Patents

Literature

136results about How to "Elastic fit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

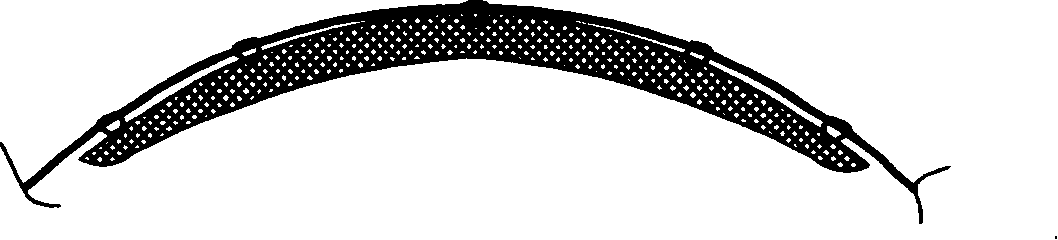

Stabilization device for bones comprising a spring element and manufacturing method for said spring element

ActiveUS20050154390A1Easy to implementElastic fitSuture equipmentsInternal osteosythesisCoil springBiomedical engineering

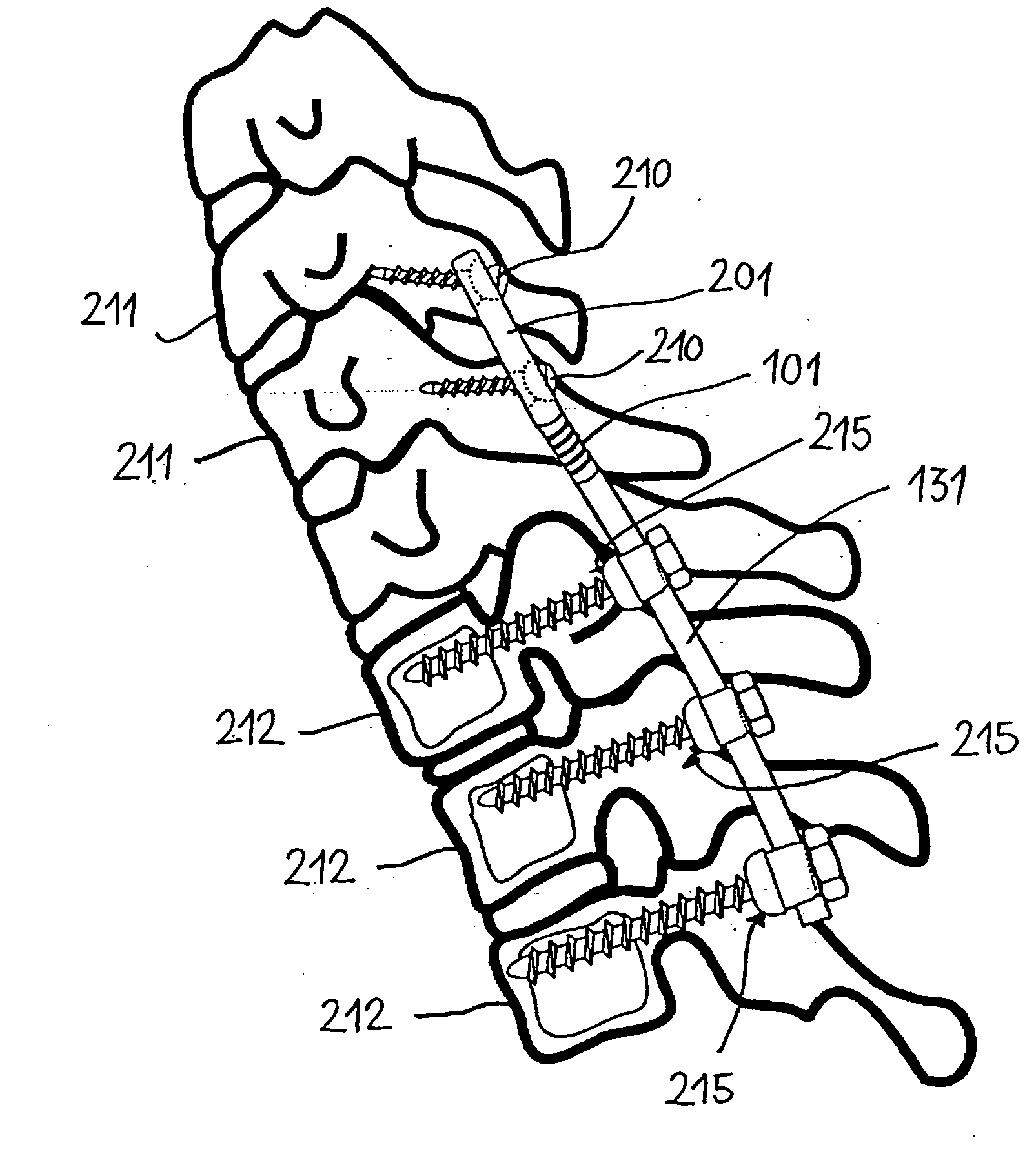

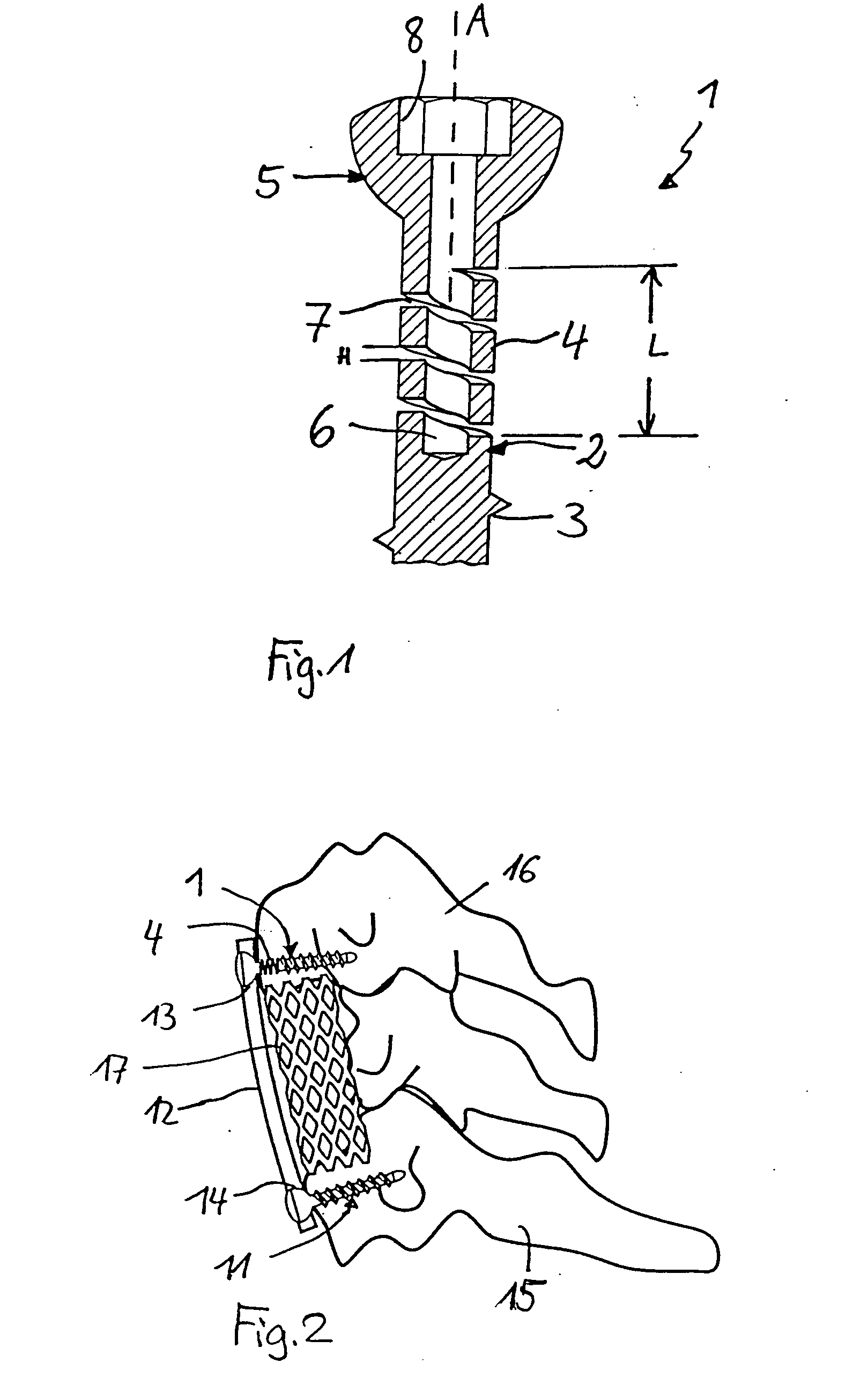

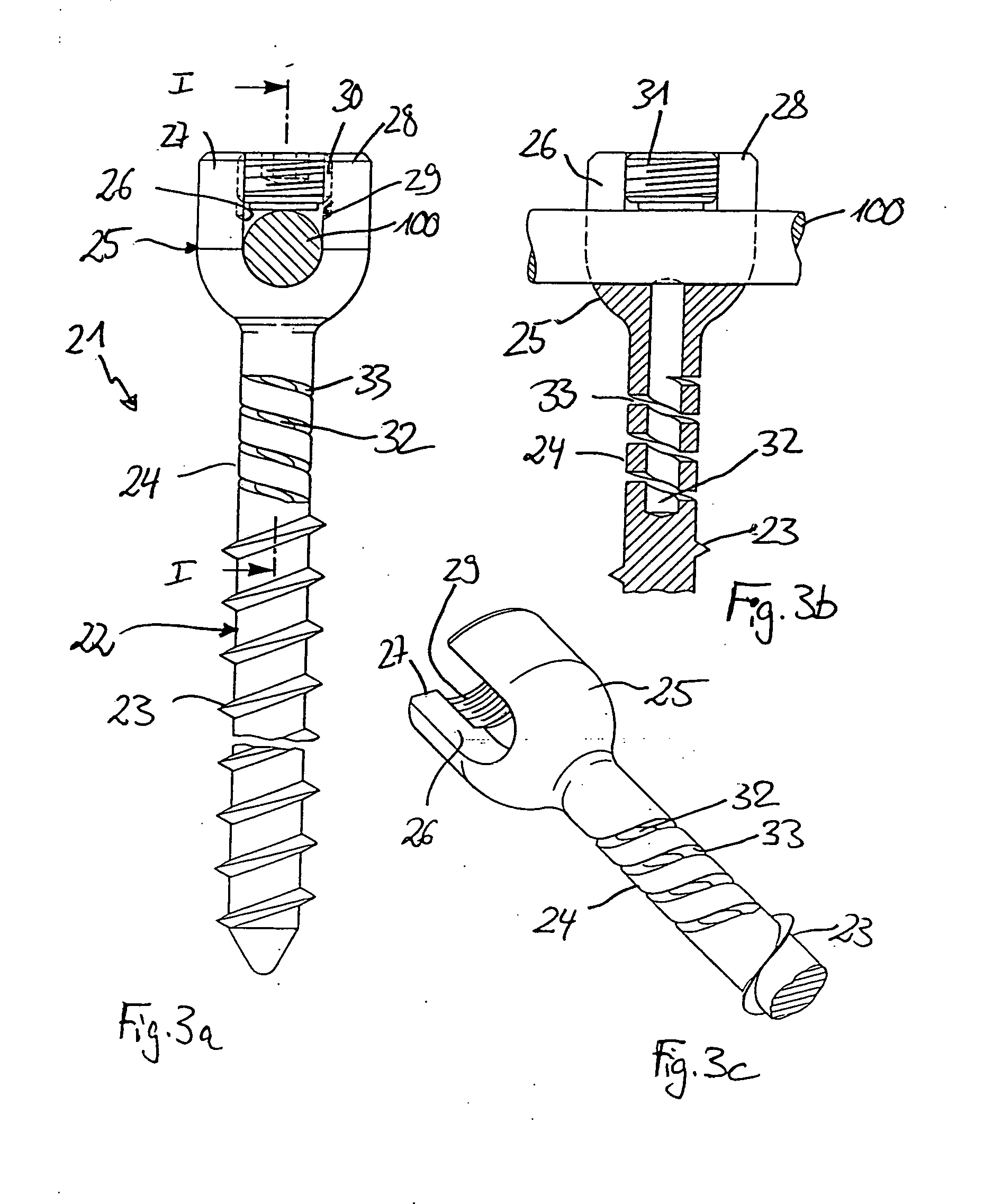

An elastic or flexible element for use in a stabilization device for bones or vertebrae is provided. The elastic or flexible element is provided in the form of an essentially cylindrical body with a first end and a second end opposite thereto, wherein at least one of the opposite ends of the cylindrical body comprises a coaxial bore hole with an internal thread for connecting to a shaft and / or a head of a bone screw or for connecting to a rod section. The present invention further provides a bone anchoring element, e.g. a bone screw, with a shaft for the anchoring in a bone, whereby the shaft comprises an elastic or flexible section which is formed integrally with the shaft or as a separate elastic or flexible element. It is preferable for the elastic section to be implemented in the form of a helical spring. Moreover, the present invention provides a stabilization device for bones, for instance for vertebrae, said device comprising at least one bone anchoring element according to the invention, a second bone anchoring element and a rod or plate connecting the bone anchoring elements.

