White-gasoline-resistant styrene-acrylic emulsion, white-gasoline-resistant emulsion gloss oil and preparation methods thereof

A technology of acrylic emulsion and styrene, applied in textiles and papermaking, non-fiber pulp addition, papermaking, etc., can solve the problems of damaged printed products, loss, waste, etc., and achieve the effect of improving polarity, improving ability, and full hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

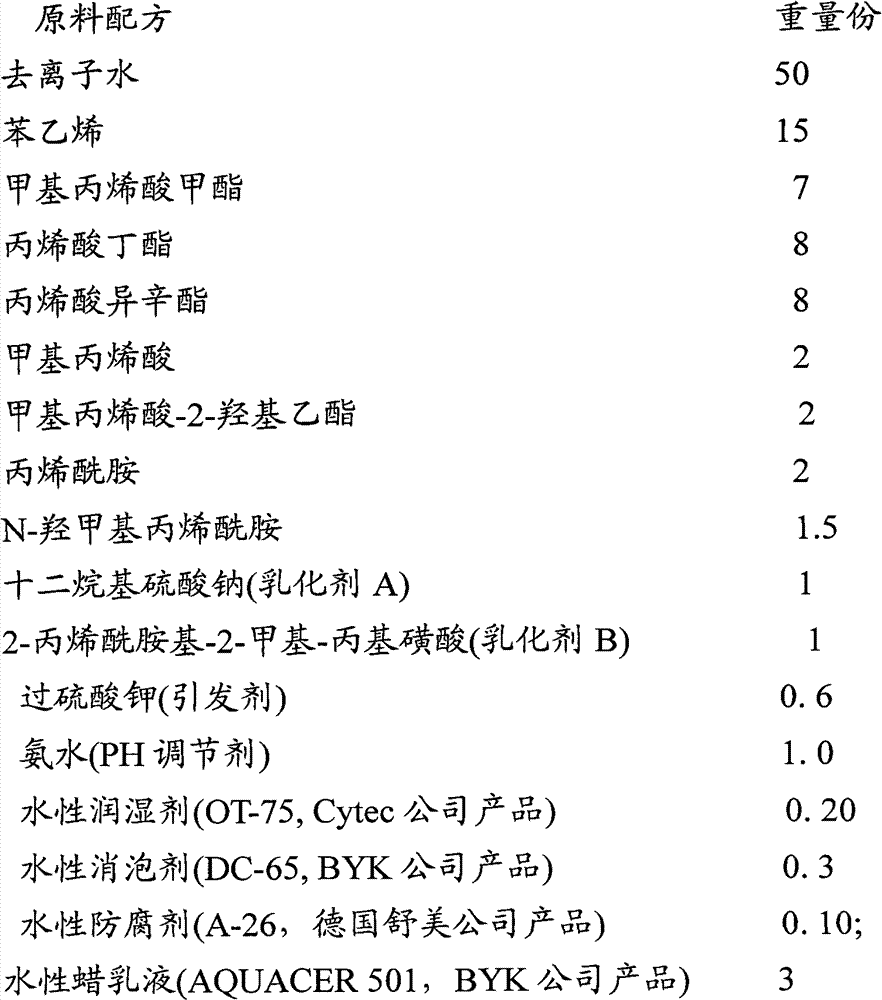

Embodiment 1

[0029] This embodiment provides a white electric oil-resistant styrene-acrylic emulsion and emulsion varnish. The invention uses monomers, emulsifiers, initiators, pH regulators, water-based additives and deionized water as raw materials, which are pre-emulsified The emulsion and emulsion varnish with a solid content of 40-50% are prepared by each step of seed reaction, polymerization reaction and compounding;

[0030] Specifically include:

[0031]

[0032] The preparation method of above-mentioned resistance to white electric oil styrene-acrylic acid emulsion, emulsion varnish, carries out according to the following steps:

[0033] A. Preparation of pre-emulsion: weigh alkyl methacrylate, alkyl acrylate, hydroxyalkyl ester, alkyl carboxylic acid and polymerizable monomer raw materials directly into the reaction kettle, start the mixer, and then add 75 % emulsifier and 75% water mixture at room temperature emulsification for 1 hour;

[0034] B. Preparation of seed emulsi...

