Tatami bed core and preparation method thereof

A technology of tatami mats and bed cores, applied in chemical instruments and methods, mattresses, spring mattresses, etc., can solve the problems of coconut palm fiber being susceptible to moisture and mildew, poor air permeability and elasticity, and harmful to human health, and achieve good moisture absorption and ventilation Non-toxic, soft touch, not easy to delaminate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

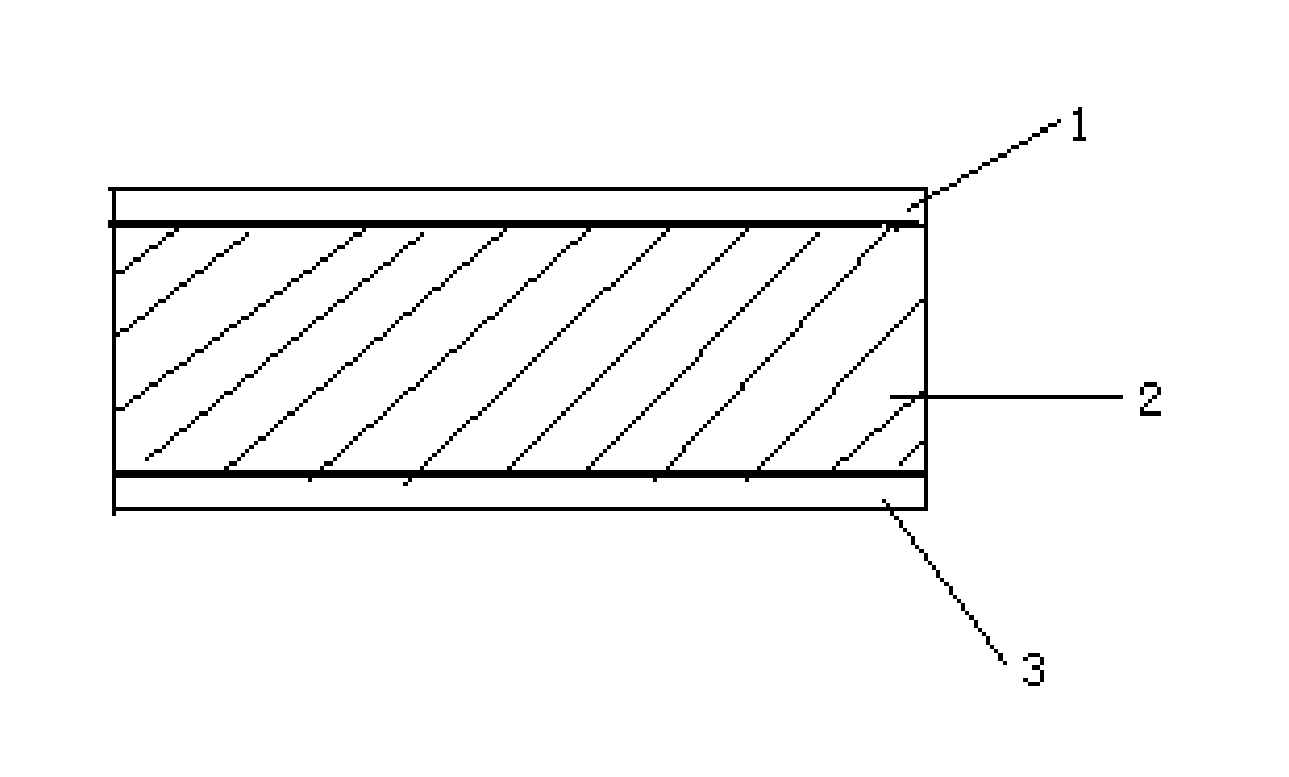

[0032] A tatami bed core includes an intermediate layer 2 and a surface layer arranged on the upper and lower surfaces of the intermediate layer 2. The surface layer is composed of 15% PLA fiber and 85% jute fiber by weight percentage. The middle layer 2 is composed of the following components by weight percentage: 55% coconut palm fiber, 5% moon peach fiber, and 40% PP fiber.

[0033] The preparation method includes the following steps:

[0034] In the first step, the components are weighed, opened and mixed, pre-laid, carded, air-laid, and needle punched according to the required proportions to prepare the upper surface layer 1 and the lower layer 3 non-woven layers respectively. The non-woven layers of the surface layer 1 and the lower layer 2 use 15% PLA fiber and 85% jute fiber, and the needle punching density in the needle punching process is 88 punches / cm 2 ;

[0035] In the second step, according to the ratio of 55% coconut palm fiber, 5% moon peach fiber, and 40% PP fiber, ...

Embodiment 2

[0049] A tatami bed core, comprising an intermediate layer 2 and a surface layer arranged on the upper surface of the intermediate layer 2. The surface layer is composed of the following components by weight percentage: 40% PP fiber and 60% bamboo fiber. The intermediate layer 2 It is composed of the following components by weight percentage: 85% moon peach fiber, 5% hemp fiber and 10% ES fiber.

[0050] The preparation method includes the following steps:

[0051] In the first step, the components are weighed, opened and mixed, pre-laid, carded, air-laid, and needle punched according to the required proportions to prepare the upper surface layer 1 and the lower layer 3 non-woven layers respectively. The non-woven layer of the surface layer 1 is made of 440% PP fiber and 60% bamboo fiber. The needle punching density in the needle punching process is 44 punches / cm 2 ;

[0052] In the second step, according to the ratio of 85% moon peach fiber, 5% hemp fiber and 10% ES fiber, the inte...

Embodiment 3

[0064] A tatami bed core includes a middle layer 2 and a surface layer arranged on the upper and lower surfaces of the middle layer 2. The surface layer is composed of 35% 4080 fiber, 35% hemp fiber and 30% by weight. % Bamboo fiber, the middle layer 2 is composed of the following components by weight percentage: 60% coconut palm fiber, 15% moon peach fiber and 15% ES fiber.

[0065] The preparation method includes the following steps:

[0066] In the first step, the components are weighed, opened and mixed, pre-laid, carded, air-laid, and needle punched according to the required proportions to prepare the upper surface layer 1 and the lower layer 3 non-woven layers respectively. The non-woven layers of the surface layer 1, the lower layer 3 are made of 35% 4080 fiber and 65% hemp fiber, and the needle punching density in the needle punching process is 150 punches / cm 2 ;

[0067] In the second step, according to the proportion of 60% coconut palm fiber, 15% moon peach fiber and 15% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com