Production method for improving surface quality of steel plate

A production method and surface quality technology, applied in workpiece surface treatment equipment, metal rolling, manufacturing tools, etc., can solve problems such as poor effect, small effect, neglect of material effect, etc., and achieve continuous and stable surface quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

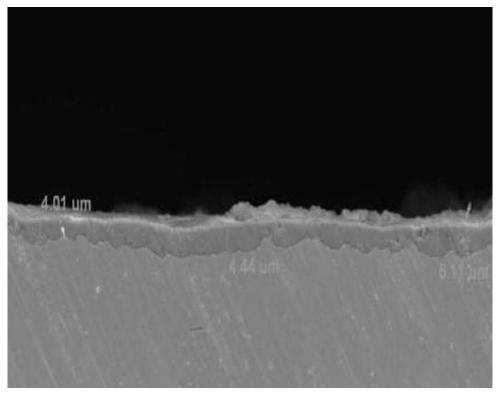

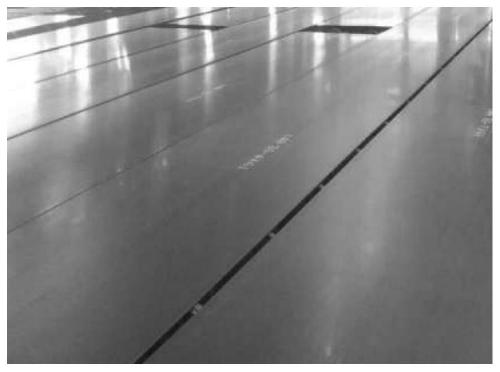

Image

Examples

Embodiment 1

[0036] A kind of production method of improving steel plate surface quality that the present embodiment provides, comprises:

[0037] S1, its chemical composition and mass percentage are as follows: C: 0.02%~0.10%, Si≤0.15%, Mn: 0.80%~2.20%, P≤0.020%, S≤0.0050%, Ni≤0.30%, Nb≤0.070% , Cu≤0.50%, N≤0.0050%, Ti: 0.006%~0.020%, Cr≤0.30%, Al: 0.015%~0.050%, the balance is Fe and impurities;

[0038] S2. The oxygen blowing top-bottom double blowing converter is used for smelting, and the molten steel whose purity meets the requirements is obtained through LF refining treatment and RH vacuum degassing operation;

[0039] S3. CCM pouring adopts full protection pouring, and the superheat of the tundish meets 33°C to ensure smooth pouring and good melting of mold slag. After 48 hours of pile cooling, the billets are inspected;

[0040] S4. The billet that has passed the table inspection is heated by a walking heating furnace, the heating time is 12.1min / cm, the soaking time is 55min, an...

Embodiment 2

[0045] A kind of production method of improving steel plate surface quality that the present embodiment provides, comprises:

[0046]S1, its chemical composition and mass percentage are as follows: C: 0.10%~0.30%, Si≤0.15%, Mn: 0.30%~1.80%, P≤0.020%, S≤0.0050%, Ni≤0.30%, Nb≤0.070% , Cu≤0.50%, N≤0.0050%, Ti: 0.006%~0.020%, Cr≤0.30%, Al: 0.015%~0.050%, the balance is Fe and impurities;

[0047] S2. The oxygen blowing top-bottom double blowing converter is used for smelting, and the molten steel whose purity meets the requirements is obtained through LF refining treatment and RH vacuum degassing operation;

[0048] S3. CCM pouring adopts full-protection pouring, and the superheat of the tundish meets 37°C to ensure smooth pouring and good melting of mold slag. After 48 hours of pile cooling, the billets are inspected;

[0049] S4. The billet that has passed the table inspection is heated by a walking heating furnace, the heating time is 12.6min / cm, the soaking time is 53min, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com