Patents

Literature

190results about How to "Wear cool and comfortable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of cold black suiting

InactiveCN102618992AAvoid damageImprove insulation effectFibre treatmentDyeing processColour fastnessPolyester

The invention relates to a preparation method of cold black suiting. In the suiting, 52% of polyester fiber and 48% of polyester fiber by weight are used as raw materials; and the suiting is prepared by top dyeing and recombing, spinning, weaving and after-treatment. The method comprises the following steps of: before dyeing wool, performing pretreatment on wool; adjusting the pH value with alkali to adjust the wool to a neutral state; dyeing, wherein the dye adopts a Nylosan dyeing agent produced by the Clariant cooperation, the dyeing is started at 40 DEG C, and the temperature is increased to 100 DEGE C and kept for 60 minutes before after-treatment; performing cold black auxiliary treatment on the dyed wool, wherein the cold black auxiliary is the CWF cold black auxiliary produced by the Clariant cooperation; performing a dip dyeing technology, heating to 100 DEG C, and treating for 45-55 minutes at the temperature; and cleaning with an efficient cleaning agent ND-9 produced by the Nigeria Mita Auxiliaries Co., Ltd., Jiangyin. Through the invention, the prepared cold black suiting has good color fastness and low ultraviolet transmittance and is cool and suitable for summer.

Owner:JIANGSU NIJIAXIANG GROUP WORSTED TEXTILE

Shell fabric of blending bamboo fibers and polyesters

Owner:DAIFUNI HOUSEHOLD DECORATION PRODS FUSN CITY

Manufacturing process for anti-bacterial and allergy-free textile fabric

InactiveCN105239250ASoft textureWear cool and comfortableSolvent-treatmentFabric breaking/softeningYarnPectinase

The invention discloses a manufacturing process for an anti-bacterial and allergy-free textile fabric. The fabric is made of the raw materials in the following weight parts: 9-14 parts of bamboo charcoal fibers, 15-25 parts of activated carbon fibers, 20-25 parts of apocynum venetum fibers, 10-20 parts of corduroy fibers, 6-10 parts of dacron, 5-8 parts of alkaline pectinase, 5-8 parts of bi-palmitoyl quadrol sodium dipropionate, 4-8 parts of tea saponin, 7-15 parts of chinlon, 9-13 parts of gabardine, 6-11 parts of bamboo fibers, 5-10 parts of fully drawn yarns, 5-8 parts of sisal hemp, 7-15 parts of jeans flocking, 10-20 parts of sheep wool, and 10-17 parts of cotton fibers. The textile fabric is woven by using various fiber materials, and can effectively absorb various dusts and has excellent sterilization and anti-bacterial effects. The textile fabric has effective allergy-free effect. The fabric is soft in texture, and is breathable and absorbs moisture, and the fabric is cool and comfortable to wear.

Owner:NANSHING CORP

Crease-resistance comfortable blend fiber

The invention discloses a crease-resistance comfortable blend fiber formed by blending and weaving a first crease-resistance comfortable fiber and a second crease-resistance comfortable fiber; the first crease-resistance comfortable fiber is formed by blending and weaving polylactic acid fiber, polyester fibres and cuprammonium fiber; the second crease-resistance comfortable fiber is formed by blending and weaving polyurethanes fiber, soybean protein fiber and newdal fiber. The crease-resistance comfortable blend fiber is formed by blending and weaving various fibers, is good in drapability, crease-resistance and stiff, fresh and cool in wearing, good in moisture absorption permeability, and elastic and close-fitting.

Owner:TAICANG LIANGXIN CHEM FIBER CO LTD

Cotton, ramie and bamboo blended grey yarns and production process thereof

InactiveCN103952824AGood moisture absorption and heat dissipation performanceGood moisture absorptionYarnYarnMoisture absorption

The invention discloses cotton, ramie and bamboo blended grey yarns. The cotton, ramie and bamboo blended grey yarns comprise the following components in percentage by weight: 40 to 60 percent of pure cotton fibers, 20 to 30 percent of ramie fibers and 15 to 20 percent of bamboo fibers. According to different using fields of a fabric; the weight ratio of the components can be adjusted correspondingly; three fibers are produced by adopting an embedded blending process. The cotton, ramie and bamboo blended grey yarns integrate the advantages of the cotton fibers, the ramie fibers and the bamboo fibers, have a unique style, high strength, high abrasion resistance, drapability, a soft hand feeling, excellent dyeing performance, high breathability, excellent moisture absorption property, excellent moisture desorption property, a silk-like feeling, are cool and comfortable to wear, are high-end apparel shell fabrics, and are suitable for making T-shirts, high-end fashionable dresses, high-end shirts, underwear and bedding articles.

Owner:安徽泰鸿嘉纺织有限公司

Polyurethane foaming sole and production method thereof

InactiveCN108329451ARaw materials are easy to getSimple preparation processSolesInsolesPolyesterPolyol

The invention discloses a polyurethane foaming sole and a production method thereof. The polyurethane foaming sole is prepared form foaming liquid and graphene, wherein the foaming liquid is preparedfrom the following components in parts by weight: 18 to 36 parts of polyester polyol, 20 to 40 parts of isocyanate, 0 to 1.5 parts of hardening agent, 0.3 to 0.4 part of catalyst and 0.1 to 0.13 partof water; the weight of the graphene accounts for at least 1 percent of the weight of the foaming liquid at least. All components in raw materials are mixed and then are injected into a mold and are heated and foamed; after a mixture is cooled and molded, a sole finished product is obtained. The polyurethane foaming sole provided by the invention has the advantages of easiness for obtaining the raw materials, simple production technology, easiness for operation, capability of realizing batch production and high economic benefits; the sold is integrally molded and does not need to be adhered byglue so that the sole is economical and environmentally friendly; the adjusting range of thickness and hardness is large and the variety of products is more, so that the sole is adaptive to market requirements; the graphene is added so that the bending resistance and the wear resistance of the product are improved; the polyurethane foaming sole is suitable for producing shoe pads; the heat dissipation efficiency of the shoe pads is improved through the graphene and people feel cool and comfortable when wearing the shoe pads.