Owner:BIEDERMANN TECH GMBH & CO KG

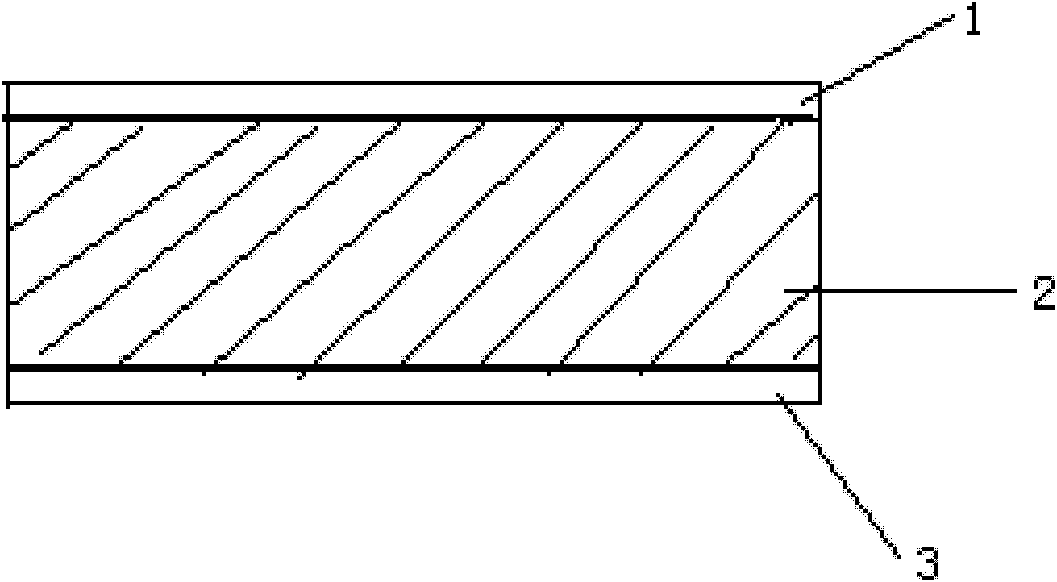

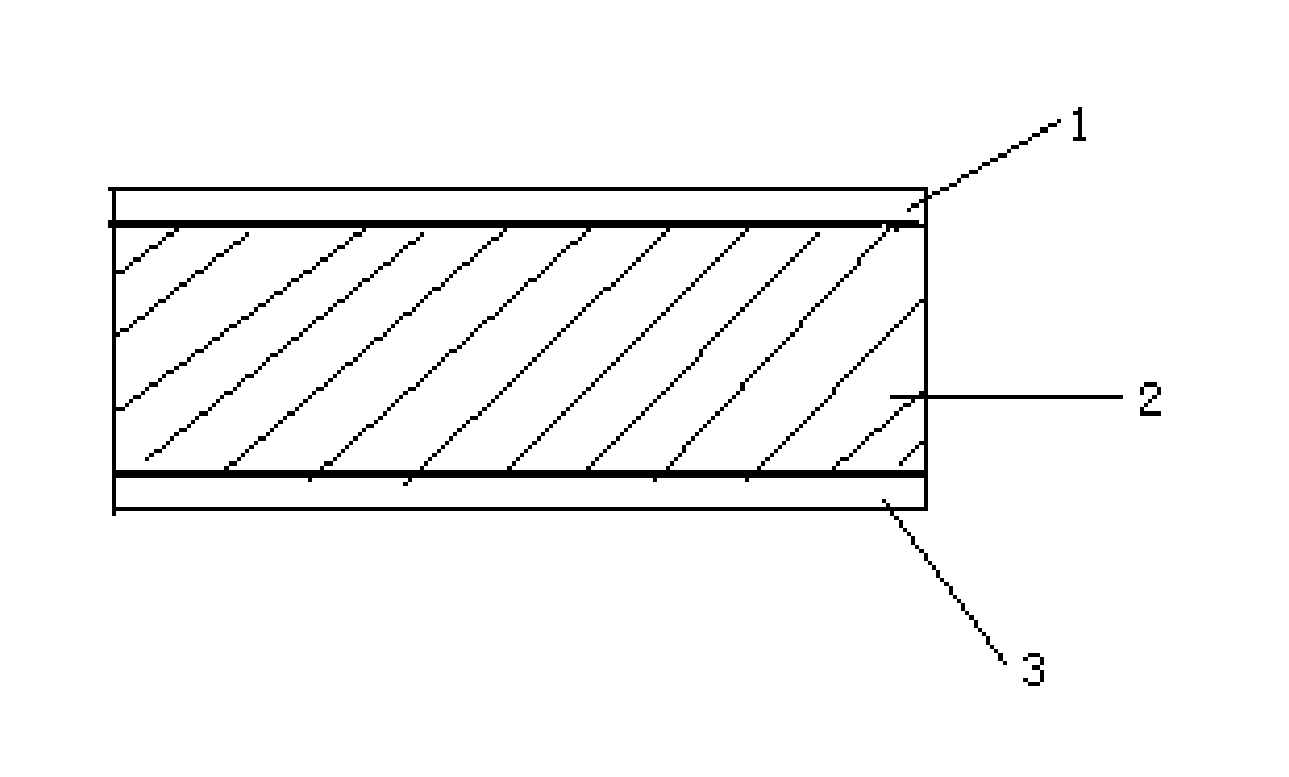

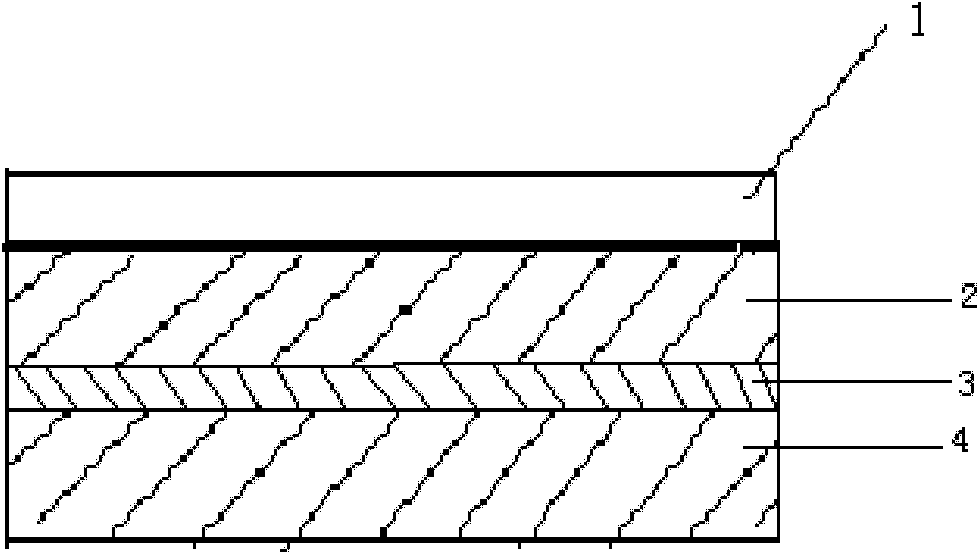

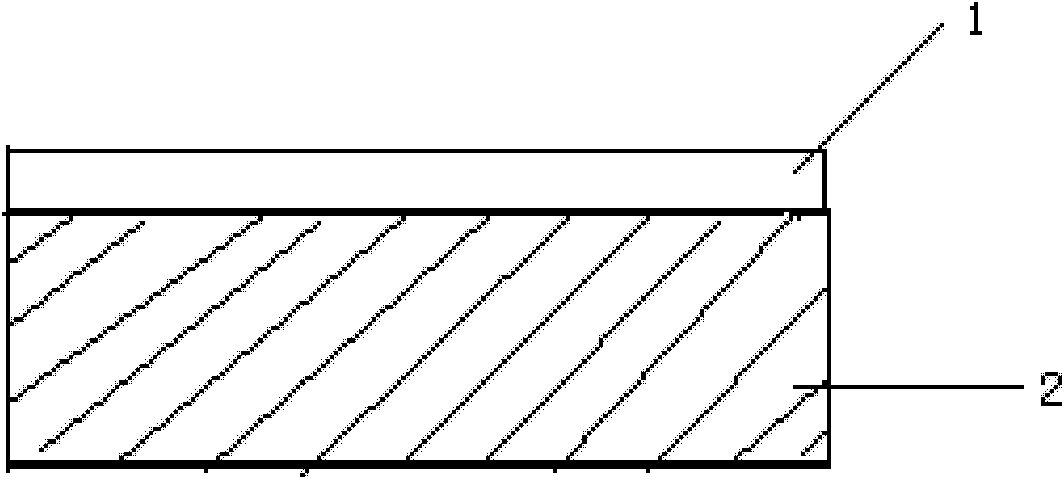

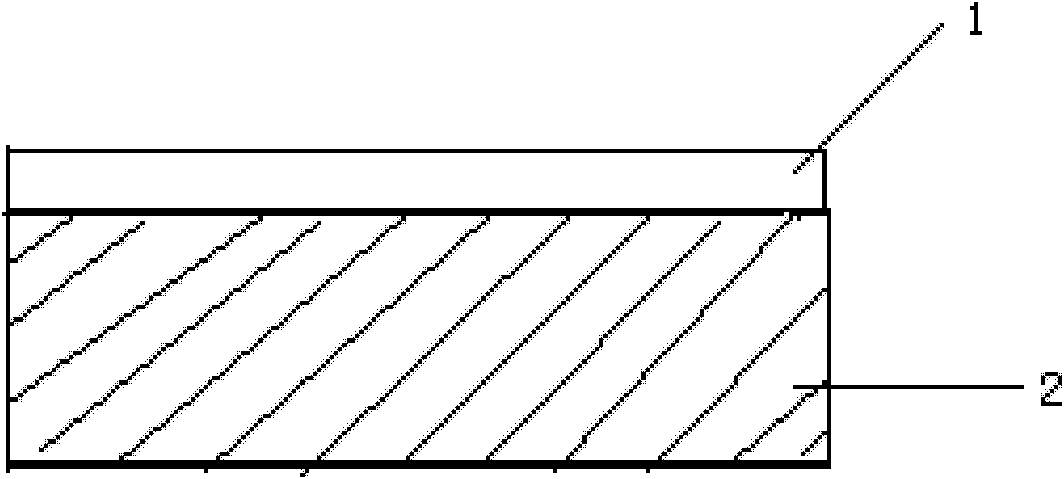

Universal health-care board and preparation method thereof

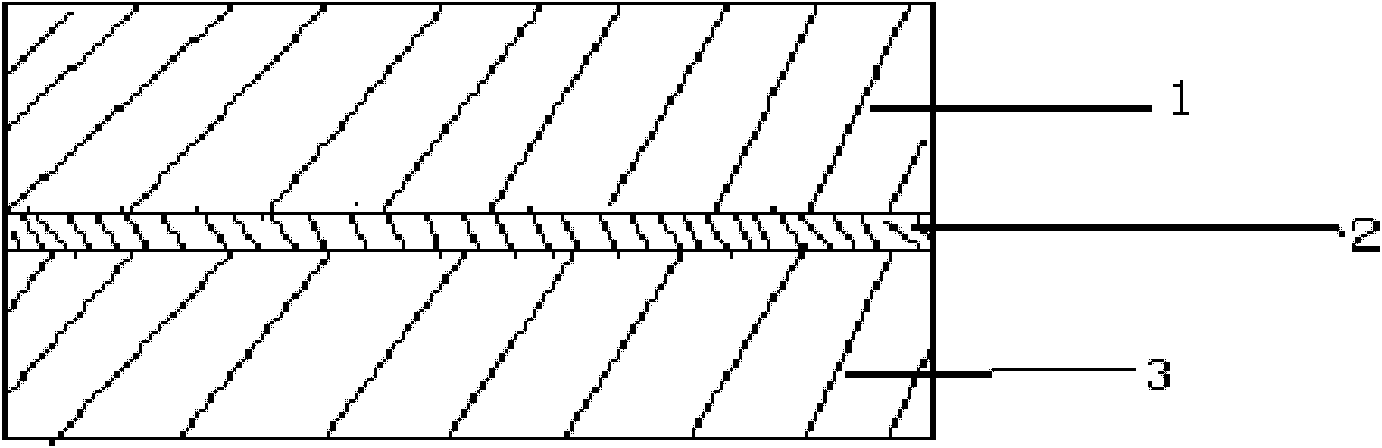

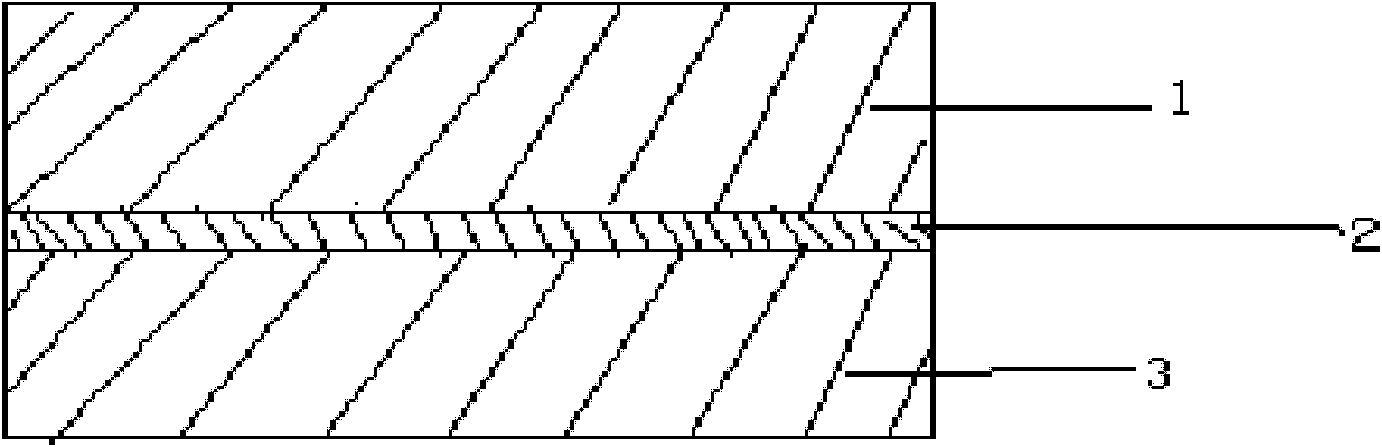

ActiveCN102514254AGood elastic recoveryGood strength and elasticityStuffed mattressesLamination ancillary operationsFiberSurface layer

Owner:JIANGSU REDBUD DYEING TECH CO LTD

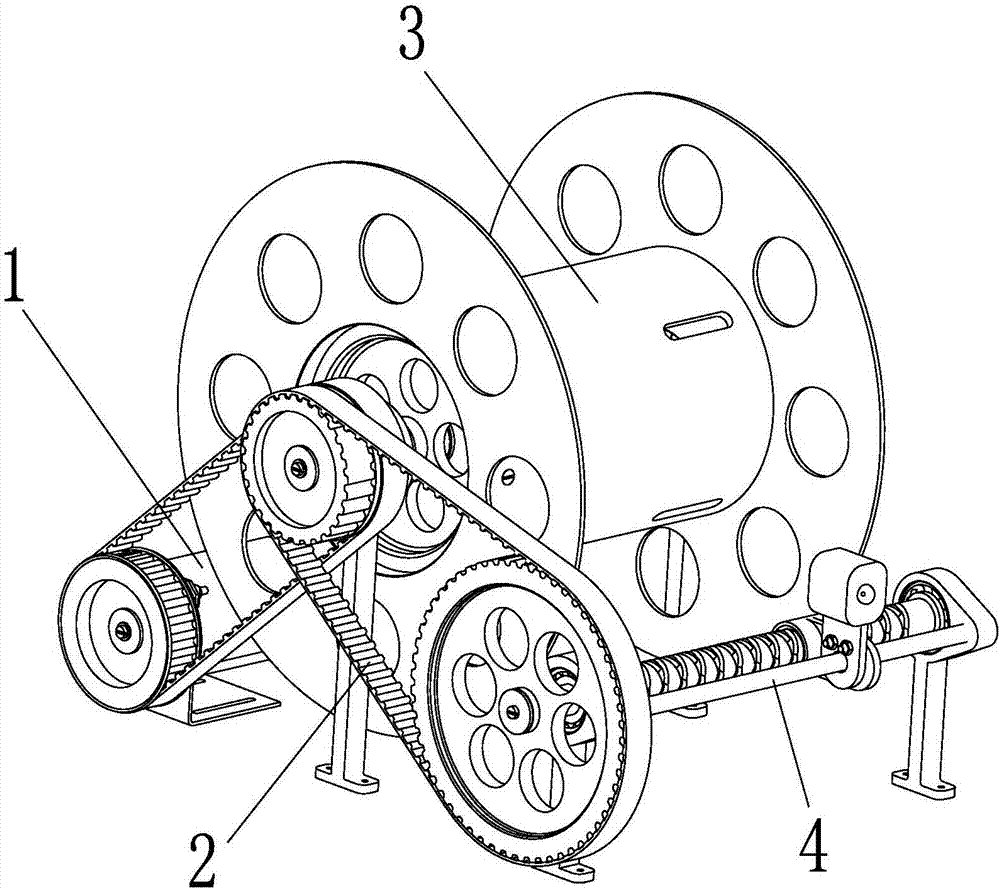

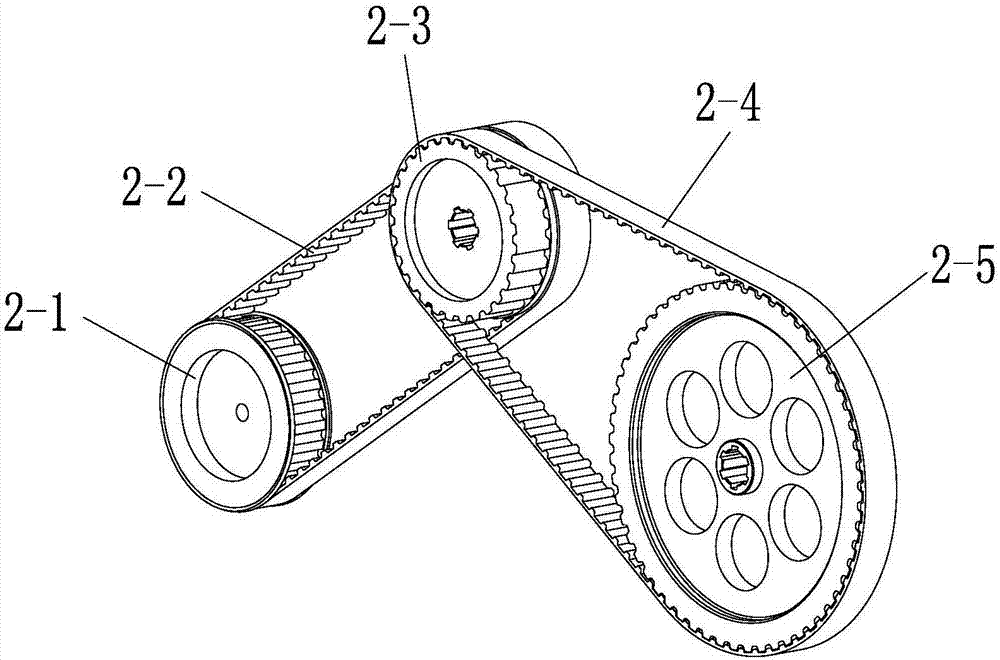

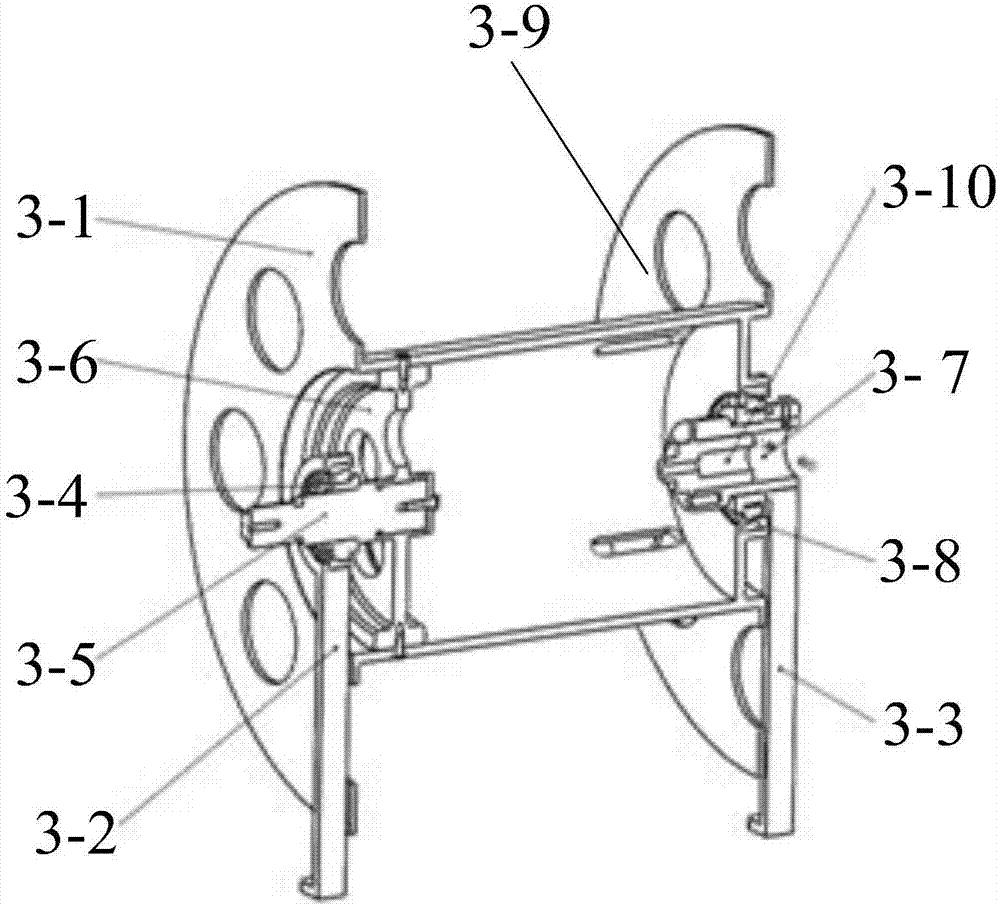

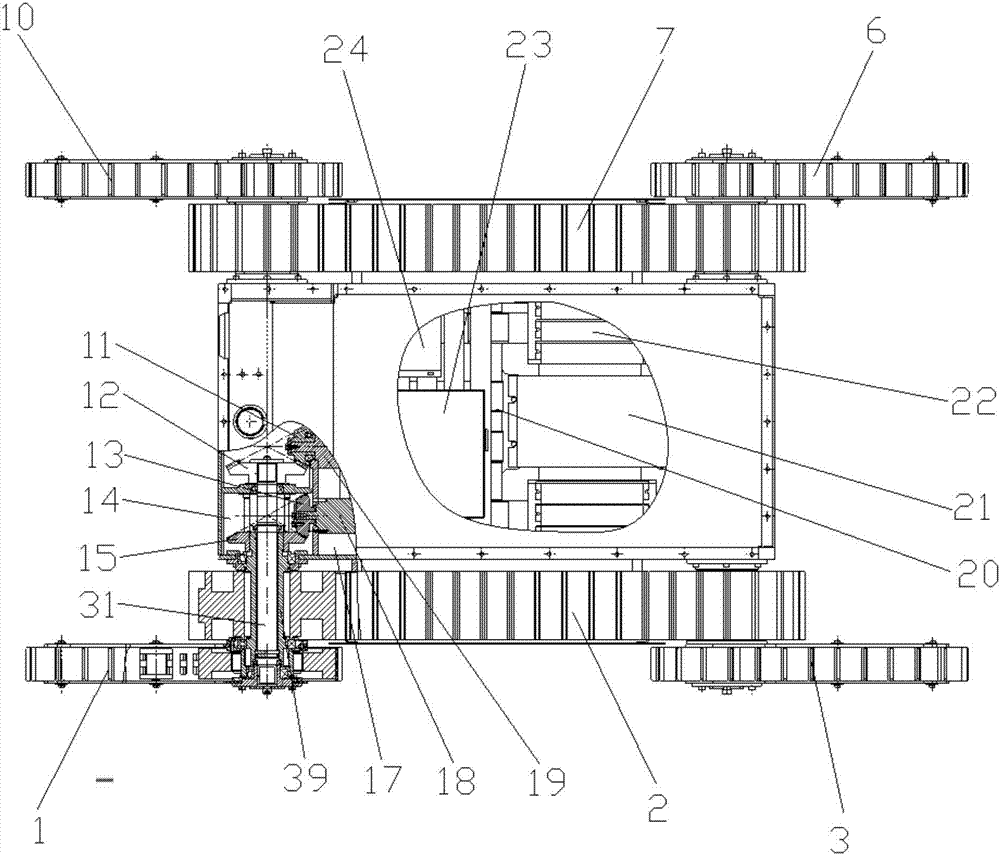

Cable taking-up and paying-off device and cable taking-up and paying-off method for wire control robot

ActiveCN107187960AStable and reliable cable releaseStable and reliable collectionOptical axisEngineering

The invention discloses a cable taking-up and paying-off device for a wire control robot. The cable taking-up and paying-off device for the wire control robot comprises a synchronous belt transmission mechanism, a cable winding mechanism, a cable arranging mechanism and a cable taking-up and paying-off motor. The synchronous belt transmission mechanism comprises a main driving synchronous belt wheel, a winding drum driving synchronous belt wheel, a lead screw driving synchronous belt wheel, a winding drum driving synchronous belt and a lead screw driving synchronous belt. The cable winding mechanism comprises a winding drum, a first winding drum support, a second winding drum support, a first winding drum bearing, a winding drum driving shaft, a winding drum driving wheel, a second winding drum bearing, a winding drum supporting shaft and a winding drum follower wheel. The cable arranging mechanism comprises a bidirectional lead screw, a first lead screw support, a second lead screw support, a first lead screw bearing, a second lead screw bearing, a lead screw sliding block, an unthreaded shaft and a cable guiding block. The invention further discloses a cable taking-up and paying-off method of the cable taking-up and paying-off device for the wire control robot. According to the cable taking-up and paying-off device and cable taking-up and paying-off method for the wire control robot, a cable can be taken up and paid off in order, the tightness is proper, the stability and effectiveness are good, the probability of intertwining and breaking of the cable is lowered, the practicability is high, and using and popularization are convenient.

