Natural fiber composite plate and manufacturing method thereof

A natural fiber and composite board technology, applied in chemical instruments and methods, lamination devices, lamination, etc., to achieve the effect of not easy to delaminate, horizontal strength balance, convenient handling and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In the first step, weighing, opening and mixing, pre-forming, carding, air-forming, and acupuncture are carried out according to the composition of 100% PP fibers to obtain the bonding layer 2, needle board cloth in the acupuncture process The needle density is 1000 pieces / m, the acupuncture frequency is 1500 times / min, and the speed is 2 m / min.

[0040] The second step: according to the ratio of 20% ES fiber and 60% flax fiber, carry out weighing, opening and mixing, pre-forming, carding, and air-forming to prepare upper layer 1 and lower layer 3, wherein pre-forming, carding, The speed of the air-laid process is 5m / min, and the thickness of the upper and lower layers is 3cm respectively;

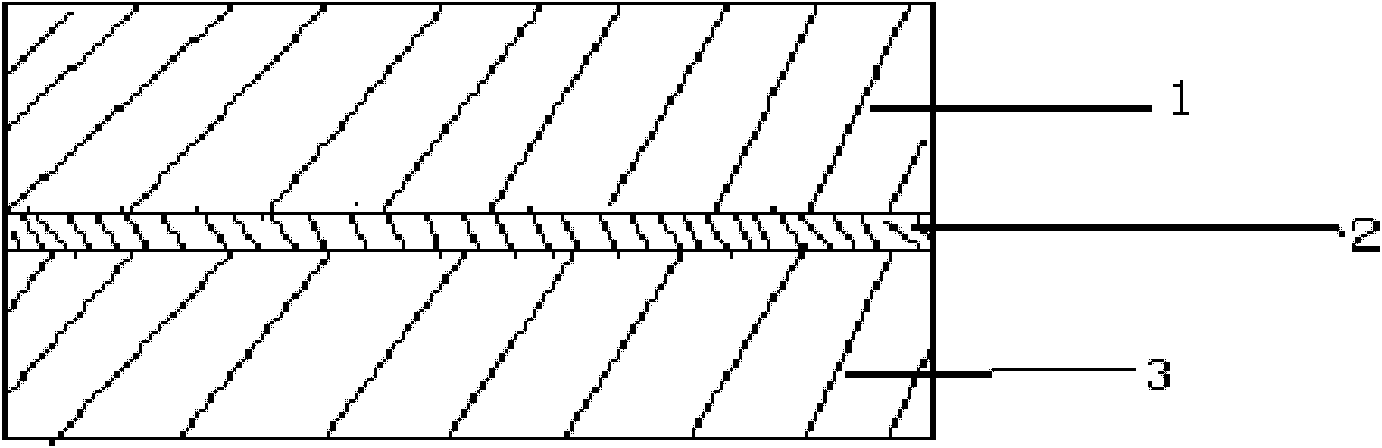

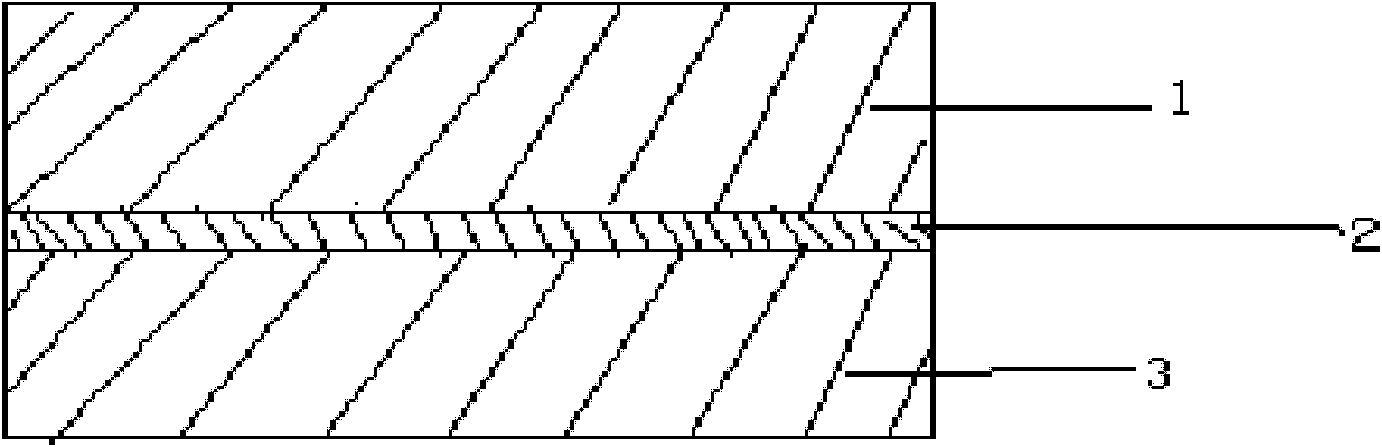

[0041] The third step: the upper layer 1 and the lower layer 3 prepared by the adhesive layer 2 prepared in step S01 and step S02 according to figure 1 Lay together in the order shown, and then enter the oven together, cold rolling, cooling, cutting, inspection and packaging, the o...

Embodiment 2

[0045] In the first step, according to the composition of 80% PE / PET sheath-core fiber and 20% vinylon fiber, carry out weighing, opening and mixing, pre-forming, carding, air-laying, and needle-punching to obtain the adhesive layer 2 , the density of needle board needles in the acupuncture process is 3000 pieces / m, the acupuncture frequency is 1000 times / min, and the speed is 10 m / min;

[0046] The second step: according to the ratio of 30% ES fiber, 10% jute fiber, 50% coconut fiber, 10% bamboo charcoal fiber, weighing, opening and mixing, pre-forming, carding, air-laid to make the upper layer 1. The lower layer 3, wherein the speed of the pre-forming, carding, and air-laying processes is 10m / min, and the thickness of the upper and lower layers is 2.5cm respectively;

[0047] The third step: the upper layer 1 and the lower layer 3 prepared by the adhesive layer 2 prepared in step S01 and step S02 according to figure 1 Lay together in the order shown, and then enter the oven...

Embodiment 3

[0051] In the first step, according to the composition of 60% 4080 fiber, 20% polyester fiber and 20% nylon fiber, the bonding layer is obtained by weighing, opening and mixing, pre-forming, carding, air-laid and needle punching 2. The bonding layer adopts the needle board cloth needle density of 5000 pieces / m in the acupuncture process, the acupuncture frequency is 100 times / min, and the speed is 18 m / min;

[0052] The second step: according to the ratio of 40% PE / PET core fiber, 30% sisal fiber, 10% palm fiber, 20% coconut shell fiber, weighing, opening and mixing, pre-forming, carding, air-forming The upper layer 1 and the lower layer 3 are prepared by netting, wherein the speed of the pre-forming, carding, and air-forming processes is 18m / min, and the thickness of the upper and lower layers is 3cm respectively;

[0053] Step 3: Lay the adhesive layer 2 prepared in step S01 and the upper layer 1 and lower layer 3 prepared in step S02 together in order, and then enter the ov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com