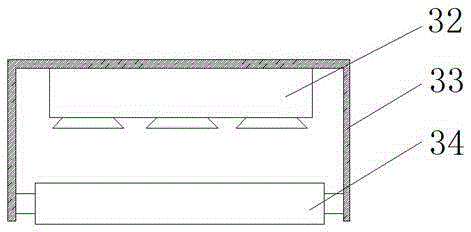

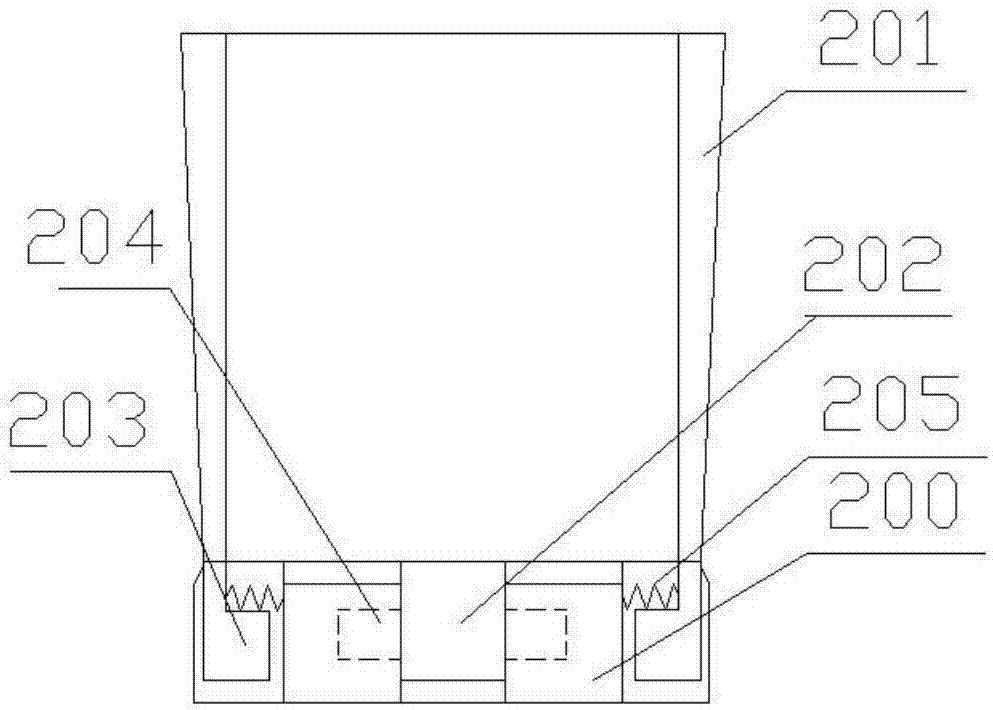

The invention discloses a panel welding clamping device convenient to adjust. The panel welding clamping device convenient to adjust comprises fixing bases, containing plates, pressing plates, side edge sliding grooves and connecting sliding grooves. The upper portions of the fixing bases are in penetrating connection with first threaded rods. A bearing table is fixed to the upper portion of a base. The containing plates are fixed to the lower portions of the inner side walls of the fixing bases. The upper portions of the containing plates are connected with bottom sliding blocks fixed to thebottoms of side clamping plates. The pressing plates are arranged above the side clamping plates. Connecting springs are arranged below the pressing plates. Surface sliding grooves are reserved in theupper surfaces of the containing plates, and the side edge sliding grooves are formed in the inner side walls of the fixing bases. The connecting sliding grooves are formed in the upper surface of the base, and limiting holes are reserved in the base. According to the panel welding clamping device convenient to adjust, the upper end faces of the bearing table, a supporting table and the containing plates are located at the same horizontal line position, and therefore panels can be well supported when placed on the device; and the situation of unevenness is avoided, and welding between the panels becomes more accurate.