Owner:XIAN UNIV OF SCI & TECH

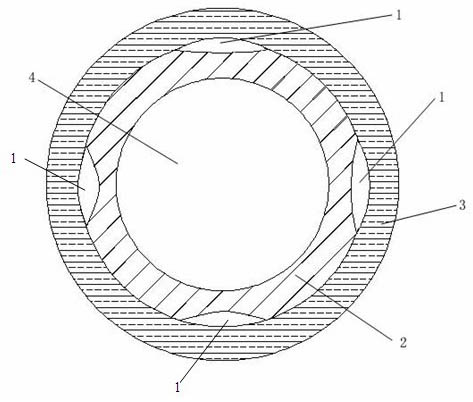

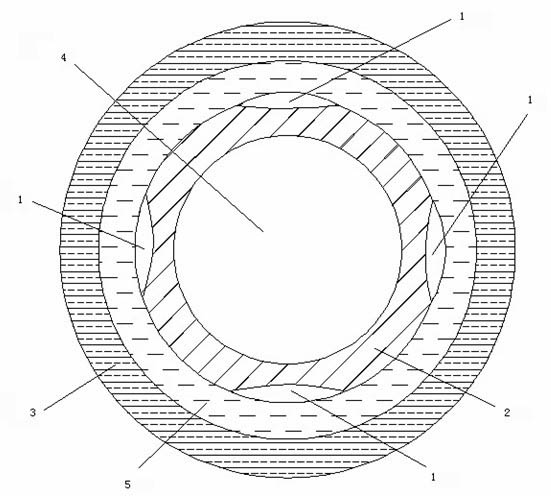

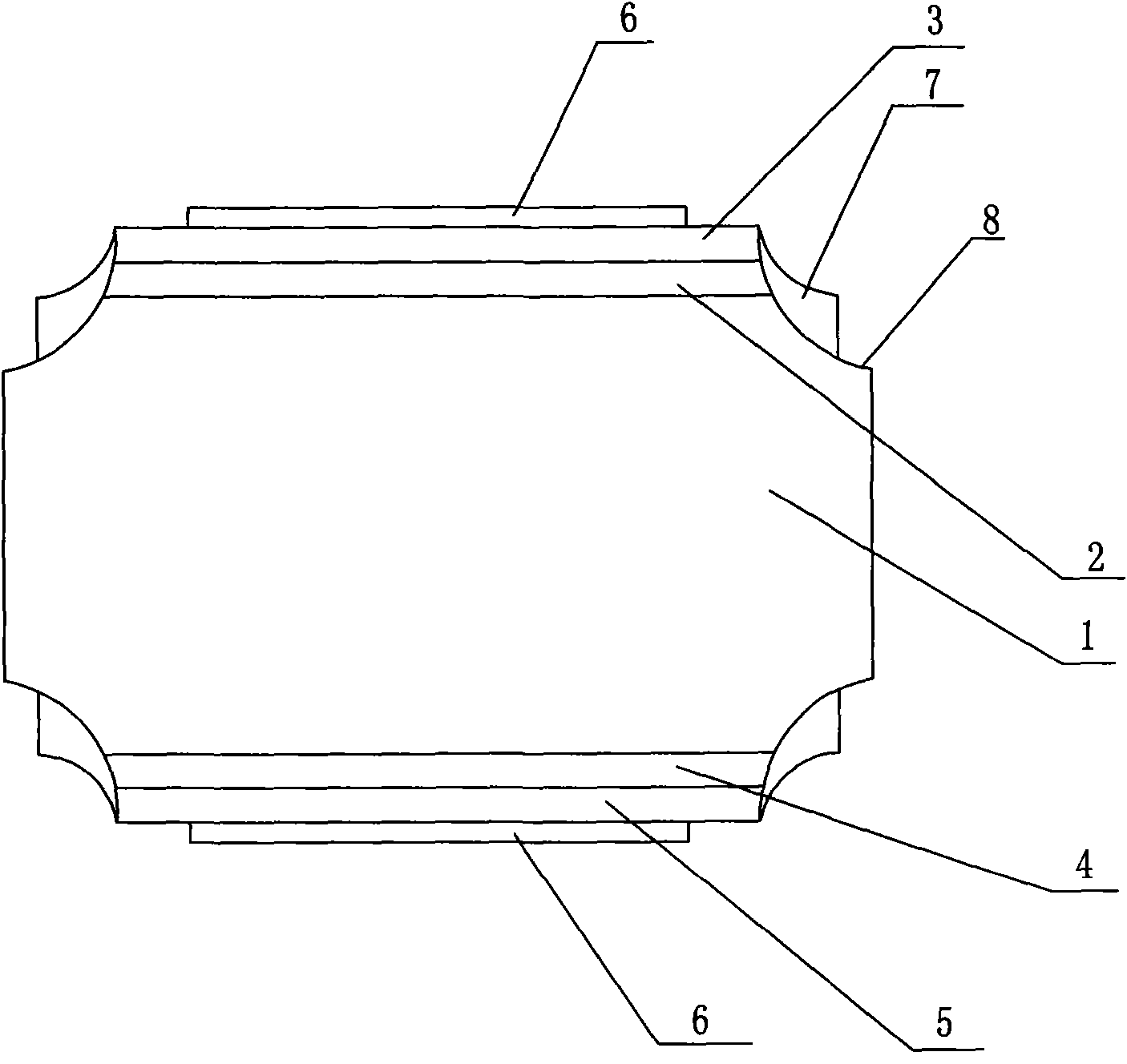

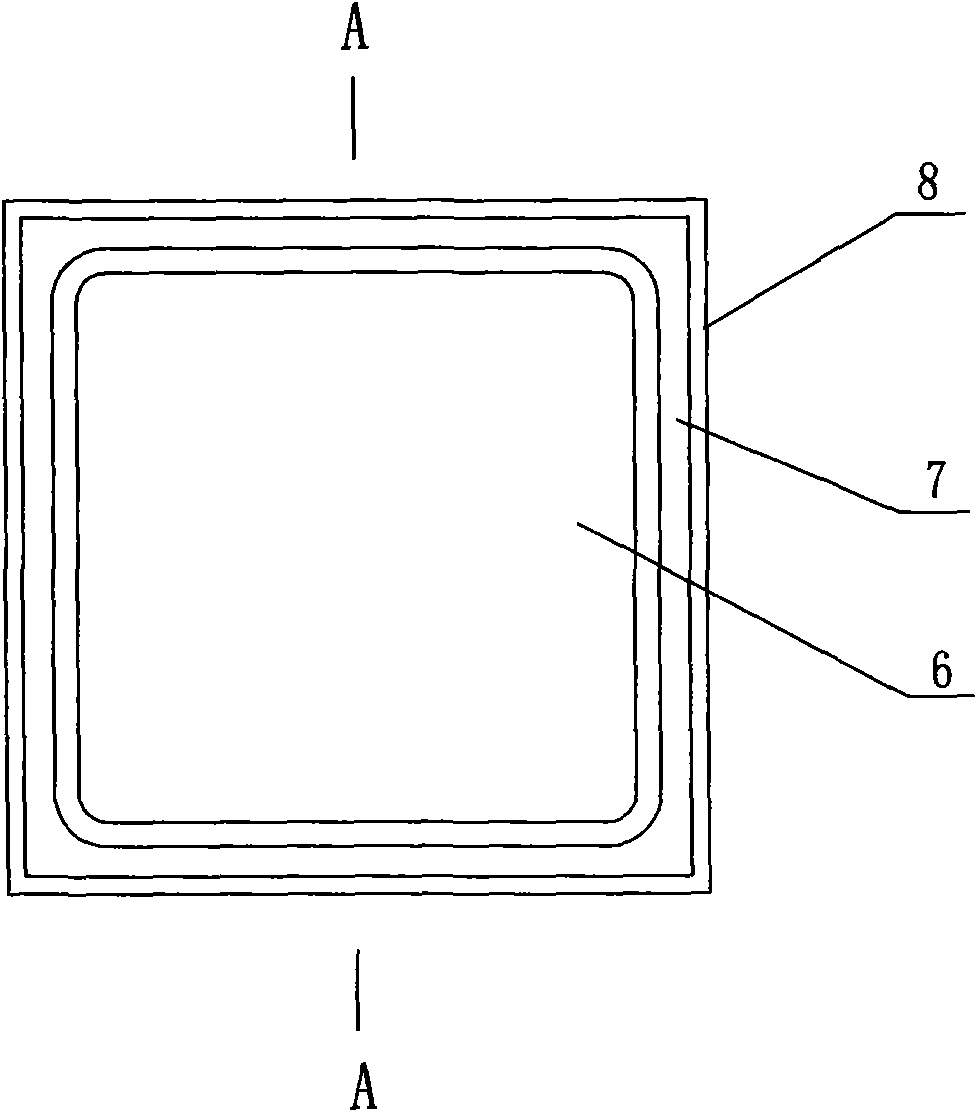

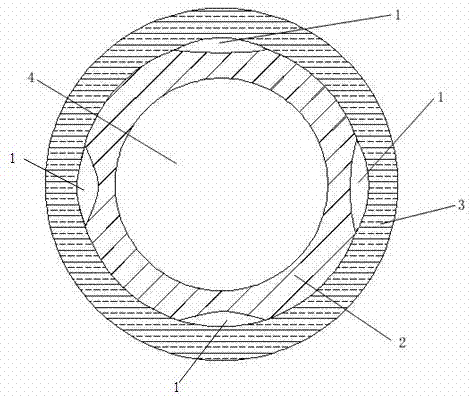

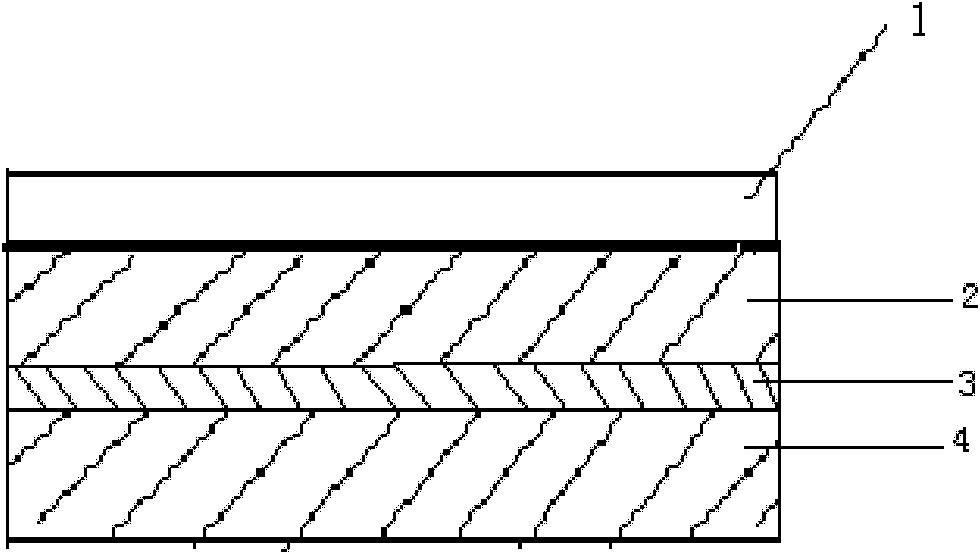

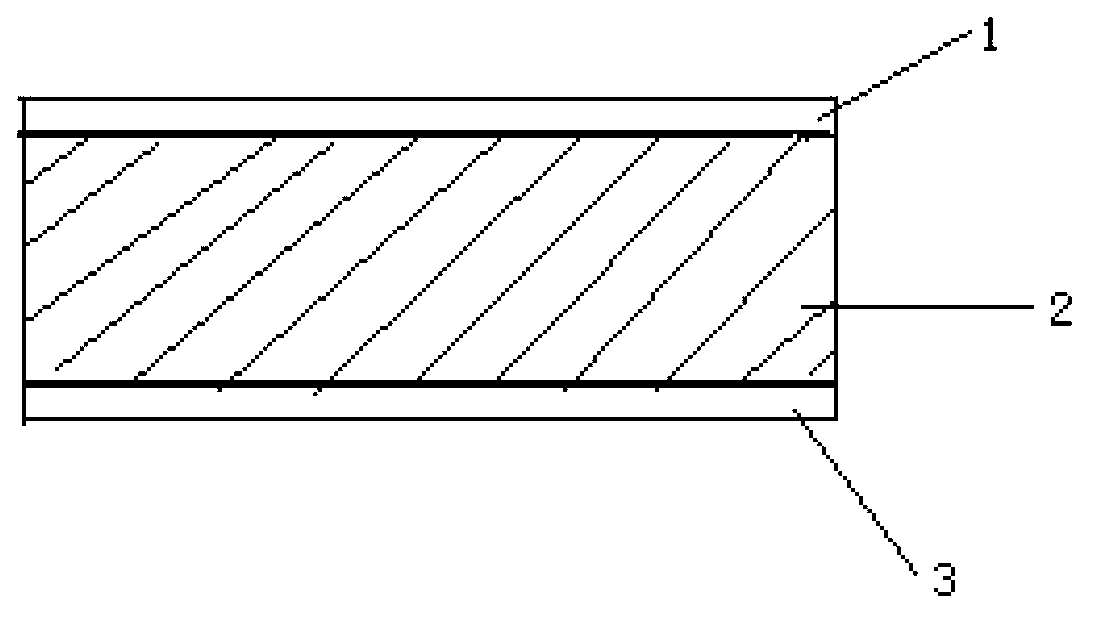

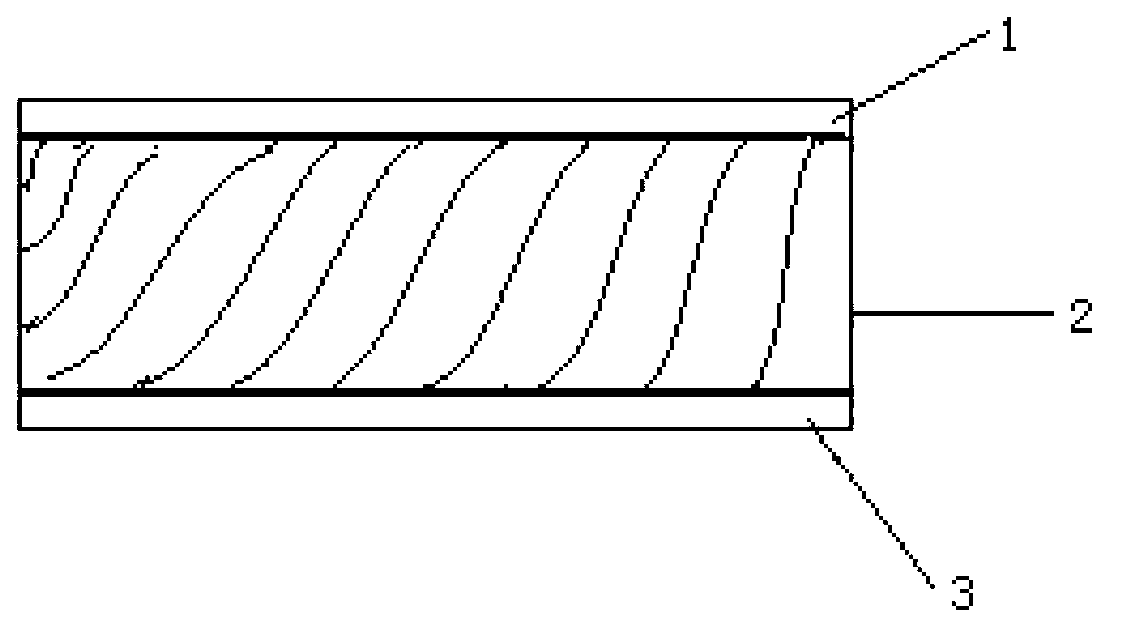

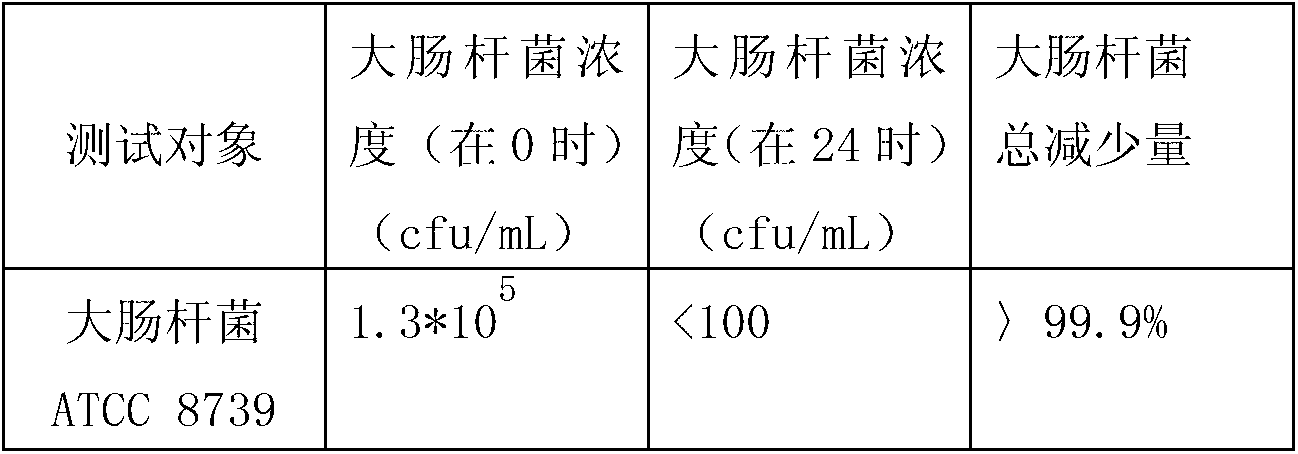

Nerve conduit and preparation method thereof

ActiveCN102688076AAddress barriers to developmentModerate intensitySurgeryCatheterCatheterNerve repair

The invention discloses a nerve conduit and a preparation method thereof. The nerve conduit consists of an inner layer, an outer layer and at least one minitype cavity for storing a bioactive factor solution, wherein the inner layer is of a hydrophilic cell scaffold layer, and the outer layer is of a hydrophobic nerve conduit scaffold layer. The nerve conduit can further comprise a transition layer between the inner layer and the outer layer. The preparation method of the nerve conduit comprises the steps of preparing the inner layer by adopting an electrostatic spinning method, then adding the material for preparing the cavity, then preparing the outer layer, and taking out or dissolving the material for preparing the cavity, thus obtaining the nerve conduit. The nerve conduit has the minitype cavity, so that bioactive factors can be loaded by a manner of injection, soaking and the like as required before operation, thus not only leading the production quality to be easily controlled, but also being capable of greatly improving the survival rate of the bioactive factors, more efficiently promoting the regeneration of nerves, and enhancing the restoration effect of nerves.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

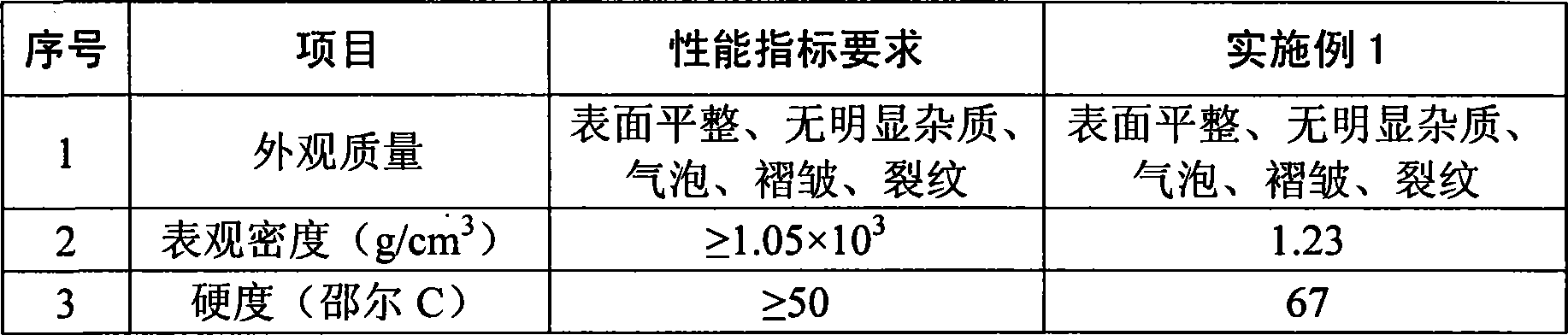

Molded normal temperature curing urethane resin composition and preparation method thereof

