High-capacity and high-compaction artificial graphite negative electrode material, preparation method thereof and lithium ion battery

An artificial graphite negative electrode, high-pressure compaction technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of slow liquid absorption, easy overpressure, etc., achieve fast infiltration, high compaction density, and improve electrochemical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

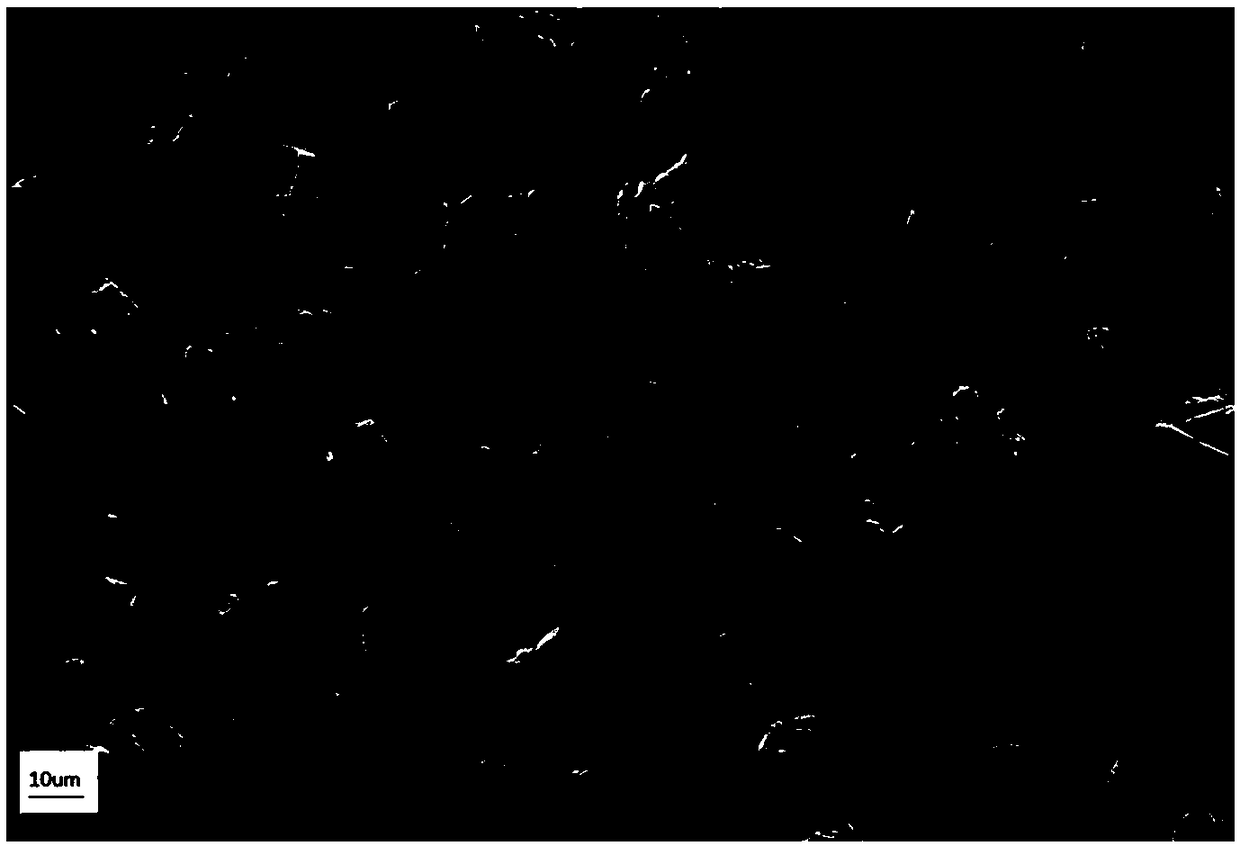

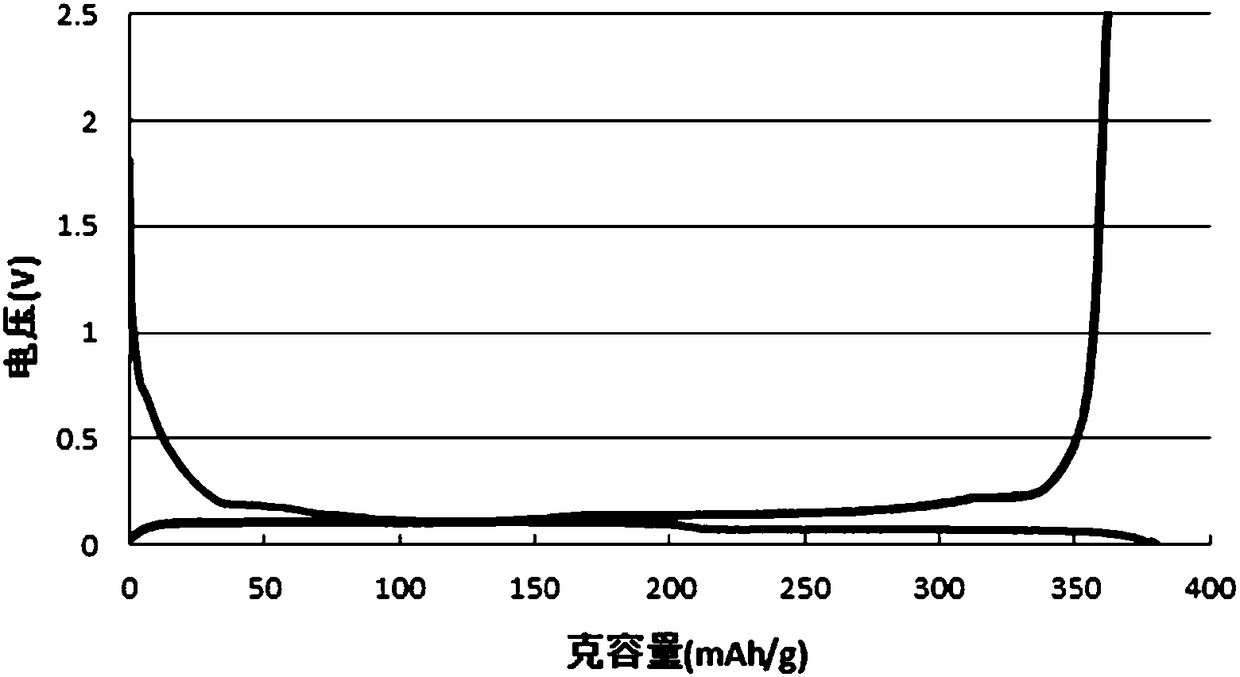

Image

Examples

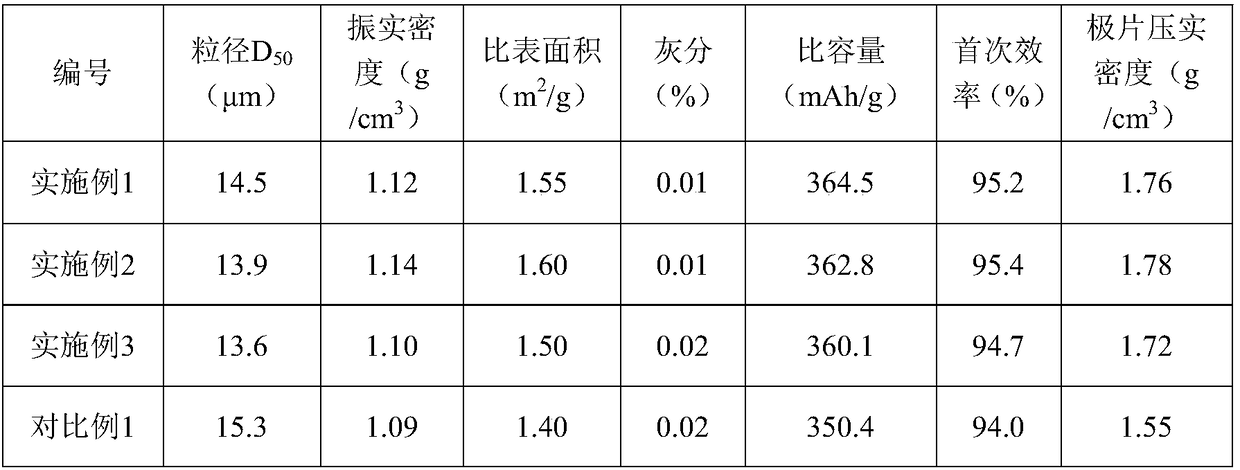

Embodiment 1

[0024] The high-capacity and high-pressure compacted artificial graphite negative electrode material of this embodiment is prepared by the following steps:

[0025] 1) Grinding calcined petroleum coke and calcined coal-based needle coke into D 50 Particle size is 10μm, tap density is 0.60g / cm 3 raw material powder;

[0026] 2) Add calcined petroleum coke raw material powder and calcined coal-series needle coke raw material powder to the mixer according to the mass ratio of 60:40, and mix them evenly with auxiliary material pitch to obtain a mixture. The mass ratio of raw material powder to auxiliary material pitch is 100:5;

[0027] 3) Put the mixture in N 2 Under protection, heat treatment at 600°C for 10h in a vertical kettle, and then raise the temperature to 3200°C for graphitization treatment for 40h, and the graphitized products are mixed and sieved to obtain the artificial graphite negative electrode material.

[0028] The lithium ion battery of the present embodime...

Embodiment 2

[0030] The high-capacity and high-pressure compacted artificial graphite negative electrode material of this embodiment is prepared by the following steps:

[0031] 1) Grinding calcined petroleum coke and calcined coal-based needle coke into D 50 Particle size is 10μm, tap density is 0.60g / cm 3 raw material powder;

[0032] 2) Add calcined petroleum coke raw material powder and calcined coal-based needle coke raw material powder to the mixer at a mass ratio of 70:30, and mix them with auxiliary material asphalt to obtain a mixture. The mass ratio of raw material powder to auxiliary material asphalt is 100:5;

[0033] 3) Put the mixture in N 2 Under protection, heat treatment at 560°C for 12 hours in a vertical kettle, and then raise the temperature to 3100°C for graphitization treatment for 45 hours, and the graphitized products are mixed and sieved to obtain the artificial graphite negative electrode material.

[0034] The lithium-ion battery of this example is prepared b...

Embodiment 3

[0036] The high-capacity and high-pressure compacted artificial graphite negative electrode material of this embodiment is prepared by the following steps:

[0037] 1) Grinding calcined pitch coke and calcined coal-based needle coke into D 50 Particle size is 10μm, tap density is 0.60g / cm 3 raw material powder;

[0038] 2) Put calcined pitch coke raw material powder and calcined coal-based needle coke raw material powder into the mixer at a mass ratio of 80:20, and mix them with auxiliary material pitch to obtain a mixture. The mass ratio of raw material powder to auxiliary material pitch is 100:10;

[0039] 3) put the mixture in N 2 Under protection, heat treatment at 700°C for 8 hours in a vertical kettle, and then raise the temperature to 3300°C for graphitization treatment for 40 hours, and the graphitized products are mixed and sieved to obtain the artificial graphite negative electrode material.

[0040] The lithium-ion battery of this example is prepared by using th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com