Owner:ANHUI ORIGINAL POWER PRODUCTIVITY PROMOTION CENT CO LTD

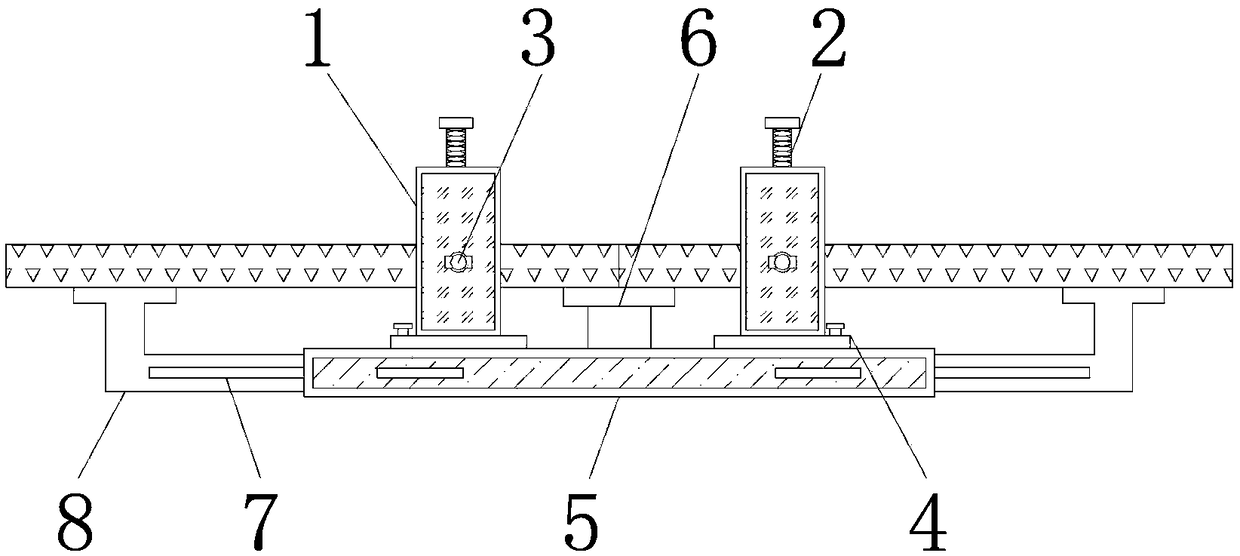

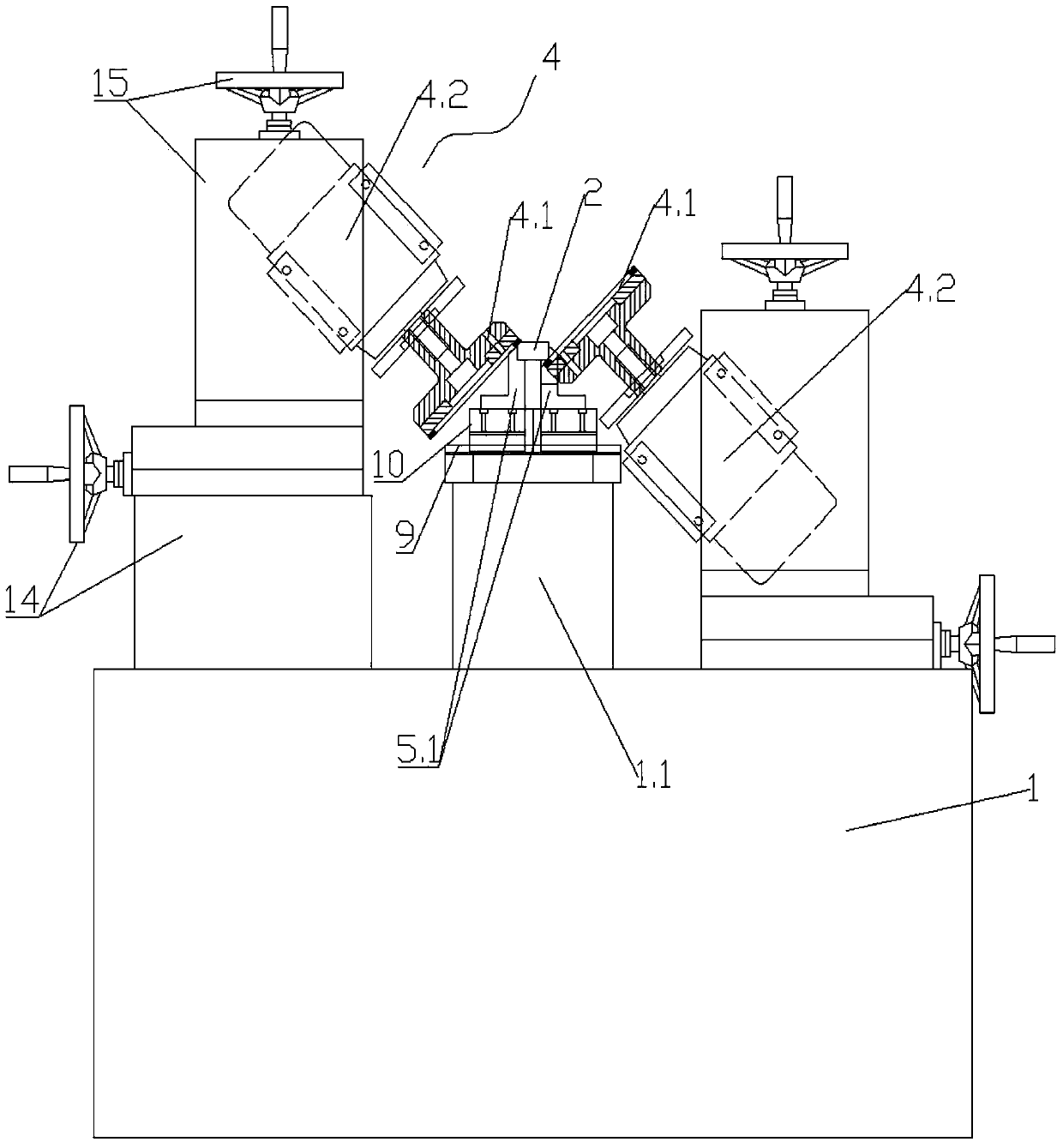

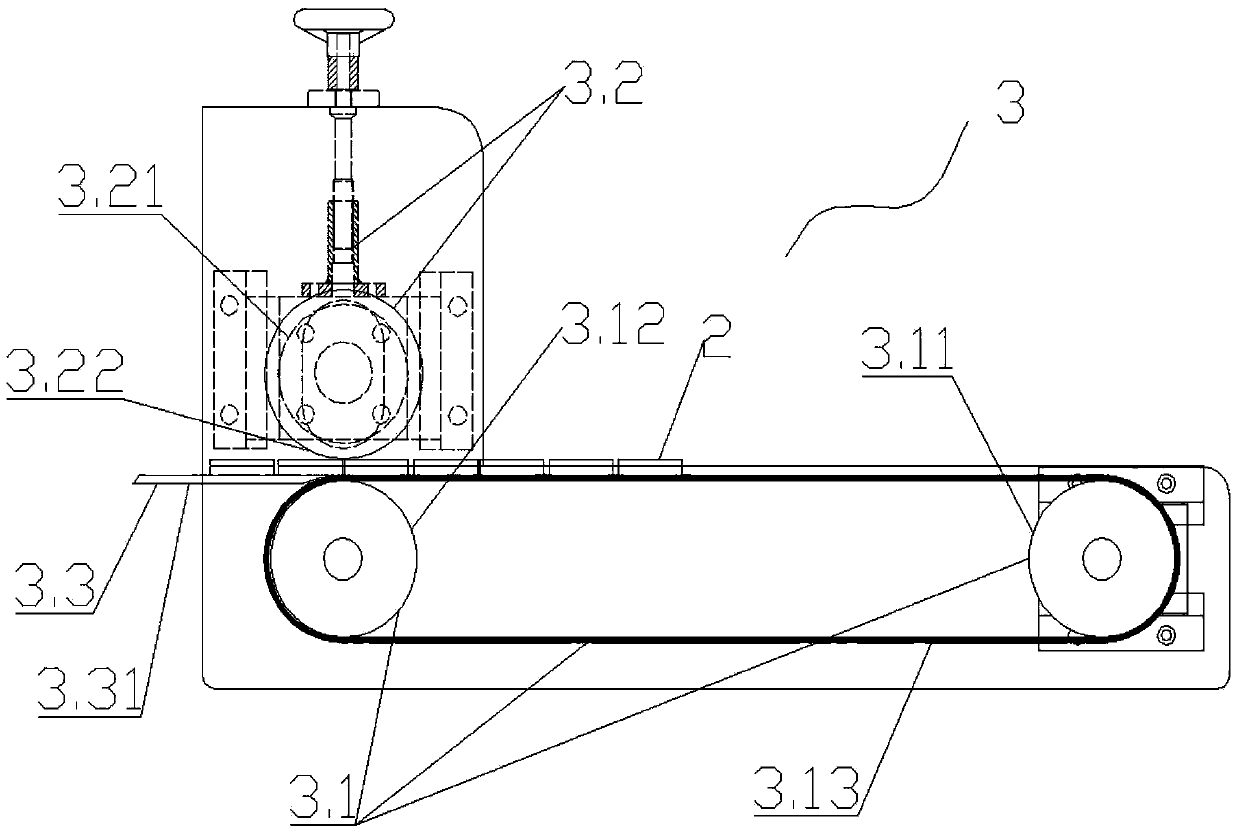

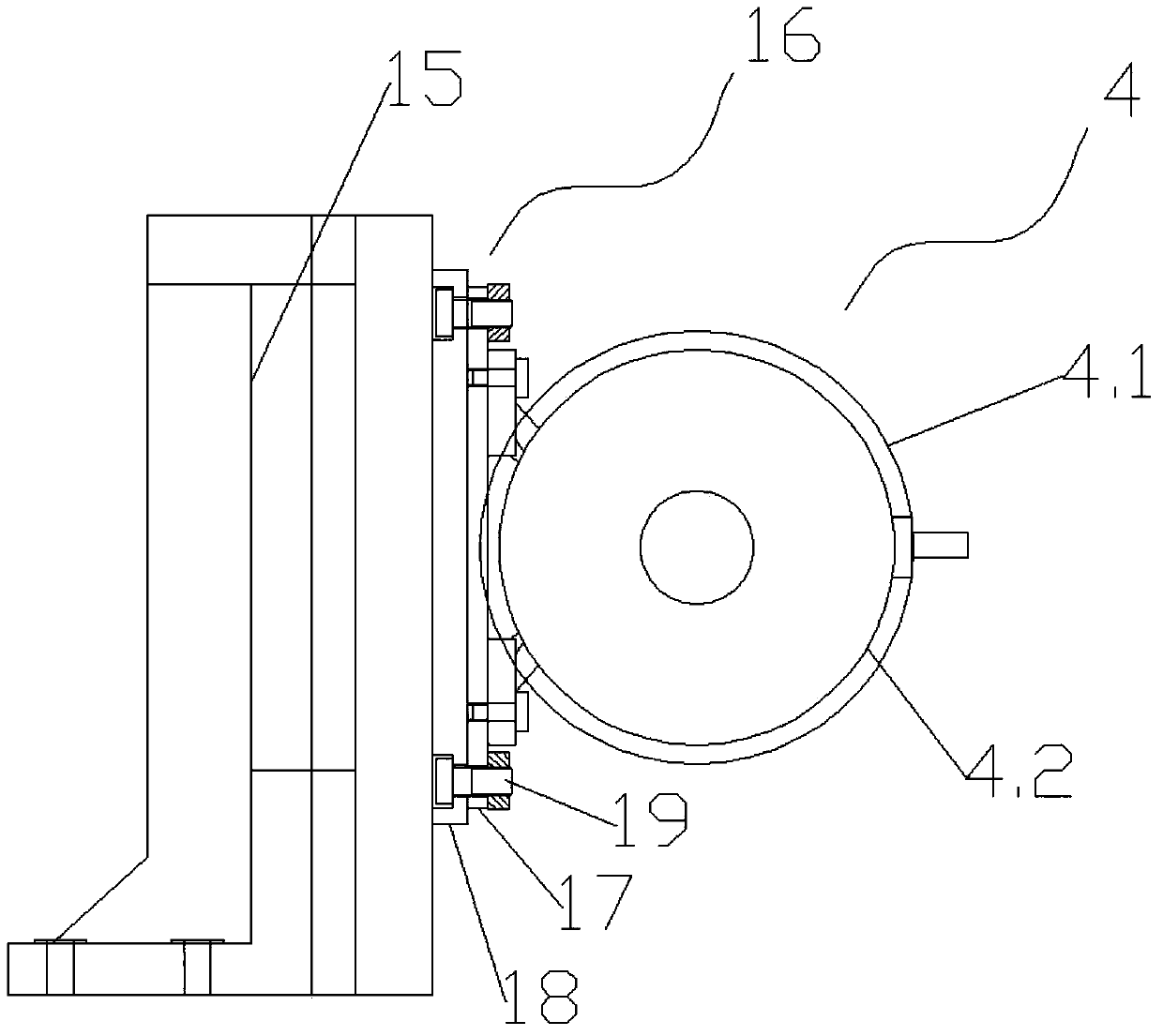

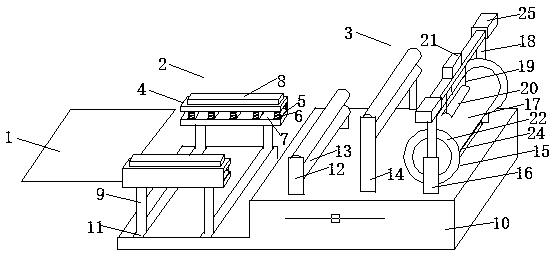

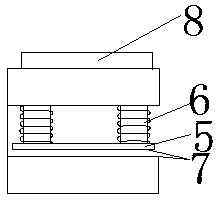

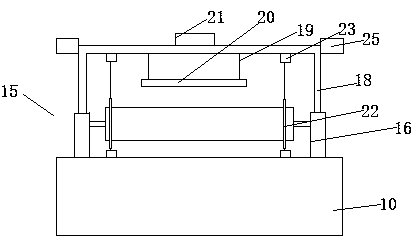

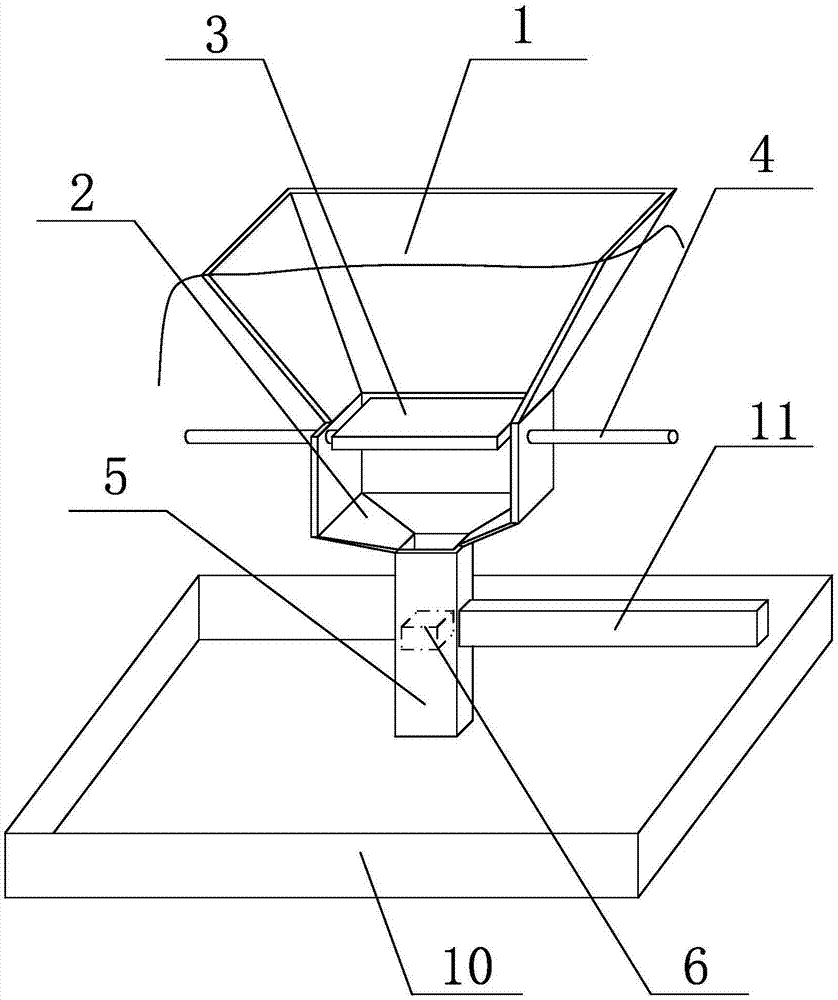

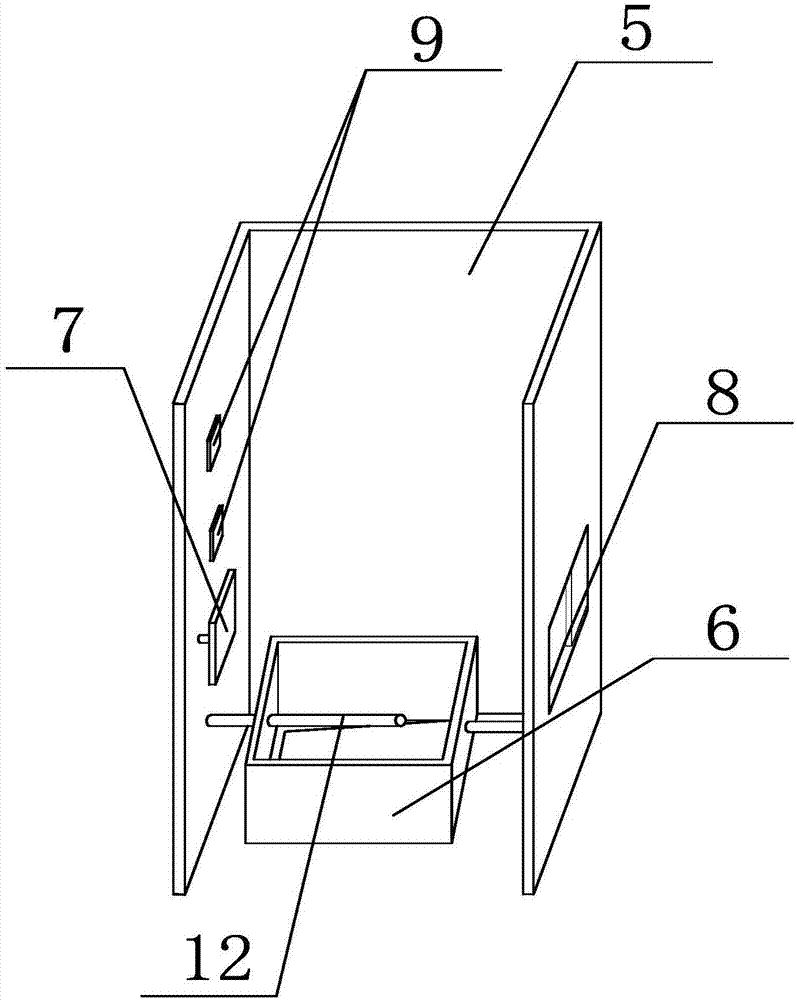

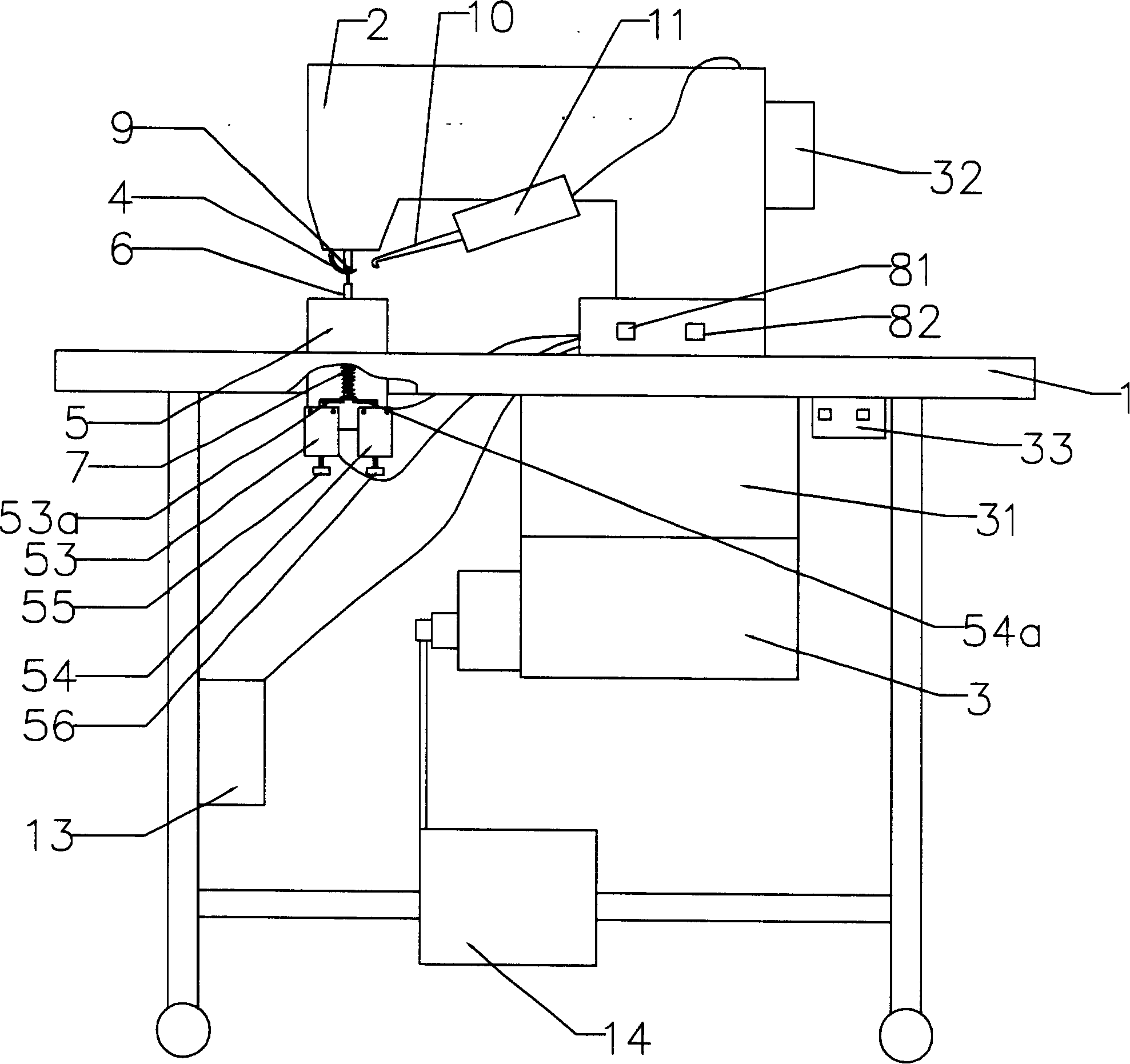

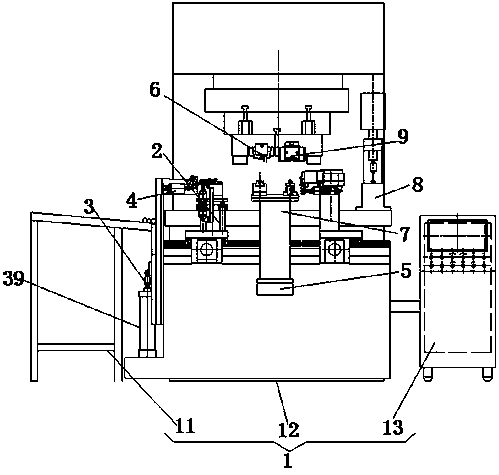

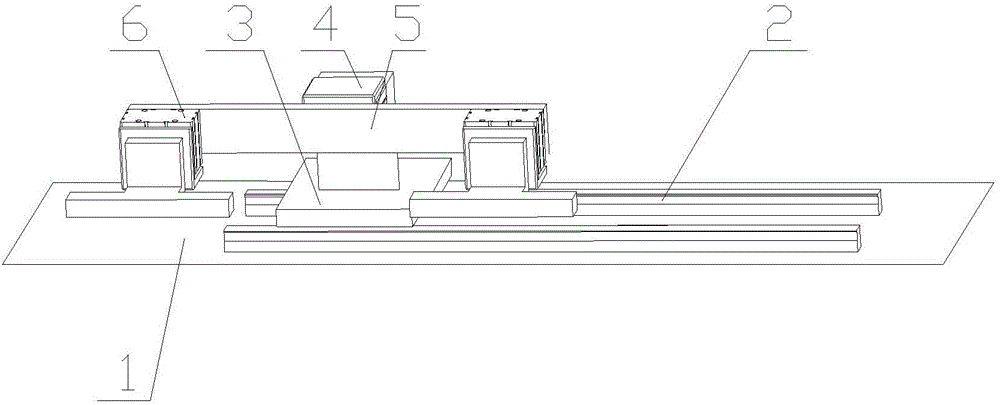

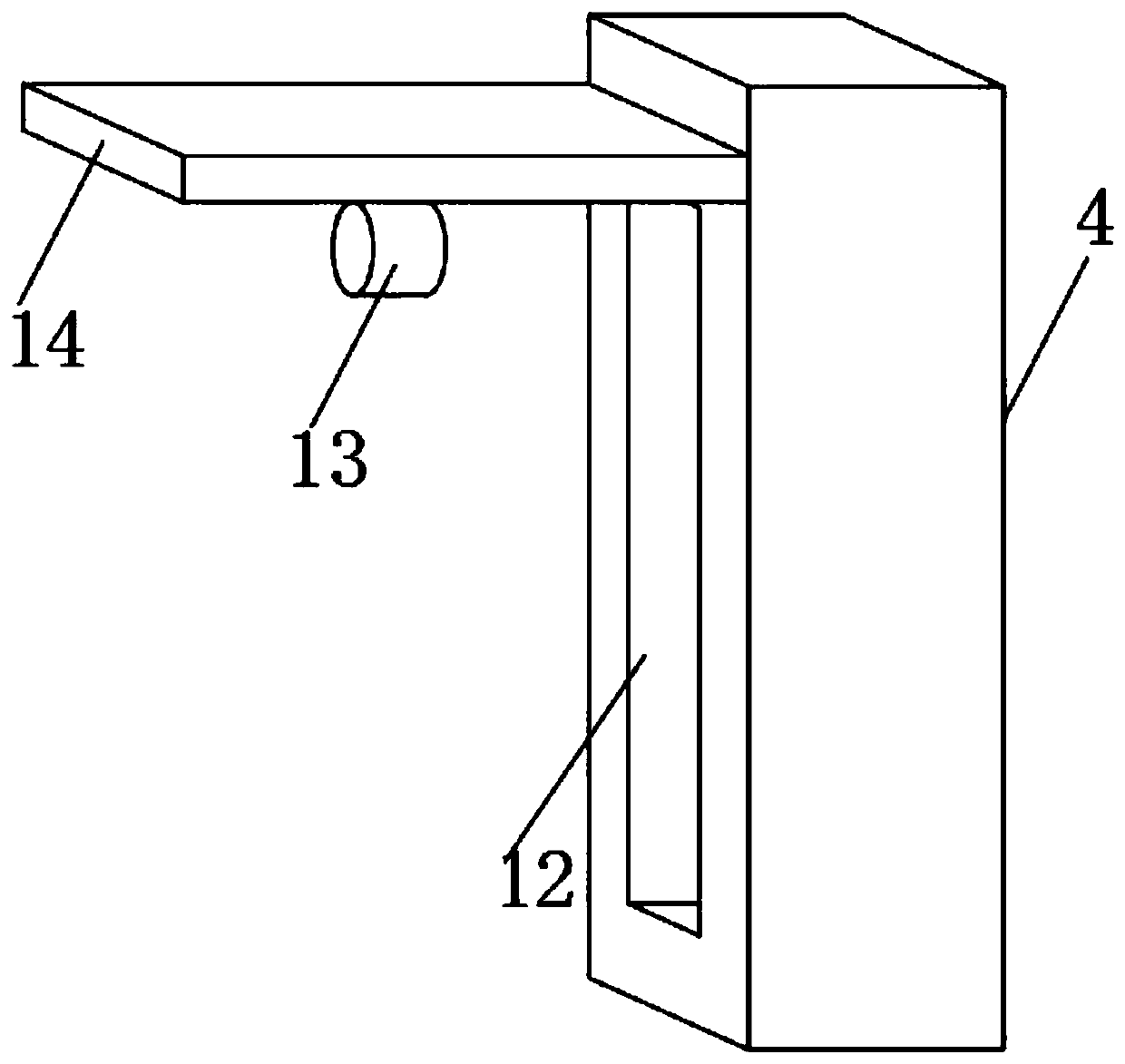

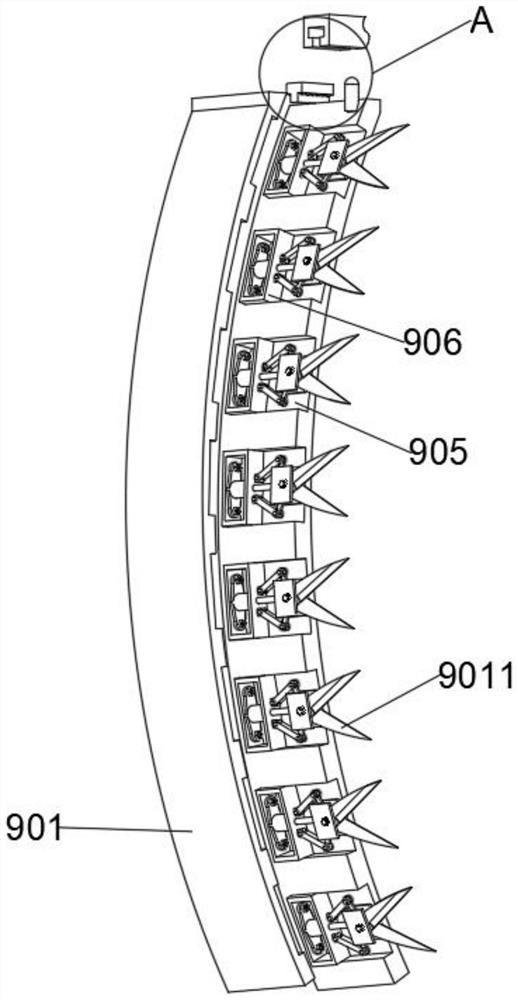

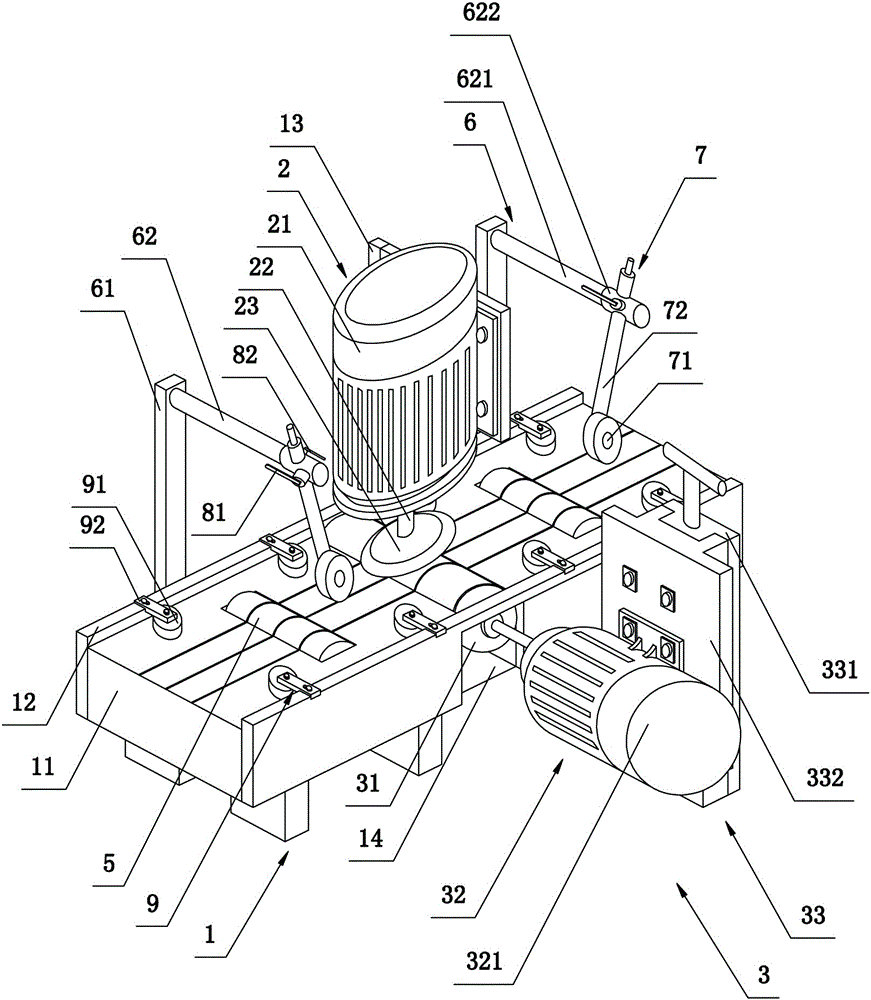

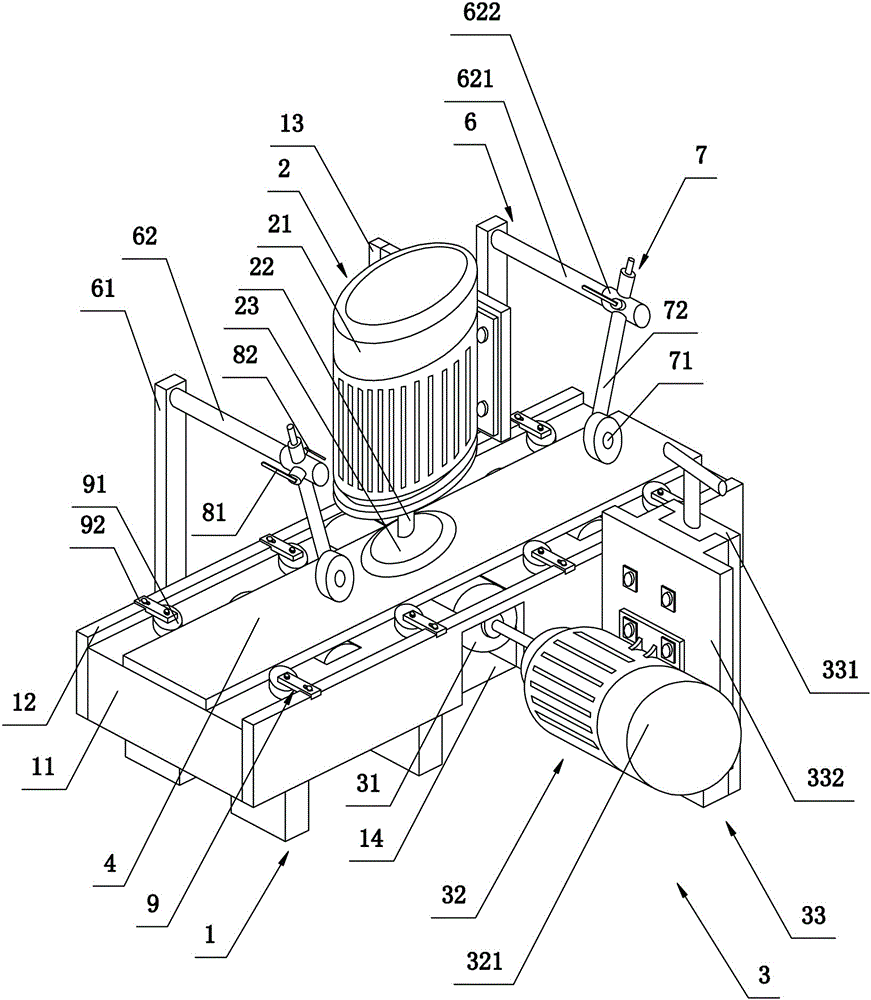

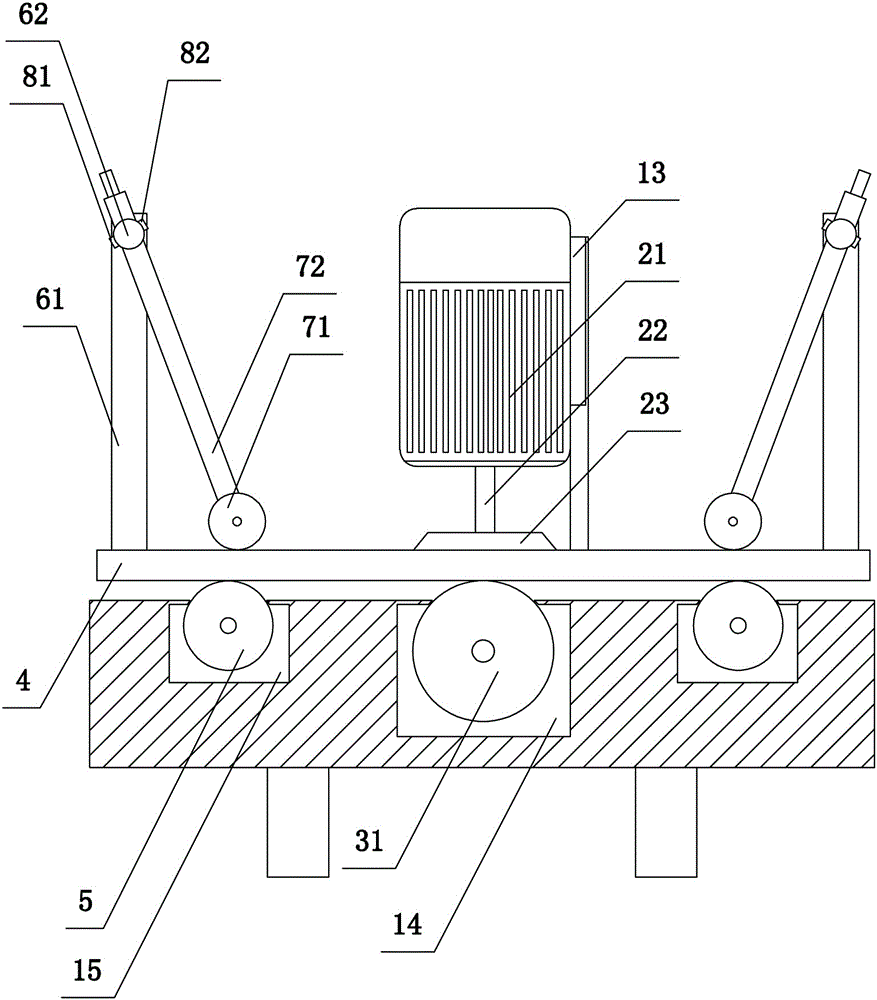

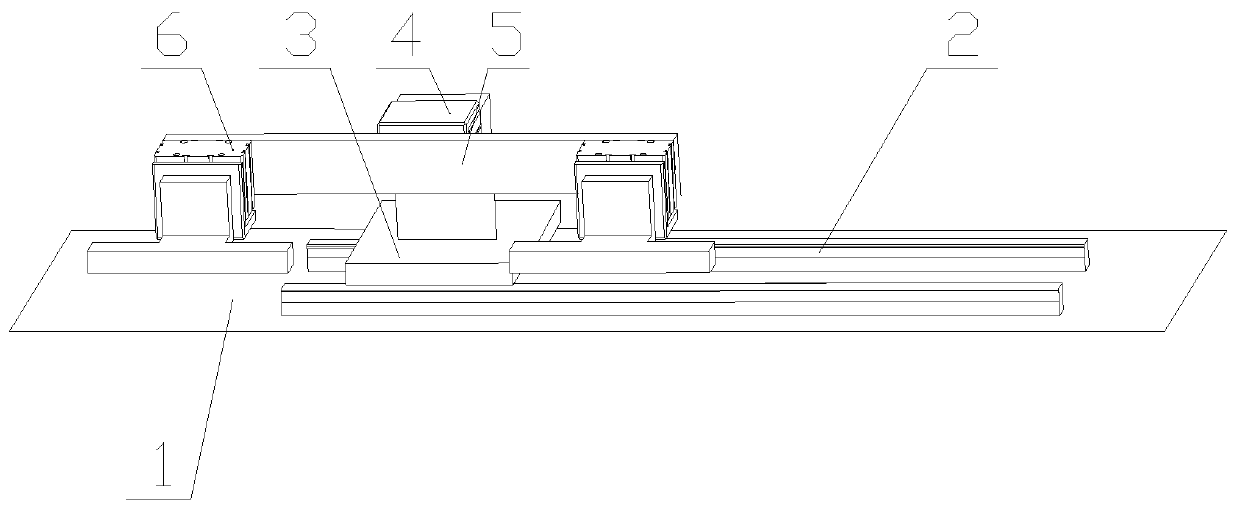

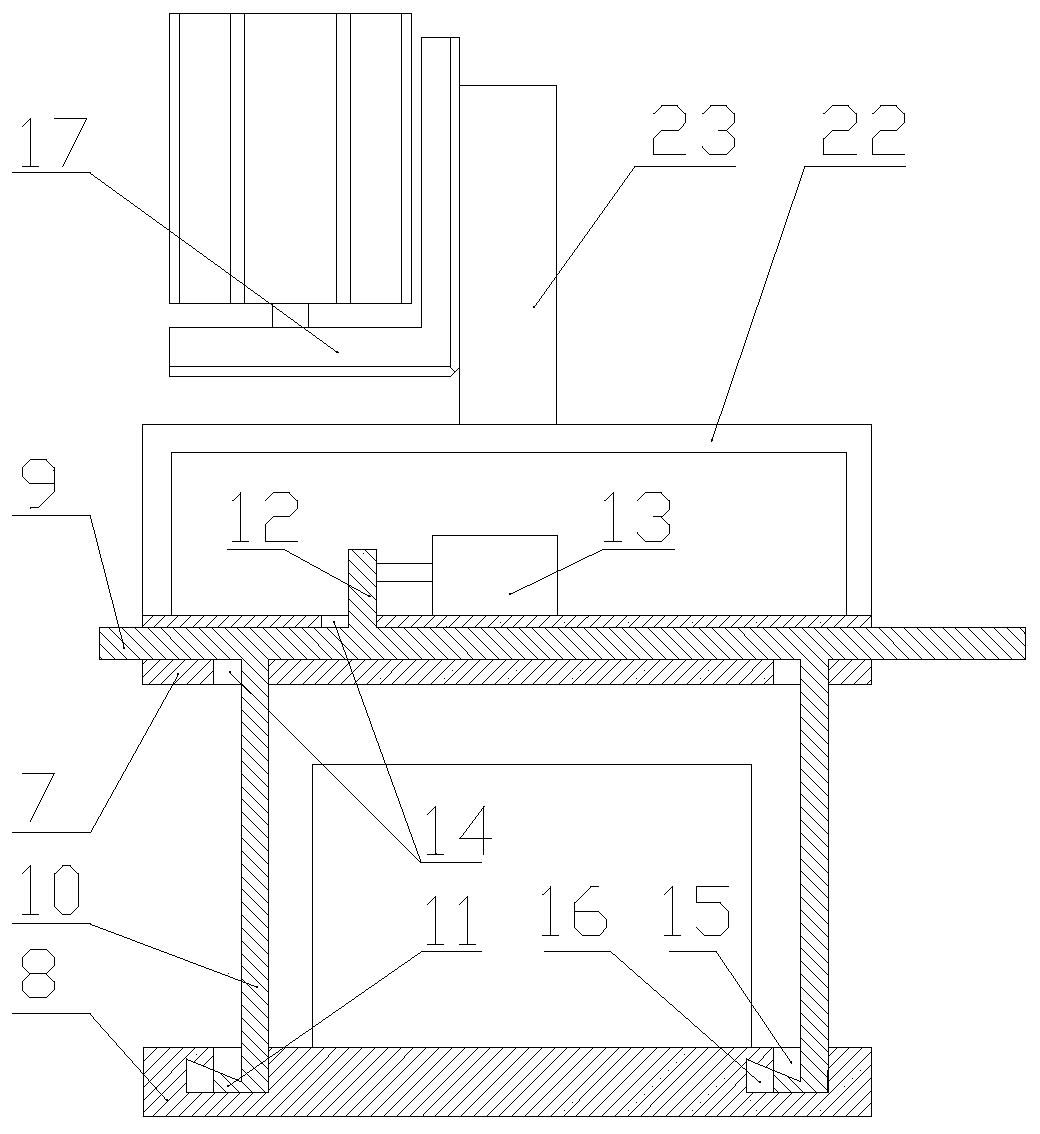

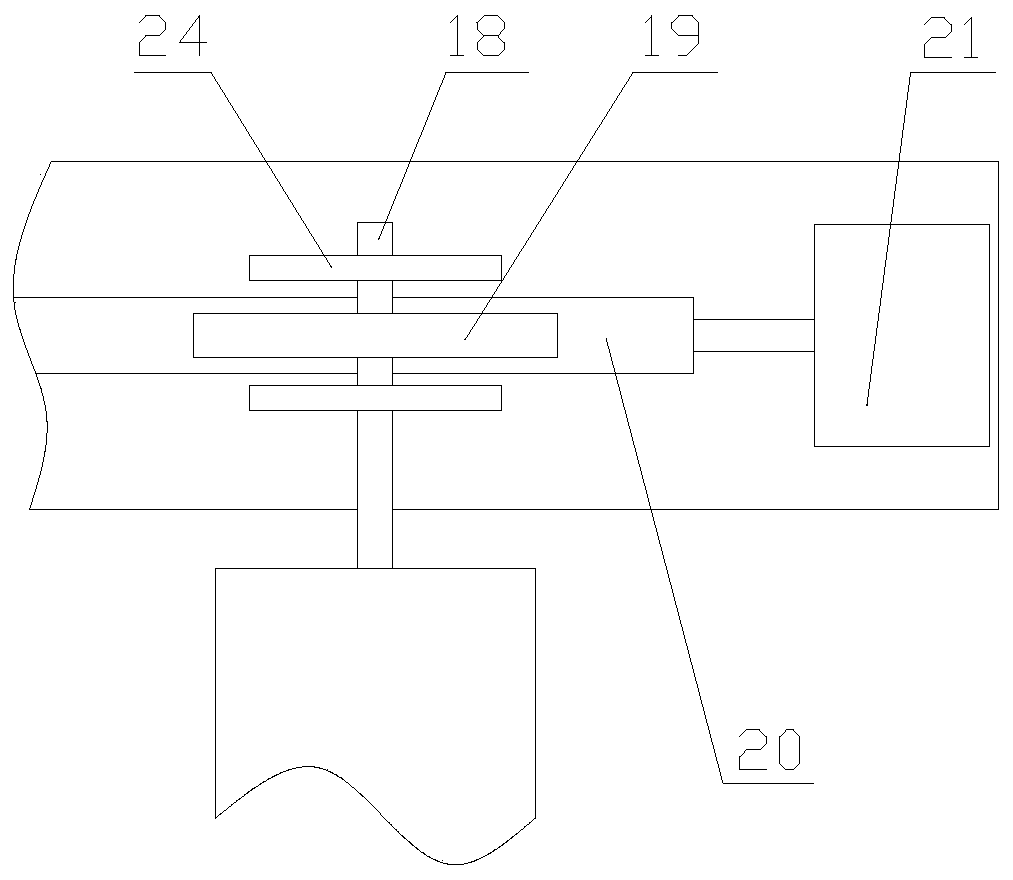

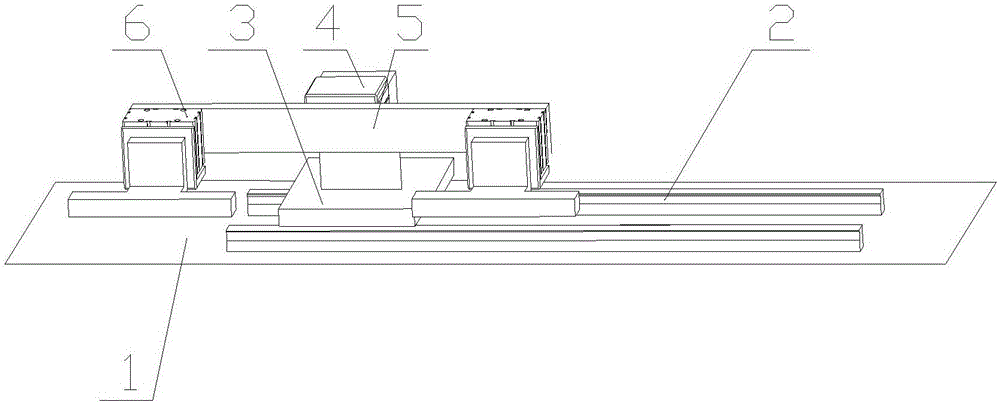

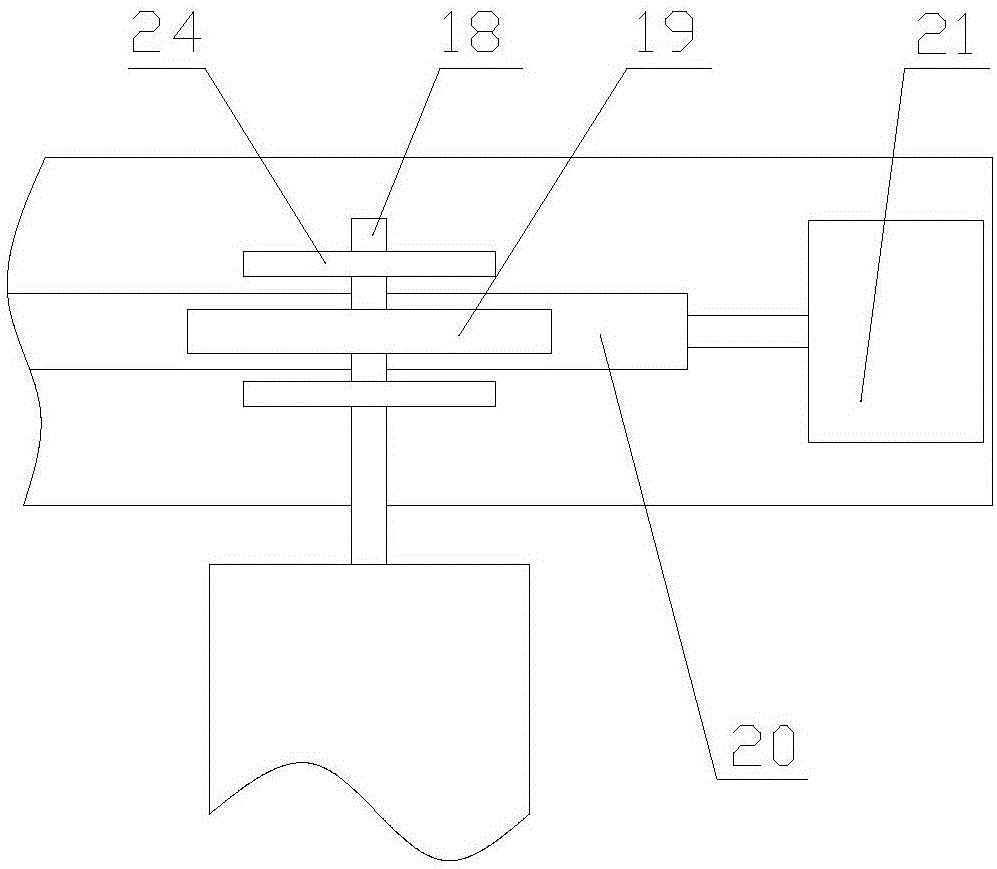

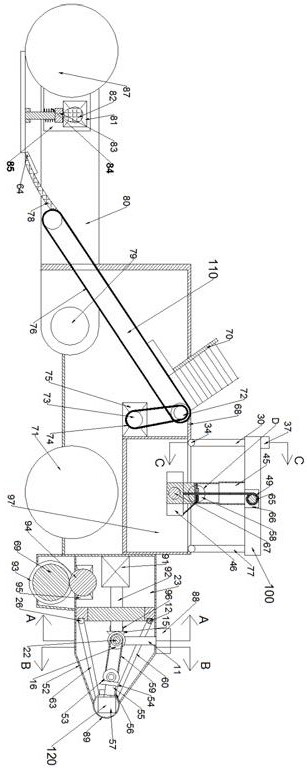

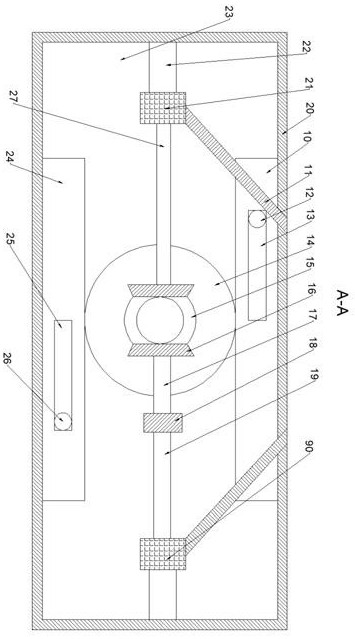

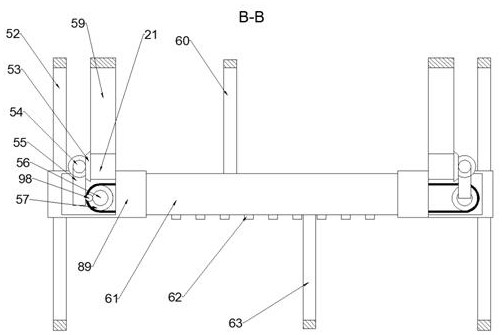

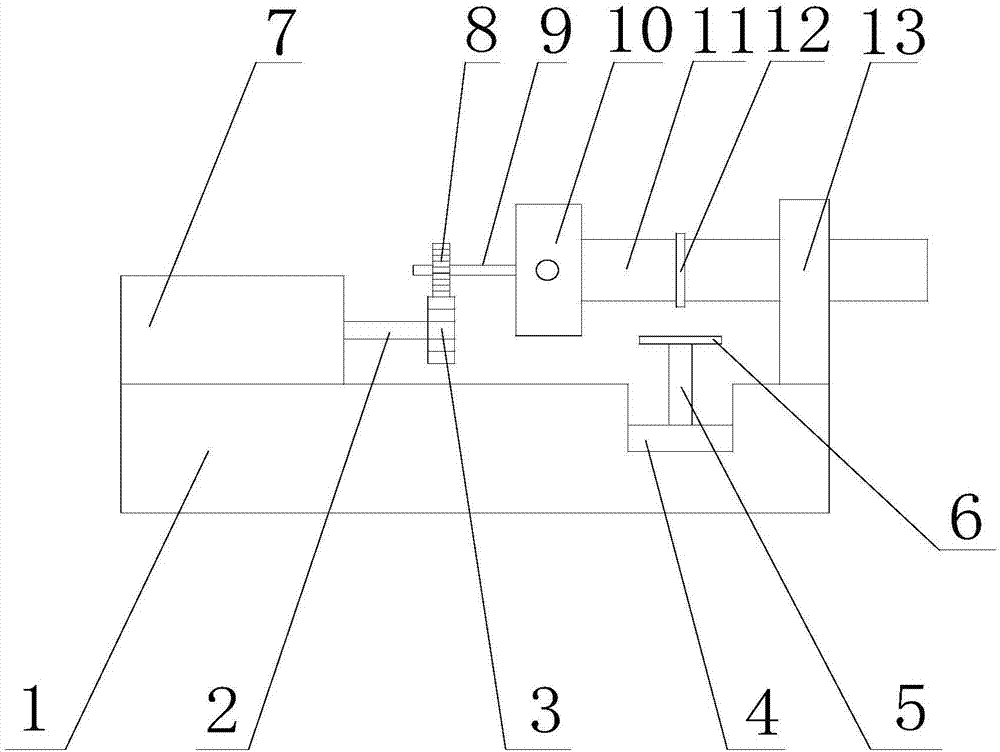

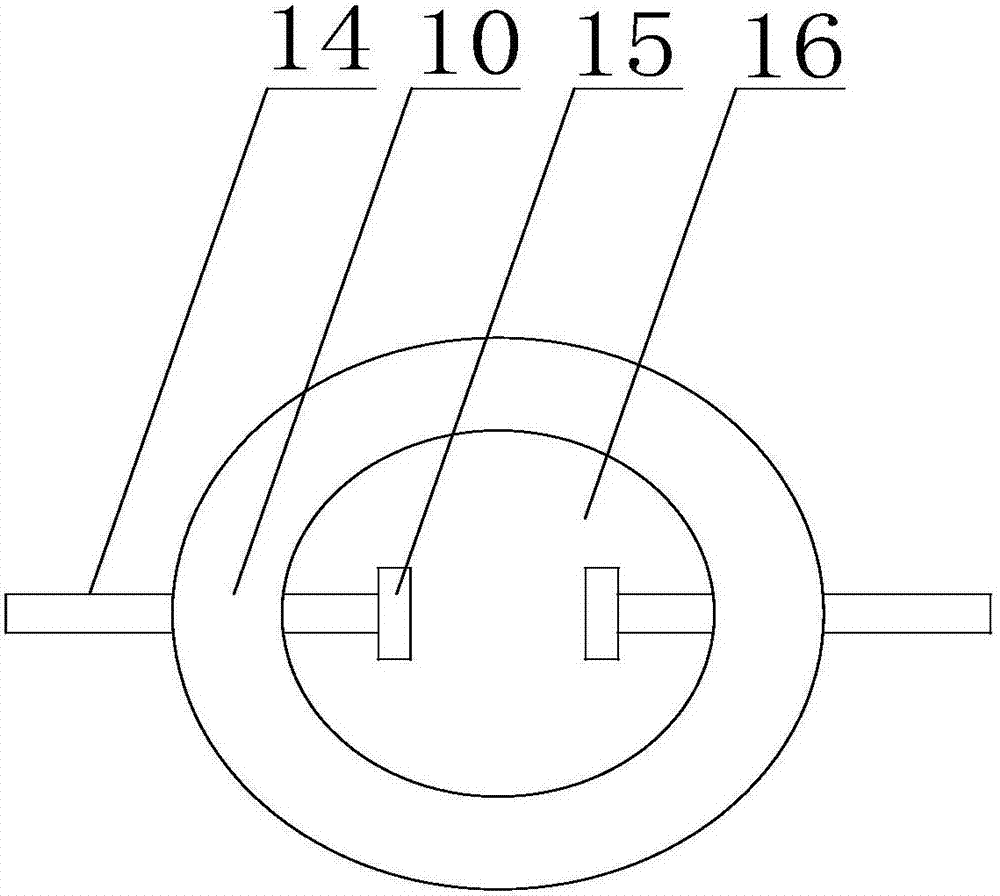

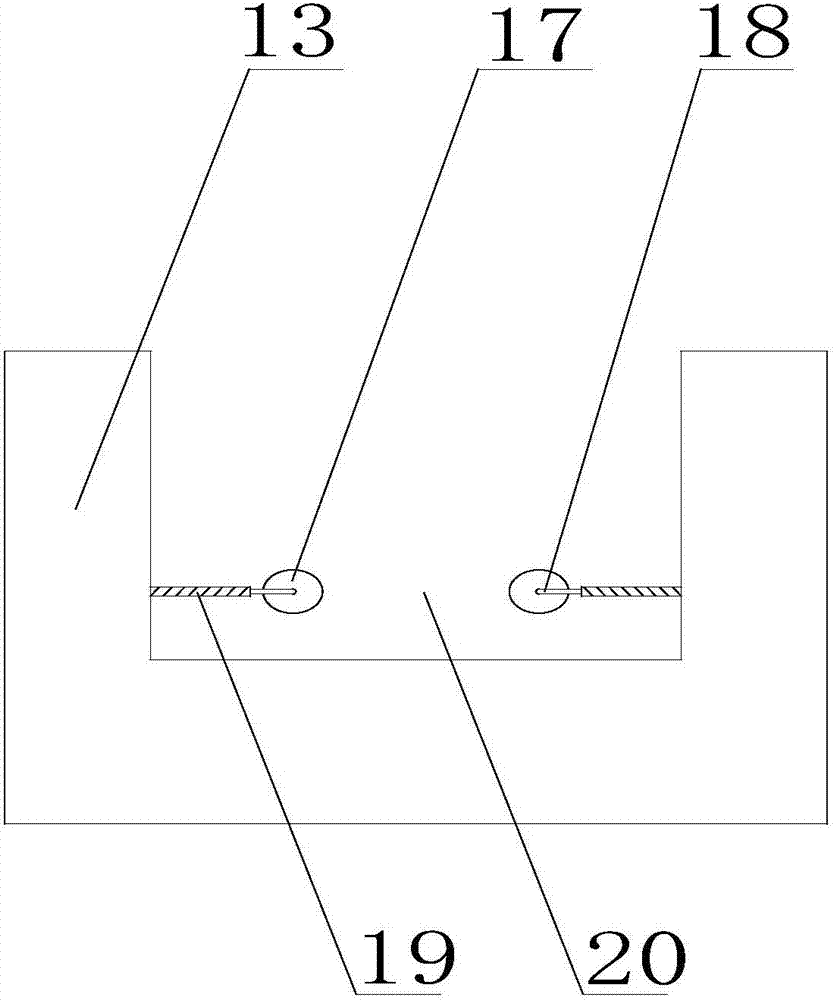

Automatic chamfering machine

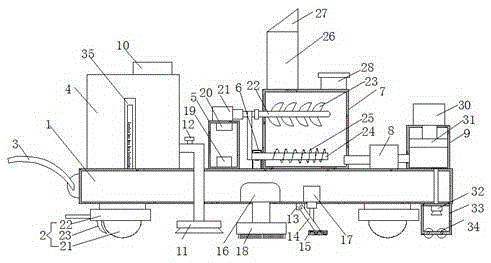

ActiveCN103737443AQuality improvementThere will be no unevennessEdge grinding machinesGrinding carriagesTime segmentEngineering

The invention discloses an automatic chamfering machine. The chamfering machine comprises an engine base (1), a conveying mechanism (3), four sand wheel chamfering mechanisms (4) and a guide rail clamping mechanism (5), wherein the conveying mechanism (3) is arranged at one end of the engine base (1) and is used for conveying a work-piece (2), the four sand wheel chamfering mechanisms (4) are arranged on the engine base (1) and simultaneously chamfer the two groups of long opposite sides (2.1) of the workpiece (1), and the guide rail clamping mechanism (5) is used for clamping and smoothly moving the clamped work-piece (2) and is arranged on the working table (1.1) of the engine base (1); two of the sand wheel chamfering mechanisms (4) are respectively located at one group of long opposite sides (2.1) used for processing the work-piece (2) at the two sides of the guide rail clamping mechanism (5) in parallel, and the other two sand wheel chamfering mechanisms (4) are respectively located at the other group of long opposite sides (2.1) used for processing the work-piece (2) at the two sides of the guide rail clamping mechanism (5) in parallel. The automatic chamfering machine is not manually operated, can simultaneously chamfer the two groups of long opposite sides of the work-piece, and can continuously work for a long time segment, and has the advantages of good chamfering quality and high efficiency.

Owner:宁波市鄞州启威机械科技有限公司

Cloth rolling machine