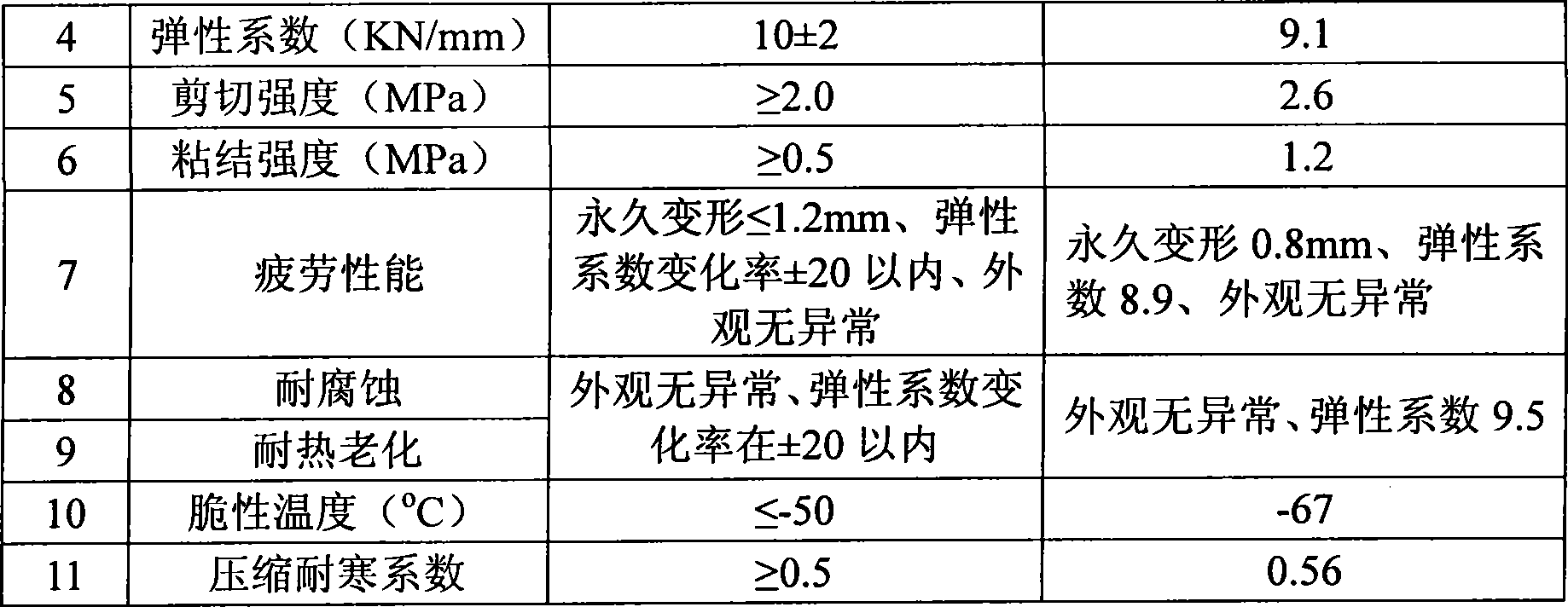

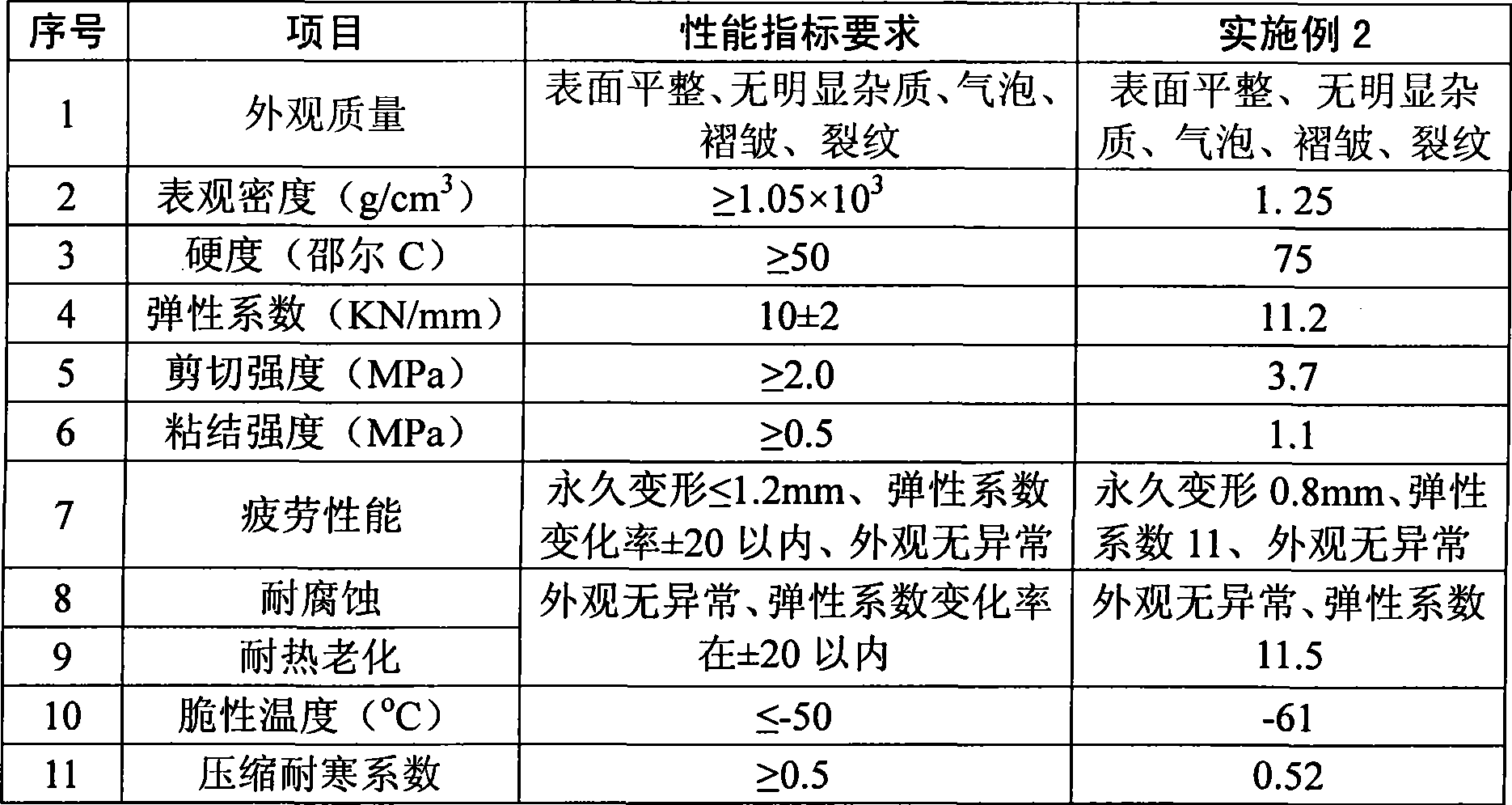

The invention discloses molded normal temperature curing urethane resin composition and a preparation method thereof. The compound comprises A type substance and B type substance which are packed independently, wherein the A type substance comprises prepolymer prepared by polymer polylol and isocyanate, carbon soot, filling, ultraviolet light absorbing agent, chemical inhibitor, wetting agent, deicer, foam suppressor, coupling agent and plasticizer; the B type substance is chain extendor; and the ratio of the quantity of active functional group substance of the B type substance to the quantity of active functional group substance of the A type substance is 0.8-1.0. The preparation method comprises the following steps: preparing and cooling the prepolymer capped by the isocyanate for reservation; preparing the A type substance; directly packing the chain extendor or packing the chain extendor after being diluted to be used as the B type substance; evenly mixing the measured A and B types of substances and maintaining the mixture under normal temperature to obtain the molded normal temperature curing urethane resin composition. The molded normal temperature curing urethane resin composition has good constructional processing property and is easy and convenient to prepare.

Owner:胡旻辉

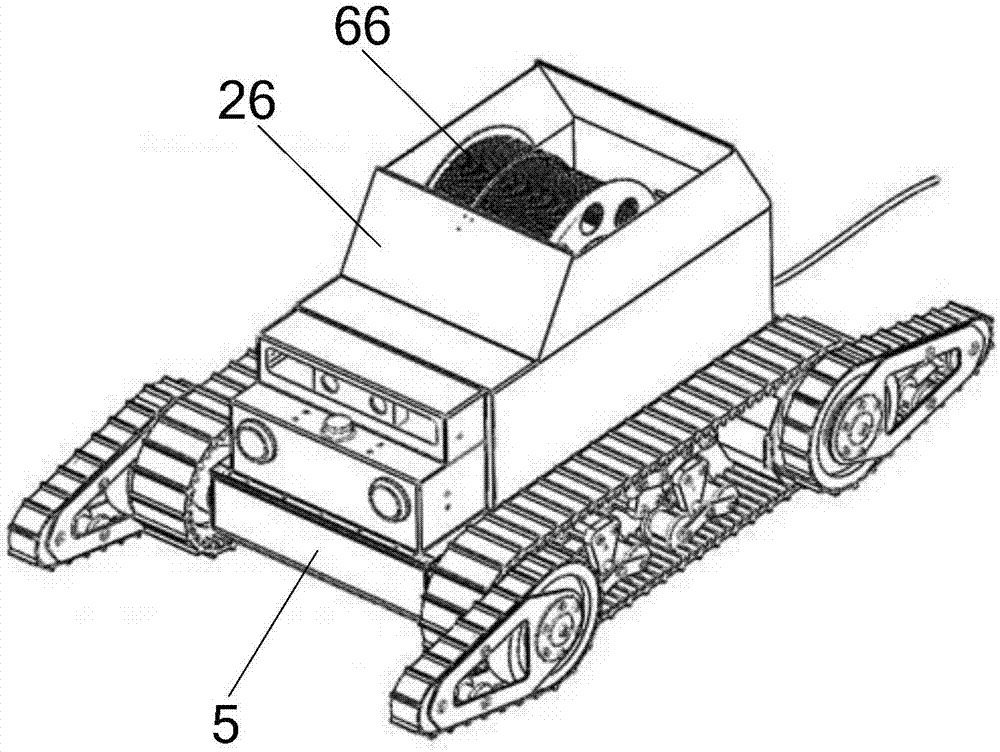

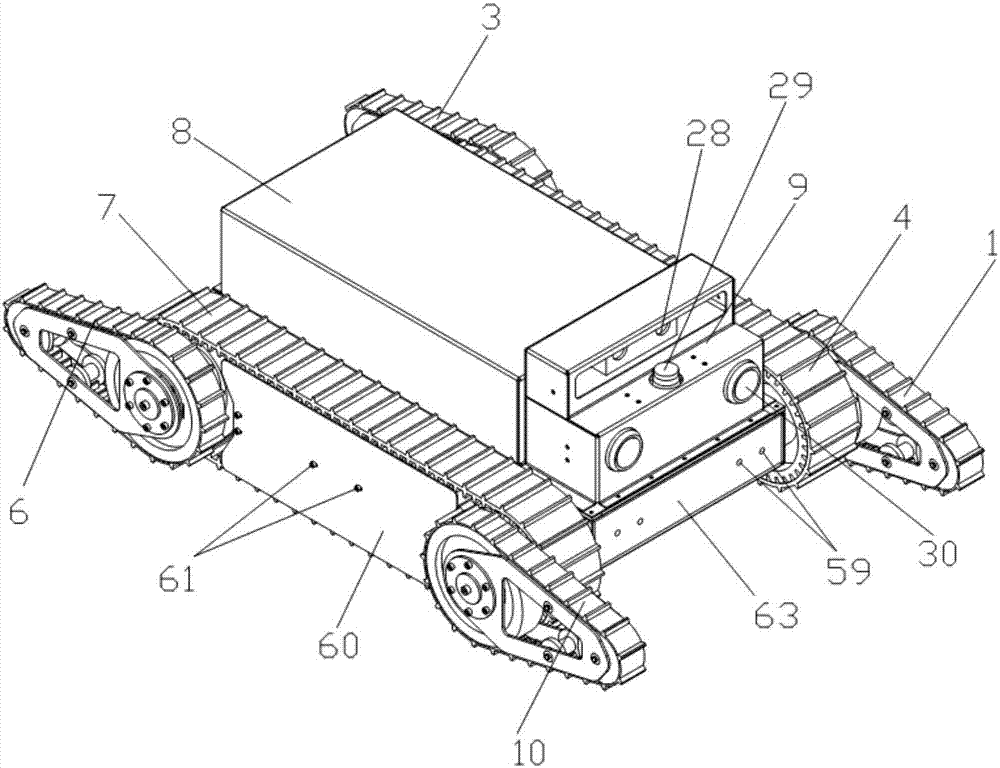

Wire-control coalmine rescue detection robot and cable extension and retraction method thereof

ActiveCN107139159ACompact structureNovel and reasonable designManipulatorControl signalControl theory

The invention discloses a wire-control coalmine rescue detection robot and a cable extension and retraction method thereof. The wire-control coalmine rescue detection robot comprises a robot body and a cable extension and retraction box arranged at the top of the robot body. A cable extension and retraction device is arranged in the cable extension and retraction box. The robot body comprise a robot body cabinet, two travelling track assemblies and four swinging arm track assemblies. The robot body cabinet comprises a lower cabinet cavity, an upper cabinet cavity, a sensor cavity, three gear cavities and two supporting wheel cavities. The cable extension and retraction device comprises a cable extension and retraction motor, a synchronous belt transmission mechanism connected with an output shaft of the cable extension and retraction motor, and a cable winding mechanism and a cable arranging mechanism which are both connected with the synchronous belt transmission mechanism. The cable extension and retraction method of the wire-control coalmine rescue detection robot comprises the steps of cable connection and cable extension and retraction. By adoption of the wire-control coalmine rescue detection robot and the cable extension and retraction method thereof, cables are extended and retracted in order and are appropriate in degree of tightness, cable entanglement and breaking are reduced, and stable transmission of control signals, relevant sensor information and a power supply can be guaranteed.

Owner:XIAN UNIV OF SCI & TECH

Bidirectional trigger diode chip production method

ActiveCN101651102ASuit one's needsAvoid stressSemiconductor/solid-state device manufacturingSemiconductor devicesManufacturing technologySemiconductor

The invention discloses a bidirectional trigger diode chip production method, belonging to the filed of the semiconductor device production technology. The independent bidirectional trigger diode chipis produced according to the following processing steps of silicon slice cleaning, first-time diffusing, second-time cleaning, second-time diffusing, first-time photoetching, table-top forming, glasspassivating, second-time photoetching, two-surface coating, third-time photoetching, fourth-time photoetching and final scribing. The breakdown voltage of the bidirectional trigger diode chip can beadjusted in a large range according to the requirement of the user; the bidirectional trigger diode chip can be packaged in various ways so as to meet the requirements of different users and circuits;the reliability of the bidirectional trigger diode chip is improved due to the fourth-time photoetching process; and the bidirectional trigger diode chip can be used for the production of the four-inch silicon slice so that the production efficiency of the four-inch silicon slice is improved and the finished product ratio is high.

Owner:NANTONG MINICHIP MICRO ELECTRONICS

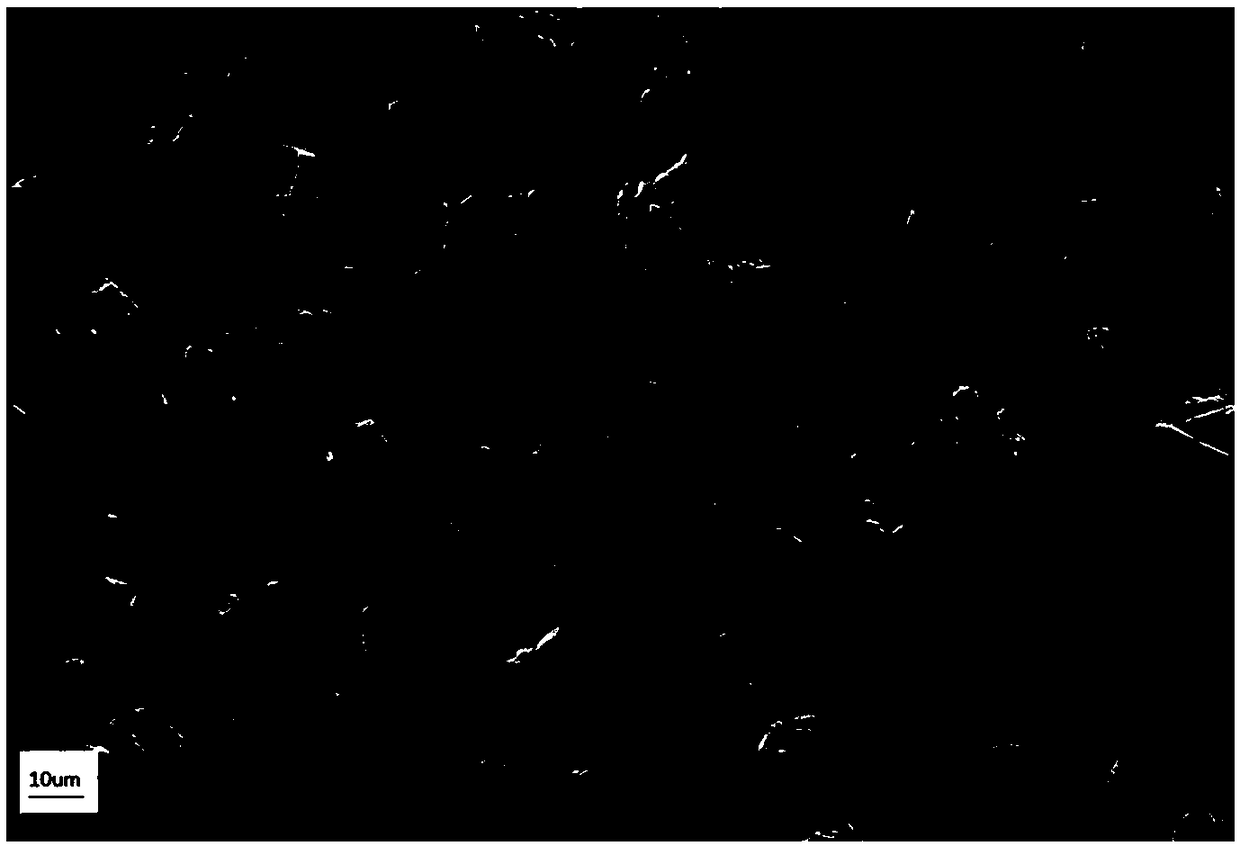

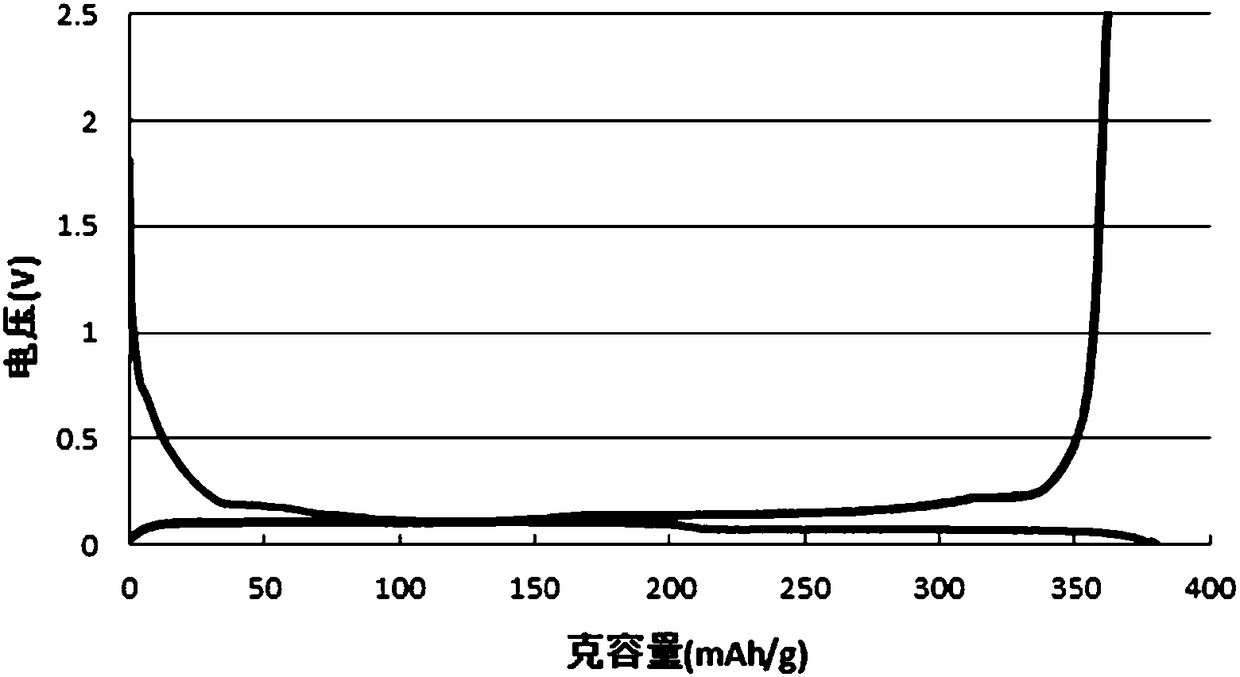

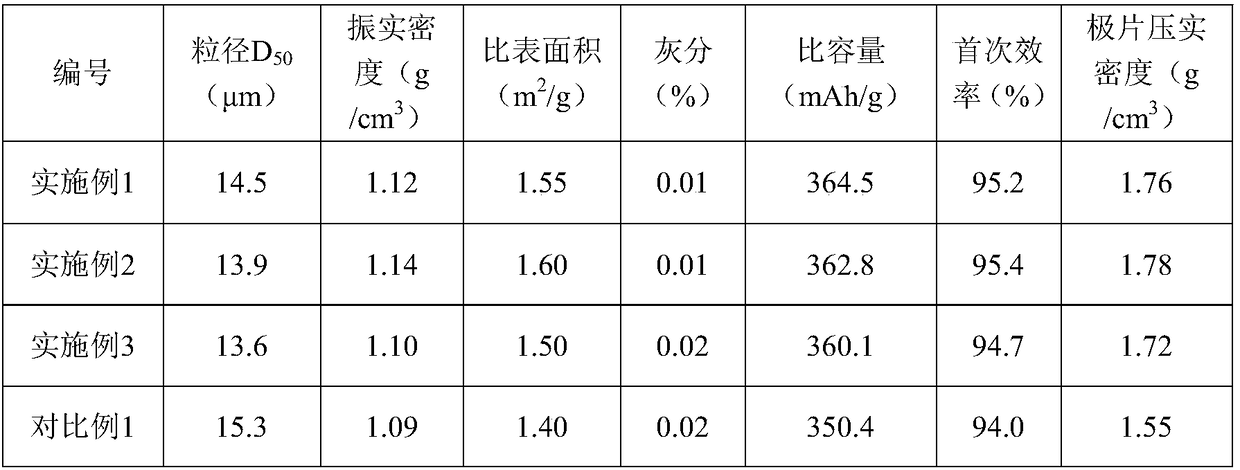

High-capacity and high-compaction artificial graphite negative electrode material, preparation method thereof and lithium ion battery

InactiveCN108550850AIncrease compaction densitySolve the problem of easy overvoltageCell electrodesSecondary cellsMixed materialsGraphite

The invention relates to a high-capacity and high-compaction artificial graphite negative electrode material, a preparation method thereof and a lithium ion battery. The preparation method comprises the steps of selecting at least two of pitch coke, petroleum coke and needle coke as graphite raw materials, and uniformly mixing with a coating agent to obtain a mixed material; and performing graphitization on the mixed material at 3,000-3,300 DEG C under a protection atmosphere to obtain the high-capacity and high-compaction artificial graphite negative electrode material. According to the preparation method of the high-capacity and high-compaction artificial graphite negative electrode material, the problem that the material is easy to press excessively due to inappropriate selection of theraw material cokes is solved by selection and matching of raw material cokes with different hardness, and the prepared graphite negative electrode material has appropriate hardness and rebound rate.A pole plate prepared from the artificial graphite negative electrode material is high in compaction density, an electrolyte is rapidly immersed, and the electrochemical performance of the lithium ionbattery is prolonged.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG +1

