Blind seam shoulder pad sewing machine

A technology for sewing machines and shoulder pads, which is applied in the field of sewing machines to achieve the effects of easy operation, stable process quality, and consistent sewing tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

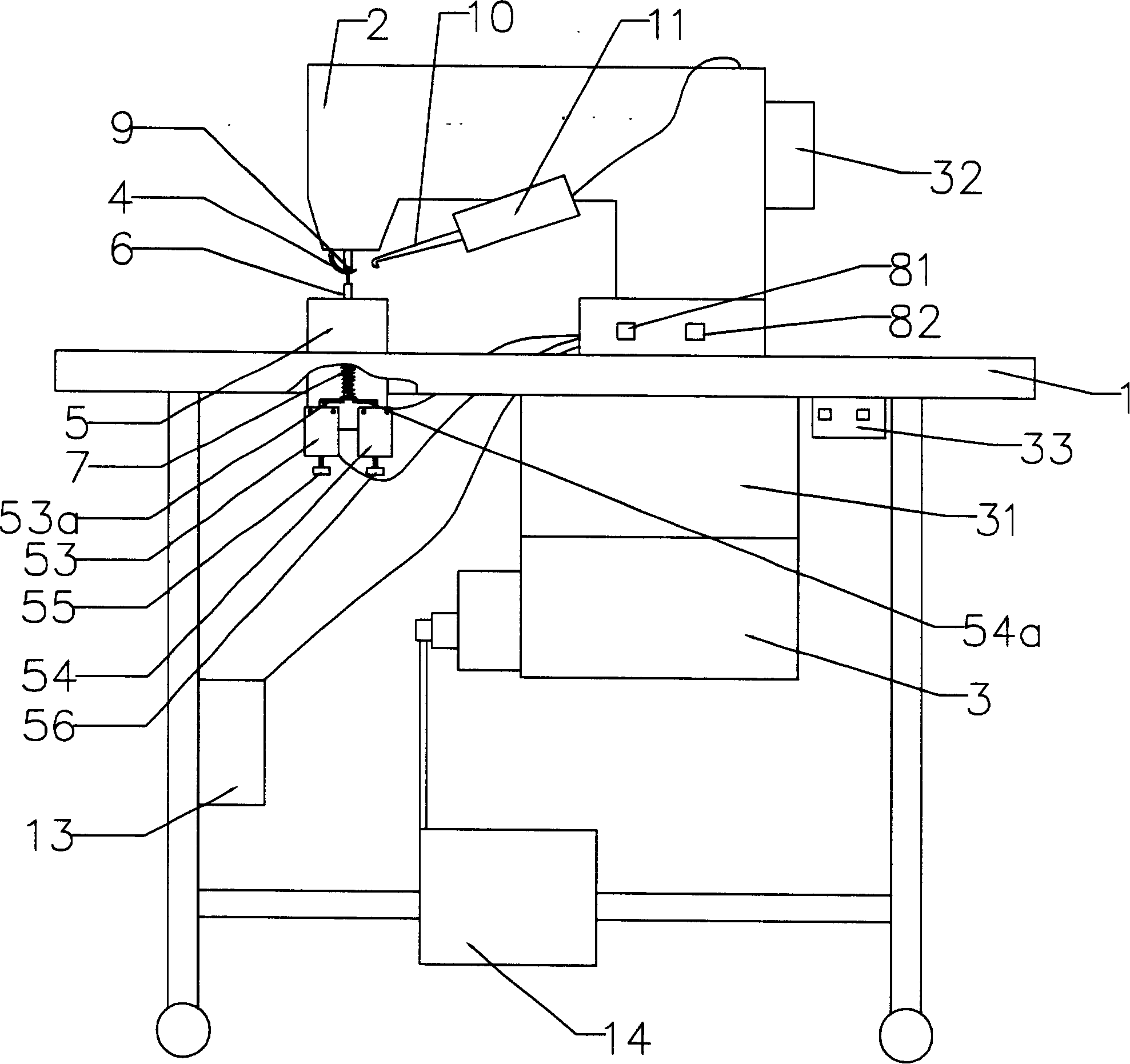

[0021] The machine head in the embodiment of the blind seam shoulder pad sewing machine of the present invention is transformed from a blind seam machine (such as the GL13101-2 type blind seam machine produced by Shanghai Industrial Sewing Machine Factory). The mop mechanism of the blind stitching machine is equipped with a cloth guide plate 9 on the fixed presser foot (the fixed presser foot is also called the needle plate) of the head part. like figure 1 , Figure 5 As shown, it includes a frame 1, a blind stitch machine head 2 installed on the top of the frame 1 and an electrical control device 3 installed on the lower part of the frame for controlling the movement of the needle on the machine head, an electric control switch 33 and an electrical control device 3-phase connection for controlling power on and off. The motor 31 is electrically connected with the electric control device 3, and drives the machine needle 4 on the machine head 2 and the thread take-up fork asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com