The invention provides a cloth rolling machine which sequentially comprises a conveying belt, a front locating device and a rear rolling device sequentially from left to right. The front locating device comprises two locating clamping plates which are arranged oppositely front and back and are the same in structure. The locating clamping plates are shaped like a question mark. Each locating clamping plate comprises an upper end clamping plate, a lower end clamping plate and a connecting plate for connecting the left side of the upper end clamping plate and the left side of the lower end clamping plate. Multiple pressing plates are connected to the portion, parallel to the corresponding upper end clamping plate, of the bottom of each upper end clamping plate. The two ends of each pressing plate are connected to the bottom surface of each upper end clamping plate through an adjusting rod. The tops of the locating clamping plates are provided with air cylinders for controlling the adjusting rods to telescope. The rear rolling device comprises a first guide frame, a second guide frame and a cloth rolling frame. The cloth rolling machine has the beneficial effects that the overall structure is simple, the industry cloth rolling efficiency is extremely high, the edges of rolled cloth are uniform, and wrinkling of a cloth body is avoided.

Owner:ANHUI HUAYE ADVANCED MATERIALS CO LTD

Ship deck painting device with flushing device

ActiveCN105396747ATo achieve a uniform effect of spray paintQuality improvementLiquid surface applicatorsCoatingsMarine engineeringControl valves

The invention discloses a ship deck painting device with a flushing device. The ship deck painting device comprises a base. Sliding devices are arranged at four corners of the bottom of the base. A handle is arranged on the left side of the base. A water tank, a control box, a bearing seat, a storage box, a high-pressure pump and a feeding box are sequentially arranged on the upper surface of the base from left to right. A water inlet is formed in the top of the water tank, the bottom of the right side of the water tank is connected with a spraying head below the base through a water spraying pipe, and the water spraying pipe is provided with a control valve. A connecting block is arranged on the lower surface of the middle of the base, and the surface of the connecting block is connected with a supporting frame through bolts. The ship deck painting device with the flushing device achieves the effect of evenly painting a ship deck, protects a ship body against damage, and improves the quality and durability of the deck. A paint spraying head and a coating roller are improved, the effect of uniform spraying is achieved, and the phenomenon of unevenness is avoided.

Owner:JIANGSU NEW HANTONG SHIP HEAVY IND

Preparation method of bi-color artificial quartz stone slate

InactiveCN107601966AReduce usageOvercome the defect of low strengthCeramic shaping apparatusGlass particleHardness

The invention discloses a preparation method of a bi-color artificial quartz stone slate. The method comprises steps as follows: (1) raw materials are weighed in proportion and stored separately; (2)an antibacterial agent is added to resin and stirred and mixed in vacuum; pigments, a coupling agent, glass particles, artificial quartz particles, natural quartz sand and quartz powder are stirred and mixed in vacuum; finally, a curing agent is added and stirred and mixed in vacuum, and a mixture is obtained; (3) the mixture is uniformly spread on a template; (4) the template is sent into a vacuum vibration forming press for vibratory pressing forming; (5) primary curing and secondary curing are performed sequentially after vibratory pressing forming. The mechanical properties such as hardness, toughness and the like of the artificial quartz stone slate are effectively improved through optimization and improvement of a raw material formula, matching of different raw materials and improvement of the preparation method, the artificial quartz stone slate has high anti-bacterial ability and lasting anti-bacterial action, and the comprehensive performance of the artificial quartz stone slate is improved.