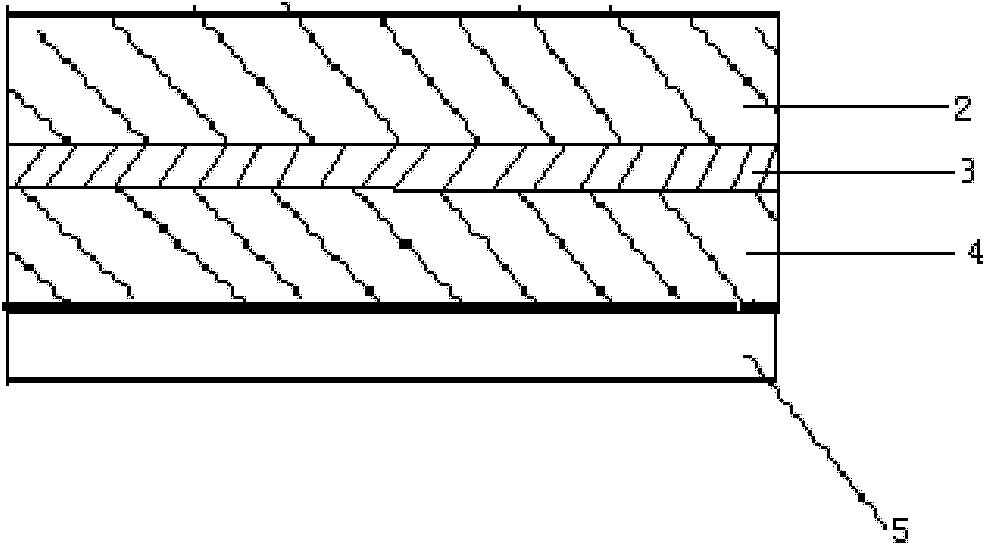

Nerve conduit and preparation method thereof

The invention discloses a nerve conduit and a preparation method thereof. The nerve conduit comprises an inner layer, a transition layer, an outer layer and at least one cavity used for storing a bioactive factor solution, wherein the outer surface of the inner layer is sequentially coated with the transition layer and the outer layer; the cavity is positioned between the inner surface of the outer layer and the outer surface of the transition layer and / or between the outer surface of the inner layer and the inner surface of the transition layer; the inner layer is a hydrophilic cytoskeleton layer made by adopting an electrostatic spinning method; and the outer layer is a hydrophobic nerve conduit scaffold layer made by adopting the electrostatic spinning method. The nerve conduit can be used for loading bioactive factors before an operation in a required mode, such as injection, soaking and the like due to the miniature cavity, so that the production quality of the product is easy to control, the survival rate of the bioactive factor can be greatly improved, the nerve regeneration can be promoted in high efficiency, and the nerve repairing effect can be reinforced.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

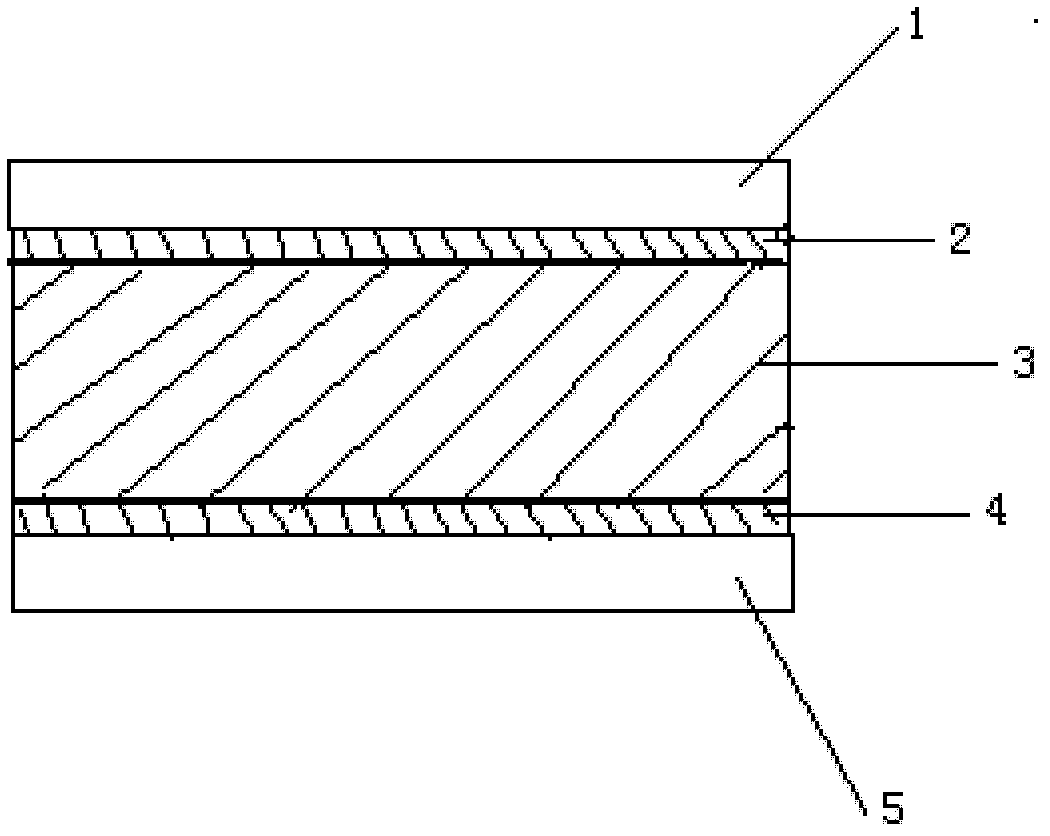

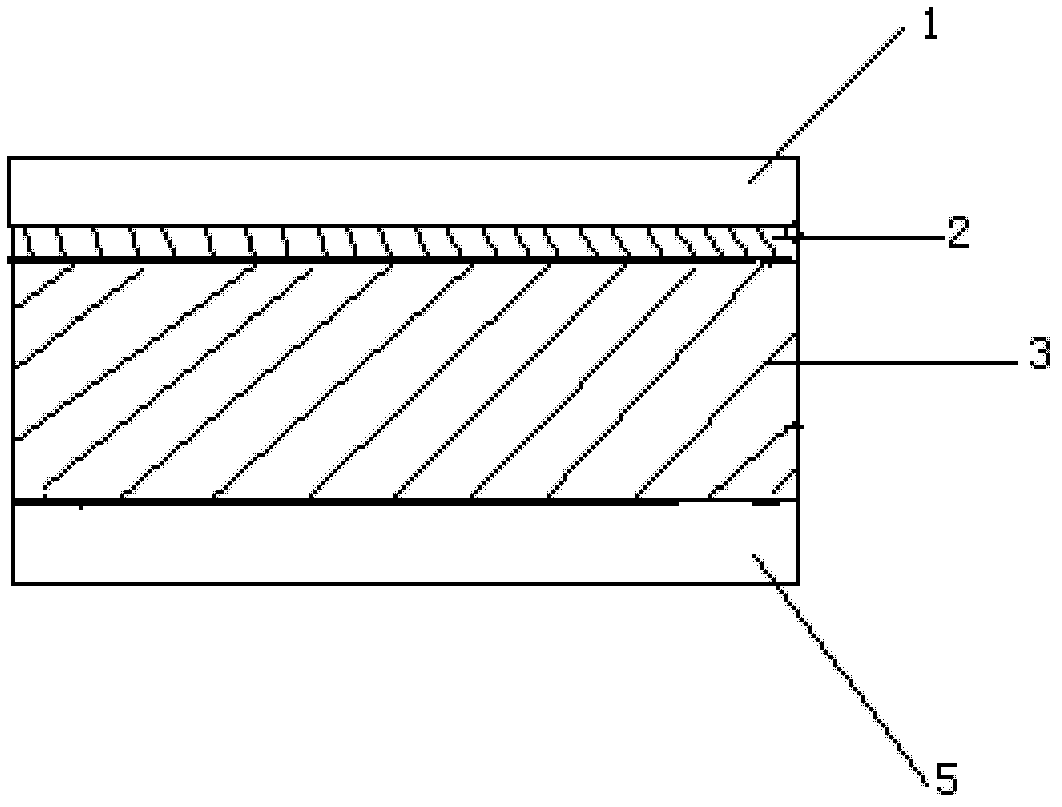

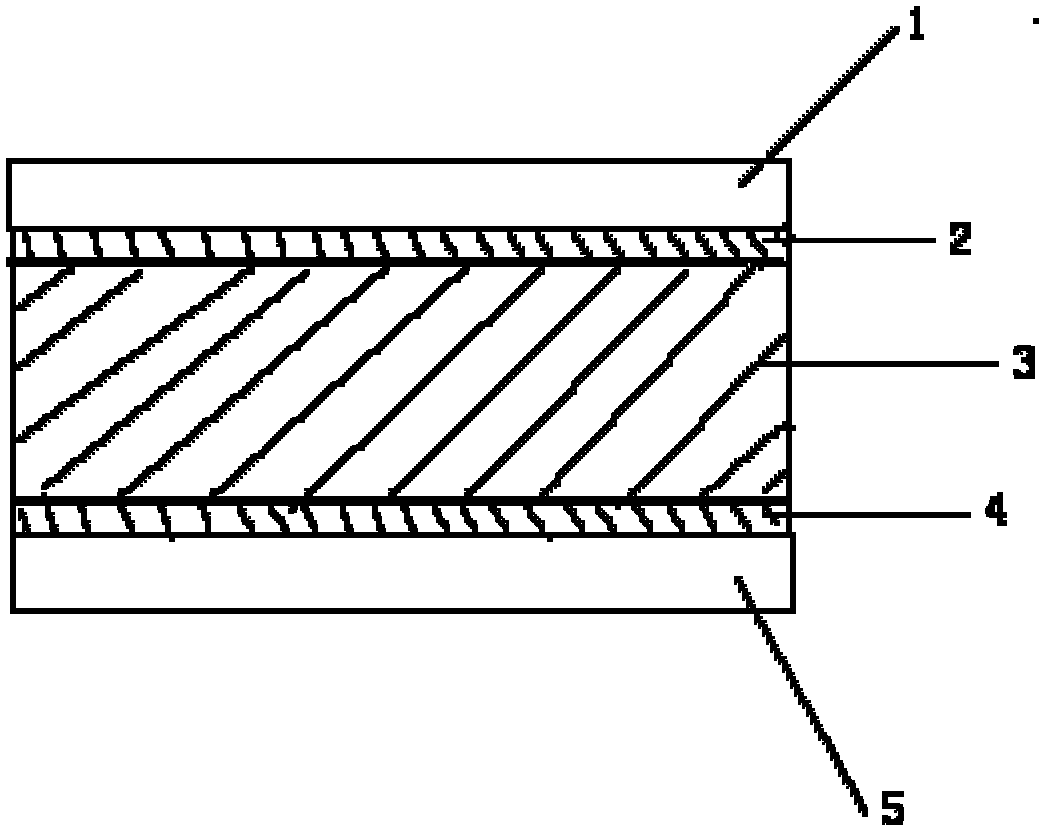

Tatami bed core and preparation method thereof

InactiveCN103054382AGood against insectsGood antibacterialStuffed mattressesSpring mattressesHemp fiberSurface layer

The invention discloses a tatami bed core. The tatami bed core comprises at least one middle layer and a surface layer which is arranged on the upper surface or the lower surface of the middle layer, wherein the surface layer is a non-woven layer which comprises the following components in percentage by weight: 15-40% of low melting point fibers and 60-85% of raw bamboo fibers and / or hemp fibers; and the middle layer comprises the following components in percentage by weight: 5-85% of alpinia fibers, 15-40% of low melting point fibers and the balance of other fibers. The invention further discloses a preparation method of the tatami bed core; and the preparation method comprises the following steps: respectively preparing each layer including an upper surface layer, a lower surface layer and the middle layer; laying the upper surface layer, the lower surface layer and the middle layer in sequence; drying the upper surface layer, the lower surface layer and the middle layer in a drying box; and coldly rolling, cooling, cutting, inspecting and packaging the upper surface layer, the lower surface layer and the middle layer to obtain the tatami bed core. Through adoptions of the tatami bed core and the preparation method thereof disclosed by the invention, technical problems of mildews, insects, easiness for layering and cracking, insufficient elasticity, poor ventilating property and the like in a current bed mattress are solved.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Method for manufacturing redwood furniture

ActiveCN103817764ASolve the problem of not leaving expansion jointsMild colorWood working apparatusWaxSurface layer

The invention discloses a method for manufacturing redwood furniture. Expansion and cracking caused by wood characteristic changes are reduced to the largest extent, losses of original waxiness of wood are reduced, the mechanical property of the wood is increased, and reduction of the original toughness of the wood is lowered. A mortise and tenon joint structure is high in precision, high in efficiency and proper in looseness. The natural texture, color and flavor of furniture materials can be kept, and the color is gentle and natural. The real materials of the furniture are easy to recognize. Fineness of engraving, polishing and other manufacturing processes is easy to recognize. Wax on the surface of the furniture is natural and environmentally friendly, and the furniture conforms to healthy life positions. In the use process, the gloss of the surface layer of the waxed furniture is lighter and lighter.

Owner:江苏虞林世家红木家具有限公司

Composite health care pad and manufacture method thereof

InactiveCN102514257AGuaranteed performanceGuaranteed breathabilityStuffed mattressesLamination ancillary operationsFiberSurface layer

The invention discloses a composite health care pad, which comprises a middle layer, wherein an upper surface layer and a lower surface layer are respectively arranged on the upper surface and the lower surface of the middle layer, a layer of blocking layer is respectively arranged between the middle layer and the upper surface layer and / or between the middle layer and the lower surface layer. The upper surface layer and the lower surface layer are non-woven layers containing 5%-50% low-melting-point fibers, and the middle layer is a non-woven layer containing the following components: fibrilia and 5%-50% of low-melting-point fibers. The blocking layers are non-woven layers containing 5%-100% of fibrilia, and the content of fibrilia in the composite health care pad ranges from 5% to 65%. The invention further discloses a manufacture method of the composite health care pad, which includes the following steps: respectively manufacturing the middle layer, the upper surface layer, the lower surface layer and the blocking layers, sequentially overlaying all the layers, and carrying out procedures including drying in a drying oven, cold rolling, cooling, cutting, inspection and packing. The composite health care pad and the manufacture method thereof solve the problems that the existing mattress can become damp and mildewed easily, can be damaged by worms, is apt to be layered, and is poor in ventilation and inconvenient to use caused by the fact that hard fibers in the middle of the mattress prick out.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