Owner:惠州市鑫华骏贸易有限公司

Silk blend-fiber fabric

The invention discloses a silk blend-fiber fabric. The silk blend-fiber fabric is woven through mulberry silk fiber, tussah silk fiber, castor silk fiber and cassava silk fiber in a blended manner. The fabric fiber components of the silk blend-fiber fabric include, by weight percentage: 45% to 49% of the mulberry silk fiber, 18% to 22% of the tussah silk fiber, 13% to 17% of the castor silk fiber and 12% to 22% of the cassava silk fiber. The fabric is woven through the mulberry silk fiber, the tussah silk fiber, the castor silk fiber and the cassava silk fiber in the blended manner and has the advantages that the fabric is soft, cool and comfortable to wear, heat insulation is achieved, skin is nourished, human health is promoted, static electricity is resisted, and pests are controlled.

Owner:TAICANG XINTAI KNITTING

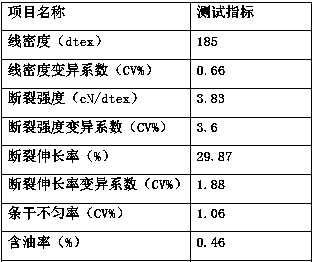

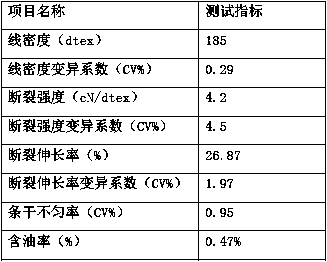

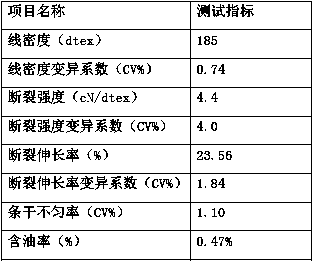

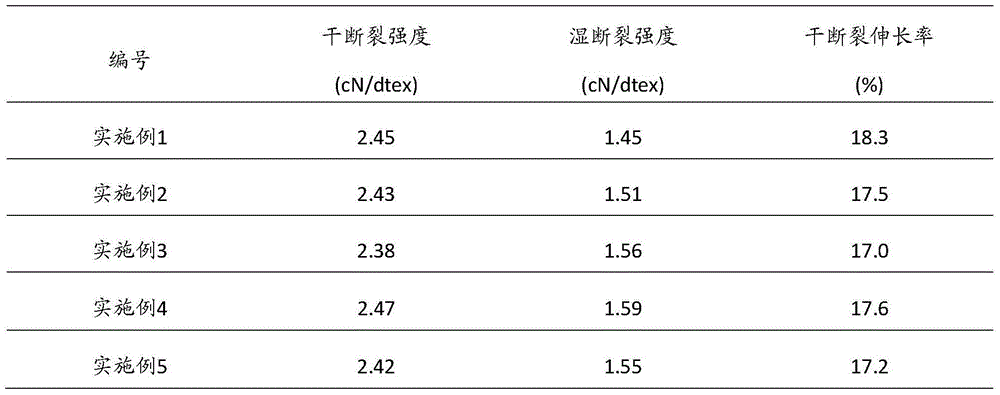

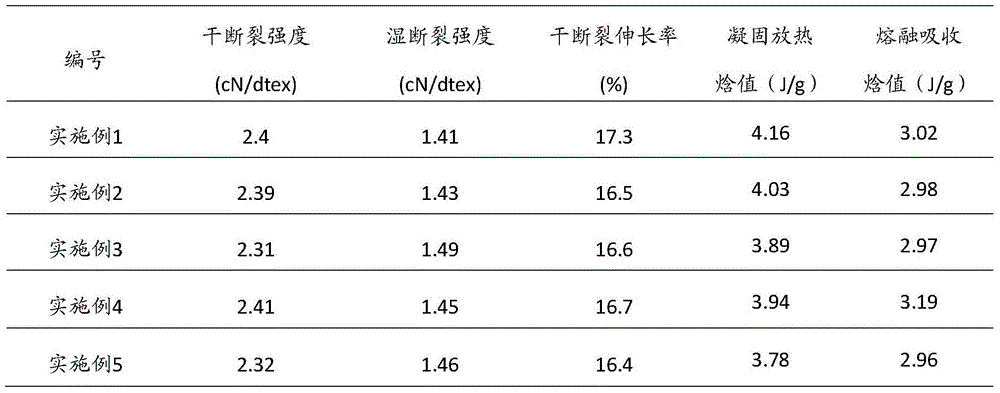

Preparation method of superfine denier moisture absorption and sweat release ice cool antibacterial fiber

InactiveCN107761189ASimple production processShort stayArtificial filament supportMelt spinning methodsPolyesterChemistry

The invention relates to the technical field of production of polyester fibers, in particular to a preparation method of a superfine denier moisture absorption and sweat release ice cool antibacterialfiber. The preparation method comprises the following steps: (1) preparing a polyester melt; (2) preparing a nanometer ice cool jade powder mixed with trace amount of the polyester melt; (3) preparing a cross-shaped cross section polyester fiber; and (4) winding and forming the polyester fiber. According to the preparation method of the obtained superfine denier moisture absorption and sweat release ice cool antibacterial fiber, a certain amount of the nanometer ice cool jade powder is added, so that the fiber achieves the antibacterial effect while the heat conductivity coefficient of the fiber is improved, and the fiber is mixed together with the cross-shaped cross section abnormal fiber, so that the fiber achieves the effects of transporting moisture, releasing sweat, cooling, and being antibacterial and bacteriostatic. In addition, the nanometer ice cool jade powder and a fiber-forming polymer are tightly combined, last permanently, and do not fall off even after the fiber is washed and worn for a long period of time, in addition, the superfine denier moisture absorption and sweat release ice cool antibacterial fiber is in contact with the skin for long, and has the effects ofimproving blood microcirculation, promoting metabolism, preventing diseases and eliminating fatigue.