Owner:佛山市欧泊石业有限公司

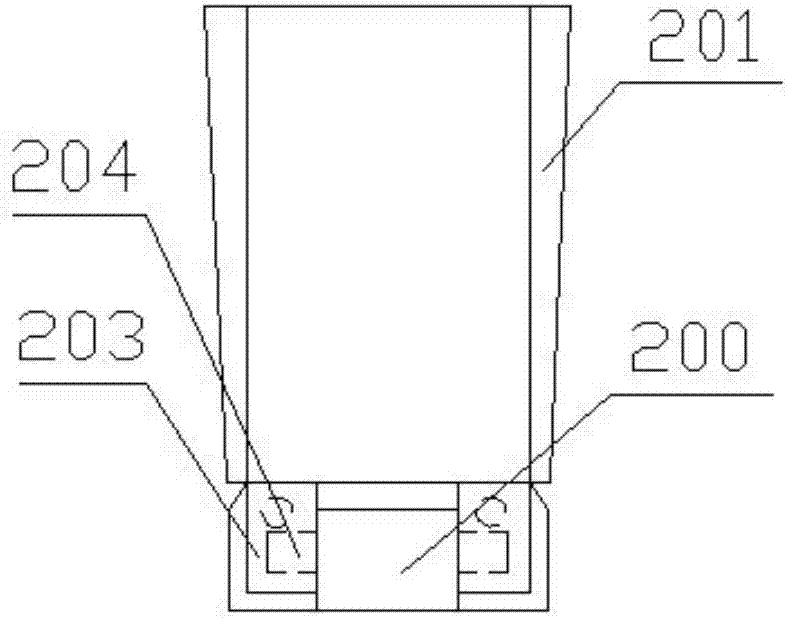

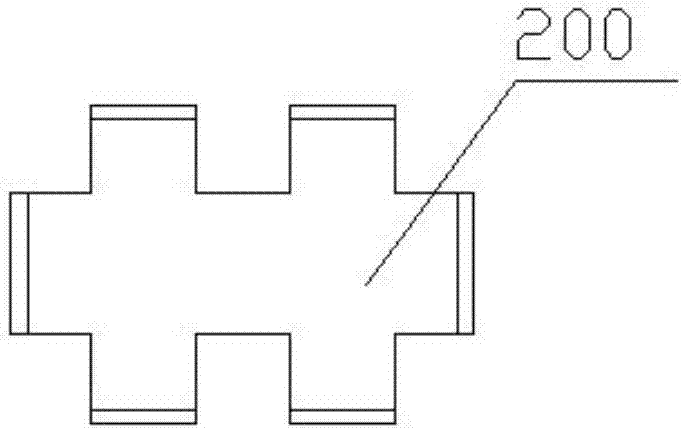

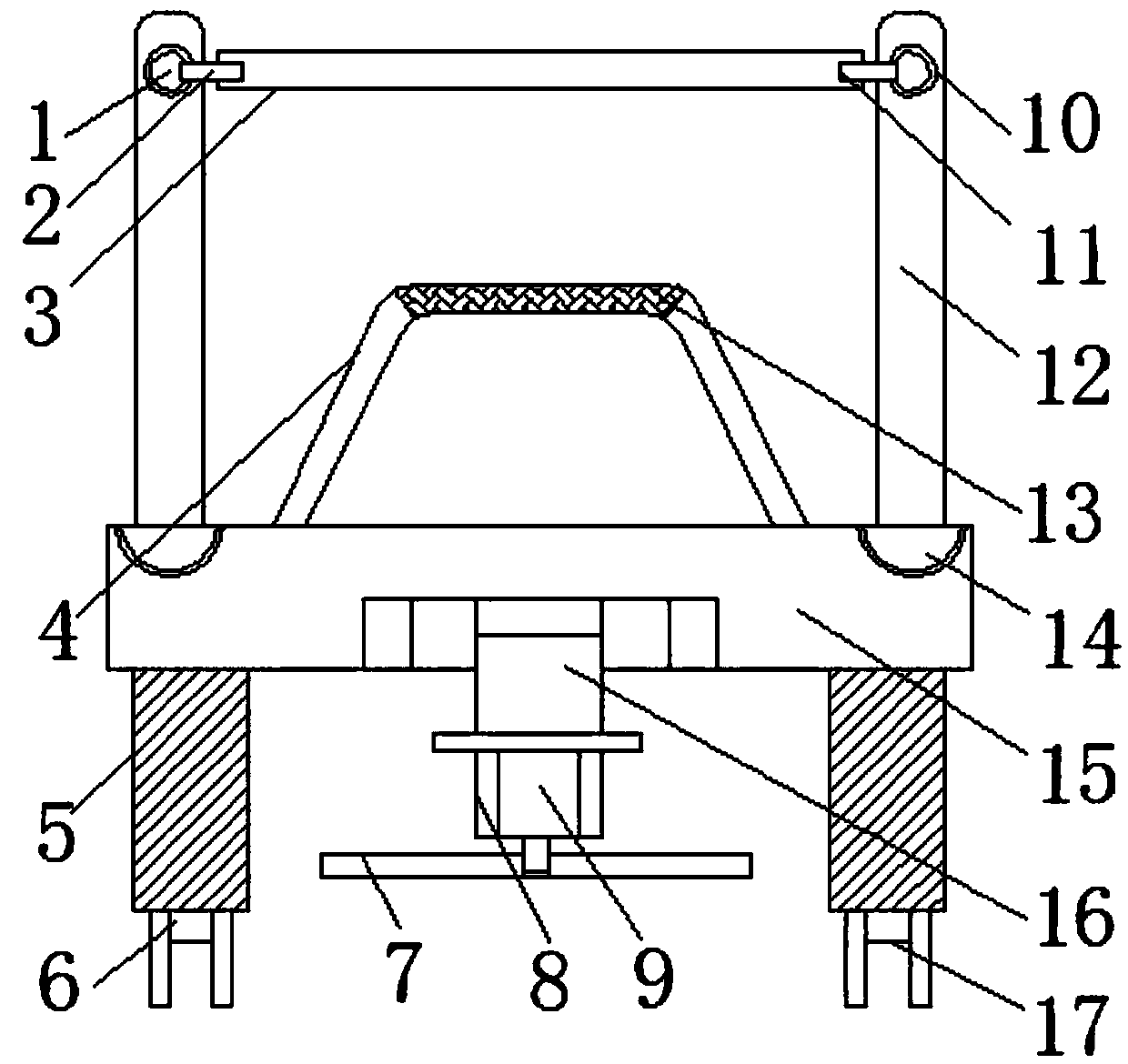

Square cell clamp and ejection mechanism

ActiveCN107546394AEasy to changeLow positioning accuracy requirementsFinal product manufacturePrimary cellsEngineering

The invention relates to a square cell clamp. The square cell clamp is characterized by comprising a lining part and a clamping part; a lining clamping region is arranged in the clamping part; the lining part is arranged in the lining clamping region of the clamping part; the lining part comprises a bottom plate and multiple side plates, and each side plate is rotationally arranged on the side part of the bottom plate separately; the cell is placed in a region formed by the bottom plate and the multiple side plates in a surrounding manner; the inner side surface of each side plate is a vertical surface matched with the side surface of the cell; the thickness of each side plate is decreased from the top to bottom gradually to form an inclined surface on the outer side surface of the side plate; a first hole is formed in the bottom of the clamping part; the lining part and the cell are jacked out of the clamping part by a lining ejection rod which penetrates through the first hole; a second hole corresponding to the first hole is formed in the bottom of the lining part; and the cell is jacked out of the lining part by a cell ejection rod which penetrates through the second hole. By adoption of the lining part and the clamping part which can be opened automatically, scraping of the cell surface caused by friction between the cell and the lining can be avoided.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

Traditional Chinese medicine decoction pieces sorting device conducting classification by weight and size

The invention discloses a device for sorting traditional Chinese medicine decoction pieces according to weight and size. The two ends of the plate are connected to the inner wall of the material distribution pipe through the connecting shaft; the bottom of the material distribution pipe is connected with a sorting cylinder, and a weighing box is arranged in the sorting cylinder, and a weight sensor is arranged on the bottom plate of the weighing box; There is a push plate above the top of the sorting cylinder, and a screening port is opened on the inner wall of the sorting cylinder; multiple splints are connected to the side wall of the sorting cylinder above the push plate; a sorting storage box is provided below the sorting cylinder, and the weight sensor and control connected to the device. The sorting device of the present invention can classify the used pieces of Chinese medicine according to a range of size and weight, which is beneficial to the subsequent use of the pieces that look similar in size and will not appear uneven. The phenomenon of uniformity improves the appearance of the finished product, which is conducive to packaging and sales.