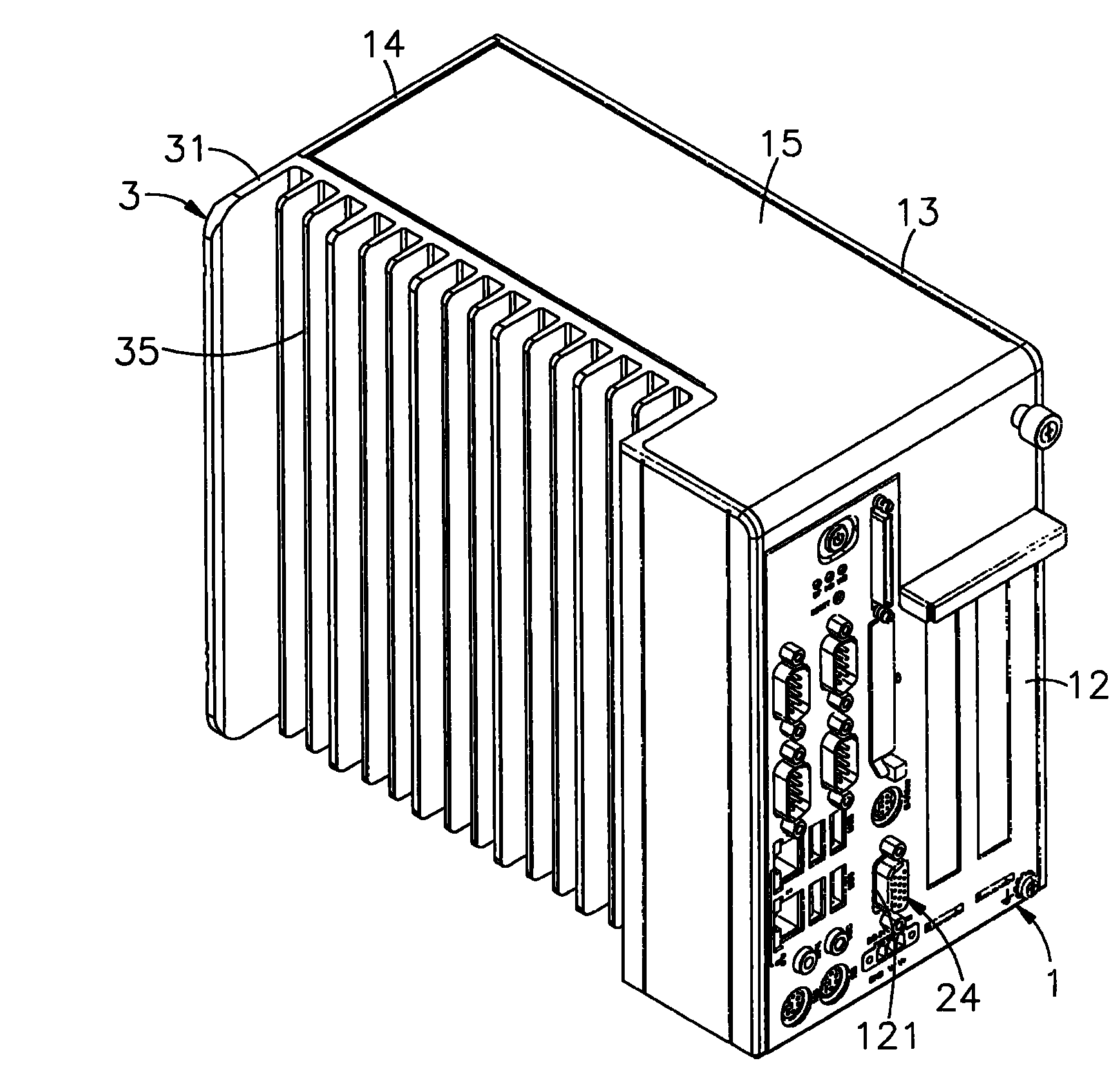

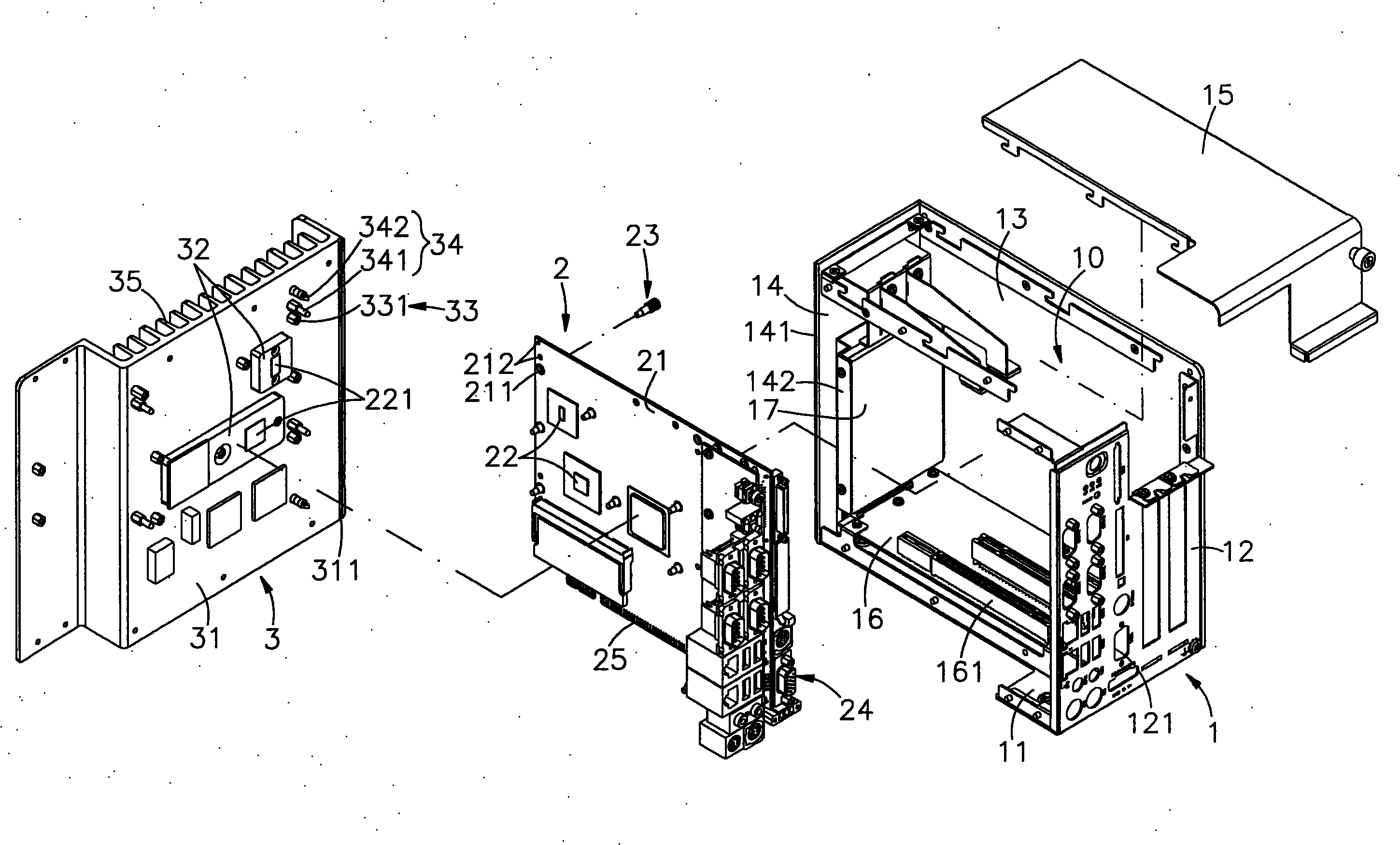

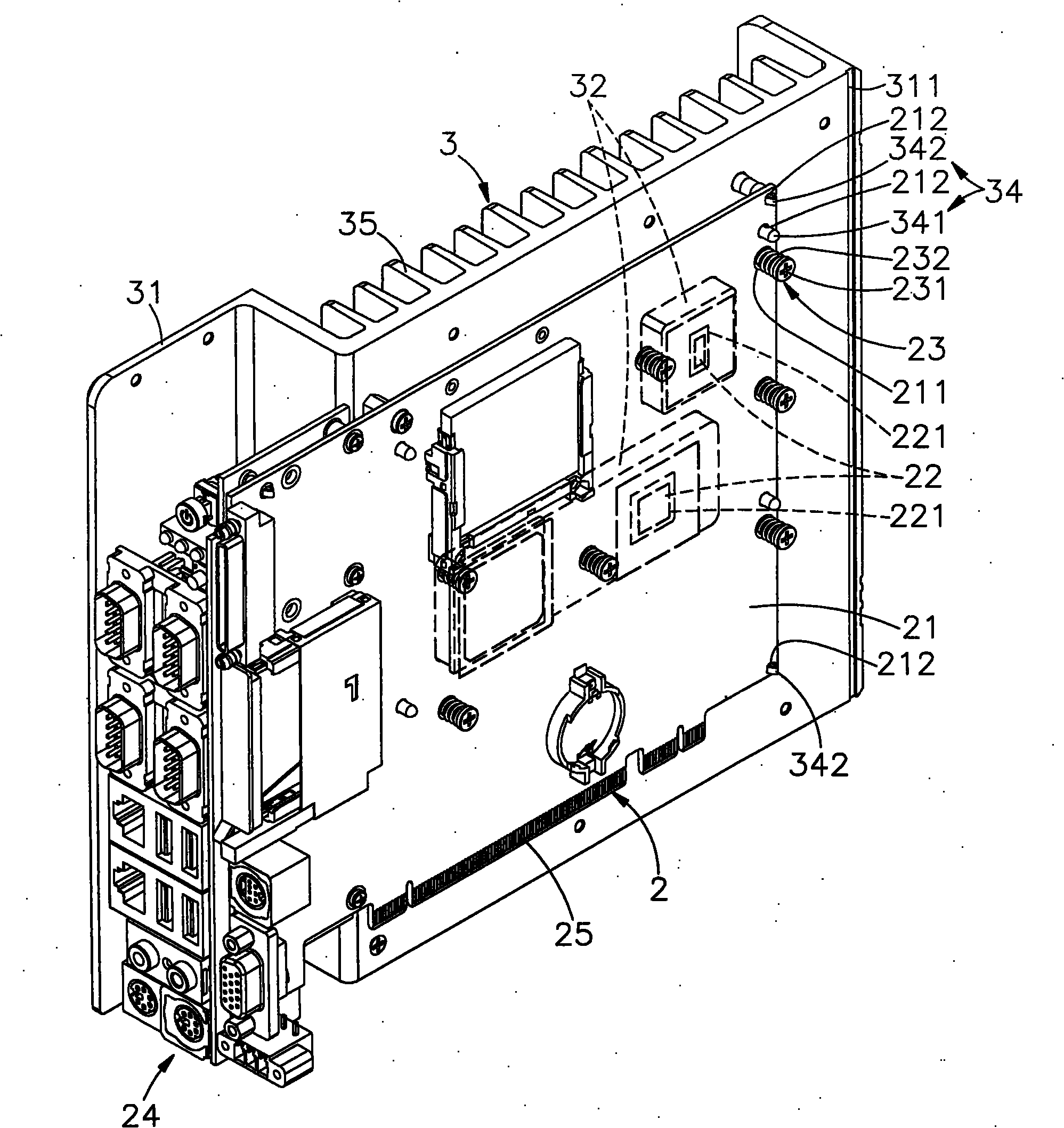

Elastic thermal conduction structure for multiple heat sources of fanless electronic device

ActiveCN102159052AIncrease elasticityElastic fitCooling/ventilation/heating modificationsEngineeringElectron

The invention provides an elastic thermal conduction structure for multiple heat sources of a fanless electronic device. The invention adopts the following technical scheme: the structure comprises a case and an outer shell, wherein housing space capable of housing a circuit substrate is formed inside the case; the circuit substrate is provided with a plurality of heating sources in different height; two or more through holes for elastic positioning parts to penetrate through and a plurality of joint holes arranged at the corners outside the through holes are respectively arranged around eachheating source so that the outer shell is combined at the side of the case; thermal conduction media are arranged in preset gaps respectively formed by a plurality of protruding parts on the inner side wall surface of a radiating base of the outer shell and the heating sources; a plurality of positioning portions at the corners outside the protruding parts respectively penetrate through the jointholes on the circuit substrate; then the elastic positioning parts are locked in corresponding fixing portions around the protruding parts to form a whole; and the thermal conduction media can be thermal pads or radiating grease to ensure good elastic pushing and sticking and close states between the heating sources and the protruding parts on the radiating base so as to effectively reduce the thermal resistance, so the integral thermal conduction effect can be improved.

Owner:ADLINK TECH INC

Healthcare environment-friendly mattress and preparation method thereof

ActiveCN102517796AGood moisture absorption and air permeabilityLight in massNon-woven fabricsCooking & bakingCarding

The invention discloses a healthcare environment-friendly mattress, which comprises the following ingredients of: 5%-50% of low-melting-point fiber and 5%-65% of bastose. The invention further discloses a preparation method of the healthcare environment-friendly mattress, and the preparation method comprises the following steps of: weighing the ingredients according to the required proportion; carrying out loosening and mixing; carrying out pre-laying; carding; carrying out air laying; entering a baking oven; carrying out cold rolling; cooling; and cutting, checking and packaging, wherein thespeed of the processes of pre-laying, carding and air laying is 0-20 m / min, the temperature of the baking oven is 180-230 DEG C, the temperature of cold rolling is 5-20 DEG C, and the cooling temperature is 0-25 DEG C. With the adoption of the healthcare environment-friendly mattress and the preparation method of the healthcare environment-friendly mattress, disclosed by the invention, the problem that the traditional mattress is easily mildewed due to wetting, deteriorated due to worms and easily delaminated is solved.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

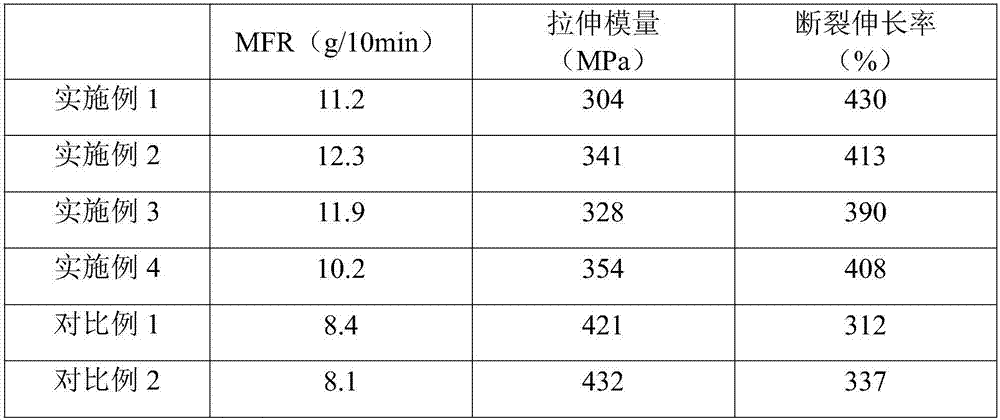

TPO automotive trim material with simulated stitching effect and preparation method thereof

ActiveCN107189232ASuitable melt fluidityElastic fitSynthetic resin layered productsVehicle componentsLow-density polyethyleneSurface layer

The invention discloses a TPO automotive trim material with simulated stitching effect. The TPO automotive trim material comprises a sponge layer, a TPO surface layer and a paint from the lower part to the upper part in sequence, wherein the TPO surface layer is prepared by performing extrusion molding on a TPO material; the TPO material comprises the following components in parts by weight: 20 to 40 parts of polypropylene, 10 to 20 parts of low density polyethylene, 5 to 12 parts of polyurethane, 40 to 55 parts of rubber, 12 to 20 parts of tackifying resin, 8 to 14 parts of an inorganic filler, 0 to 8 parts of color master, and 2 to 5 parts of an assistant. The invention further discloses a preparation method of the TPO automotive trim material with simulated stitching effect. The TPO trim material can achieve authentic stitching effect of an automotive trim instrument board or a door sheet, and ensures that automotive trim is high-end oriented; the production technology is simple, the manufacture time can be greatly shortened through a one-step shaping technology, the rejection rate is reduced, and the cost is reduced.

Owner:BENECKE CHANGSHUN AUTO TRIMZHANGJIAGANG

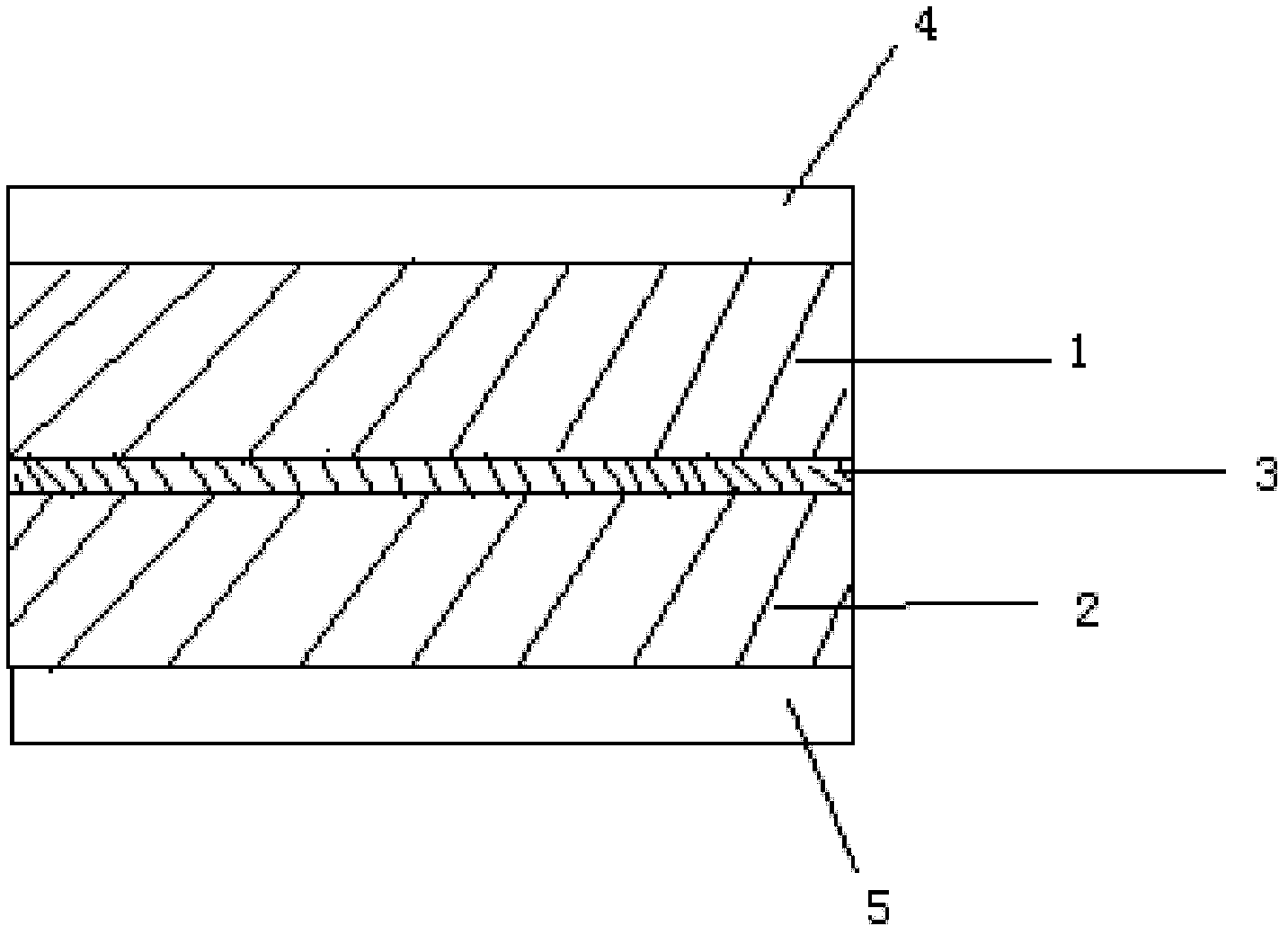

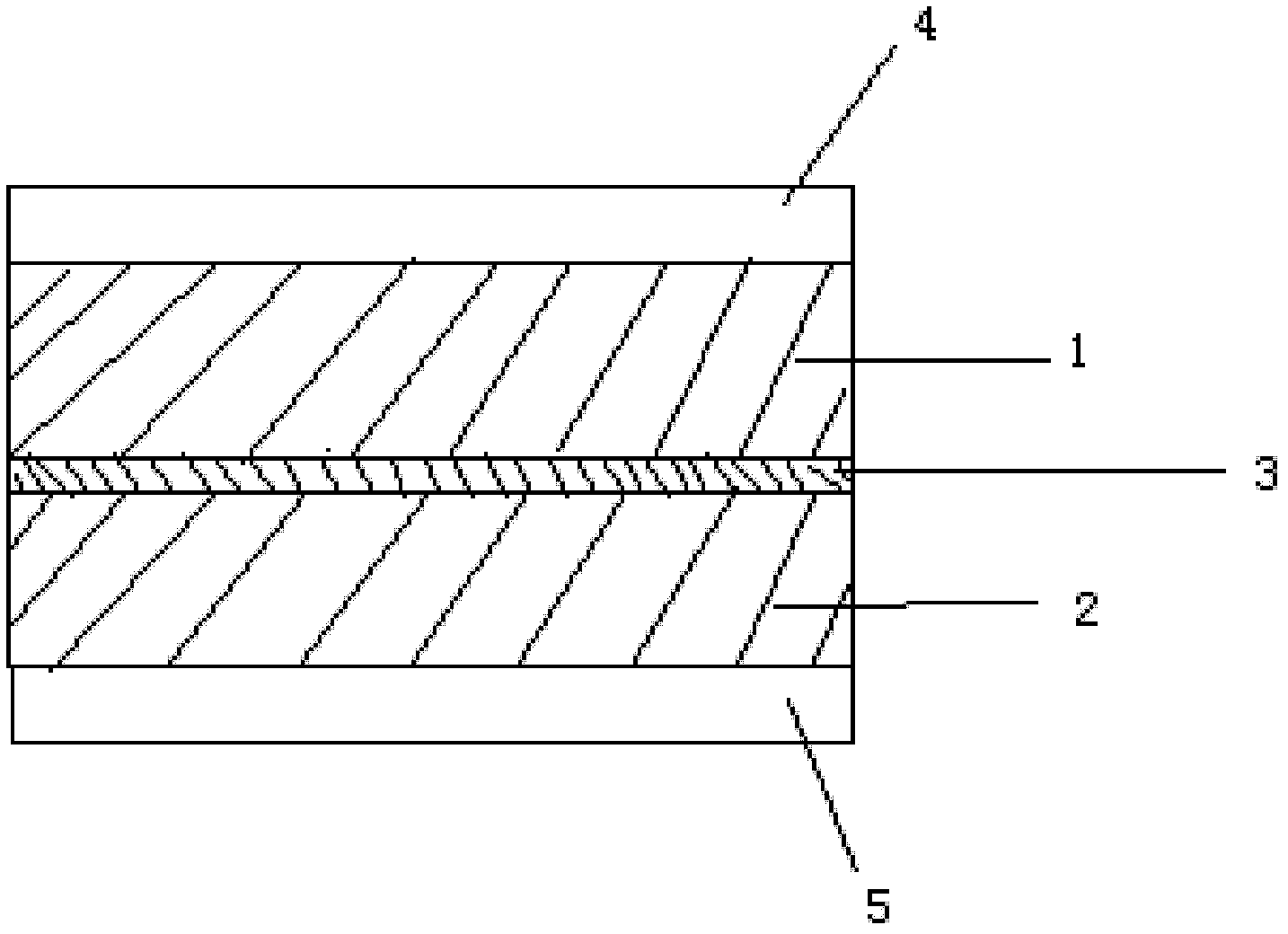

Composite health care pad and manufacture method thereof

ActiveCN102514273AGood elastic recoveryGood strength and elasticityStuffed mattressesLayered productsSurface layerFiber

The invention discloses a composite health care pad, which comprises a middle layer and a surface layer arranged on the upper surface or the lower surface of the middle layer, wherein the middle layer comprises a first middle layer, a sticking layer and a second middle layer. The surface layer is a non-woven layer containing 5%-50% of low-melting-point fibers, the first middle layer and the second middle layer are non-woven layers containing the following components: fibrilia and 5%-50% of low-melting-point fibers, the sticking layer is a non-woven layer containing 50%-100% of low-melting-point fibers, and the content of fibrilia in the composite health care pad ranges from 5% to 65%. The invention further discloses a manufacture method of the composite health care pad, which includes thefollowing steps: respectively manufacturing the layers including the two middle layers, the sticking layer and the upper surface layer or the lower surface layer, sequentially overlaying all the layers, and carrying out procedures including drying in a drying oven, cold rolling, cooling, cutting, inspection and packing. The composite health care pad and the manufacture method thereof solve the problems that the existing mattress can become damp and mildewed easily, can be damaged by worms, is apt to be layered, and is bad in ventilation.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

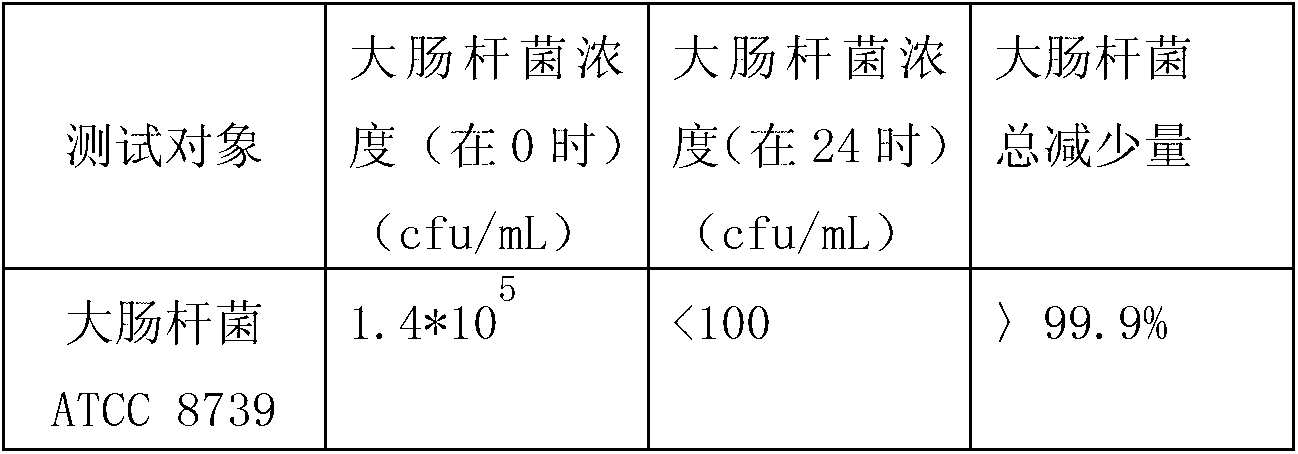

Antibacterial and odor removing fiber bed core and preparation method thereof

InactiveCN103054388AImprove bulkIncrease elasticityStuffed mattressesSpring mattressesFiberPolyester

The invention discloses an antibacterial and odor removing fiber bed core. The fiber bed core comprises at least one middle layer and a surface layer which is arranged on the upper surface or the lower surface of the middle layer, wherein the surface layer comprises a non-woven fabric prepared from the following components in percentage by weight: 15-40% of low melting point fibers and 60-85% of polyester fibers; and the middle layer comprises the following components in percentage by weight: 60-85% of raw bamboo fibers and 15-40% of low melting point fibers. The invention further discloses a preparation method of the fiber bed core; and the preparation method comprises the following steps: respectively preparing each layer including an upper surface layer, a lower surface layer and the middle layer; laying the upper surface layer, the lower surface layer and the middle layer in sequence; drying the upper surface layer, the lower surface layer and the middle layer in a drying box; and coldly rolling, cooling, cutting, inspecting and packaging the upper surface layer, the lower surface layer and the middle layer. The fiber bed core disclosed by the invention has the advantages as follows: antibacterial and odor removing properties, elasticity and bulkiness, healthcare property, ultraviolet resistance, moisture absorbing and removing properties and environment friendliness of the fiber bed core are greatly improved when being compared with those of a traditional mattress.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Crease-resistance comfortable blend fiber

The invention discloses a crease-resistance comfortable blend fiber formed by blending and weaving a first crease-resistance comfortable fiber and a second crease-resistance comfortable fiber; the first crease-resistance comfortable fiber is formed by blending and weaving polylactic acid fiber, polyester fibres and cuprammonium fiber; the second crease-resistance comfortable fiber is formed by blending and weaving polyurethanes fiber, soybean protein fiber and newdal fiber. The crease-resistance comfortable blend fiber is formed by blending and weaving various fibers, is good in drapability, crease-resistance and stiff, fresh and cool in wearing, good in moisture absorption permeability, and elastic and close-fitting.

