Natural fiber health-care board and preparation method thereof

A natural fiber and health-care board technology, applied in the field of composite boards, can solve problems such as delamination, and achieve the effects of ensuring durability, light weight, and good moisture absorption and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In the first step, each component is weighed, opened and mixed, pre-laid, carded, air-laid, and needle punched according to the ratio of 10% PP fiber and 90% elastic chemical fiber. For spinning layer, the needle board cloth needle density in the needle punching process is 1000 pieces / m, the needle punching frequency is 1500 times / min, and the speed is 2 m / min.

[0043] The second step: According to the proportion of 20% ES fiber, 60% flax fiber, 20% bamboo charcoal fiber, weigh, open and mix, pre-web, card, air-laid intermediate layer 2, of which pre-web The speed of carding and air-laid process is 5m / min;

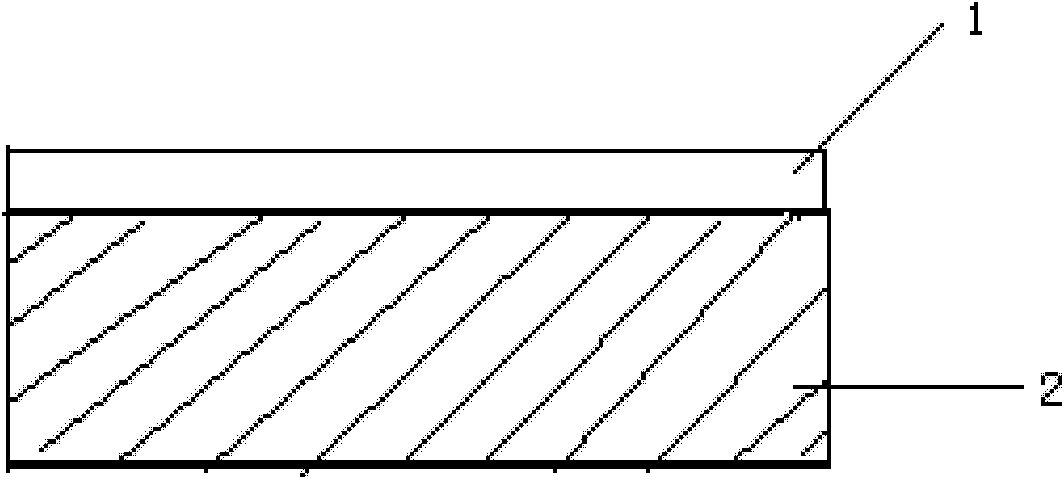

[0044] The third step: the non-woven layer prepared in step S01 and the intermediate layer 2 prepared in step S02 according to figure 1 Spread together in the order shown, then enter the oven, cold rolling, cooling, cutting, inspection and packaging together. The oven temperature is 230℃, the baking time in the oven is 2min, the cold rolling temperature is 5℃, and the c...

Embodiment 2

[0048] In the first step, each component is weighed, opened and mixed, pre-laid, carded, air-laid, and needle punched according to the ratio of 40% PE / PET sheath-core fiber and 60% jute fiber to obtain the upper surface layer. 1 non-woven layer, the needle board cloth needle density in the needle punching process is 3000 pieces / m, the needle punching frequency is 1000 times / min, and the speed is 10 m / min;

[0049] Step 2: According to the ratio of 30% ES fiber, 20% jute fiber, and 50% coconut palm fiber, the intermediate layer 2 is prepared by weighing, opening and mixing, pre-netting, carding, and air-laying. The speed of netting, carding and air-laid process is 10m / min;

[0050] The third step: the non-woven layer prepared in step S01 and the intermediate layer 2 prepared in step S02 according to figure 1 Spread together in the order shown, then enter the oven, cold rolling, cooling, cutting, inspection and packaging together. The oven temperature is 210℃, the baking time in the ...

Embodiment 3

[0054] In the first step, each component is weighed, opened and mixed, pre-laid, carded, air-laid, and needle punched according to the ratio of 25% 4080 fiber, 45% elastic chemical fiber and 30% kenaf fiber. Obtain the non-woven layer of the lower layer 3, the needle board cloth needle density in the needle punching process is 5000 pieces / m, the needle punching frequency is 100 times / min, and the speed is 18 m / min;

[0055] Step 2: According to the proportion of 40% PE / PET sheath-core fiber, 20% sisal fiber, 10% brown fiber, 30% coconut husk fiber, carry out weighing, opening and mixing, pre-netting, carding, air flow Intermediate layer 2 is obtained by web forming, in which the speed of pre-web, carding and air-laid processes is 18m / min;

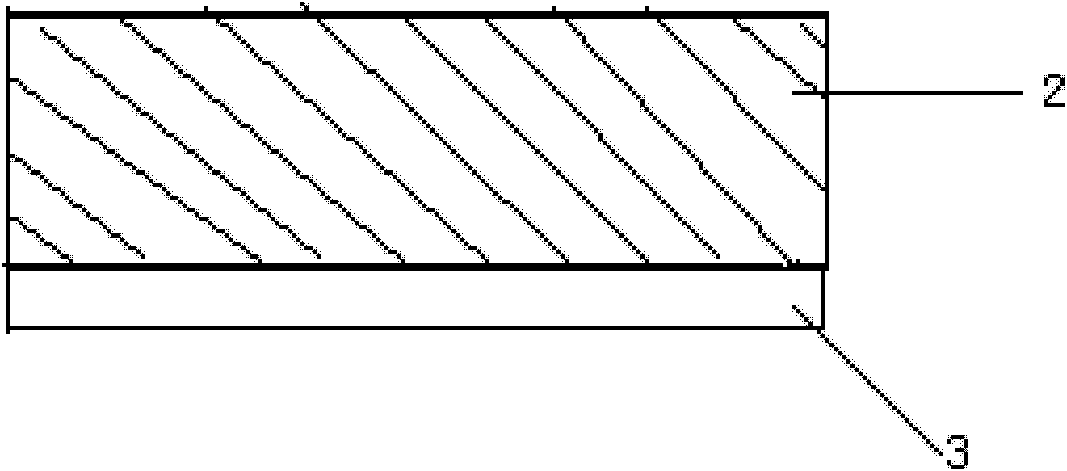

[0056] The third step: the non-woven layer prepared in step S01 and the intermediate layer 2 prepared in step S02 according to figure 2 Spread together in the order shown, then enter the oven, cold-roll, cool, cut, inspect and pack together. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com