Owner:谭证书

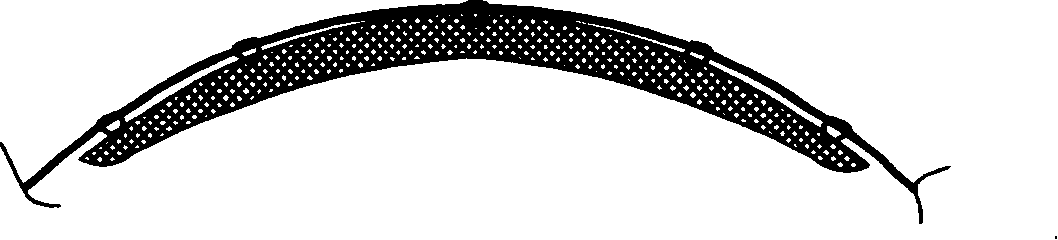

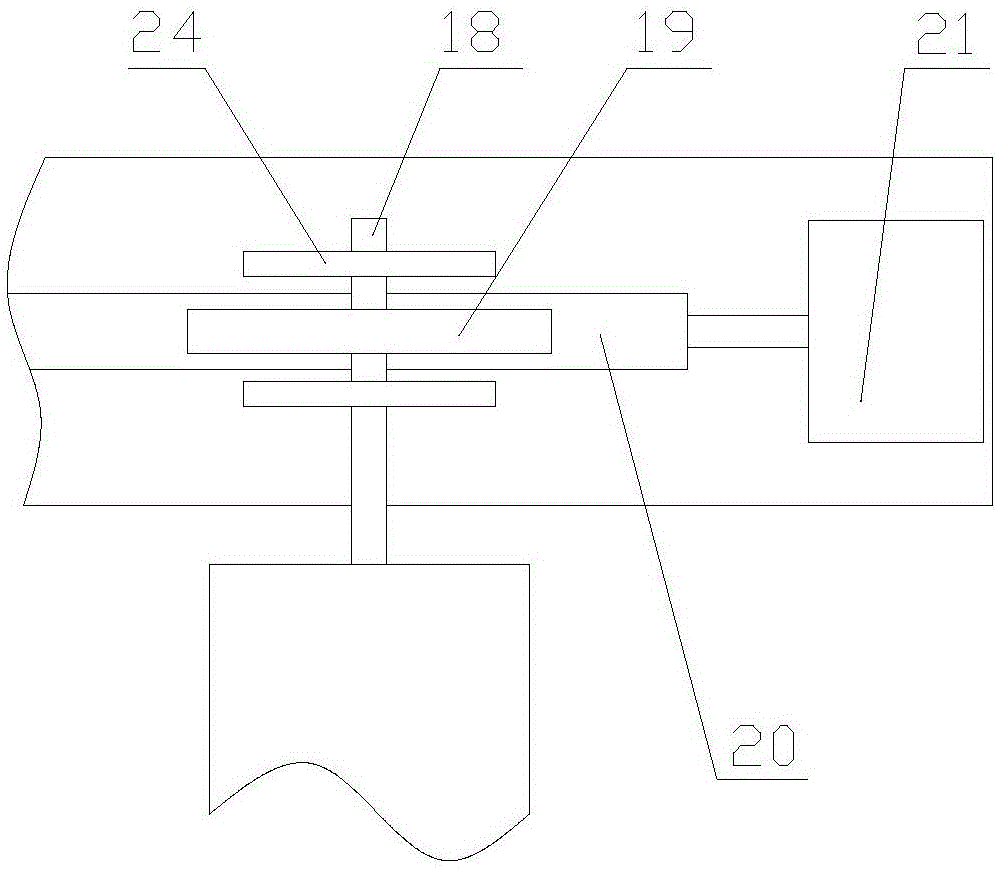

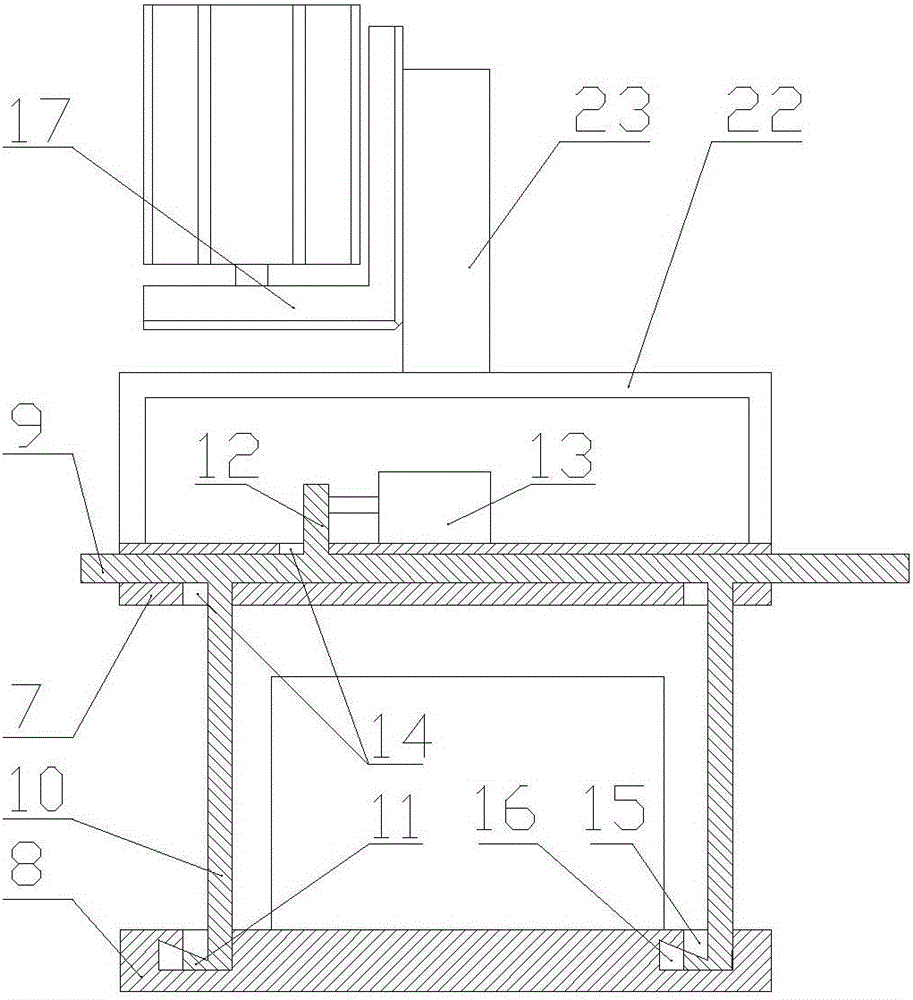

Blind seam shoulder pad sewing machine

InactiveCN101191276AThere will be no unevennessRealize the blind seam effectNeedle severing devicesSewing-machine control devicesElectrical controlEngineering

The invention discloses a shoulder pad blind-stitch machine which mainly aims to overcome the defects that when equipment like the prior temporary stitch machine, a button sewing machine and so on are used for tailoring a shoulder pad, stitches penetrate through the whole thickness and the shoulder pad is made to be irregular on the surface and too tight in tailoring, and replaces hand sewing shoulder pad to improve efficiency. The invention comprises a machine frame, a blind-stitch machine handpiece which is arranged on the upper part of the machine frame, and an electrical control device which is arranged on the lower part of the machine frame and used for controlling machine needle motion on the handpiece, wherein, a feed mechanism used for adjusting height of a shoulder pad is arranged on the machine frame facing to a machine needle on the handpiece and connected with a motor output shaft in the electrical control device through a driving mechanism. By utilization of the shoulder pad blind-stitch machine to tailor the shoulder pad, stitches can not penetrate through the bottom surface of the shoulder pad, and tailoring tightness and tailoring depth can be adjusted, thereby the shoulder pad has the advantages of unlikely occurrence of irregular phenomenon, proper tightness, and leveling and beautiful appearance; because no stitches are arranged on the bottom surface of the shoulder pad, blind effect which can not be reached by other sewing machines is realized.

Owner:GUANGZHOU KEQI AUTOMATIC EQUIPS

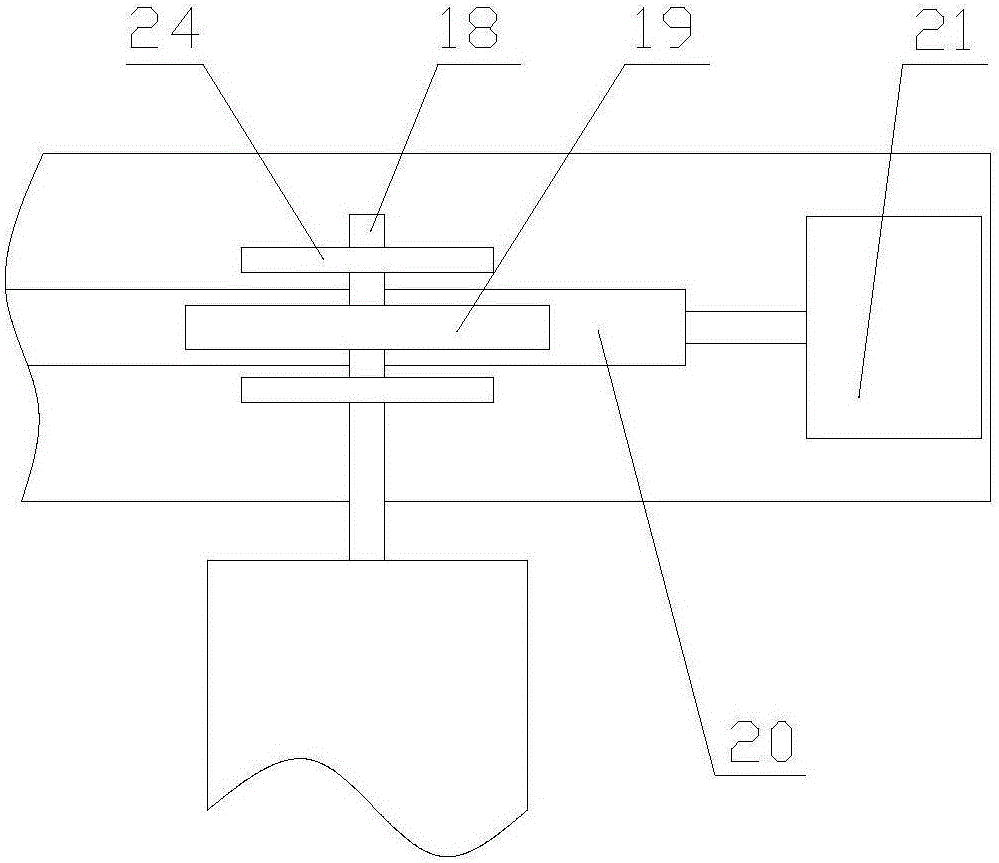

Transfer device of casting mould

ActiveCN106424676AExtended service lifeQuality is not affectedMould handling equipmentsUltimate tensile strengthMechanical engineering

The invention discloses a transfer device of a casting mould, and the transfer device reduces labor intensity of workers, is high in casting quality, and improves production efficiency. The transfer device comprises a working platform, wherein two guide rails which are parallel to each other are arranged on the working platform; a movable supporting base is arranged on the two guide rails; one drive device is connected with the movable supporting base, and is used for driving the movable supporting plate to translate along the two guide rails; a translation air cylinder is arranged on the movable supporting base; a piston rod of the translation air cylinder extends to one side of each of the two parallel guide rails in the horizontal direction, and is perpendicular to the two guide rails; a mounting arm parallel to the two guide rails is fixedly arranged on the piston rod of the translation air cylinder; and the two ends of the mounting arm are separately equipped with mould loading devices.

Owner:江苏苏铁冶金机械制造有限公司

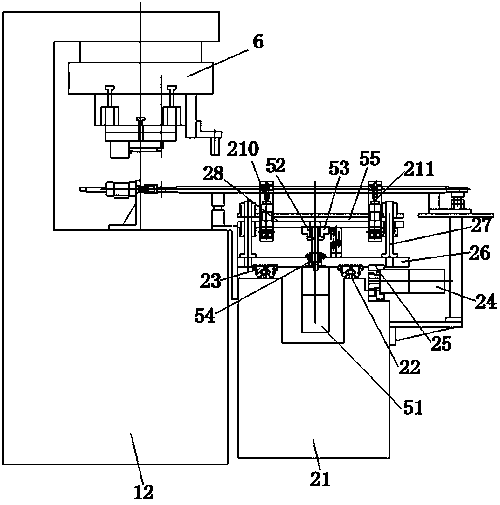

High-precision carrying mechanical arm numerical control machine tool and operation method thereof

ActiveCN110153259ARealize automatic processingRealize automatic positioningMetal-working feeding devicesStripping-off devicesNumerical controlPunching

The invention relates to the technical field of numerical control mechanical equipment, and discloses a high-precision carrying mechanical arm numerical control machine tool and an operation method thereof. The high-precision carrying mechanical arm numerical control machine tool comprises a machine body, a feeding and discharging mechanism is arranged on one side of the machine body, a punching mold is arranged at the position, on one side of the feeding and discharging mechanism, of the upper portion of the machine body, a punching auxiliary platform is arranged under the punching mold, a chamfering machine tool is arranged at the position, on one side of the punching auxiliary platform, of the upper portion of the machine body, the feeding end of the feeding and discharging mechanism isprovided with a parallel positioning mechanism, a punching positioning mechanism is arranged on one side of the parallel positioning mechanism, the machine body comprises a shell, one side of the shell is provided with a connecting frame, the top end of the connecting frame is in an inclined shape, the tail end of the connecting frame is connected with the punching positioning mechanism, and a control box is arranged on the other side of the shell. Automation machining of the material is achieved, the forging, cutting and punching can be carried out on two materials at the same time, and workefficiency is improved.

Owner:江苏新悦自动化有限公司

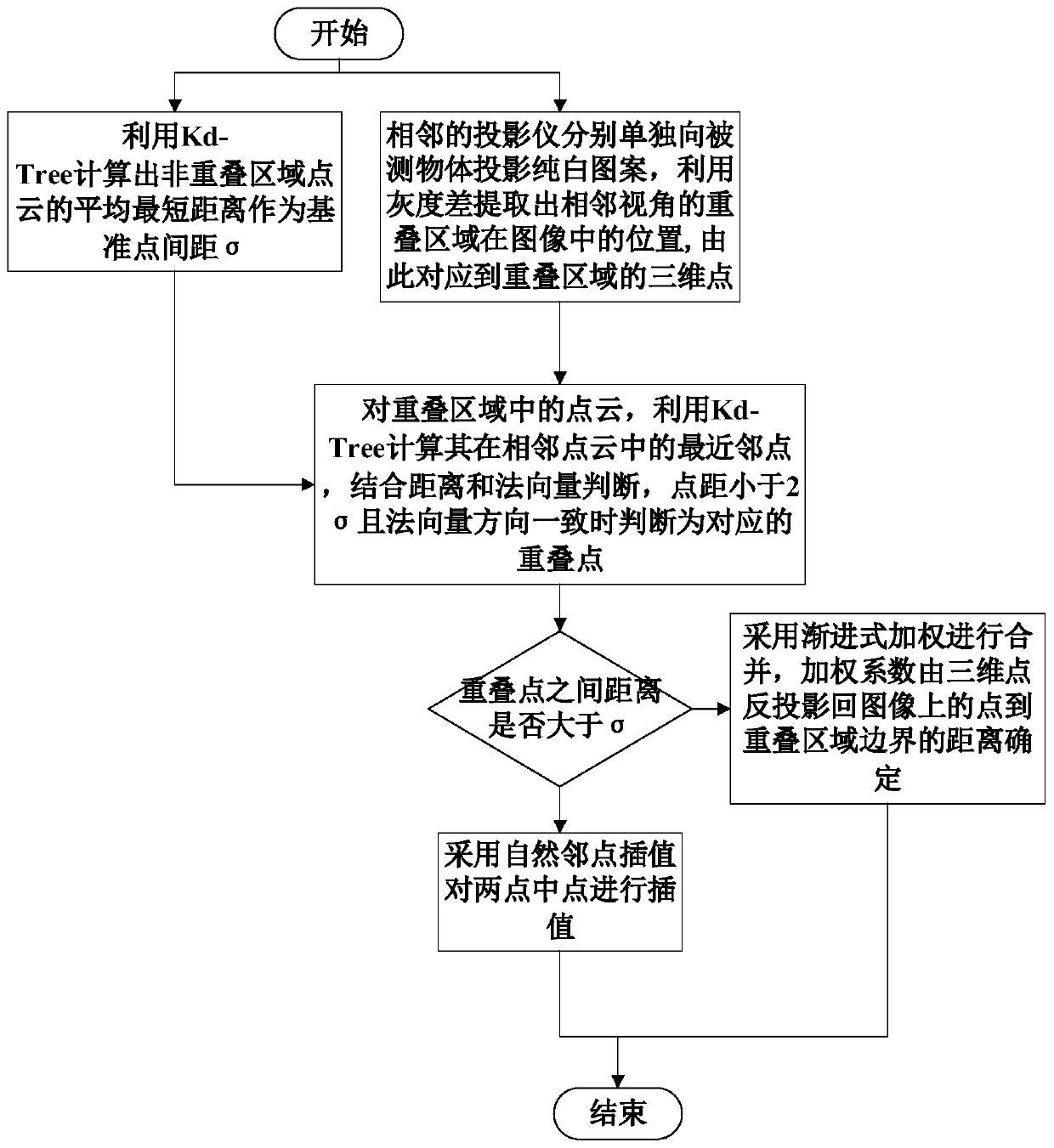

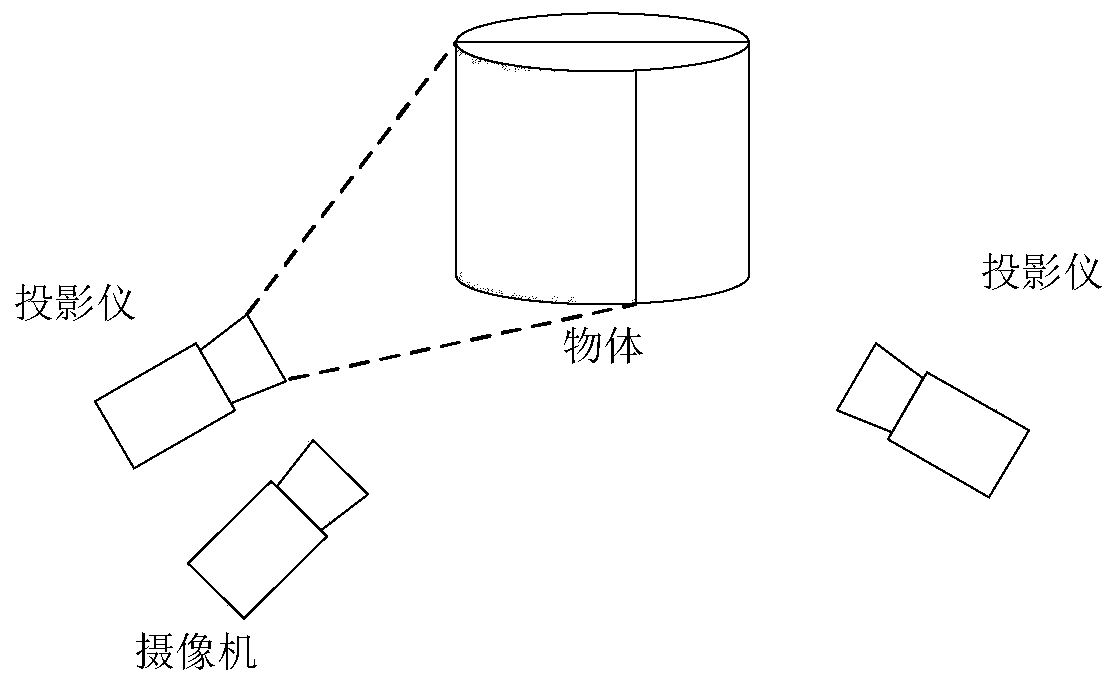

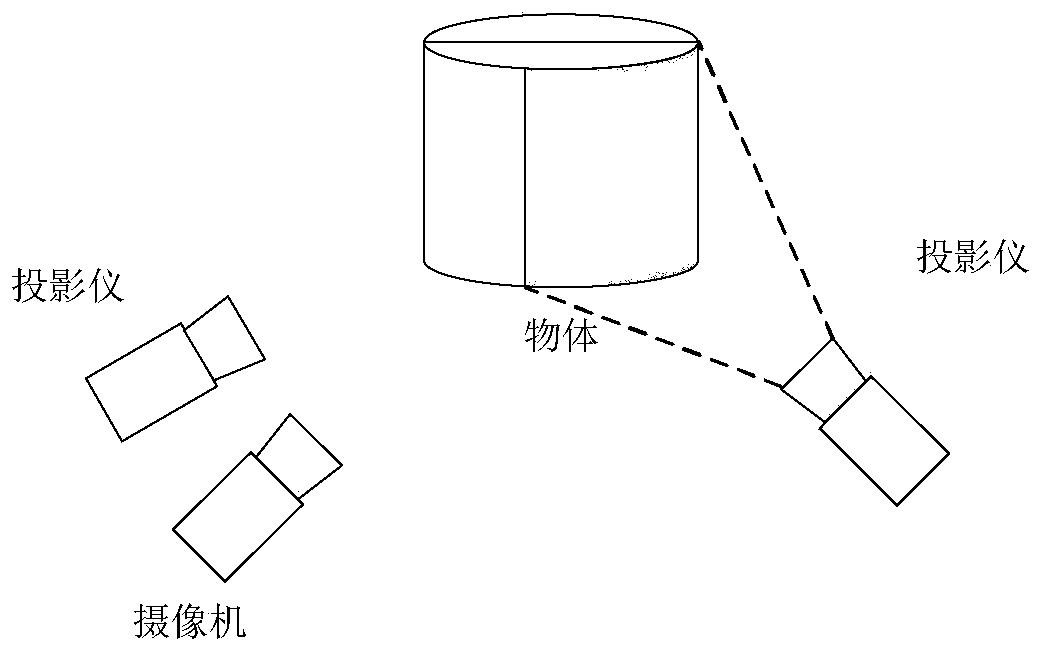

Multi-view point cloud fusion method based on projection

ActiveCN110136077AQuickly identify overlapping areasProcessing speedImage enhancementImage analysisPoint cloudThree-dimensional space

The invention discloses a multi-view point cloud fusion method based on projection, and the method comprises the steps: enabling adjacent projectors to project pure white patterns to a measured objectseparately, extracting the pixel point positions of the overlapped areas of the adjacent projectors in the image, and enabling the pixel points to be reconstructed to a three-dimensional space to obtain the point cloud of the overlapped areas; using the Kd-Tree to calculate the average shortest distance sigma of the point clouds in the non-overlapping region as a reference point interval, and then for point clouds in overlapping region, calculating nearest neighbor point of point clouds in adjacent point clouds by using Kd-Tree; combining distance and normal vector judgment, judging the overlapped points as corresponding overlapped points when the point distance is less than 2 sigma and the normal vector direction is consistent, finally calculating the distance between the corresponding overlapped points; if the distance sigma is less than the normal vector direction, performing merging by adopting progressive weighting, and determining a weighting coefficient according to the distance from the point on the three-dimensional point back projection image to the boundary of the overlapped region; and if the distance is greater than sigma, interpolating the midpoints of the two pointsby adopting natural adjacent point interpolation.