Owner:新凤鸣集团股份有限公司

Anti-fluffing and pilling finishing method for wool fabric

InactiveCN107869045AHigh fastnessProportionally largeUltrasonic/sonic fibre treatmentAnimal fibresMegasonic cleaningMoisture absorption

The invention discloses an anti-fluffing and pilling finishing method for a wool fabric. The anti-fluffing and pilling finishing method comprises the following steps: firstly, performing ultrasonic cleaning on a wool fabric in a cleaning solution for 25-40 minutes; performing oxygen low-temperature plasma treatment on the cleaned wool fabric by using a low-temperature plasma treatment instrument for 2-4 minutes at the pressure intensity of 30-40pa and the power of 80-100w; performing twice-soaking and twice-rolling treatment on the pretreated wool fabric in a soaking and rolling anti-fluffingand pilling finishing solution by using a padder, wherein the temperature of the anti-fluffing and pilling finishing solution is 25-35 DEG C; the pH value of the anti-fluffing and pilling finishing solution is 6.5-7.2; the rotation speed of the twice-soaking and twice-rolling padder is 13-15r / minute; the rolling residue rate is 75-85%; finally drying the treated wool fabric by using a drying machine. The invention provides the anti-fluffing and pilling finishing method for the wool fabric, the wool fabric finished by using the method has the advantages of being high in solidness, high in softness, large in proportioning, good in drapability, good in moisture absorption and air permeability, cool and comfortable, free of fluffing or wrinkling, good in tidiness and attractive in appearance,and is low in manufacturing cost and simple to operate.

Owner:SUZHOU EMBROIDERY COLORFUL WORLD EMBROIDERY CRAFT CO LTD

Two-layer composite sound insulation fabric

InactiveCN103660417AImprove sound absorptionLow costSynthetic resin layered productsAluminum silicateEngineering

The invention discloses a two-layer composite sound insulation fabric which is formed by compositing and weaving an upper high-strength sound insulation fabric layer and a lower natural sound insulation fabric layer, wherein the high-strength sound insulation fabric layer is formed by blending and weaving 35-42% by weight of aluminum silicate cotton fiber and 58-65% by weight of acrylic cotton fiber; the natural sound insulation fabric layer is formed by blending and weaving 44-51% by weight of coconut silk fiber and 49-56% by weight of pina fiber. Due to adoption of the two-layer structural design, the upper high-strength sound insulation fabric layer has the characteristics of good sound insulation effect and low cost, the lower natural sound insulation fabric layer has the effect of further sound insulation, and meanwhile, the fabric is environment-friendly and non-pollution, and is moisture absorbable and breathable, and is cool and comfortable.

Owner:WUJIANG YUANMING PRINTING FACTORY

Anti-fluff fabric

The invention discloses an anti-fluff fabric which is formed by warp and weft in a mutually woven mode. The warp is woven by polyester fiber and linen fiber in a blending mode. The weft is woven by viscose and palace fiber in a blending mode. The warp comprises, by weight, 54% to 62% of the polyester fiber and 38% to 46% of the linen fiber respectively. The warp comprises, by weight, 48% to 56% of the viscose and 44% to 52% of the palace fiber respectively. The anti-fluff fabric is formed by the warp and the weft in a mutually woven mode, so that the structure is compact; the warp is composed of the polyester fiber and the linen fiber and the weft is composed of the viscose and the palace fiber, so that the anti-fluff fabric is capable of absorbing moisture, air permeable, cool, comfortable, free of wrinkles and fluff, tidy and attractive.

Owner:WUJIANG XUYANG TEXTILE

Environmentally-friendly blending fiber

InactiveCN105088456AWear moisture-absorbing and breathableWear cool and comfortableYarnProtective garmentEnvironmentally friendlySilk fiber

The invention discloses environmentally-friendly blending fiber. The environmentally-friendly blending fiber is formed by blending and weaving first environmentally-friendly fiber and second environmentally-friendly fiber. The first environmentally-friendly fiber is formed by blending and weaving wood fiber, silkworm protein fiber and natural color cotton fiber. The second environmentally-friendly fiber is formed by blending and weaving nano-antibacterial regeneration protein fiber, jute fiber and copper ammonia silk fiber. The environmentally-friendly blending fiber is formed by blending and weaving multiple kinds of fiber and has the advantages of being environmentally friendly, free of pollution, hygroscopic and breathable in wearing, cool, comfortable, soft, close-fitting and hygienical.

Owner:TAICANG LIANGXIN CHEM FIBER CO LTD

Preparation method of flax-viscose-mint fiber and sock

InactiveCN104947219AImprove performanceWith health functionArtificial filaments from viscosePanty-hoseCelluloseEmulsion

The invention provides a preparation method of flax-viscose-mint fiber. The preparation method comprises the following steps: dipping flax pulp, and carrying out pressing and smashing to obtain alkali cellulose, wherein the average degree of polymerization of the flax pulp is 400 to 450; yellowing the alkali cellulose, adding a bamboo charcoal-mint emulsion, and carrying out dissolving and filtering to obtain a spinning solution; spinning with the spinning solution to obtain the flax-viscose-mint fiber. As the bamboo charcoal-mint emulsion is added after yellowing, the performance of the flax-viscose-mint fiber can be improved; moreover, as bamboo charcoal and mint have a health-care function and a refreshing fragrance, a sock made of the flax-viscose-mint fiber can be endowed with a health-care function, and can perform a cool and comfortable effect when being worn by a user.