Owner:TAICANG LIANGXIN CHEM FIBER CO LTD

Compound health protection bed core and preparation method thereof

InactiveCN103054386ANot easy to layerNot easy to be environmentally friendlyUpholstery manufactureStuffed mattressesSurface layerNatural fiber

The invention discloses a compound health protection bed core. The bed core comprises at least one intermediate layer and a surface layer arranged on the upper surface or the lower surface of the intermediate layer, wherein the surface layer is a non-woven layer comprising the following components in percentage by weight: 15-40% of low-melting point fiber and 60-85% of bamboo hemp fiber; the bamboo hemp fiber consists of bamboo fiber and fibrilia; the intermediate layer comprises the following components in percentage by weight: 60-85% of compound natural fiber and 15-40% of low-melting point fiber; the compound natural fiber consists of coconut fiber, bamboo fiber and fibrilia; and the content ratio of the coconut fiber to the bamboo fiber to the fibrilia is 1: 1: (1-3): 2: 1. The invention further comprises a preparation method for the compound health protection bed core; the method comprises the following steps of: respectively preparing various layers which comprise the upper surface layer, the lower surface layer and the intermediate layer, laying the layers sequentially, and preparing the bed core through procedures of oven, cold rolling, cooling, cutting, examining and packaging. The compound health protection bed core and the preparation method thereof solve the technical problems, such as high possibility of layering and rupture, weak elasticity, weak air permeability, mustiness and the like in the existing mattresses.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

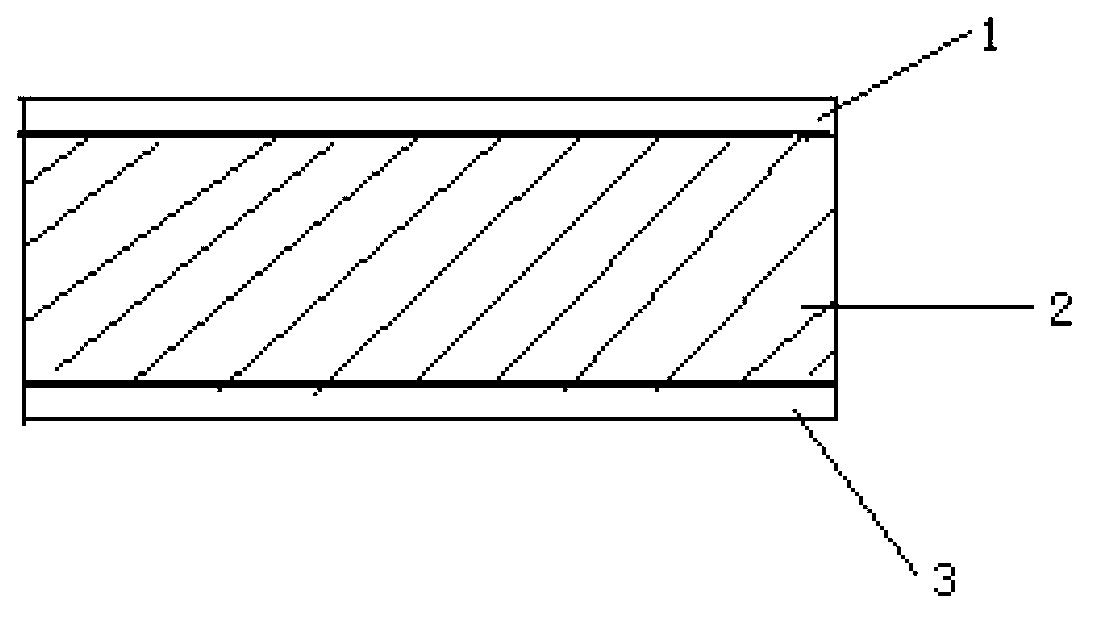

Natural fiber composite plate and manufacturing method thereof

InactiveCN102514255AGood moisture absorption and air permeabilityLight in massLaminationLamination apparatusMetallurgyNatural fiber

The invention discloses a natural fiber composite plate, which comprises an upper layer, a lower layer and a bonding layer for bonding the upper layer and the lower layer, wherein the upper layer and the lower layer are nonwoven layers comprising the following components: 5 to 50 percent of low melting point fibers and 5 to 65 percent of jute fibers; and the bonding layer is a nonwoven layer comprising 50 to 100 percent of low melting point fibers. The invention also discloses a method for manufacturing the natural fiber composite plate, which comprises the following steps of: respectively preparing various layers, namely the upper layer, the lower layer and the bonding layer; and sequentially spreading the layers, drying in an oven, performing cold rolling, cooling, cutting, checking and packaging to obtain the natural fiber composite plate. By the natural fiber composite plate and the method for manufacturing the natural fiber composite plate, the problem that the conventional mattress is easily moulded with damp, goes bad due to moths and is easily layered is solved.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Composite environmental-friendly cushion and preparation method thereof

InactiveCN102514258AGuaranteed performanceGuaranteed breathabilityStuffed mattressesLamination ancillary operationsFiberSurface layer

The invention discloses a composite environmental-friendly cushion which comprises a middle layer and upper and lower surface layers. The middle layer comprises a first middle layer, a second middle layer and a bonding layer. The upper and lower surface layers are non-woven layers comprising 5 percent to 50 percent of low melting point fibers. The first and second middle layers are non-woven layers which respectively comprise the following components: bastose and 5 percent to 50 percent of low melting point fibers. The bonding layer mainly consists of the low melting point fibers. In the whole composite environmental-friendly cushion, the content of the bastose is within the range of 5 percent to 65 percent. The invention also discloses a preparation method of the composite environmental-friendly cushion, which comprises the following steps of: respectively preparing the middle layer, the upper and lower surface layer and the bonding layer; then sequentially paving the layers; and preparing the composite environmental-friendly cushion by processes of processing by an oven, cold milling, cooling, cutting, inspecting and packaging. Due to the adoption of the composite environmental-friendly cushion and the preparation method thereof, which are disclosed by the invention, the problem that the existing mattress is easy to affect with damp, mildew, breed worms and deteriorate, is easy to layer and has poor air permeability is solved.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

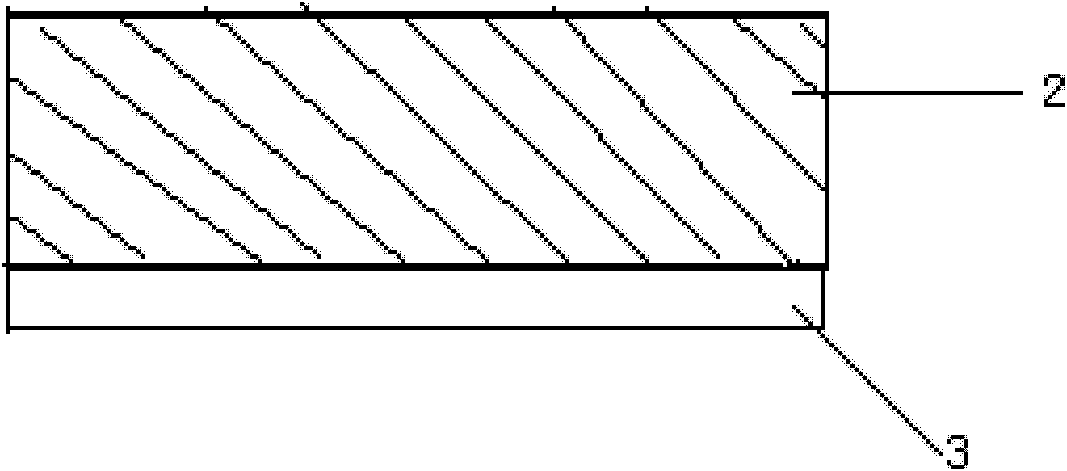

Natural fiber health-care board and preparation method thereof

ActiveCN102514256AGuaranteed performanceGuaranteed breathabilityLaminationLamination apparatusPolymer scienceSurface layer

The invention discloses a natural fiber health-care board which consists of a middle layer and a surface layer arranged on the upper surface or the lower surface of the middle layer. The surface layer is a non-woven layer comprising 5 percent to 50 percent of low melting point fibers. The middle layer is a non-woven layer which comprises the following components: bastose and 5 percent to 50 percent of low melting point fibers. In the natural fiber health-care board, the content of the bastose is within the range of 5 percent to 65 percent. The invention also discloses a preparation method of the natural fiber health-care board, which comprises the following steps of: respectively preparing the middle layer and the upper or lower surface layer; then sequentially paving the layers; and preparing the natural fiber health-care board by processes of processing by an oven, cold milling, cooling, cutting, inspecting and packaging. Due to the adoption of the natural fiber health-care board and the preparation method thereof, which are disclosed by the invention, the problem that the existing mattress is easy to affect with damp, mildew, breed worms and deteriorate, is easy to layer and has poor air permeability is solved.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Multifunctional soft fabric

The invention discloses multifunctional soft fabric. The multifunctional soft fabric is formed by pineapple leaf fibers, mulberry bark fibers, tribute silk fibers and imported long-staple cotton fibers in a blending weaving mode. The multifunctional soft fabric comprises, by weight, 14-19% of the pineapple leaf fiber, 17-22% of the mulberry bark fiber, 24-28% of the tribute silk fiber and 31-45% of the imported long-staple cotton fiber. Due to the fact that the multifunctional soft fabric is formed by the pineapple leaf fibers, the mulberry bark fibers, the tribute silk fibers and the imported long-staple cotton fibers in the blending weaving mode, the woven multifunctional soft fabric has the advantages of being excellent in softness and comfort, having the antibiosis effect, the deodorization effect and the health care effect of natural fibers, absorbing moisture, and being breathable, elastic and skin-friendly.

Owner:WUJIANG LINGTONG TEXTILE FINISHING

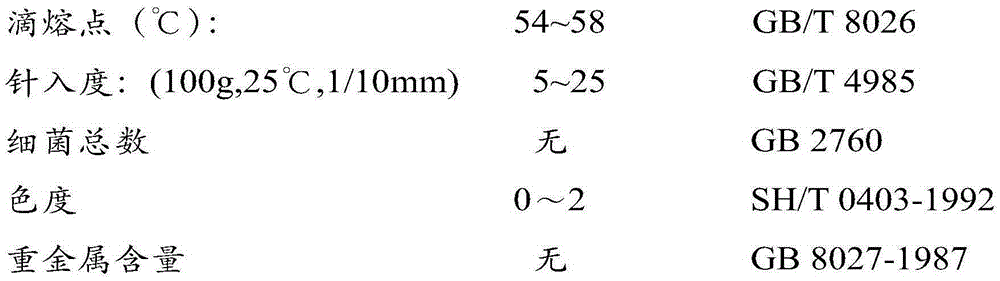

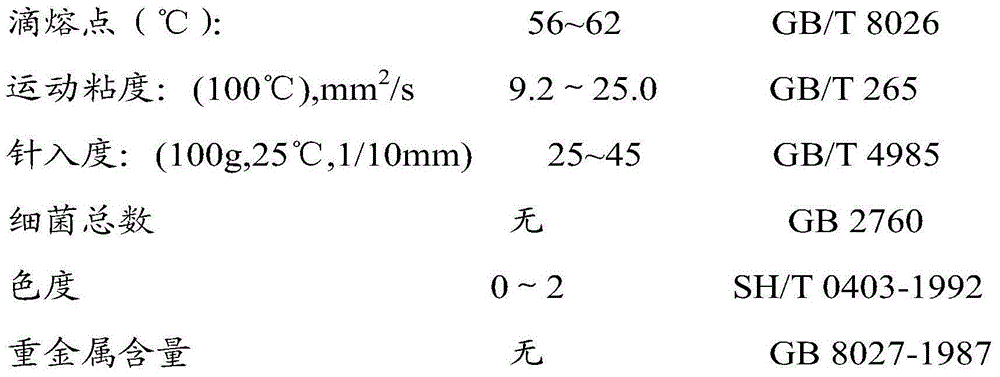

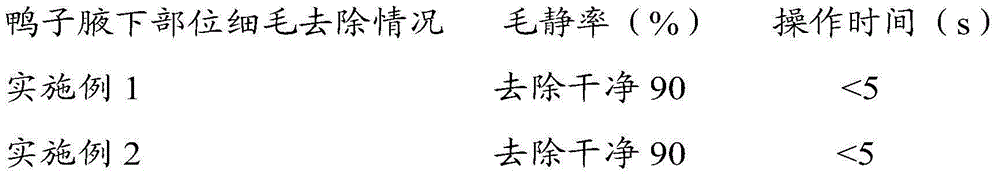

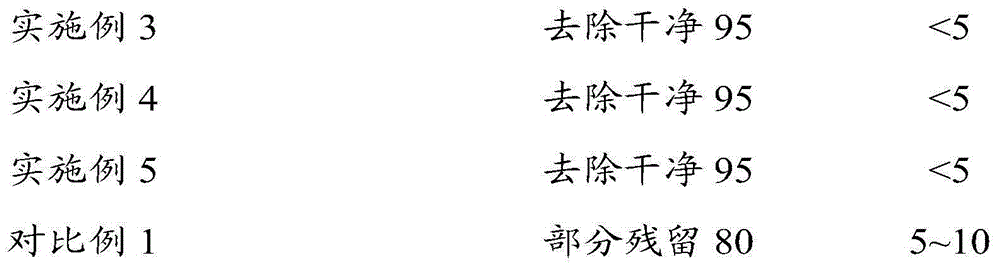

Solid depilatory wax for human bodies, and preparation method thereof

The invention relates to a depilatory wax, and concretely provides a solid depilatory wax for human bodies, and a preparation method thereof. The solid depilatory wax for human bodies comprises a tackifier, a plasticizer, a flexibilizer, a film forming agent, a stabilizer and a waxy substance. The preparation method of the solid depilatory wax comprises the following steps: heating the waxy substance for fusing, adding the tackifier, the plasticizer, the flexibilizer, the film forming agent and the stabilizer, and stirring until uniform mixing. The solid depilatory wax for human bodies has good adhesion, good film forming ability and good toughness, so the solid depilatory wax has a high depilation effect, has a very good removal effect on hair in positions difficult to process, such as underarm hair and bikini hair; and the solid depilatory wax for human bodies also has the advantages of good peeling effect, no skin sticking, and convenient and fast operation. The method has the advantages of simple process, convenient operation, and convenience for large scale production.

Owner:GUANGZHOU DEXIN WAX PROD

Electric wire connector

ActiveCN107317205AGuaranteed contact effectWind evenlyLine/current collector detailsStructural engineeringWire fixation

