Preparation method of flax-viscose-mint heat-insulating fiber and sock

A mint and viscose technology, applied in the textile field, can solve the problems of low price, low economic benefit, and unfavorable development of the mint industry, and achieve the effect of increasing health care functions, improving performance, and being cool and comfortable to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

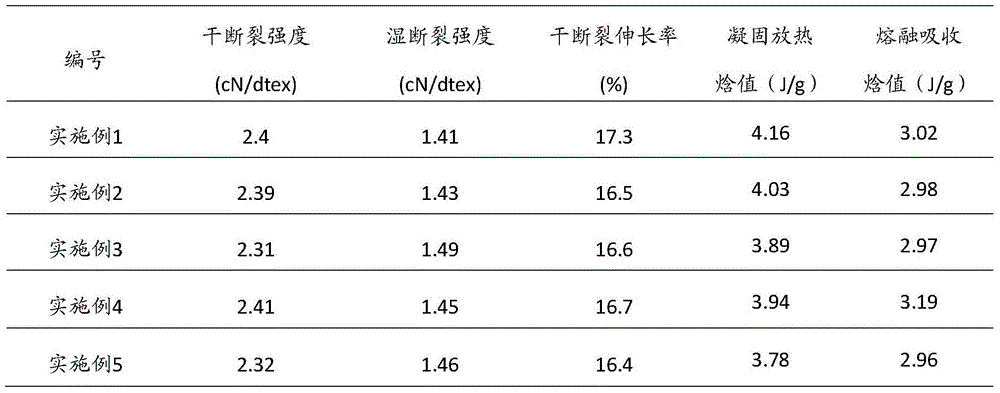

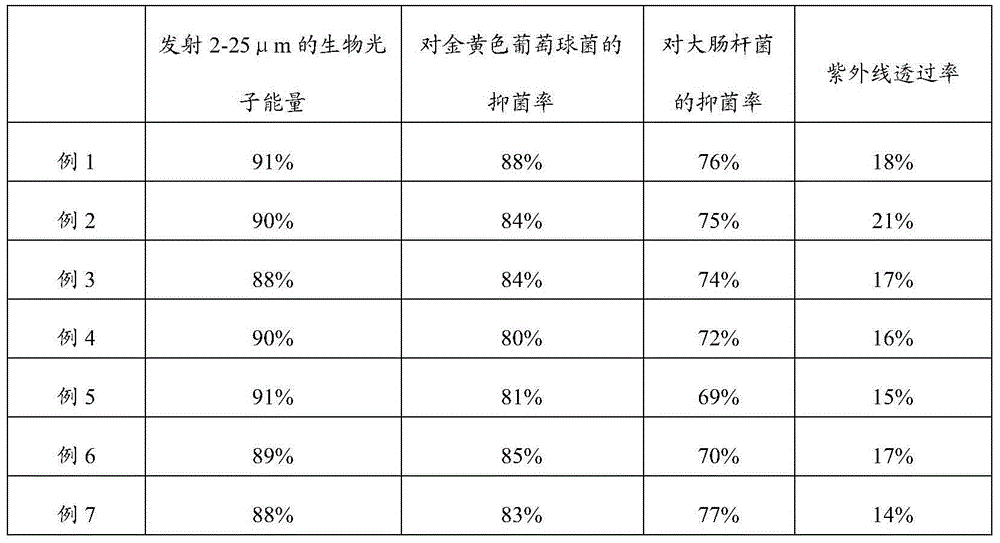

Examples

preparation example Construction

[0024] The preparation method of bamboo charcoal mint emulsion, bamboo charcoal is processed into superfine nano-powder, is fully mixed with peppermint oil again, makes bamboo charcoal reach saturation to the adsorption of peppermint oil, then adds water, emulsifying dispersant, mechanical Stir to obtain a uniform bamboo charcoal mint emulsion.

[0025] The microcapsules prepared in Chinese patent 200780044818.1 are used, and the microcapsules include a capsule core and a capsule wall, and the capsule wall is made of acrylic acid and / or C1-C24 alkyl esters of methacrylic acid, acrylic acid, methacrylic acid and / or Or maleic acid, cross-linking agent, the capsule core is a relative substance, the ratio of capsule core to capsule wall is 70:30-93:7, preferably 72:28-90:10

Embodiment 1

[0027] Put 15 kg of hemp pulp with an average degree of polymerization of 450, a cellulose content of 92%, an ash content of 0.14%, an iron content of 20 ppm, and a whiteness of 79% into the dipping tank, dipping at 95°C for 20 minutes, and dipping Alkali 220g / L is used; the impregnated hemp pulp is squeezed, pulverized and cooled to obtain alkali cellulose; the alkali cellulose is put into a yellowing machine for yellowing, the initial temperature of yellowing is 21°C, and the final temperature is At 28°C, the amount of carbon disulfide is 38% of the hemp pulp. After yellowing for 70 minutes, add bamboo charcoal peppermint oil and mix with microcapsules. The microcapsules are prepared using Example 3b of Chinese patent 200780044818.1;

[0028] Control adding bamboo charcoal peppermint oil to add ratio accounts for the mass percent of fiber is 0.05%, and microcapsule accounts for the weight percent of fiber is 10%, finally obtains spinning glue through caustic soda dissolution,...

Embodiment 2

[0031] Put 15kg of hemp pulp with an average degree of polymerization of 410, a cellulose content of 90%, an ash content of 0.13%, an iron content of 20ppm, and a whiteness of 78% into the dipping pot, dipping at 90°C for 25 minutes, and dipping Alkali 225g / L is used; the impregnated hemp pulp is squeezed, pulverized and cooled to obtain alkali cellulose; the alkali cellulose is put into a yellowing machine for yellowing, the initial temperature of yellowing is 25°C, and the final temperature is At 24°C, the amount of carbon disulfide is 39% of the hemp pulp. After yellowing for 75 minutes, add bamboo charcoal peppermint oil and mix with microcapsules. The microcapsules are prepared using Example 3c of Chinese patent 200780044818.1;

[0032] Control adding bamboo charcoal peppermint oil to add ratio accounted for 0.06% by weight of fiber, microcapsule accounted for 9% by weight of fiber, finally through caustic soda dissolution, mixing, defoaming, filtration, aging to obtain sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com