Owner:湖南莎丽袜业股份有限公司

Multifunctional breathable fabric

InactiveCN103462270AGood moisture absorption and air permeabilityWear cool and comfortableProtective garmentSpecial outerwear garmentsPolyesterMoisture

The invention discloses multifunctional breathable fabric which is formed by blending and weaving polyester fibers, natural silk fibers, natural wool fibers and ramie fibers. The multifunctional breathable fabric is composed of, by weight, 10-15% of the polyester fibers, 24-29% of the natural silk fibers, 20-35% of the natural wool fibers and 31-36% of the ramie fibers. The fabric is formed by blending and weaving the polyester fibers, the natural silk fibers, the natural wool fibers and the ramie fibers, thereby being good in moisture-absorbing and breathing performance and cool and comfortable to wear, the polyester fibers, the natural wool fibers and the ramie fibers have a function of resisting and absorbing ultraviolet rays and can protect human skin, and the polyester fibers also have effect of enabling the fabric not to deform.

Owner:WUJIANG HAIFENG WEAVING

Polyester taffeta rip-stop fabric and production method for same

The invention discloses a polyester taffeta rip-stop fabric and a production method for the same. The fabric is woven fabric, formed by grid circulation units and contains 60% to 100% of melted terylene-yarns. The grid circulation unit has a high tightness area and a low tightness area; the v terylene-yarns have a melting area and a non-melting area; the surface of the fabric has a concave-convex effect; and vertical height difference of the concave and convex parts is two to six mm. The fabric can be applied to spring-summer high-grade fashionable dresses, skirts and shirts; and the fabric has strong stereo perception, light texture, soft hand feeling and coolness as well as comfortableness.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