Owner:SOUTHEAST UNIV

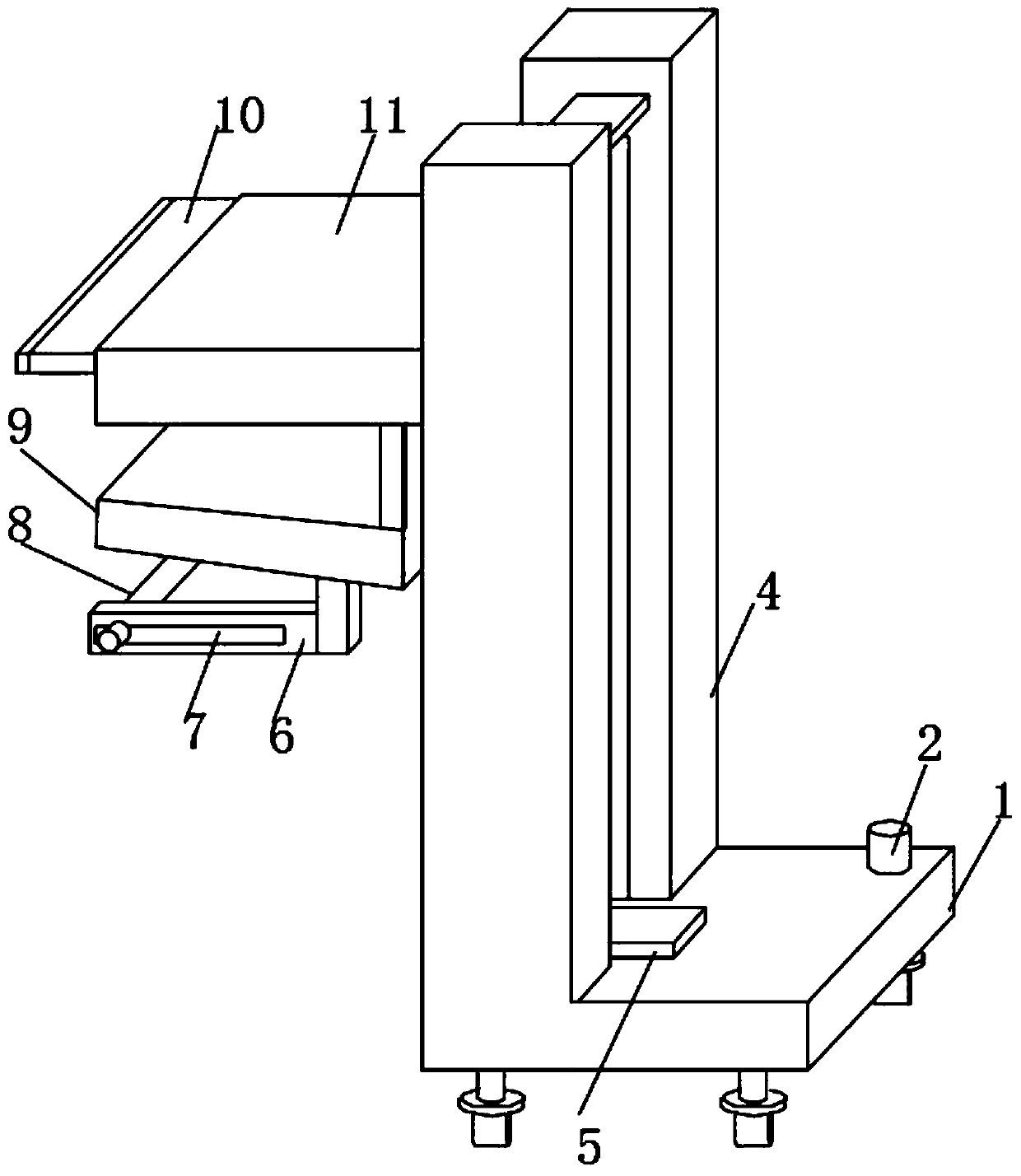

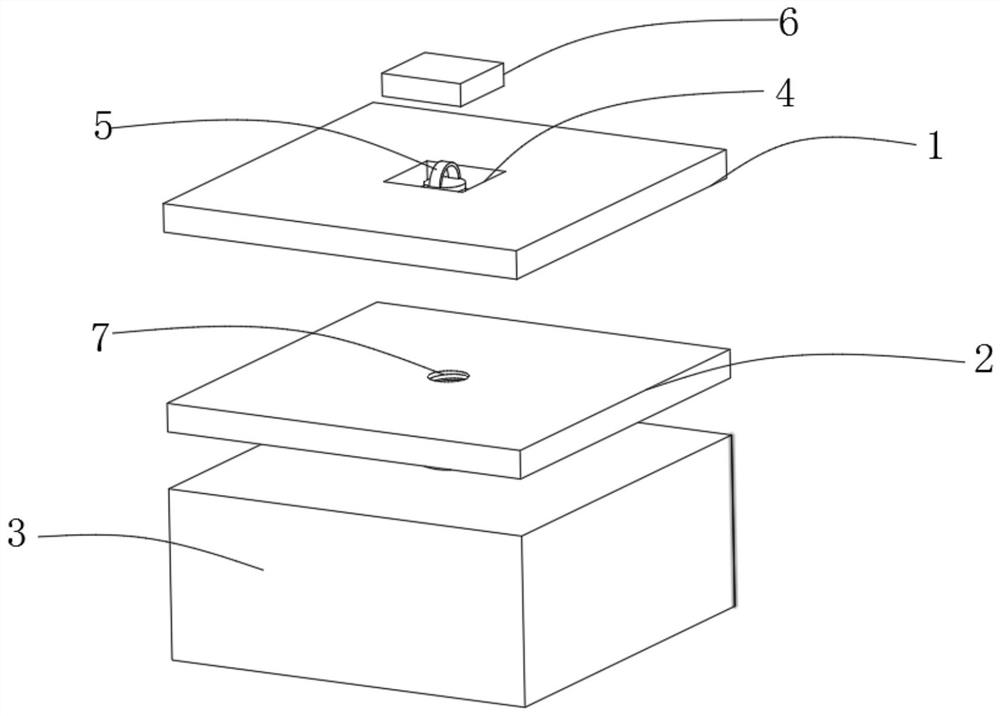

Loading device for casting moulds

ActiveCN106735132AExtended service lifeQuality is not affectedMould handling equipmentsPush pullEngineering

The invention discloses a loading device for casting moulds. According to the loading device for the casting moulds, the labor intensity of workers is lowered, the casting quality is higher, and production efficiency is improved. The loading device comprises an upper plate, a lower plate and a lifting device. The upper plate is internally slidably matched with a sliding plate, two hook plates are arranged below the sliding plate, and each hook plate comprises a vertical plate and a hook head located at the lower end of the corresponding vertical plate. The vertical plates are arranged in the transverse direction of the sliding plate, a connecting plate upwards extending is arranged at the upper end of the sliding plate, and a push-pull air cylinder is fixed to the upper end of the upper plate. A piston of the push-pull air cylinder is fixedly connected with the connecting plate and is used for pushing the sliding plate to longitudinally slide along the upper plate. Position giving openings for the vertical plates and the connecting plate to longitudinally slide along the upper plate are formed in the sliding plate. The lower plate is used for loading the moulds, and inserting grooves are formed in the lower plate, correspond to the hook heads and are used for inserting of the hook heads. A hook groove is formed in one side of each inserting groove, and the hook heads can be pushed to be matched with the hook grooves under the effect of the push-pull air cylinder. The lifting device is connected with the upper plate and used for driving the upper plate to rise and fall.

Owner:重庆市璧山正发有色金属有限公司

Automatic-controlled wall mud screeding device and using method thereof

ActiveCN109853914AWell mixedGood effect in useGrinding carriagesGrinding drivesAutomatic controlStructural engineering

Owner:浙江飞锐科技有限公司

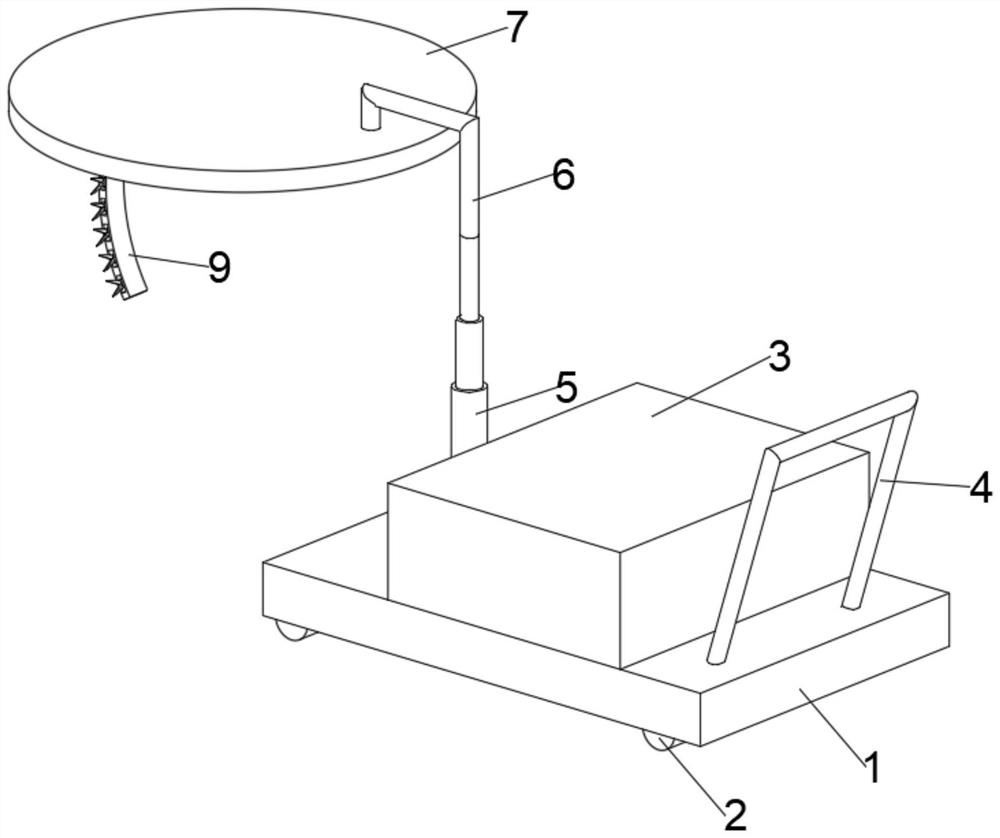

Hand push type environment-friendly lawn trimmer

The invention discloses a hand-push type environment-friendly lawn trimmer. The lawn trimmer comprises an armrest, a stepping motor, a spiral lifter and annular grooves. The armrest is welded to the side of a fixed plate, second mounting holes are symmetrically formed in the top of the fixed plate, and vertical rods are screwed into the second mounting holes. First mounting holes are formed in theends, away from the second mounting holes, of the vertical rods, cross bars are fixed to the inner sides of the first mounting holes, and bumps are arranged on the inner sides of the cross bars. A sun-protective rain baffle plate is connected between the cross bars, and clamping slots corresponding to the bumps are formed in both sides of the sun-protective rain baffle plate. As the hand-push type environment-friendly lawn trimmer is provided with the spiral lifter and the stepping motor, when the trimmer is working, the height of a mounting groove from the ground is adjusted by the spiral lifter, thereby changing the height of the stepping motor in the mounting groove from the ground, facilitating the adjustment of a cutting blade to the trimming length of a lawn, and making the lawn betrimmed neatly without any unevenness.

Owner:HEFEI DONGLU MACHINERY MFG

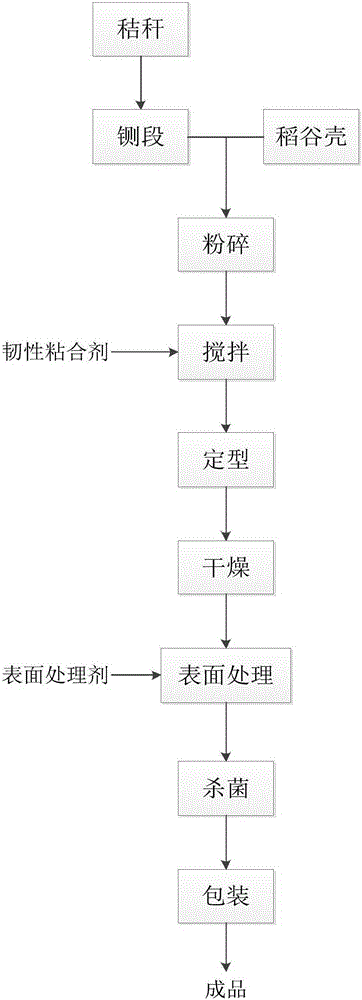

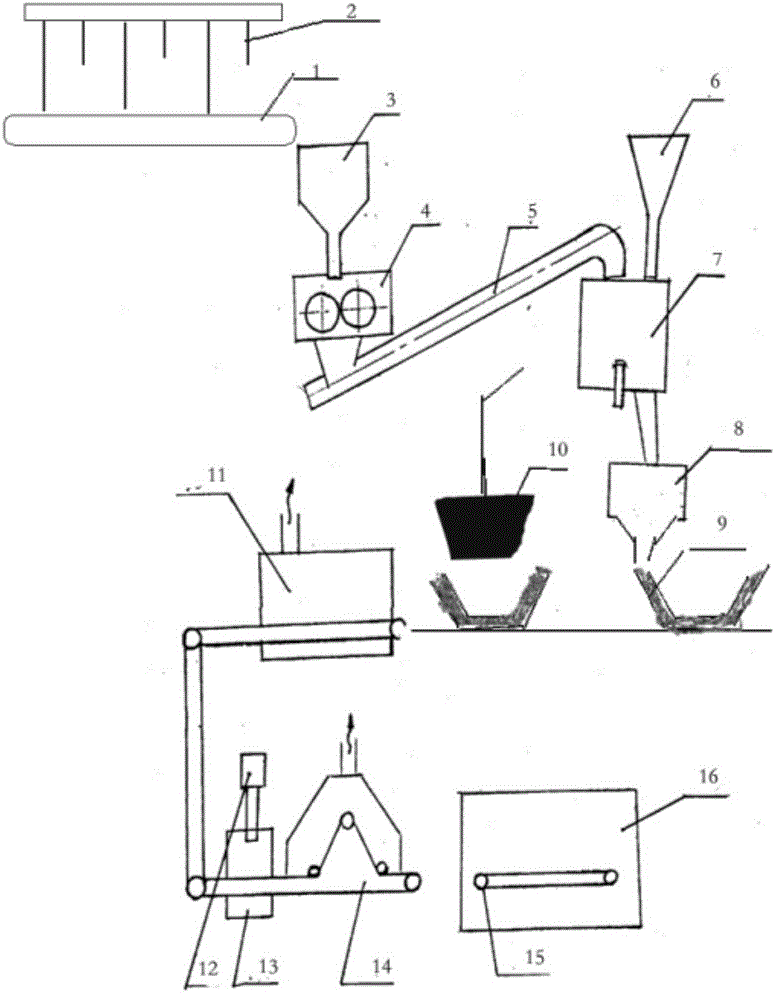

Manufacturing method for disposable novel environment-friendly utensil

InactiveCN105216087AThere will be no unevennessGuaranteed crushing efficiencyDomestic articlesHollow articlesFiberAdhesive

The invention discloses a manufacturing method for a disposable novel environment-friendly utensil. Adopted facilities and equipment comprise a conveyer belt, a straw chopper, a pulverizer, a powder conveying system, a plant fiber and adhesive mixing and stirring machine, a control storage tank, templates, a pressing machine, a drying box, a surface treatment chamber, a drying solidification chamber, an agent supplying system, a conveyer belt and a sterilizing chamber. Straw and rice hulls serve as raw materials and are subjected to section chopping through the straw chopper, pulverizing and grinding are conducted in the pulverizer, the materials are blended with a flexible adhesive for stirring, a disposable non-toxic environment-friendly and easily-degradable material is obtained, and then the material is subjected to forming, drying, surface treatment with a homemade surface treatment agent, and sterilization to be made into the environment-friendly utensil.

Owner:CHANGZHOU UNIV

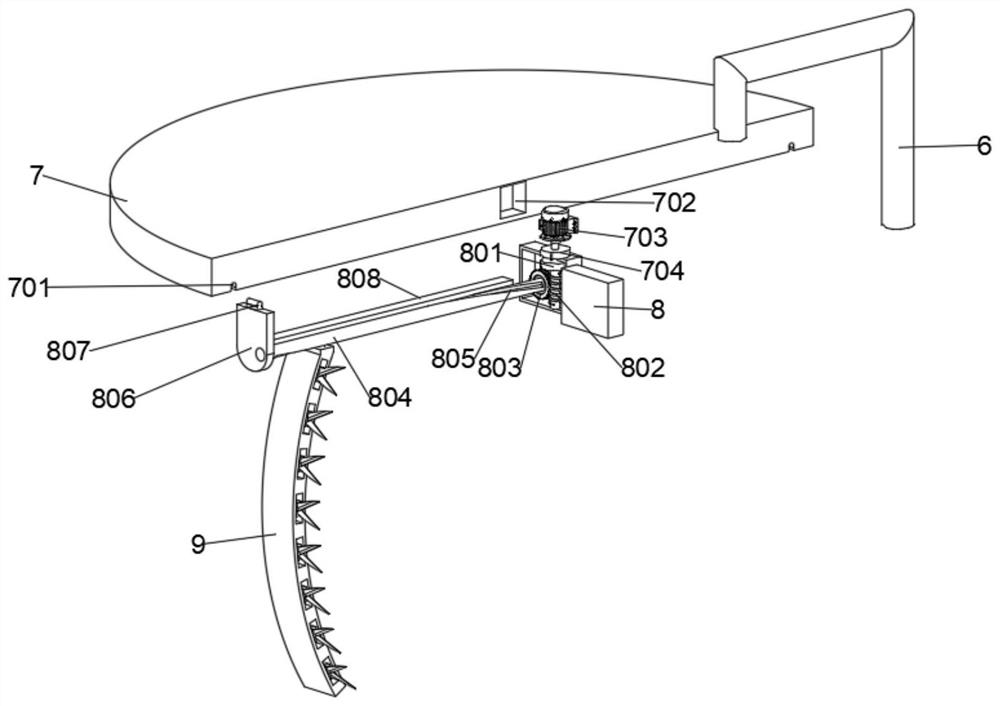

Pruning and cutting device for branches and leaves at high positions of garden trees

PendingCN113647261AContoured shape for easy adjustmentImprove work efficiencyHedge trimming apparatusCuttersAgricultural engineeringStructural engineering

The invention discloses a pruning and cutting device for high branches and leaves of garden trees, and belongs to the technical field of tree branch and leaf pruning. The pruning and cutting device for high branches and leaves of garden trees comprises a moving plate, a pruning assembly is arranged below a limiting rod, an electric control hydraulic rod is fixedly arranged in the middle of the inner side of a supporting frame through a screw, the piston end of the electric control hydraulic rod penetrates through the inner wall of the supporting frame to extend to the outside and is fixedly provided with a U-shaped block, the outer side of the supporting frame is symmetrically and rotationally connected to two supporting rods through hinge pins, pruning knives are connected to the outer end of the connecting rod in a welding mode, the outer side of the U-shaped block is provided with an adjusting hand wheel, the threaded end of the adjusting hand wheel is sleeved with a spring B, through close cooperation of the structures, the device can prune the branches and leaves of the trees through annular movement of the multiple pruning knives, the working efficiency is improved, the pruning can be completed at a time, therefore, the branches and leaves at the high positions of the trees can form a uniform appearance, the uneven condition is avoided, and the trees are more attractive.

