Preparation method of superfine denier moisture absorption and sweat release ice cool antibacterial fiber

An antibacterial fiber and ultra-fine denier technology, applied in fiber treatment, melt spinning, artificial filament physical therapy, etc., can solve problems affecting wearing comfort, high production and processing costs, mineral precipitation, etc., and achieve stable product quality Reliable, short dwell time, fast moisture wicking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

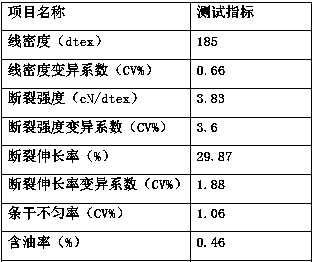

Embodiment 1

[0023] This embodiment describes a preparation method of ultrafine denier absorbent and cooling antibacterial fiber,

[0024] (1) Preparation of polyester melt

[0025] PTA and EG enter the slurry preparation tank through the PTA transmission pipeline and the EG transmission pipeline respectively, and the slurry is mixed uniformly under the action of the stirring motor, and the slurry is transported to the slurry feeding tank, and then the slurry is input into the esterification reaction In the kettle, after the esterification is completed, it passes through a metering injection pump, a catalyst feeding device, a pre-polycondensation reactor, a final polymerization reactor and other equipment to obtain a PET polyester melt. Esterification temperature is 270℃, steam pressure is 2.1kg / cm 2 , The pre-polycondensation temperature is 285°C, the final polycondensation temperature is 290°C, and the obtained polyester melt viscosity is 0.620dl / g.

[0026] (2) Preparation of micro-mixed poly...

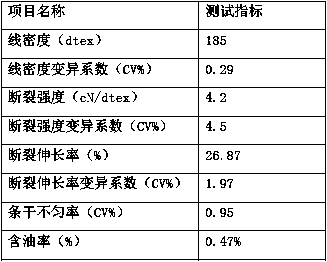

Embodiment 2

[0035] This embodiment describes a method for preparing ultrafine denier absorbent and discharging icy antibacterial fibers. The "preparation of nano-icy jade powder micro-mixed polyester melt" adopted in this embodiment is inconsistent with embodiment 1, and the others are the same as in embodiment 1.

[0036] Preparation of micro-mixed polyester melt of nano-icy jade powder

[0037] After the nano-icy jade powder is dried and extruded and melted, it is measured by a metering pump with a mass content ratio of 0.8%, and then enters the spherical cavity-shaped high-efficiency dynamic mixer; the polyester melt prepared in step (1) is transported through the melt After the pipeline is pressurized by the booster pump, the melt cooler, and the distribution valve are divided into the spinning box, and then enters the spherical cavity-shaped high-efficiency dynamic mixer to fully mix with the nano-icy jade powder to obtain a small amount of nano-icy jade powder Mixed polyester melt. The ...

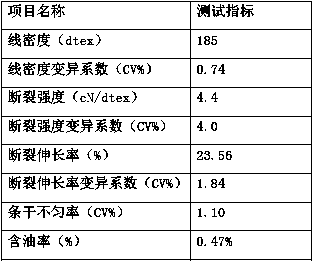

Embodiment 3

[0041] This embodiment describes a preparation method of ultra-fine denier absorbent and discharging icy antibacterial fiber. The "preparation of nano-icy jade powder micro-mixed polyester melt" adopted is inconsistent with that in Example 1, and the others are the same as in Example 1.

[0042] Preparation of micro-mixed polyester melt of nano-icy jade powder

[0043] After the nano-icy jade powder is dried and extruded and melted, it is measured by a metering pump at a mass content ratio of 1.0%, and then enters the spherical cavity-shaped high-efficiency dynamic mixer; the polyester melt prepared in step (1) is transported through the melt The pipeline is pressurized by the booster pump, the melt cooler, and the distribution valve are divided into the spinning box, and then enters the spherical cavity-shaped high-efficiency dynamic mixer to fully mix with the nano-icy jade powder to obtain a small amount of nano-icy jade powder Mixed polyester melt. The temperature of the spinn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com