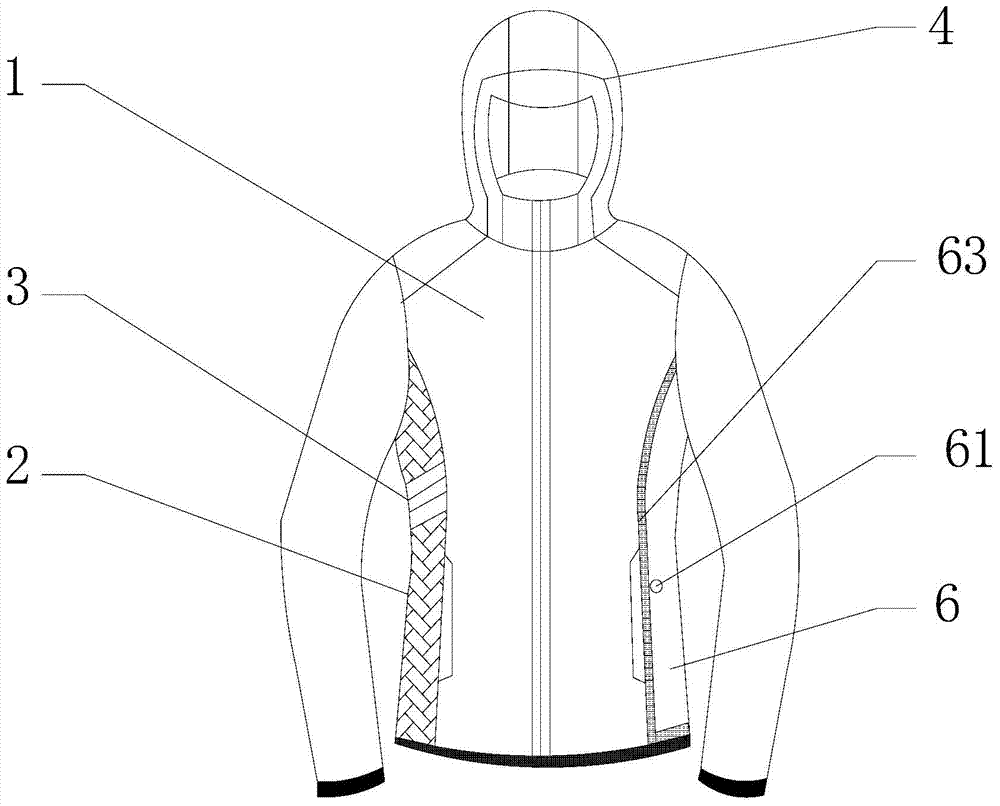

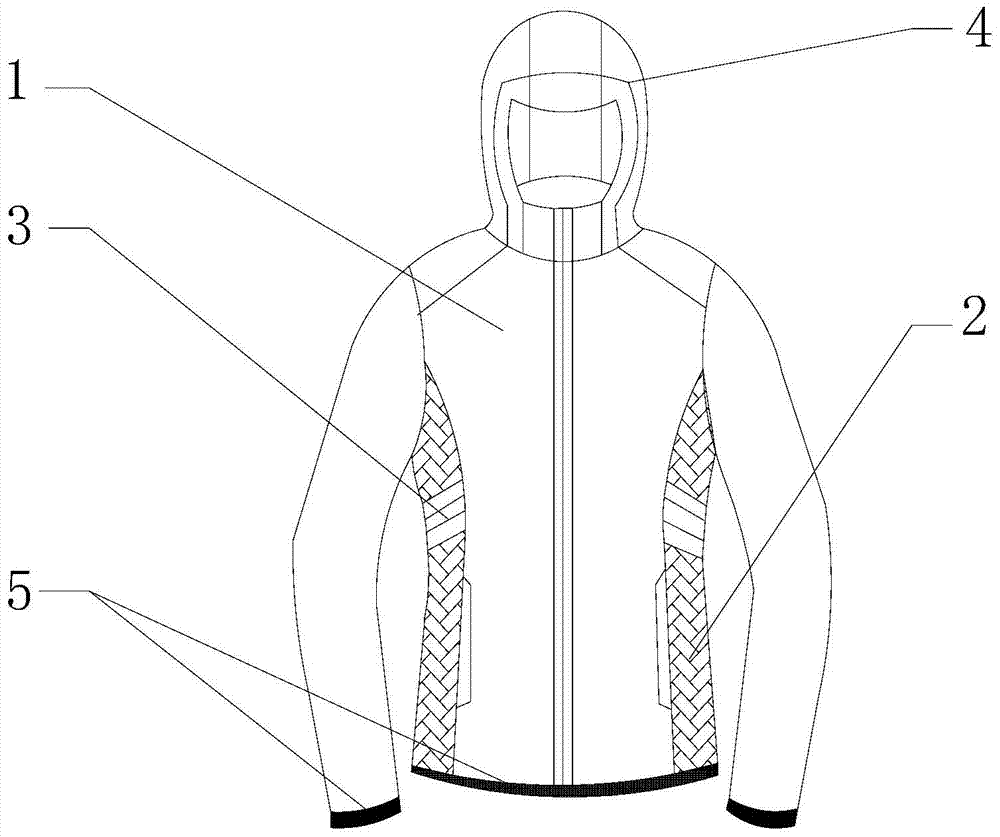

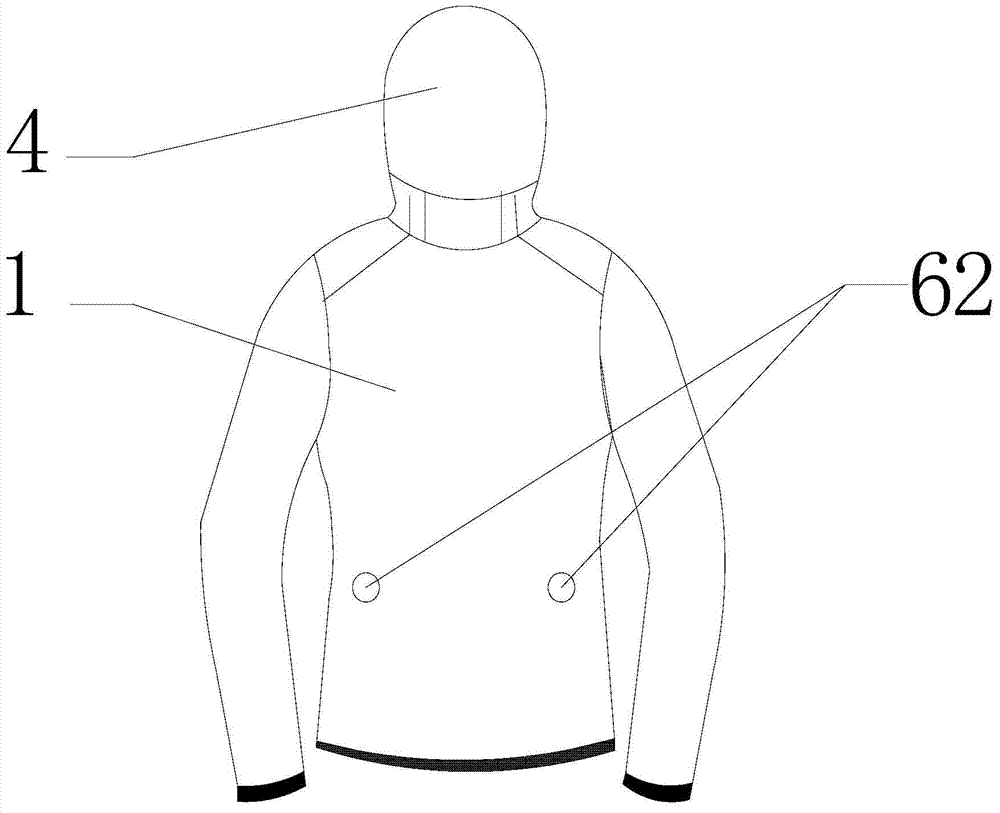

Green, environmentally friendly and anti-bacterial type sportswear

InactiveCN109419066AWear cool and comfortableNo pollution in the processProtective garmentSpecial outerwear garmentsEngineeringEnvironmental engineering

The invention discloses green, environmentally friendly and anti-bacterial type sportswear. The sportswear includes a garment body, and is characterized in that: the garment body sequentially comprises an environmentally friendly fabric layer and an antibacterial layer from the outside to the inside; the environmentally friendly fabric layer is woven by a first warp thread and a first weft thread;the first warp thread is formed by blending hemp fibers, milk silk fibers and silk fibers; the first weft thread is formed by blending soybean fibers and lyocell fibers; the antibacterial layer is woven by a second warp thread and a second weft thread; the second warp thread is formed by blending jutecell fibers and the lyocell fibers; and the second weft thread is formed by blending mint fibersand macromolecular bamboo charcoal fibers. The green, environmentally friendly and anti-bacterial type sportswear achieves the effects of green environmental protection and bacteriostasis of sportswear.

Owner:唐旭

Breathable down jacket

The invention discloses a breathable down jacket and relates to a breathable air-permeable down jacket provided with gill type breathing clothes sheets. The breathable down jacket comprises a long-sleeve jacket body, screen cloth and a movable clothes sheet. The breathable down jacket is characterized in that the net cloth is arranged from the underarm position to the lower hem of the breathable down jacket, the movable clothes sheet is arranged on the outer layer of the net cloth, and the movable clothes sheet and the net cloth are sewn to the long-sleeve clothes body. The breathable down jacket has a ventilation effect, can protect the upper body of a user fully and is capable of adapting to different weather in the morning and evening in winter, and is breathable when it gets warm again at noon and can keep warm when the temperature is low at night.

