Short-sleeve shirt with hollow-out back part

A short-sleeve, back piece technology, applied in clothing, clothing, applications, etc., can solve the problems of poor wearing effect, poor ventilation performance of short sleeves, discomfort, etc., to achieve the effect of increasing aesthetic feeling, improving ventilation performance, and cool and comfortable wearing

Inactive Publication Date: 2013-02-13

江阴第三精毛纺有限公司

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Generally, the back of the short sleeves does not have hollows. This kind of short sleeves has poor ventilation performance. When the weather is hot in summer, it is stuffy and uncomfortable, and the wearing effect is poor and uncomfortable.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

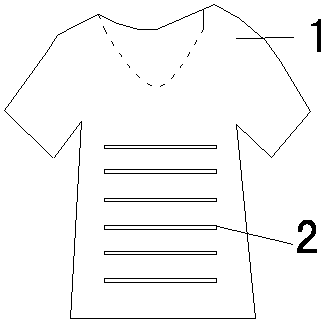

[0011] see figure 1 , the present invention relates to a short sleeve with a hollowed out back, comprising a short sleeve 1, the short sleeve 1 is made of knitted fabric, and the back of the short sleeve 1 is provided with a number of hollows 2, and the hollows 2 are holes Hollow out or bar-shaped hollow out, the hollow out of the hole is quincunx-shaped, round or heart-shaped.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a short-sleeve shirt with a hollow-out back part. The short-sleeve shirt with the hollow-out back part comprises a short-sleeve shirt (1) which is made of knitted fabrics. The short-sleeve shirt with the hollow-out back part is characterized in that a plurality of hollow-out parts (2) are formed on the back part of the short-sleeve shirt (1), wherein the hollow-out parts (2) are hole-shaped hollow-out parts or strip-shaped hollow-out parts; and the hole-shaped hollow-out parts are quincuncial, circular or heart-shaped. According to the short-sleeve shirt with the hollow-out back part, the hollow-out parts are formed on the back part of the short-sleeve shirt, so that the ventilating performance is improved, a user wearing the short-sleeve shirt can feel cool and comfortable, and various hollow-out patterns bring more aesthetics to the short-sleeve shirt.

Description

technical field [0001] The invention relates to a short sleeve, in particular to a short sleeve with a hollowed out back piece, which belongs to the field of clothing. Background technique [0002] Generally, the back of short sleeves does not have hollows. This kind of short sleeves has poor ventilation performance. When the weather is relatively hot in summer, it is stuffy and uncomfortable, and the wearing effect is poor and uncomfortable. Contents of the invention [0003] The object of the present invention is to overcome the above disadvantages and provide a short sleeve with a hollowed-out rear panel with better ventilation performance. [0004] The object of the present invention is achieved in the following way: a short sleeve with a hollowed out back piece, comprising a short sleeve, the short sleeve is made of knitted fabric, and several hollows are arranged on the back piece of the short sleeve, and the hollowed out is a hole hollowed out Or a strip-shaped hol...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A41D1/00A41D27/00

Inventor 张建良

Owner 江阴第三精毛纺有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com