Bidirectional trigger diode chip production method

A two-way triggering and diode technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as affecting product reliability, single packaging form, inconvenient production volume, etc., to avoid stress, reduce production costs, and reduce operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The bidirectional trigger diode is a special semiconductor device, and its important electrical characteristic parameters include forward and reverse breakdown voltage, dynamic rebound voltage and conduction voltage drop. The internal structure of the chip is a transistor structure, but there is no base lead, and the emitter and collector can be exchanged arbitrarily. Based on the transistor principle, by adjusting the first and second diffusion concentration and junction depth, a suitable β 0 , to ensure the trigger voltage and rebound voltage of the product. The thickness of the selected silicon wafer material must ensure a small conduction voltage drop.

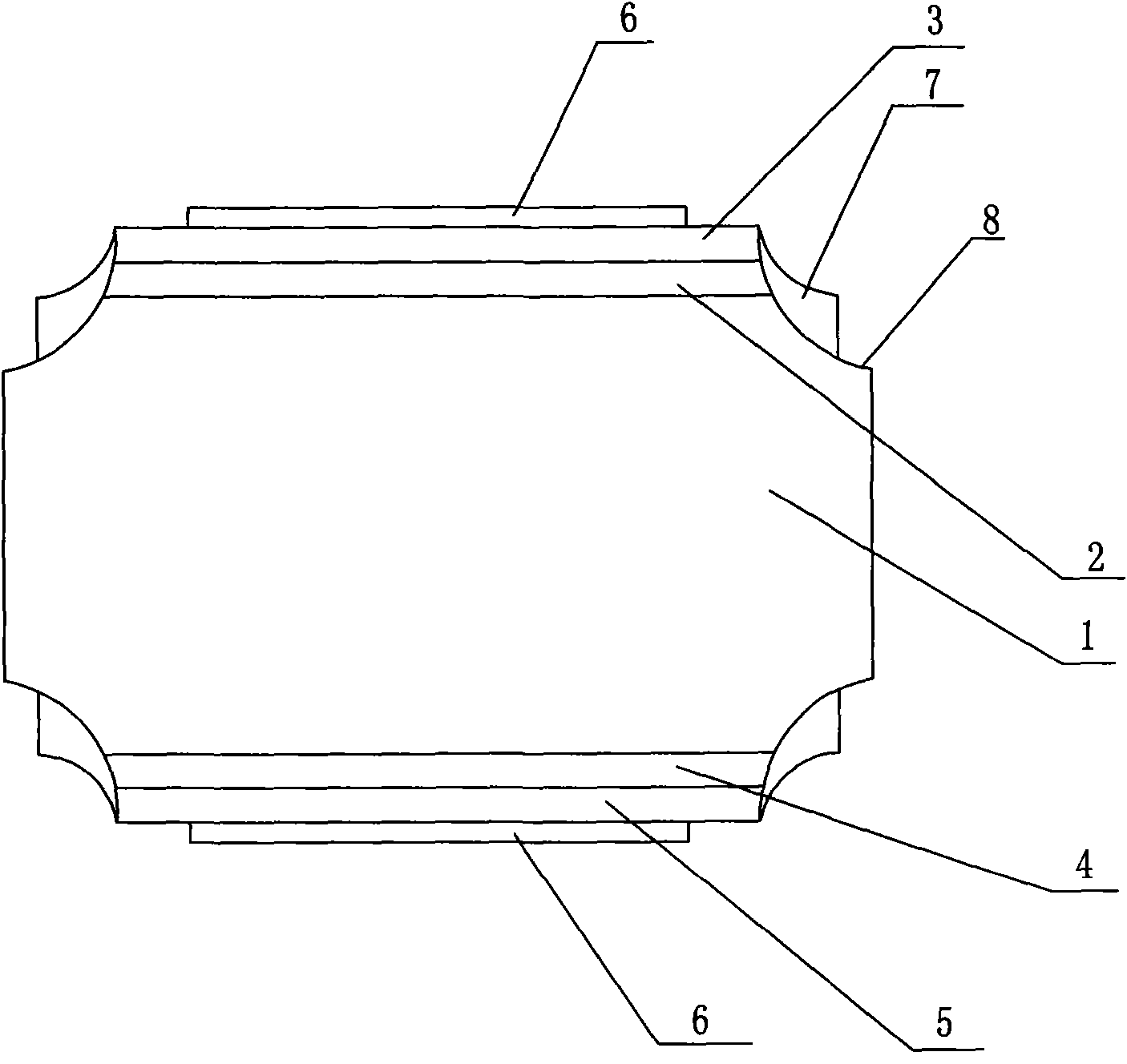

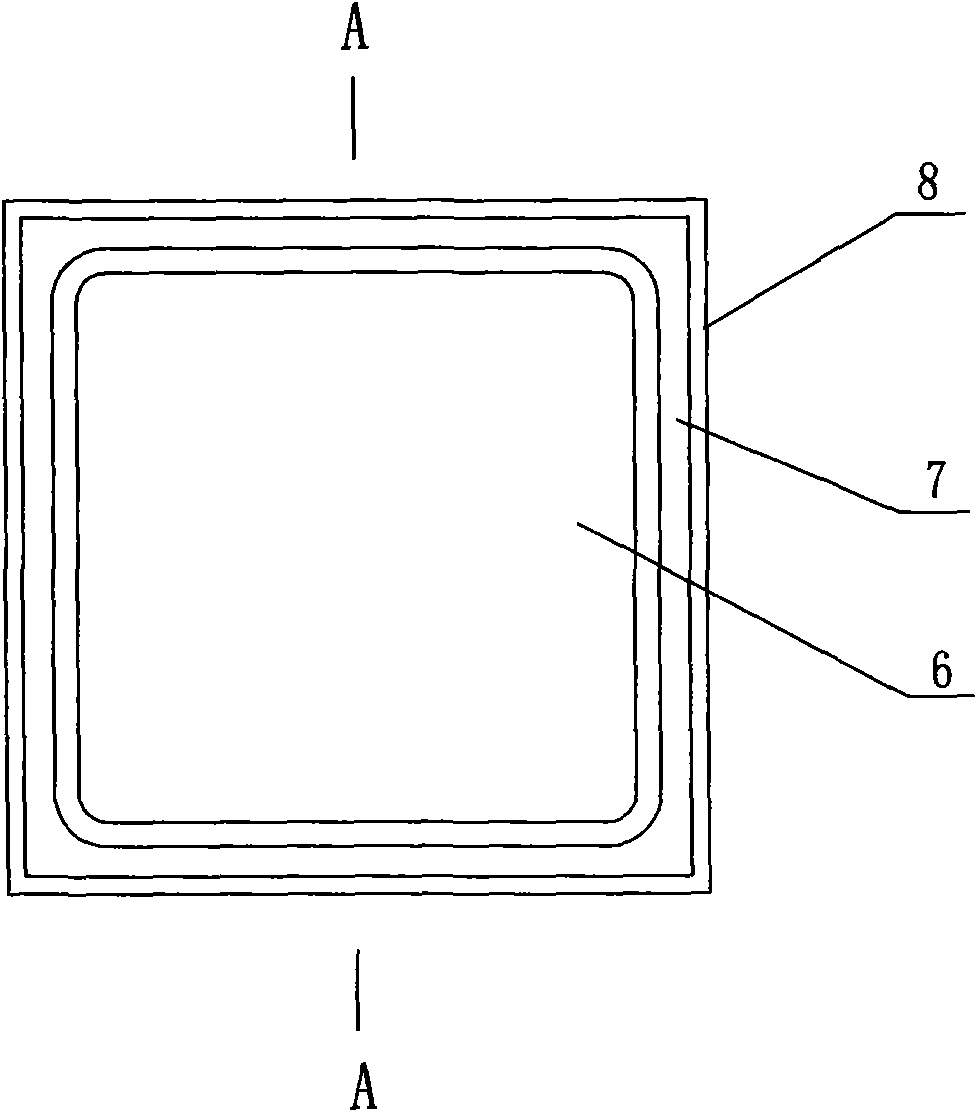

[0021] this invention figure 1 The P-type impurity diffusion in the 2nd region and 4th region is completed in the same diffusion process, figure 1 The diffusion of N+ type impurities in the 3rd and 5th regions is also completed in the same diffusion process, which ensures the symmetry of the forward and reverse b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com