Owner:惠安东风服装有限公司

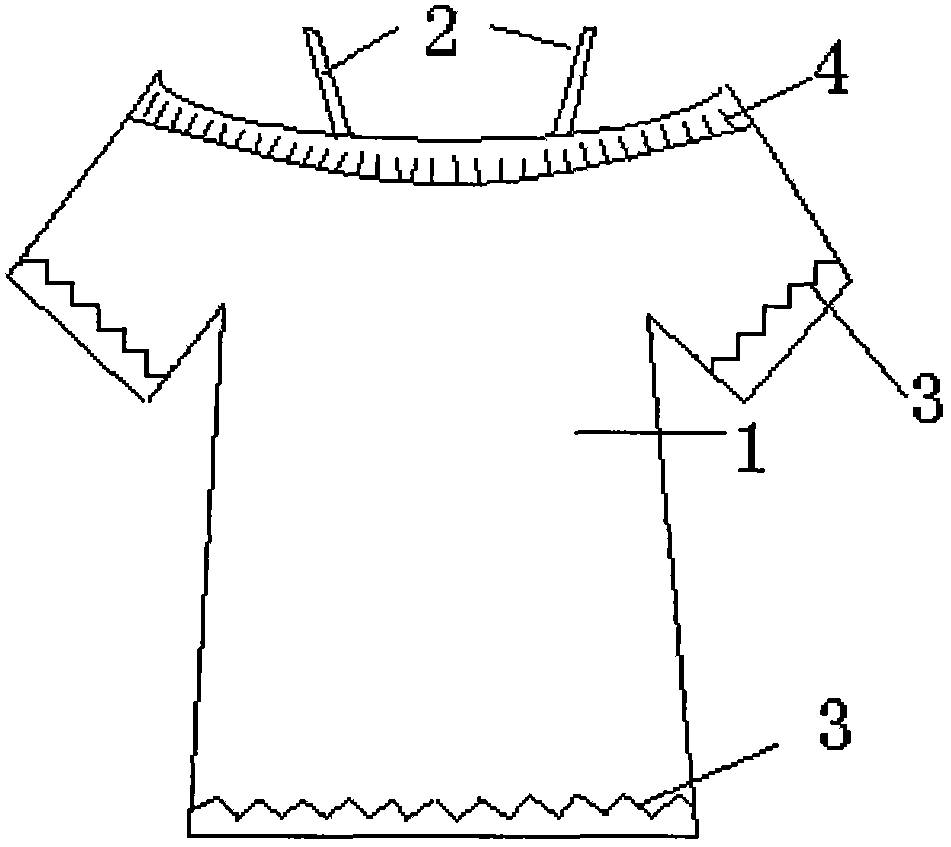

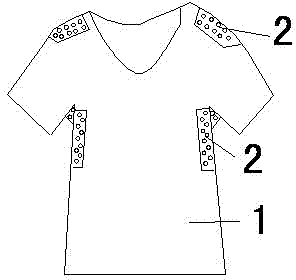

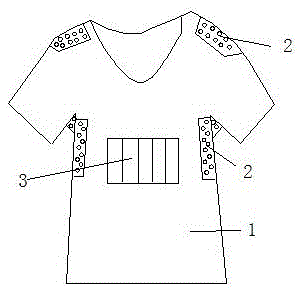

Ventilation T-shirt

InactiveCN103932417AEnhanced ventilation and perspirationWear cool and comfortableGarmentsPolyesterWear resistant

The invention relates to a ventilation T-shirt which comprises a T-shirt body (1). The ventilation T-shirt is characterized in that ventilation holes (2) are formed in the positions of the shoulders, the chest and the armpits of the T-shirt body (1), the T-shirt body (1) is made of knitted fabric, the fabric around the ventilation holes (2) is breathable fabric, the breathable fabric is formed by compositing a facing soft wear-resistant layer, a middle moisture absorption layer and a mesh breathable layer, the facing soft wear-resistant layer is attached to the inner surface of the middle moisture absorption layer, the mesh breathable layer is attached to the outer surface of the middle moisture absorption layer, the facing soft wear-resistant layer is formed by blending polyurethane elastic fibers, viscose fibers and formalized polyvinyl alcohol fibers, the middle moisture absorption layer is formed by weaving formalized polyvinyl alcohol fibers, the mesh breathable layer is made of polyester fibers, and the shape of the ventilation holes (2) is round. According to the ventilation T-shirt, due to the fact that the ventilation holes are formed in the positions of the shoulders, the chest and the armpits of the T-shirt, the ventilation and perspiration discharging functions of the T-shirt are enhanced, and the T-shirt is cool and comfortable to wear.

Owner:JIANGYIN TIANCHENG TEXTILE

Multifunctional moisture preservation fabric

InactiveCN103734953AGood moisturizing effectWear moisture-absorbing and breathableUndergarmentsProtective garmentViscoseMoisture absorption

The invention discloses a multifunctional moisture preservation fabric. The multifunctional moisture preservation fabric is formed by blending and interweaving viscose chitin fiber, ceramic fiber cotton, milk protein fiber and natural organic cotton fiber. The multifunctional moisture preservation fabric is composed of, by weight, 17% to 21% of the viscose chitin fiber, 12% to 16% of the ceramic fiber cotton, 25% to 29% of the milk protein fiber and 34% to 46% of the natural organic cotton fiber. The multifunctional moisture preservation fabric is formed by blending and interweaving the viscose chitin fiber, the ceramic fiber cotton, the milk protein fiber and the natural organic cotton fiber, the woven fabric has excellent moisture preservation performance, the effects of protecting and nourishing the skin can be achieved, and clothes made of the fabric have moisture absorption performance and breathability, are cool and comfortable, and have an antibacterial effect and a deodorization effect at the same time.