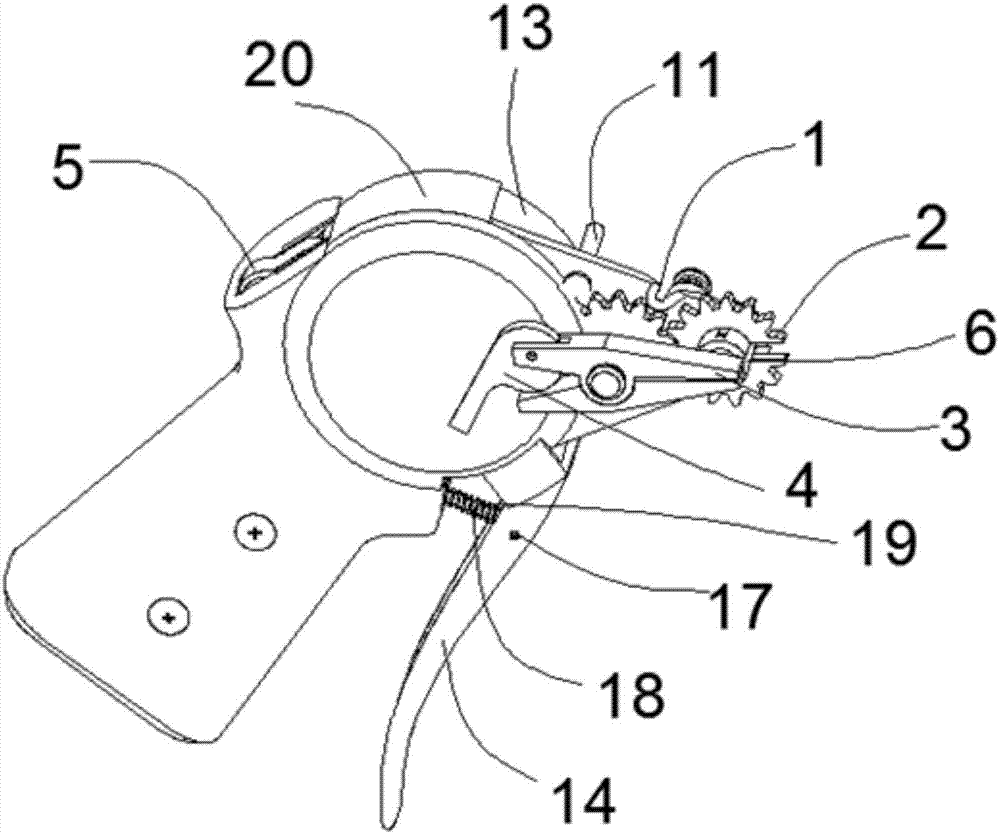

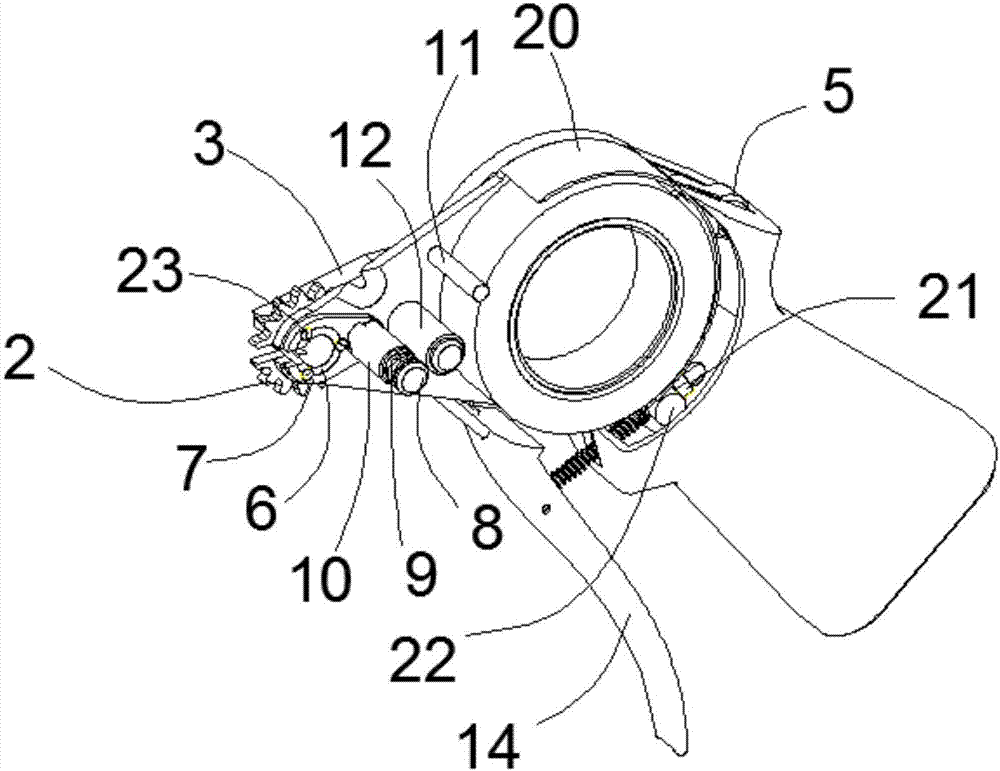

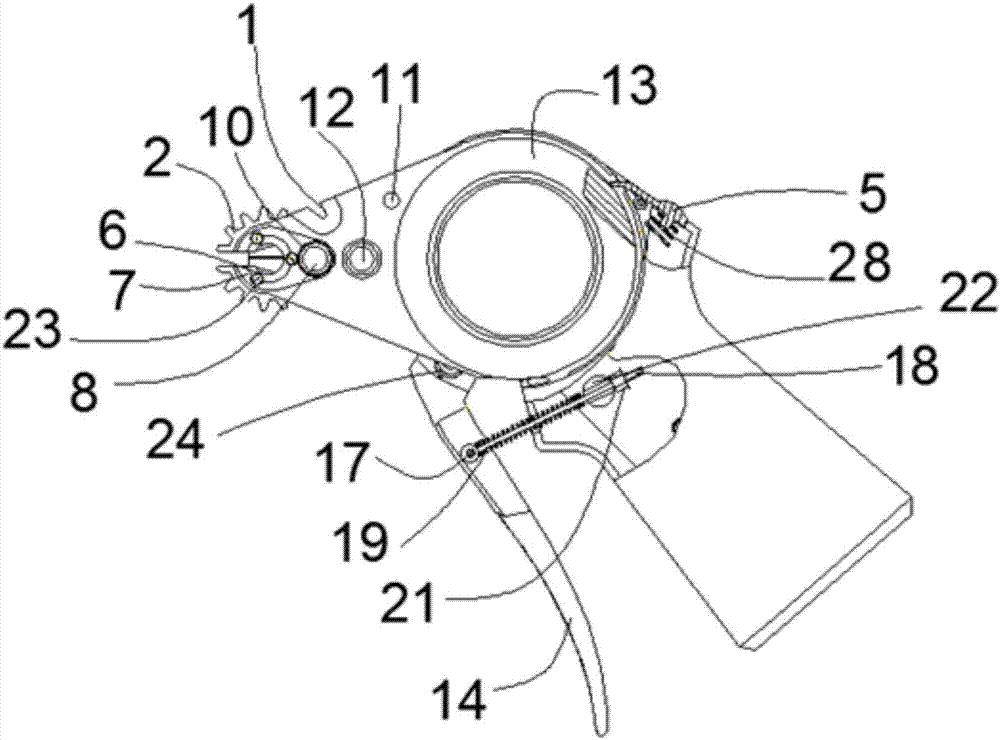

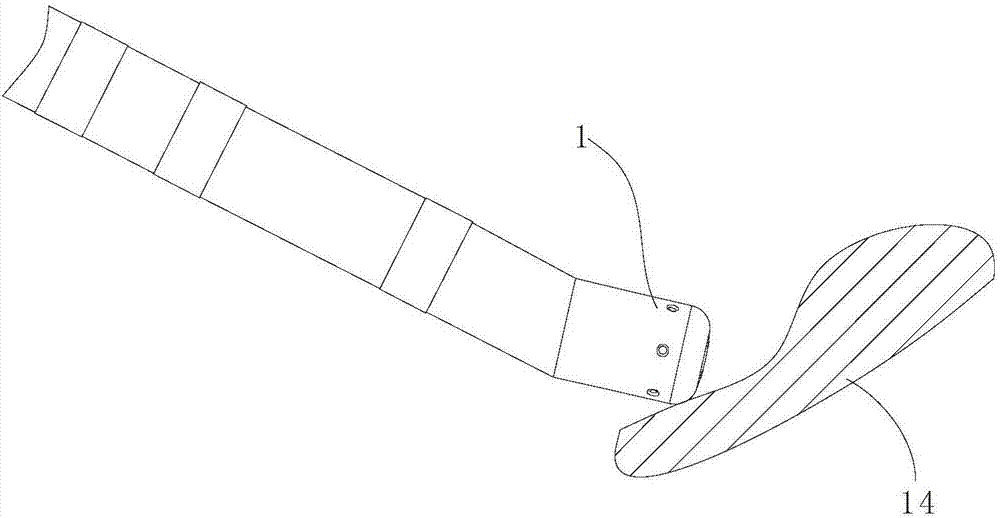

The invention discloses an electric wire connector that can reduce the labor intensity and has relatively good wiring quality. The electric wire connector comprises a wire connector main body, a wiring mechanism, a driving mechanism and an electric wire fixing device; the wiring mechanism comprises a wiring shaft rotatably arranged on the wire connector main body, and the driving mechanism is arranged on the wire connector main body and is in transmission connection with the wiring shaft; and the electric wire fixing device is arranged on the wire connector main body, and a clamping and fixing position of the electric wire fixing device corresponds to one end of the wiring shaft. The electric wire connector is used for connecting power lines, the thread residues are uniformly twined, the compactness is proper, and the lapping parts are sufficient, thereby being conducive to guaranteeing the contact performance of electric wires, meanwhile, the labor intensity is reduced, the wiring efficiency is improved, and moreover, the quality and efficiency of twining insulating tapes are improved.

Owner:PANZHIHUA UNIV

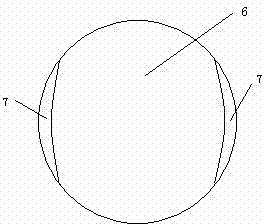

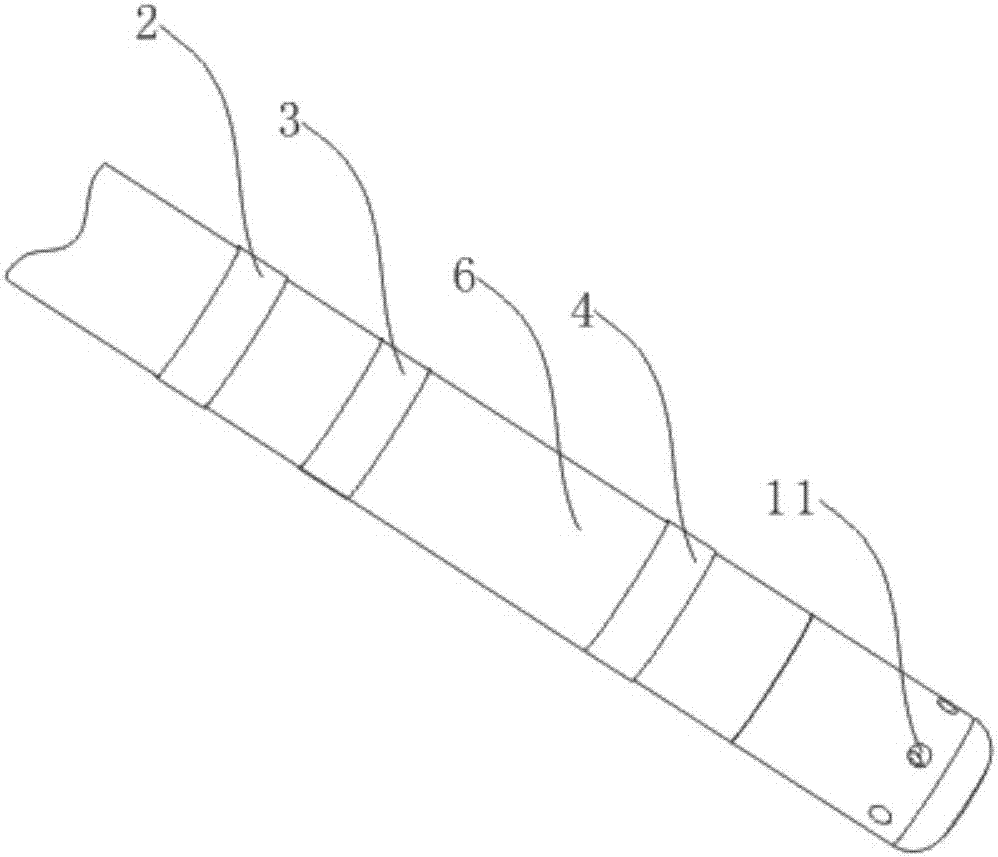

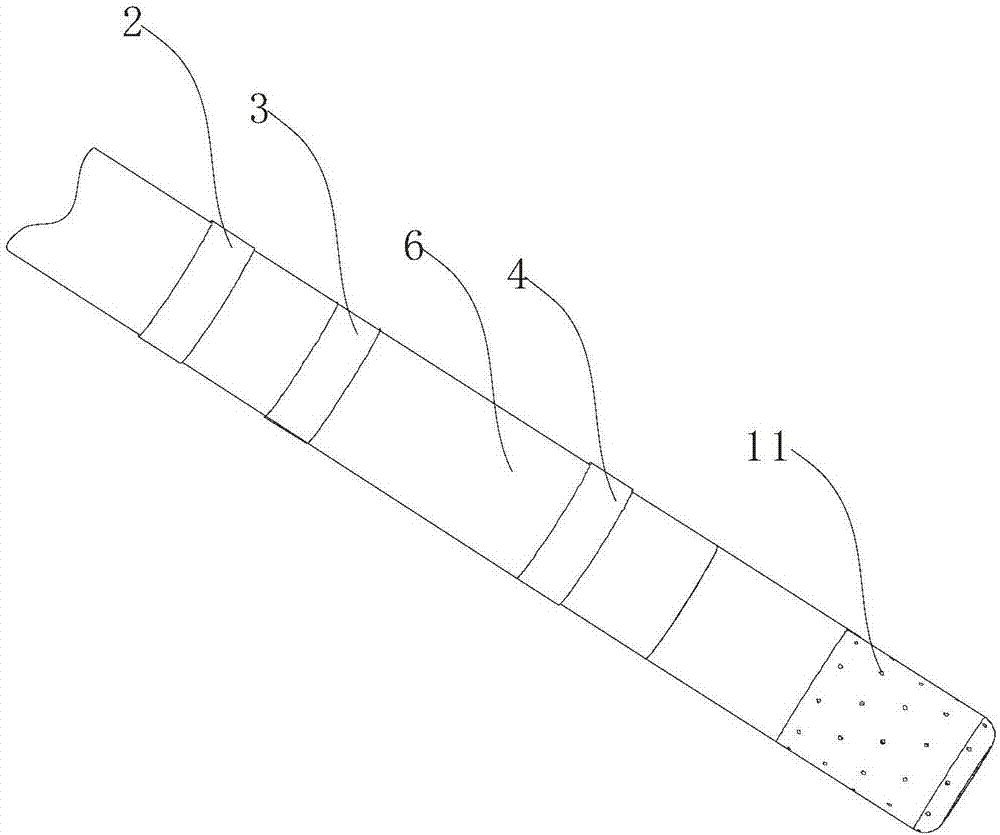

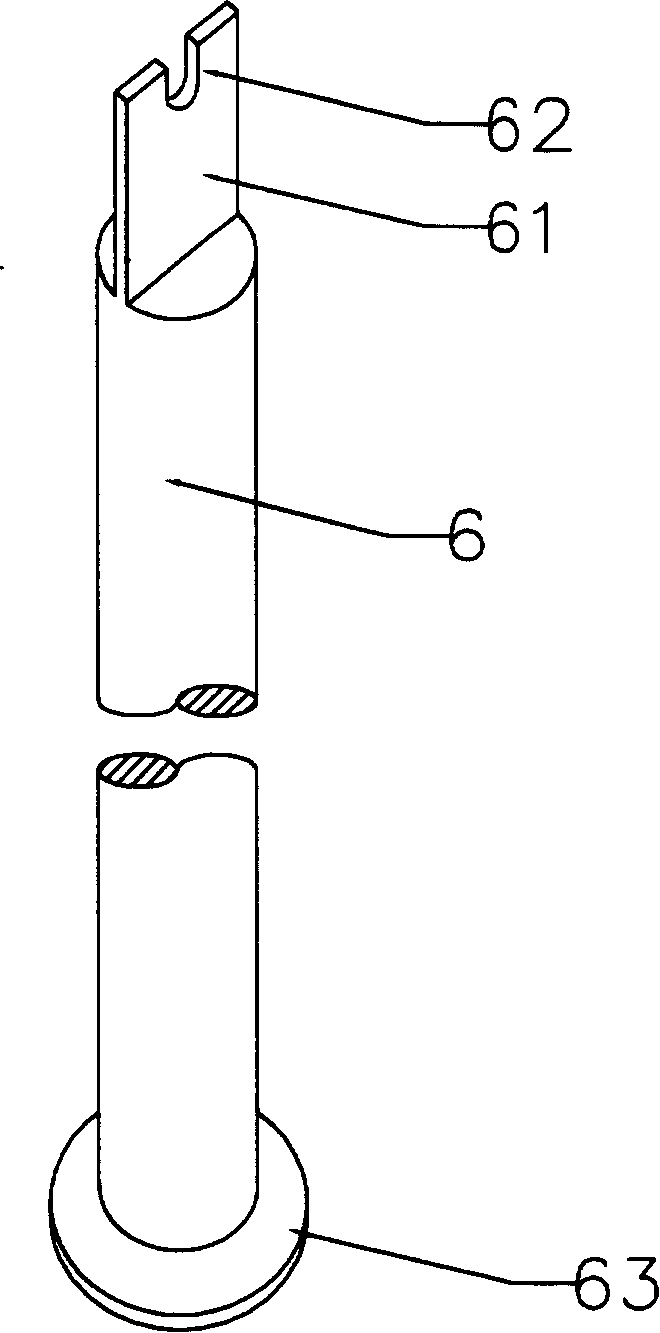

Ablation catheter having pressure detecting function

ActiveCN106974724AElastic fitGood detection effectDiagnosticsSurgical instruments for heatingElastomerCatheter

The invention relates to the field of ablation catheters, in particular to an ablation catheter having a pressure detecting function. The far end of the ablation catheter comprises an elastomer and a pressure sensor, wherein the elastomer is of a hollow-out tubular structure and comprises a section A and a section B, the section A is provided with a hollow-out structure having increased elasticity and having the end extending to the section B, and the pressure sensor is arranged at the connected area of the section A and the section B. The invention aims to provide an ablation catheter making pressure detection more accurate and a relevant structure including the ablation catheter.

Owner:四川锦江电子医疗器械科技股份有限公司

Warp-weft woven wearing-resistant shell fabric

The invention discloses a warp-weft woven wearing-resistant shell fabric which is formed by warps and wefts. The warps and the wefts are mutually woven, the warps are composed of melton fibers and vinylon fibers, the melton fibers and the vinylon fibers are blended and woven, the wefts are composed of polypropylene fibers and polyamide fabrics, and the polypropylene fibers and the polyamide fabrics are blended and woven. The warps comprise components by weight percentage of 33% to 38% of the melton fibers and 62% to 67% of the vinylon fibers, and the wefts comprise components by weight percentage of 25% to 30% of the polypropylene fibers and 70% to 75% of the polyamide fabrics. The warp-weft woven wearing-resistant shell fabric is formed by the warps and the wefts which are mutually woven so as to be compact in structure. The warps are composed of the melton fibers and the vinylon fibers and the wefts are composed of the polypropylene fibers and the polyamide fabrics, so that the warp-weft woven wearing-resistant shell fabric is formed.

Owner:WUJIANG XUYANG TEXTILE

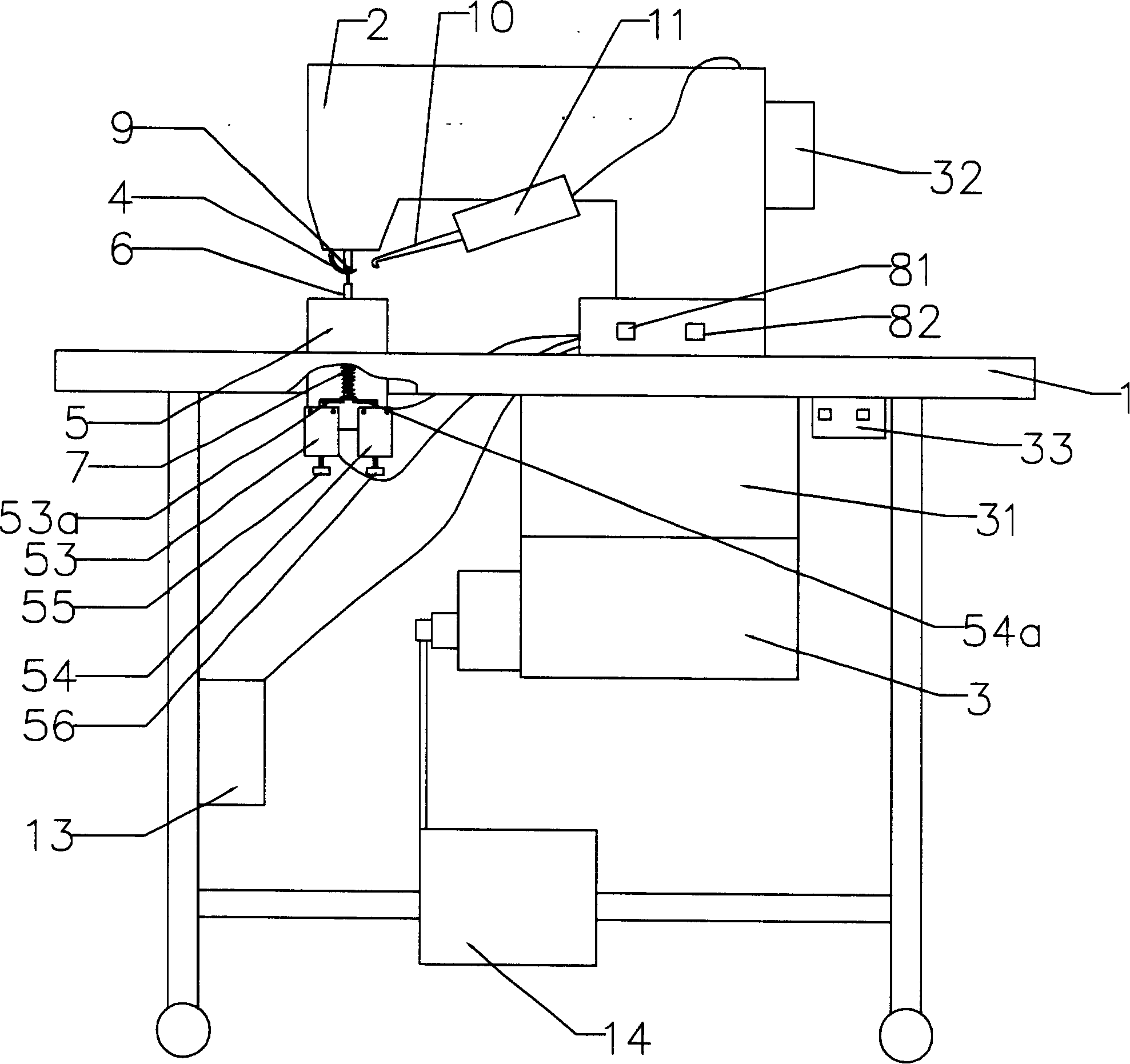

Blind seam shoulder pad sewing machine

InactiveCN101191276AThere will be no unevennessRealize the blind seam effectNeedle severing devicesSewing-machine control devicesElectrical controlEngineering

The invention discloses a shoulder pad blind-stitch machine which mainly aims to overcome the defects that when equipment like the prior temporary stitch machine, a button sewing machine and so on are used for tailoring a shoulder pad, stitches penetrate through the whole thickness and the shoulder pad is made to be irregular on the surface and too tight in tailoring, and replaces hand sewing shoulder pad to improve efficiency. The invention comprises a machine frame, a blind-stitch machine handpiece which is arranged on the upper part of the machine frame, and an electrical control device which is arranged on the lower part of the machine frame and used for controlling machine needle motion on the handpiece, wherein, a feed mechanism used for adjusting height of a shoulder pad is arranged on the machine frame facing to a machine needle on the handpiece and connected with a motor output shaft in the electrical control device through a driving mechanism. By utilization of the shoulder pad blind-stitch machine to tailor the shoulder pad, stitches can not penetrate through the bottom surface of the shoulder pad, and tailoring tightness and tailoring depth can be adjusted, thereby the shoulder pad has the advantages of unlikely occurrence of irregular phenomenon, proper tightness, and leveling and beautiful appearance; because no stitches are arranged on the bottom surface of the shoulder pad, blind effect which can not be reached by other sewing machines is realized.

Owner:GUANGZHOU KEQI AUTOMATIC EQUIPS

Fiber bed core with good elasticity and preparation method thereof

InactiveCN103054392AIncrease elastic pharyngeal refoldingImprove bulkStuffed mattressesSpring mattressesPolyesterSurface layer

The invention discloses a fiber bed core with good elasticity which comprises at least one intermediate layer and surface layers arranged on the upper surface or the lower surface of the intermediate layer; the surface layers comprise the following components in percentage by weight: 15-40 percent of low-melting point fiber and 60-85 percent of polyester fiber; the intermediate layer comprises the following components in percentage by weight: 60-85 percent of brown hemp fiber and 15-40 percent of low-melting point fiber, wherein the brown hemp fiber consists of coconut fiber and fibrilia in ratio of (1-4):1. The invention also discloses a preparation method of the fiber bed core, which comprises the following steps of: respectively preparing all the layers, i.e. the upper surface layer, the lower surface layer and the intermediate layer, then paving all the layers in sequence and preparing the fiber bed core through the baking, cold-milling, cooling, cutting, inspecting and packaging processes. The fiber bed core and the preparation method thereof have the benefits that the technical problems of easiness in layered fracture, insufficient elasticity, bad air permeability, mustiness and insects existing in the existing bed mattress are solved; and due to the content ratio of the coconut fiber to the brown hemp fiber, the fiber bed core has better elasticity and certain hardness; and fiber bed core is particularly suitable for middle-aged and elderly people.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Epilating wax for living stock and preparation method of epilating wax

The invention provides epilating wax for the living stock and a preparation method of the epilating wax and belongs to the technical field of food processing auxiliaries. The epilating wax for the living stock is mainly prepared from a tackifier, a plasticizer, a flexibilizer, a film-forming agent, a stabilizer and a wax substance. The wax substance is heated and melted, then the tackifier, the plasticizer, the flexibilizer, the film-forming agent and the stabilizer are added to the wax substance, stirred and mixed uniformly, and accordingly, the epilating wax for the living stock is prepared. The epilating wax for the living stock has good adhesive force, good film-forming performance, good rigidity and high epilating rate, has a good removal effect on feather or fur at parts where the feather or fur is difficult to deal with, such as fine feather under winds, and also has a good peeling effect, and efficient epilating can be realized at higher operation efficiency of a worker or a wax peeling machine. The method is simple in process and convenient to operate and facilitates large-scale production.

Owner:广东德馨新材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com