Owner:申伟

Waterproof composite fabric

InactiveCN103862787AImprove waterproof performanceWater resistance is not damagedSynthetic resin layered productsSurface layerThermoplastic polyurethane

The invention discloses waterproof composite fabric. The composite fabric comprises four layers, namely, a surface layer, a middle layer, a base layer and a waterproof layer. The surface layer, the middle layer and the base layer are sewed through a quilting process. The waterproof layer is integrated by a compression bonding manner. The surface layer is silk floss. The middle layer is non-woven fabric. The base layer is tower cloth. The waterproof layer is thermoplastic polyurethane (TPU) film having a thickness of 0.02 mm. The waterproof layer is integrated by the compression bonding manner adopting thermocompression bonding at 70 DEG C. The waterproof composite fabric is smooth, soft, flat, beautiful, comfortable, and good in waterproofness.

Owner:QINGDAO TONGGUANWANG IND

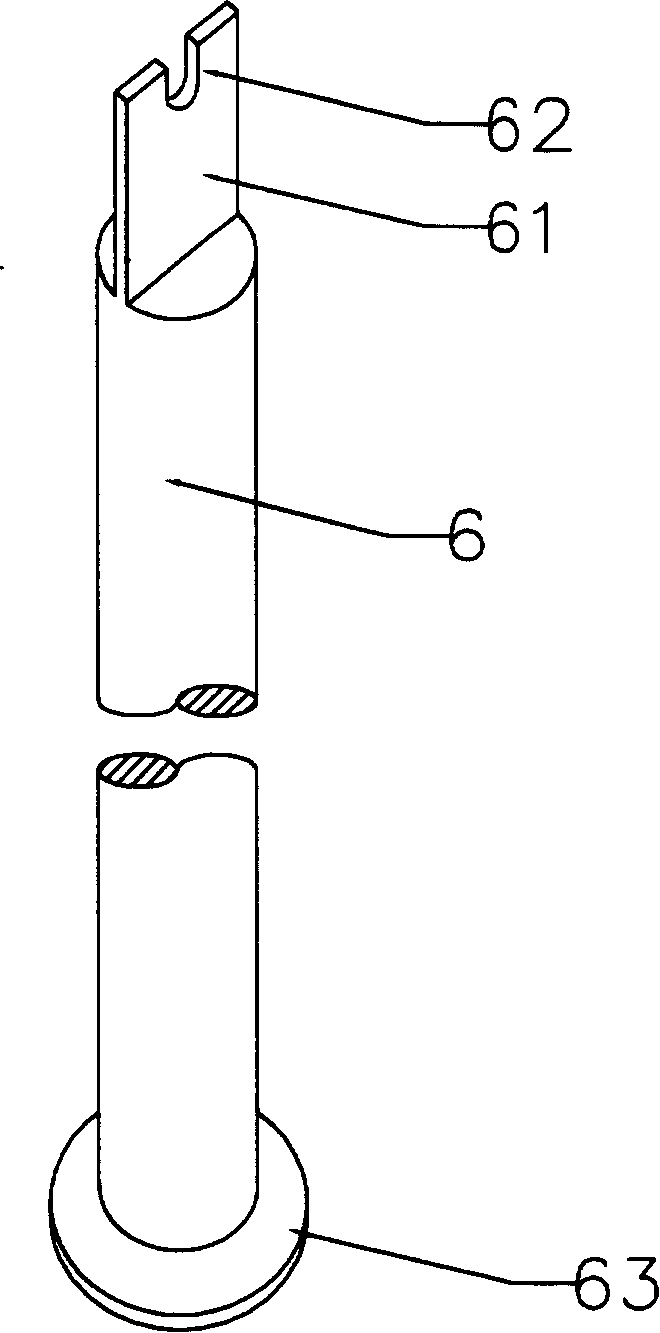

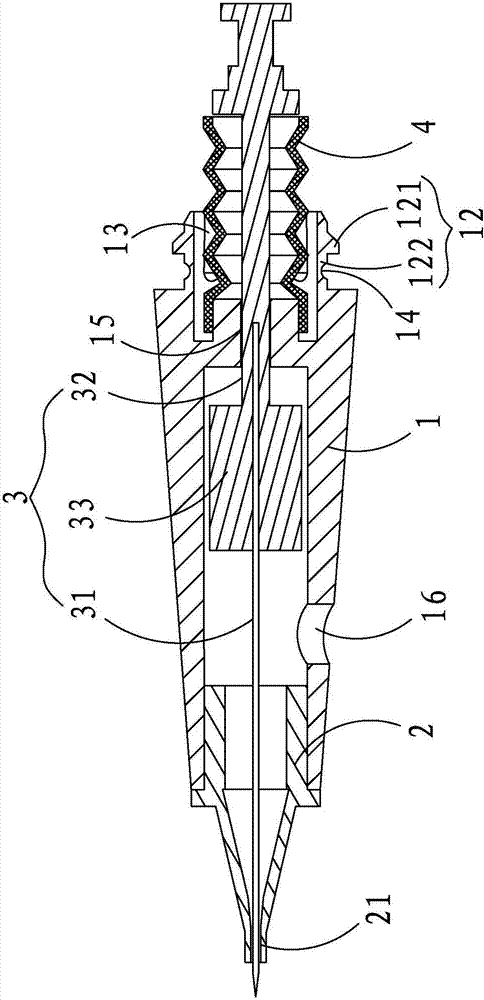

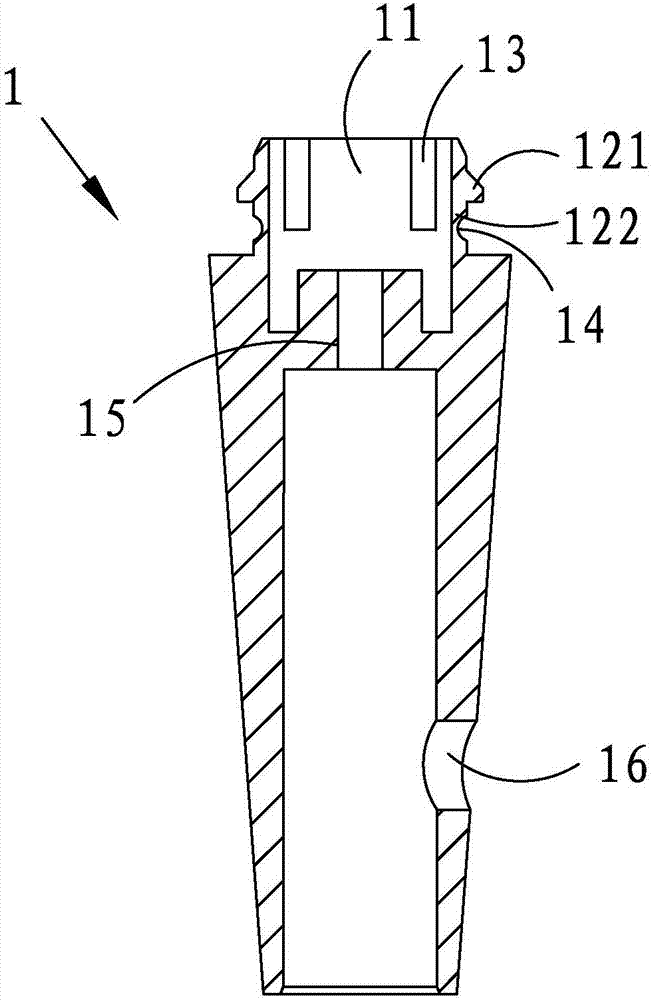

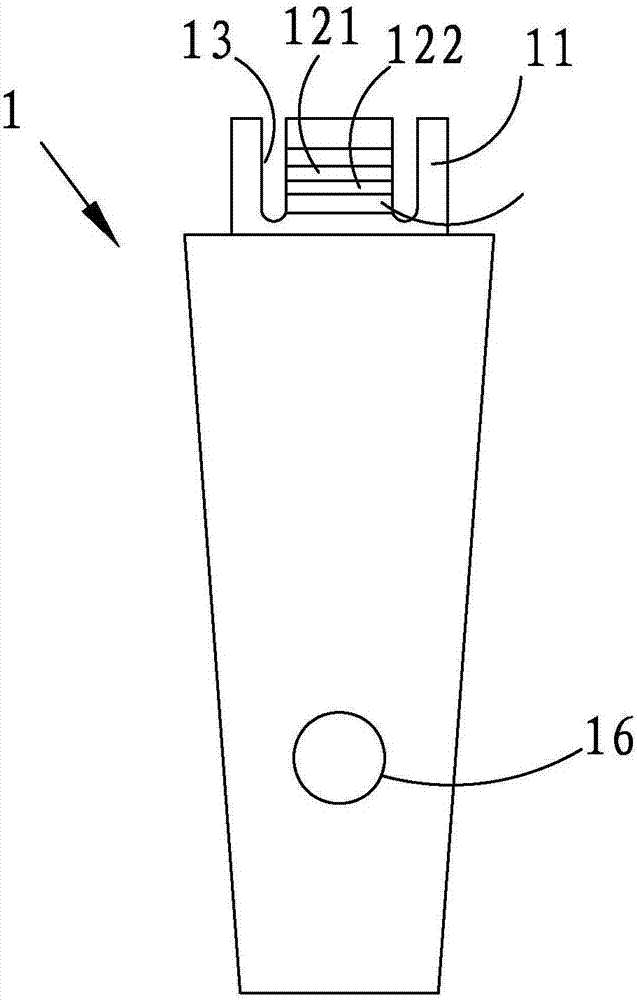

Fully-disposable integrated injection molding embroidering needle head

The invention discloses a fully-disposable integrated injection molding embroidering needle head. The fully-disposable integrated injection molding embroidering needle head is detachably connected with the front end part of an embroidering machine, and comprises a hollow tubular cylinder body, a positioning sleeve arranged on the front end part of the cylinder body, a needle body arranged in the embroidering needle head as well as an elastic piece with tendency of pushing the needle body towards the back direction of the embroidering needle head; a clamping part connected with the embroidering machine is arranged on the back end part of the cylinder body; the clamping part comprises a guide part arranged in the length direction of the embroidering needle head and a fragile locking part; the locking part cooperates with the front end part of the embroidering machine and locks the embroidering needle head and the embroidering machine; a gap is formed between the guide part and the locking part; and the locking part is easy to break when being subjected to a transverse force, and the locking part cannot be used continuously after being broken by a tangential force when being pulled out from the embroidering machine, so that reuse of the embroidering needle head is avoided from the technical method.

Owner:吴江市神灵美容医疗器材有限公司

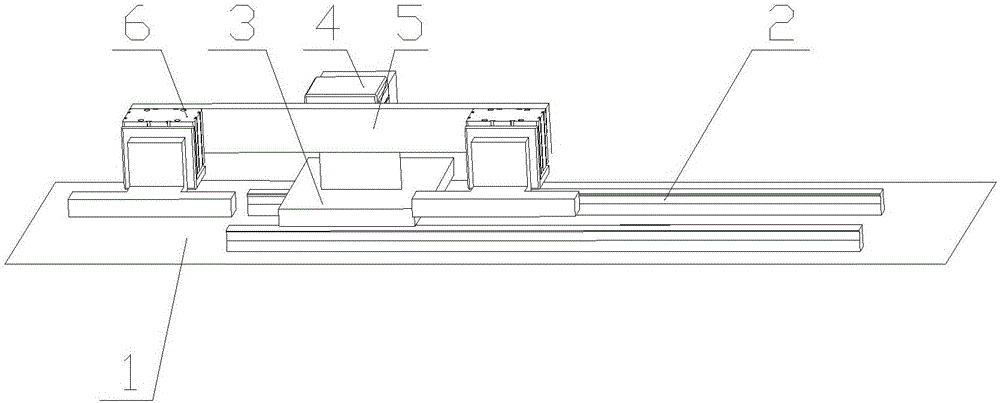

Sanding machine with improved structure

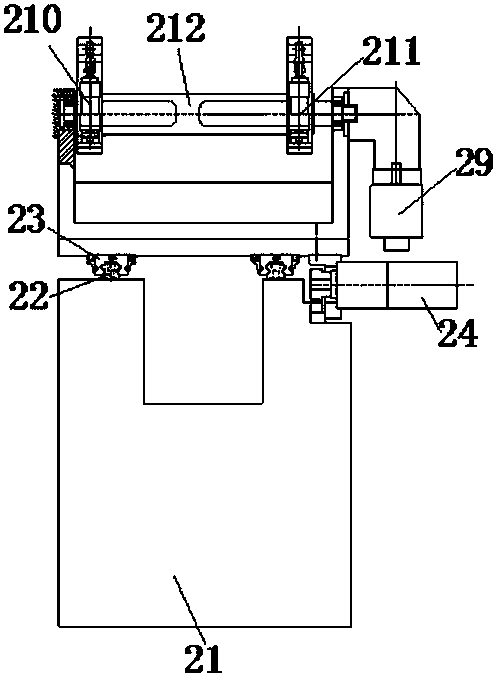

ActiveCN104985497ASimple structurePracticalGrinding drivesGrinding feedersEngineeringMechanical engineering

A sanding machine with an improved structure comprises a rack and a fine sanding mechanism for sanding the upper surface of a board, wherein the rack comprises a moving portion and two supporting portions. The moving portion is used for allowing the board to walk, and the two supporting portions are arranged on the two sides of the moving portion respectively; and the sanding machine further comprises a rough sanding mechanism for sanding the lower surface of the board, and the rough sanding mechanism comprises a rough sanding component and a driving component for providing power for the rough sanding component; the moving portion is provided with a first containing groove, and the rough sanding component is located in the first containing groove; and the horizontal height of the top end of the rough sanding component is larger than the horizontal height of the top end of the moving portion, and is smaller than the horizontal height of the bottom end of the fine sanding mechanism. The rough sanding mechanism is arranged, so that the bottom face of the board can be sanded, the condition that the bottom face of the board is uneven is avoided, and subsequent two-time coating and spraying effects cannot be affected.

Owner:福建省尤溪县红树林木业有限公司

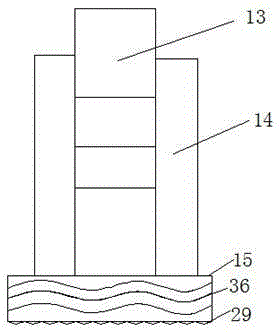

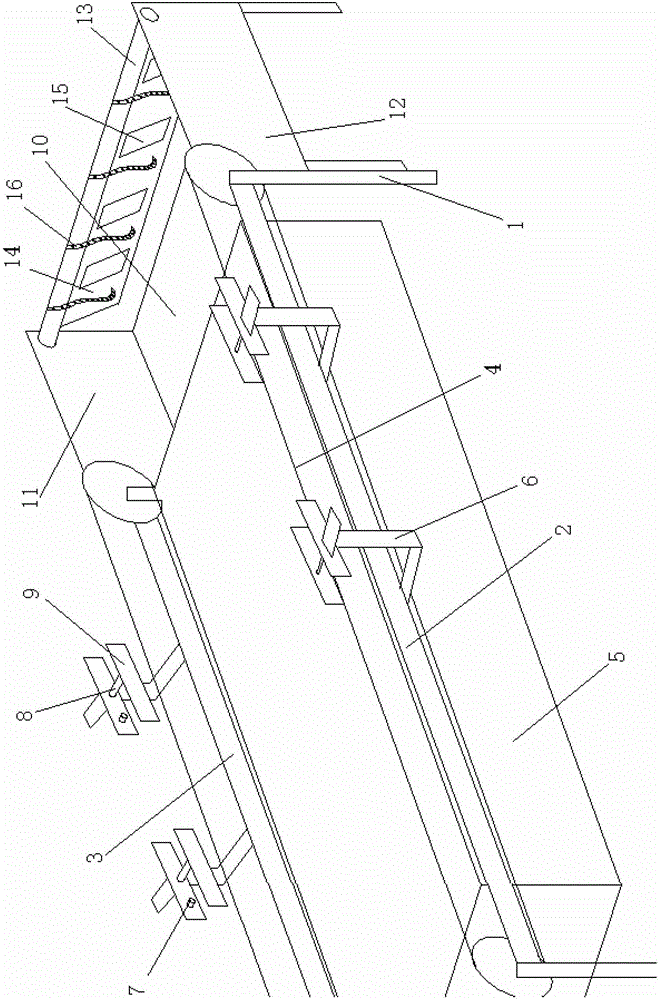

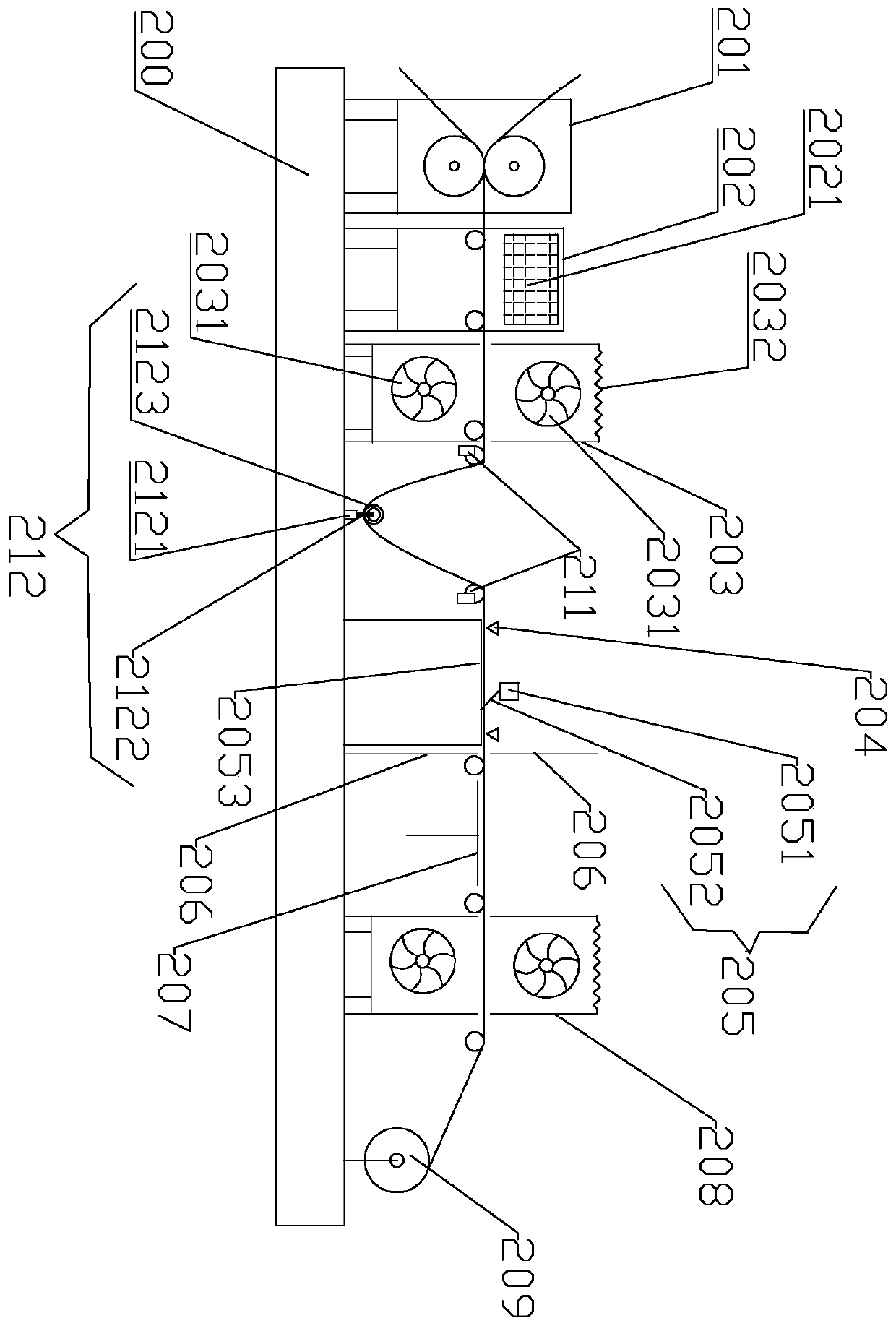

Drying delivery production line structure for lithographed sheet

InactiveCN102717594AReduce manual labor intensityImprove work efficiencyPrinting press partsPhysicsFixed frame

The invention relates to a drying delivery production line structure for a lithographed sheet. The drying delivery production line structure comprises a support, two beams which are parallel are erected on the support; a circulating conveying chain is arranged between the beams; a drying oven is arranged below the circulating conveying chain; fixed frames are fixedly arranged outside the beams; ultraviolet sensors are arranged on the fixed frames respectively; the ultraviolet sensors face the lithographed sheet on the circulating conveying chain; lithographed sheet push plates which face the circulating conveying chain are also arranged on the fixed frames and are driven by a cylinder piston rod; the ultraviolet sensors transfer a signal to a controller to control the driving of a cylinder; the discharge end of the circulating conveying chain is provided with a discharge table which is matched with the circulating conveying chain; baffles are arranged on two sides of the discharge table respectively; a rotating shaft is erected above the discharge table; a buffer plate is arranged on the rotating shaft; air vents are distributed in the buffer plate; and a plurality of chains are also arranged on the rotating shaft. By the drying delivery production line structure, the lithographed sheet is prevented from being mismatched in a drying production line, the labor intensity is low in the process, time and labor are saved, the work efficiency is improved, and the quality of the lithographed sheet is ensured during material receiving.