Owner:SUZHOU TANXI TEXTILE TECH CO LTD

Heat-resisting fabric knitted by warps and wefts

InactiveCN103361835ACompact structureImprove heat resistanceWoven fabricsMaterials scienceSilk fiber

The invention discloses a heat-resisting fabric knitted by warps and wefts, wherein the heat-resisting fabric is formed by knitting of the warps and the wefts. The warps are formed by knitting and blending of ramie fibers and linen fibers, and the wefts are formed by knitting and blending of mulberry silk fibers and plumetis fibers. The warps comprise, by weight, 37%-44% of the ramie fibers and 56%-63% of the linen fibers, and the wefts comprise, by weight, 32%-38% of the mulberry silk fibers and 62%-68% of the plumetis fibers. According to the heat-resisting fabric knitted by the warps and the wefts, the heat-resisting fabric is formed by knitting of the warps and the wefts and is compact in structure, the warps and the wefts are composed of the ramie fibers, the linen fibers, the mulberry silk fibers and the plumetis fibers, and the heat-resisting fabric formed by the warps and the wefts is good in heat resistance, can isolate high temperature when worn, and is cool and comfortable and hygroscopic and breathable.

Owner:WUJIANG XUYANG TEXTILE

Multi-purpose anti-bacterial fabric

The invention discloses a multi-purpose anti-bacterial fabric. The multi-purpose anti-bacterial fabric is composed of mercerized wool fibers, spun silk fibers and polyurethane plastic fibers with natural anti-bacterial Chinese herbal medicine powder, wherein the polyurethane plastic fibers are of a hollow structure, the natural anti-bacterial Chinese herbal medicine powder is placed in the hollow structure of the polyurethane plastic fibers, through holes are formed in the polyurethane plastic fibers, and the diameters of the through holes are smaller than that of the natural anti-bacterial Chinese herbal medicine powder. The fabric formed by blending and weaving the three fibers has the characteristics of moisture absorption, air ventilation, and coolness and comfortableness in wearing, and the natural anti-bacterial Chinese herbal medicine powder in the polyurethane plastic fibers can be in indirect contact with the skin through the through holes so as to achieve the antibacterial and deodorization effects and the sterilization and disinfection effects.

Owner:WUJIANG HAIFENG WEAVING

Short-sleeve shirt with hollow-out back part

InactiveCN102920045AWear cool and comfortableImprove ventilation performanceGarmentsEngineeringMechanical engineering

Owner:江阴第三精毛纺有限公司

Antibacterial fabric knitted by warps and wefts

InactiveCN103361837ACompact structureAntibacterialWoven fabricsAgricultural engineeringViscose fiber

The invention discloses an antibacterial fabric knitted by warps and wefts, wherein the antibacterial fabric is formed by knitting of the warps and the wefts. The warps are formed by knitting and blending of acetate fibers and viscose fibers, and the wefts are formed by knitting and blending of bamboo fibers and tencel fibers. The warps comprise, by weight, 52%-58% of the acetate fibers and 42%-48% of the viscose fibers, and the wefts comprise, by weight, 41%-46% of the bamboo fibers and 54%-59% of the tencel fibers. According to the antibacterial fabric knitted by the warps and the wefts, the antibacterial fabric is formed by knitting of the warps and the wefts and is compact in structure, the warps and the wefts are composed of the acetate fibers, the viscose fibers, the bamboo fibers and the tencel fibers, and the antibacterial fabric formed by the warps and the wefts has antibacterial, bacteriostatic and uvioresistant functions and is cool and comfortable to wear and hygroscopic and breathable.

Owner:WUJIANG XUYANG TEXTILE

Biodegradable synthetic fiber blended fabric

InactiveCN104041974APromote degradationWear cool and comfortableProtective garmentSpecial outerwear garmentsMoisture absorptionPolymer chemistry

The invention discloses biodegradable synthetic fiber blended fabric. The biodegradable synthetic fiber blended fabric is formed by weaving, by weight, polylactic acid fibers 19 percent-23 percent, chitin fibers 21 percent-25 percent, modal fibers 30 percent-34 percent and 18 percent-30 percent coconut fibers. As the fabric is formed by weaving the polylactic acid fibers, the chitin fibers, the modal fibers and the coconut fibers in a blended mode, the fabric has excellent biodegradability and is environmentally friendly and free of pollution. Besides, the woven fabric is capable of moisture absorption, breathable, cool, comfortable, soft and next to the skin during wear and has an antibacterial property and bacteria resistance.

Owner:TAICANG XINTAI KNITTING

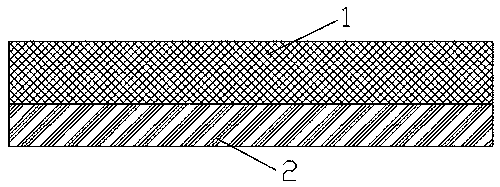

Composite environment-friendly health-care fabric

InactiveCN104029434AHealth wearWear moisture-absorbing and breathableLayered productsMinkLowering plants

The invention discloses an environment-friendly health-care fabric which is formed by weaving an upper animal fiber fabric layer and a lower plant fiber fabric layer in a combining manner, wherein the animal fiber fabric layer is formed by blending and weaving 66wt%-74wt% of cassava silk fibers and 26wt%-34wt% of mink hair fibers; the plant fiber fabric layer is formed by blending and weaving 48wt%-54wt% of apocynum venetum fibers and 46wt%-52wt% of natural bamboo fibers. By adoption of the double-layer structural design, the upper animal fiber fabric layer is noble and elegant and has health-care and warming effects, and the lower plant fiber fabric layer has the characteristics of health care, moisture absorption and breathability during wearing, coolness, comfort, bacteria resistance and deodorization.

Owner:TAICANG XINTAI KNITTING

Ultrathin anti-radiation fabric

InactiveCN103622187AUltra-thin materialThin materialTextiles and paperProtective garmentFiberMoisture absorption

The invention discloses an ultrathin anti-radiation fabric. The ultrathin anti-radiation fabric is made by blending and weaving the following components in percentage by weight: 21-25 percent of polyimide fiber, 13-18 percent of nano-silver fiber, 17-21 percent of acetate fiber and 36-49 percent of cashmere fiber. The fabric is made by blending and weaving the polyimide fiber, the nanometer silver fiber, the acetate fiber and the cashmere fiber, so that the woven fabric has a superior anti-radiation function; meanwhile, the fabric is ultrathin, wears elastic and close-fitted, has moisture absorption and air permeation functions, is cool and comfortable, and can be used for keeping a human body dry.

