Organic silicon antifouling coating containing PEG (Polyethylene Glycol)/quaternary ammonium salt and preparation method of organic silicon antifouling coating

A technology of antifouling coatings and quaternary ammonium salts, applied in antifouling/underwater coatings, biocide-containing paints, coatings, etc., can solve the problems of performance changes, low chemical activity of quaternary ammonium salts, etc., and achieve low surface energy , good anti-fouling performance, excellent anti-protein effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

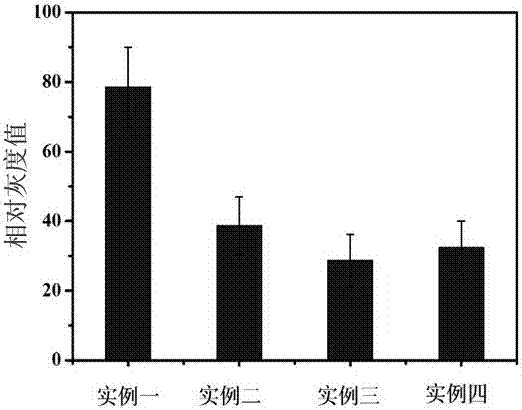

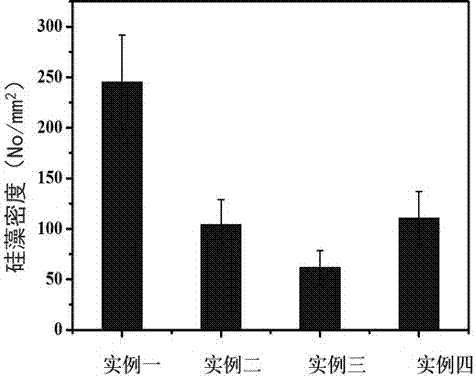

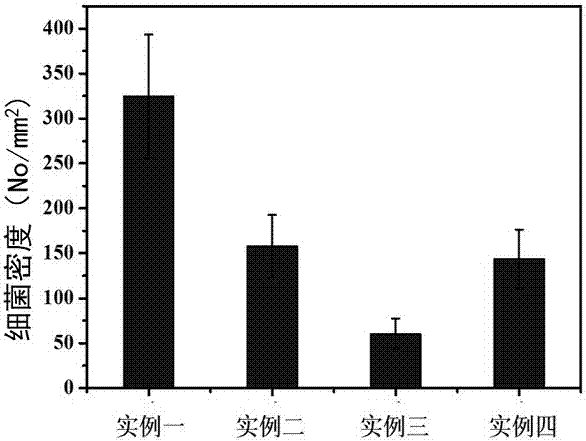

Embodiment 1

[0042] Embodiment one: the organosilicon antifouling paint containing polyethylene glycol / quaternary ammonium salt provided in this embodiment and preparation method thereof are characterized in that, it comprises the following steps:

[0043] (1) Preparation of composition 1:

[0044]Weigh 16.75g of polyethylene glycol diallyl ether with a number average molecular weight of 500, 60g of toluene, after mixing evenly, add the mixed solution together with 0.053g of Karstedt catalyst to a reflux condenser and a constant pressure dropping funnel In a four-necked round-bottomed flask with a nitrogen gas guide tube and a mechanical stirrer, the temperature was raised to 85° C. under a nitrogen atmosphere, and the temperature was maintained at reflux for 10 minutes. Weigh 75g of hydrogen-terminated silicone oil with a number average molecular weight of 12,500 and 40g of toluene, mix them evenly, pour them into a constant pressure dropping funnel, and add them to a four-necked flask wi...

Embodiment 2

[0056] Embodiment two: Please change a catalyst. Change to polyethylene glycol diallyl ether and hydrogen-terminated silicone oil with a different molecular weight.

[0057] The preparation method and product of organic fluorosilicon biomimetic antifouling resin provided in this example, its components and steps are roughly the same as Example 1, the difference is:

[0058] The amount of trimethoxysilylpropyl-N,N,N-trimethylammonium chloride used in the preparation was 0.616 g.

example 3

[0059] Example 3: Please change a catalyst. Change to polyethylene glycol diallyl ether and hydrogen-terminated silicone oil with a different molecular weight.

[0060] The preparation method and product of organic fluorosilicon biomimetic antifouling resin provided in this example, its components and steps are basically the same as Example 2, the difference is:

[0061] The catalyst used in the preparation process is dibutyltin dilaurate, and the quaternary ammonium compound used in the preparation process is tetradecyldimethyl (3-trimethoxysilylpropyl) ammonium chloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com