Owner:ANHUI HONGYANG PACKAGING GRP

Shearing machine

InactiveCN110846874AGuaranteed smoothThere will be no unevennessSevering textilesHeating/cooling textile fabricsTool bitEngineering

The invention discloses a shearing machine. The shearing machine comprises a shearing machine supporting table as well as a lining sticking device, a heating and shaping device, a first cooling box, acutting device, a steam ironing device, a second cooling box and a winding roller which are sequentially arranged on the shearing machine supporting table; two supporting blocks are arranged betweenthe first cooling box and the cutting device, and a tensioning device is arranged between the supporting blocks; the cutting device comprises a knife rest and a knife head which are symmetrically arranged on the front side and the rear side, and a cutting table is arranged below the cutting device; a pressing block is arranged above the cutting table and on the left side and the right side of thecutting device; and a partition plate is arranged between the pressing block and the steam ironing device. By adoption of the shearing machine, the circumstance that the shaped fabric is not tidy enough due to shrinkage of the fabric can be avoided, especially for some high-end fabrics, the quality of the whole clothes is improved, and the rejection rate of the fabrics is effectively reduced.

Owner:JIAXING BIANKA BAG & CASE

Assembly type floor convenient to assemble

PendingCN112095979AEasy to hideEasy to fixFalse floorsResiliently-mounted floorsEngineeringScrew thread

The invention discloses an assembly type floor convenient to assemble, and relates to the technical field of floor installation. The assembly type floor comprises a movable floor, a fixed floor and amovable block, wherein a mounting groove is formed in the upper surface of the movable floor; a fastening bolt is arranged in the mounting groove; the movable block is arranged in the mounting groove;a bolt hole is formed in the upper surface of the fixed floor; one end of the fastening bolt is arranged in the bolt hole; the fastening bolt is in threaded fit with the bolt hole; the movable blockis in sliding fit with the mounting groove; the top surface of the fixed floor is fixedly connected with a first connecting rod;, one end of the first connecting rod is connected with a damping box; and one end of the first connecting rod extends into the damping box. According to the assembly type floor, the movable block is arranged in the mounting groove, so that the fastening bolt can be conveniently hidden, the uneven condition is avoided, and the movable block can be taken out when the floor needs to be replaced; and the fastening bolt is arranged to be in threaded fit with the bolt hole, so that the movable floor can be conveniently fixed and replaced.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

Transfer device for foundry molds

ActiveCN106424676BExtended service lifeQuality is not affectedMould handling equipmentsEngineeringCasting mold

The invention discloses a transfer device of a casting mould, and the transfer device reduces labor intensity of workers, is high in casting quality, and improves production efficiency. The transfer device comprises a working platform, wherein two guide rails which are parallel to each other are arranged on the working platform; a movable supporting base is arranged on the two guide rails; one drive device is connected with the movable supporting base, and is used for driving the movable supporting plate to translate along the two guide rails; a translation air cylinder is arranged on the movable supporting base; a piston rod of the translation air cylinder extends to one side of each of the two parallel guide rails in the horizontal direction, and is perpendicular to the two guide rails; a mounting arm parallel to the two guide rails is fixedly arranged on the piston rod of the translation air cylinder; and the two ends of the mounting arm are separately equipped with mould loading devices.

Owner:江苏苏铁冶金机械制造有限公司

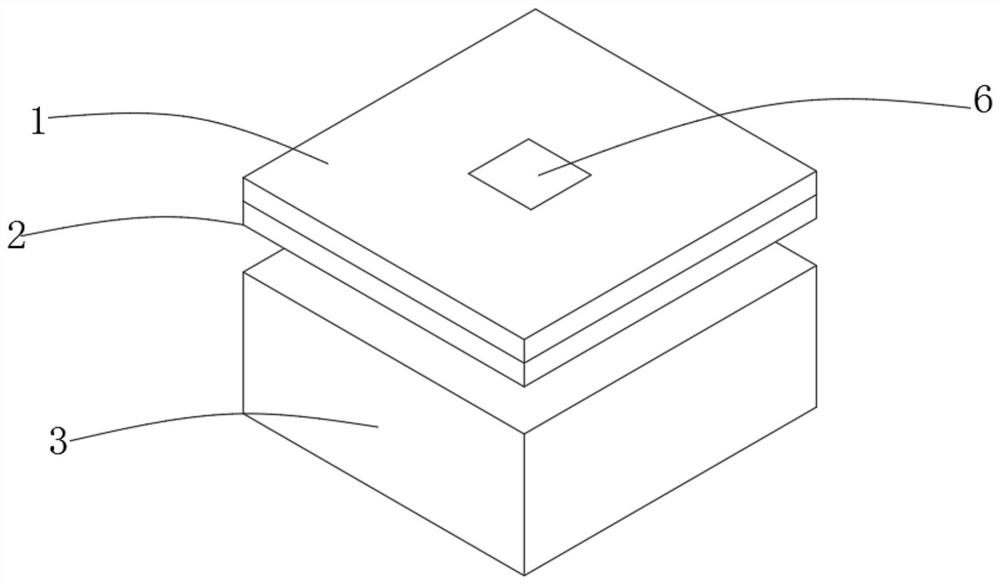

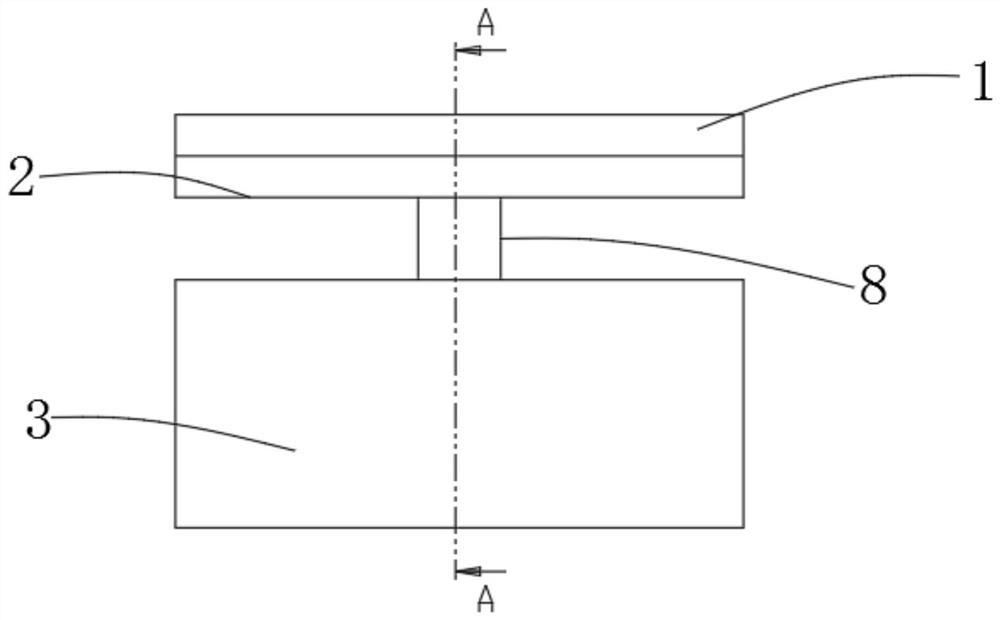

Loading device of casting mold

ActiveCN106563791AGuarantee product qualityExtended service lifeMould handling equipmentsVertical segmentPush pull

The invention discloses a loading device of a casting mold. According to the loading device, the labor intensity of workers is reduced, the casting quality is higher, and the production efficiency is improved. The loading device comprises an upper plate, a lower plate and a lifting device. The two transverse ends of the upper plate are each in sliding fit with a sliding shaft. Two hook shafts extending downwards are arranged below each sliding shaft. Each hook shaft comprises a vertical shaft and a hook head located at the lower end of the vertical segment. A connecting shaft extending upwards is arranged at the upper end of each sliding shaft. The connecting shafts of the two sliding shafts are fixedly connected through a transverse plate. A push-pull air cylinder is fixed to the upper end of the upper plate. A piston rod of the push-pull air cylinder is fixedly connected with the transverse plate and used for pushing the two sliding shafts to longitudinally slide along the upper plate. An avoiding opening is formed in each sliding shaft and allows the corresponding vertical shaft and connecting shaft to longitudinally slide along the upper plate. The lower plate is used for loading the mold and provided with inserting grooves corresponding to the hook heads to allow the hook heads to be inserted therein. A hook groove is formed in one side of each inserting groove. Under the action of the push-pull air cylinder, the hook heads can be pushed to cooperate with the hook grooves. The lifting device is connected with the upper plate and used for driving the upper plate to ascend and descend.

Owner:江苏天鼎精密机械有限公司

Non-support turnover form construction technology for highway bridge thin-wall pier

The invention discloses a non-support turnover form construction technology for highway bridge thin-wall piers. The non-support turnover form construction technology has obvious superiority and scientificity in thin-wall pier construction. Compared with support construction, the technology is advantaged by labor saving, material saving, and fast speed. The technology improves construction safety factors while creating good economic benefits.

Owner:江海滢

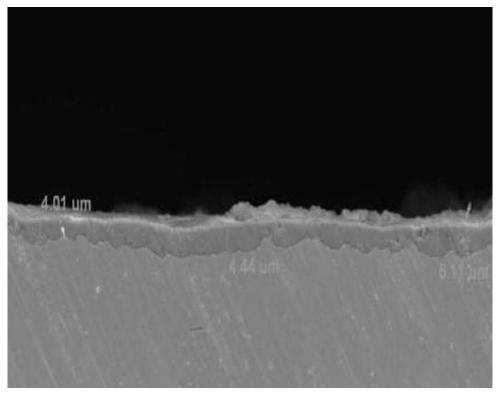

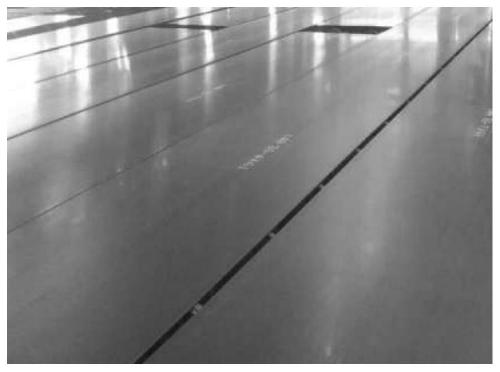

Production method for improving surface quality of steel plate

InactiveCN110157994AQuality improvementContinuous and stable qualityWork heating devicesMetal rolling arrangementsSheet steelHeating furnace

The invention discloses a production method for improving the surface quality of a steel plate. The steel plate is prepared from the following chemical components in percentage by mass: 0.02 percent to 0.30 percent of C, less than or equal to 0.15 percent of Si, 0.30 percent to 2.20 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.0050 percent of S, less than or equal to 0.30 percent of Ni, less than or equal to 0.070 percent of Nb, less than or equal to 0.50 percent of Cu, less than or equal to 0.0050 percent of N, 0.006 percent to 0.020 percent of Ti, less than or equal to 0.30 percent of Cr, 0.015 percent to 0.050 percent of Al, and the balance Fe and impurities. According to the production method for improving the surface quality of the steel plate provided by the invention, through a reasonable component design and a high-efficiency heating furnace heating temperature system, the oxidized scale generation quantity and the oxidized scale generation thickness are reduced; and by matching with a dephosphorization way in the rolling process, the manufacturing method for improving the surface quality of the steel plate is obtained, the surface quality amendment rate is reduced to 0.31 percent from 0.53 percent, and the enterprise profitability is improved.

Owner:NANJING IRON & STEEL CO LTD

Sidewalk paver

InactiveCN111827059AThere will be no unevennessImprove work efficiencyRoads maintainenceElectric machinerySprocket

The invention discloses a sidewalk paver. The sidewalk paver comprises a box body; a grabbing mechanism is arranged on the upper side of the box body; the grabbing mechanism comprises two front supporting pipes which are symmetrical front and back with a grabbing motor as the center; a chain wheel connecting rod is rotationally connected into each front supporting pipe; the upper side of each chain wheel connecting rod is fixedly connected with a first chain wheel; each first chain wheel is connected with a first transmission chain. According to the invention, a sidewalk can be automatically laid; cement can be evenly sprayed on a road to be paved through a mechanical structure, then the road is flattened, the uneven condition cannot occur, sidewalk floor tiles are tidily paved on the cement through a conveying belt, finally knocking flattening is conducted; compared with traditional manual paving, machine paving can make the sidewalk tidier and more attractive; and the working efficiency is greatly improved, and the labor cost is saved.

Owner:福州经济技术开发区畅金铭电子科技有限公司

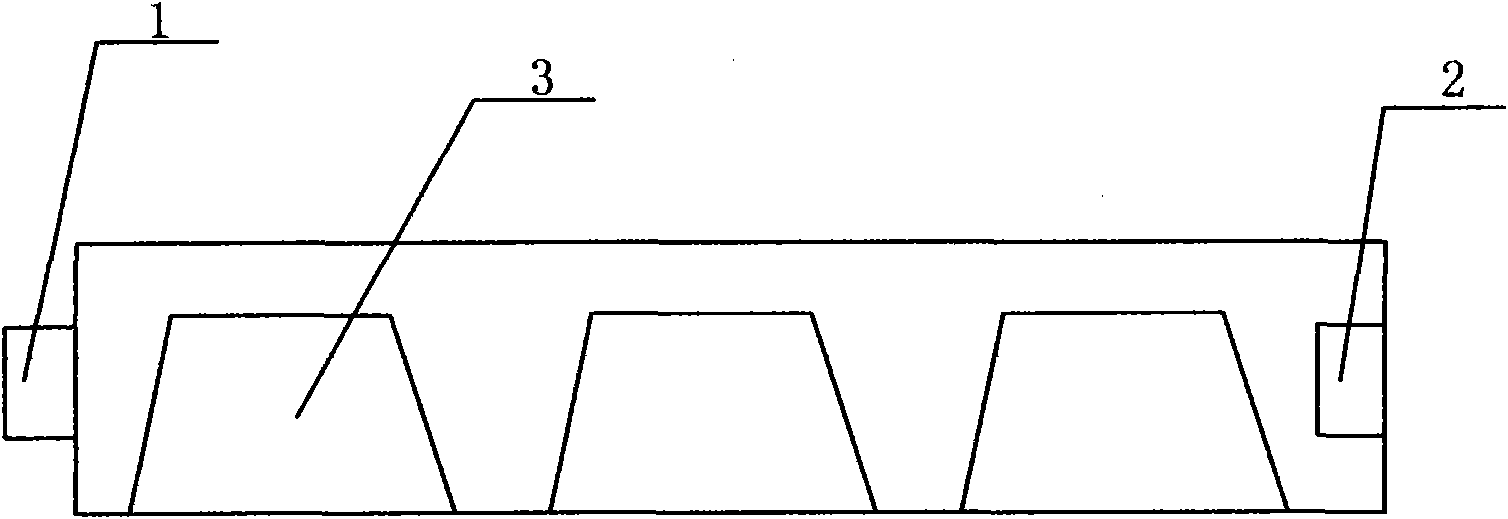

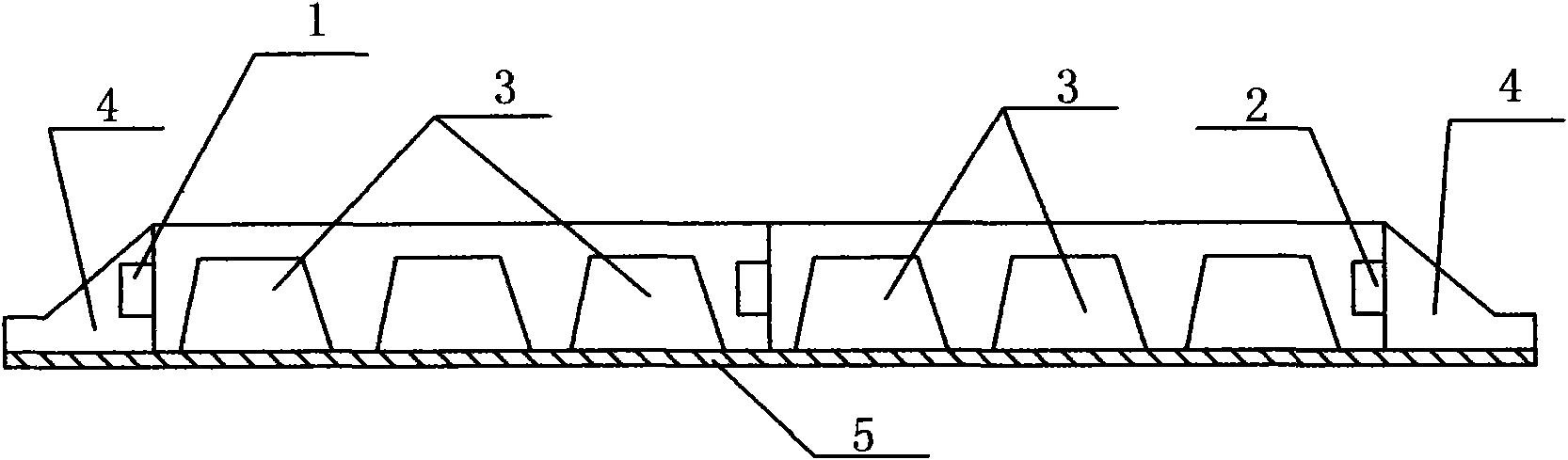

Road cornerstone

The invention relates to a road cornerstone which comprises an insertion-connecting head (1), an insertion-connecting head (2), a hollow part (3) inside the road cornerstone, a pedestrian part (4) ofthe opening of the road cornerstone and a cement concrete part (5). The insertion-connecting head (1) and the insertion-connecting head (2) are of rectangles, the length and the width of the insertion-connecting head (1) are slightly smaller than those of the insertion-connecting head (2); the hollow part (3) inside the road cornerstone is of a trapezoid; the length of the cement concrete part (5)is 2-3 centimeters; the insertion-connecting head (1) is arranged in the insertion-connecting head (2); and the pedestrian part (4) of the opening of the road cornerstone is embedded in the insertion-connecting head (1) or the insertion-connecting head (2). Every road cornerstone is connected to another in such a mode with the number as required; and when pressing a roadbed in the ground, the hollow part (3) inside the road cornerstone is embedded in the ground and just filled with cement concrete on the ground. The invention is nonpoisonous and harmless and has environmental protection, sanitation, strong strength, convenient installation, and no irregularity of the road cornerstones after installation.

Owner:青岛金炫建材有限公司

Grinding device for welding seam in surface of petroleum pipeline

InactiveCN107009245ARealize automatic rotationNo manual rotationGrinding drivesGrinding machinesDrive wheelWeld seam

The invention discloses a polishing device for the weld seam on the surface of an oil pipeline, which comprises a base on which a first driving mechanism, a first groove, and a positioning frame are arranged; A driven wheel is provided, a connecting rod is pierced on the driven wheel, a clamping block is provided on the connecting rod, a blind hole and an adjusting rod are arranged on the clamping block, the adjusting rod is inserted in the blind hole, and the first groove is provided with There is a second drive mechanism, the output shaft of the second drive mechanism is provided with a grinding disc, the positioning frame is provided with a second groove, a spring is arranged in the second groove, a support frame is provided on the spring, and a support frame is arranged on the support frame. Features rollers. The invention can efficiently grind the welding seam on the outer wall of the oil pipeline, reduce labor force, improve the grinding quality, and at the same time, can grind the welding seam to be flush with the outer diameter of the oil pipeline.

Owner:CHENGDU QIAOYI SAISI PETROLEUM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com