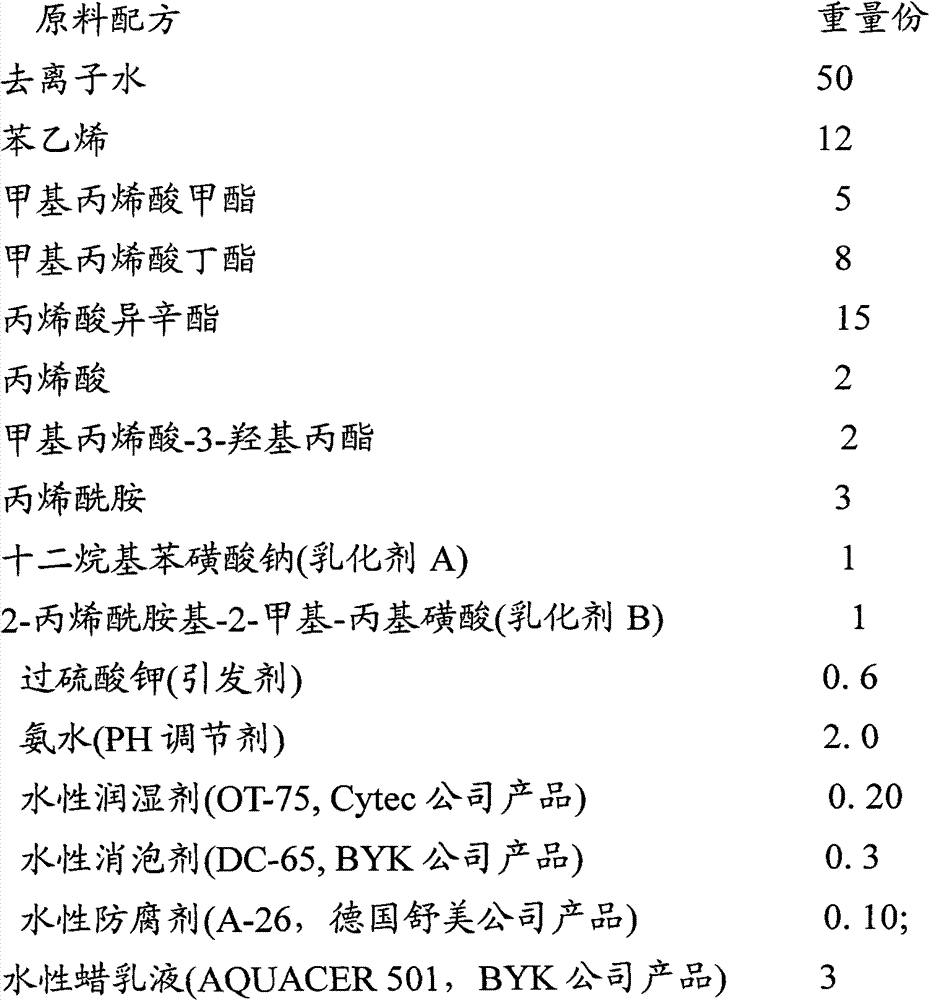

Embodiment 2

[0038] This embodiment provides a white electric oil-resistant styrene-acrylic emulsion and emulsion varnish. The invention uses monomers, emulsifiers, initiators, pH regulators, water-based additives and deionized water as raw materials, which are pre-emulsified The emulsion and emulsion varnish with a solid content of 40-50% are prepared by each step of seed reaction, polymerization reaction and compounding;

[0039] Specifically include:

[0040]

[0041] The preparation method of above-mentioned resistance to white electric oil styrene-acrylic acid emulsion, emulsion varnish, carries out according to the following steps:

[0042] A. Preparation of pre-emulsion: weigh alkyl methacrylate, alkyl acrylate, hydroxyalkyl ester, alkyl carboxylic acid and polymerizable monomer raw materials directly into the reaction kettle, start the mixer, and then add 75 % emulsifier and 75% water mixture at room temperature emulsification for 1 hour;

[0043] B. Preparation of seed emulsi...

Embodiment 3

[0047] This embodiment provides a white electric oil-resistant styrene-acrylic emulsion and emulsion varnish. The invention uses monomers, emulsifiers, initiators, pH regulators, water-based additives and deionized water as raw materials, which are pre-emulsified The emulsion and emulsion varnish with a solid content of 40-50% are prepared by each step of seed reaction, polymerization reaction and compounding;

[0048] Specifically include:

[0049]

[0050]

[0051] The preparation method of above-mentioned resistance to white electric oil styrene-acrylic acid emulsion, emulsion varnish, carries out according to the following steps:

[0052] A. Preparation of pre-emulsion: weigh alkyl methacrylate, alkyl acrylate, hydroxyalkyl ester, alkyl carboxylic acid and polymerizable monomer raw materials directly into the reaction kettle, start the mixer, and then add 75 % emulsifier and 75% water mixture at room temperature emulsification for 1 hour;

[0053] B. Preparation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com