Owner:WUJIANG HENGDELI TEXTILE MILL

Preparation method of flax-viscose-mint heat-insulating fiber and sock

InactiveCN104947220AImprove performanceWith health functionArtificial filaments from viscosePanty-hoseCelluloseEmulsion

The invention provides a preparation method of flax-viscose-mint heat-insulating fiber. The preparation method comprises the following steps: dipping flax pulp, and carrying out pressing and smashing to obtain alkali cellulose, wherein the average degree of polymerization of the flax pulp is 400 to 450; yellowing the alkali cellulose, adding a bamboo charcoal-mint emulsion and phase change microcapsules, and carrying out dissolving and filtering to obtain a spinning solution; spinning with the spinning solution to obtain the flax-viscose-mint heat-insulating fiber. As the bamboo charcoal-mint emulsion and the phase change microcapsules are added after yellowing, the performance of the flax-viscose-mint heat-insulating fiber can be improved; moreover, as bamboo charcoal and mint have a health-care function and a refreshing fragrance, and the microcapsules can be used for remaining the refreshing fragrance, a sock made of the flax-viscose-mint heat-insulating fiber can be endowed with a health function, and can perform a cool and comfortable effect all the time when being worn by a user.

Owner:湖南莎丽袜业股份有限公司

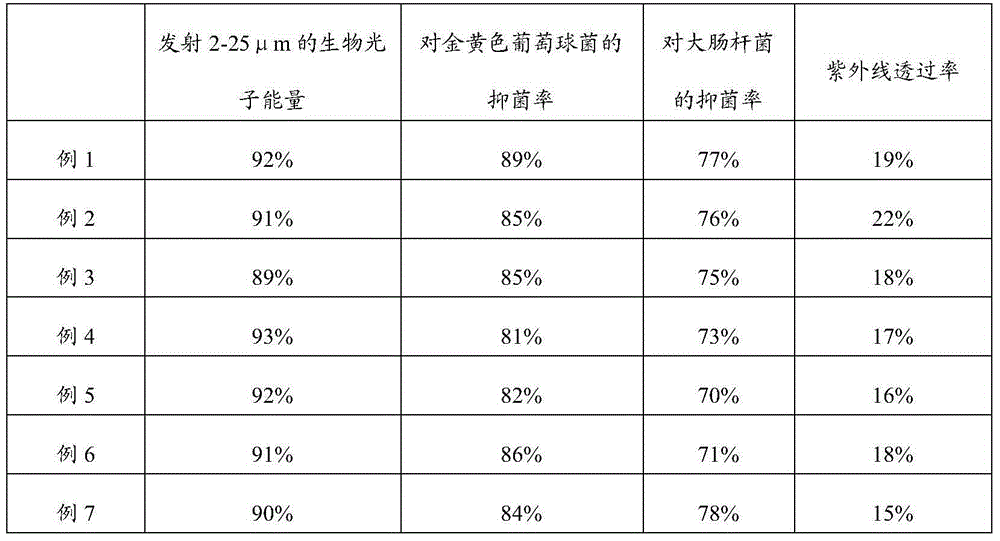

Double-layer anti-radiation and anti-bacteria fabric

InactiveCN104057650AWith UV protectionAntibacterial and deodorantSynthetic resin layered productsProtective garmentFiberCarbon fibers

The invention discloses a double-layer anti-radiation and anti-bacteria fabric. The double-layer anti-radiation and anti-bacteria fabric is formed by an upper anti-radiation fabric layer and a lower anti-bacteria fabric layer in a combining weaving mode. The anti-radiation fabric layer is formed by, by weight, 28%-37% of nanometer far-infrared ceramic fibers and 63%-72% of polyacrylonitrile fibers in a blending weaving mode. The anti-bacteria fabric layer is formed by, by weight, 57%-64% of alga carbon fibers and 36%-43% of tea leaf fibers in a blending weaving mode. The double-layer structure design is adopted, the upper anti-radiation fabric layer has the effects of preventing ultraviolet light and resisting radiation, and the lower anti-bacteria fabric layer has the advantages of resisting bacteria, keeping the human body clean, absorbing moisture and being breathable, cool and conformable.

Owner:ZHANGJIAGANG CITY YANGSHE TOWN XINMIYANG KNITTINGMILL

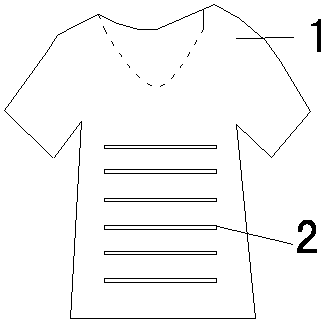

Breathable sweat-absorbing T-shirt

The invention relates to a breathable sweat-absorbing T-shirt comprises a T-shirt body (1). The T-shirt is characterized in that breathable holes (2) are formed in the shoulders, the chest and the armpits of the T-shirt body (1), the T-shirt body (1) is made of a knitted fabric, the fabric around the breathable holes (2) is PU artificial leather, the breathable holes (2) are round, sweat-absorbing cloth (3) is arranged on the armpits, the chest and the back of the T-shirt body (1) and arranged on the inner layer of the T-shirt, and the sweat-absorbing cloth (3) is made of a bamboo fiber and flax blended yarn knitted fabric. The breathable holes are formed in the shoulders, the chest and the armpits of the T-shirt, so the overall breathable property and the sweat discharging function of the T-shirt are enhanced, and the T-shirt is cool and comfortable to wear.

Owner:WUXI LINKBOY GARMENTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com