Elastic thermal conduction structure for multiple heat sources of fanless electronic device

An electronic device, elastic heat conduction technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve problems such as uneven surface, poor heat dissipation, poor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to achieve the above-mentioned purpose and effect, the technical means and structure adopted by the present invention, the features and functions of the preferred embodiments of the present invention will be described in detail as follows, so as to facilitate a complete understanding.

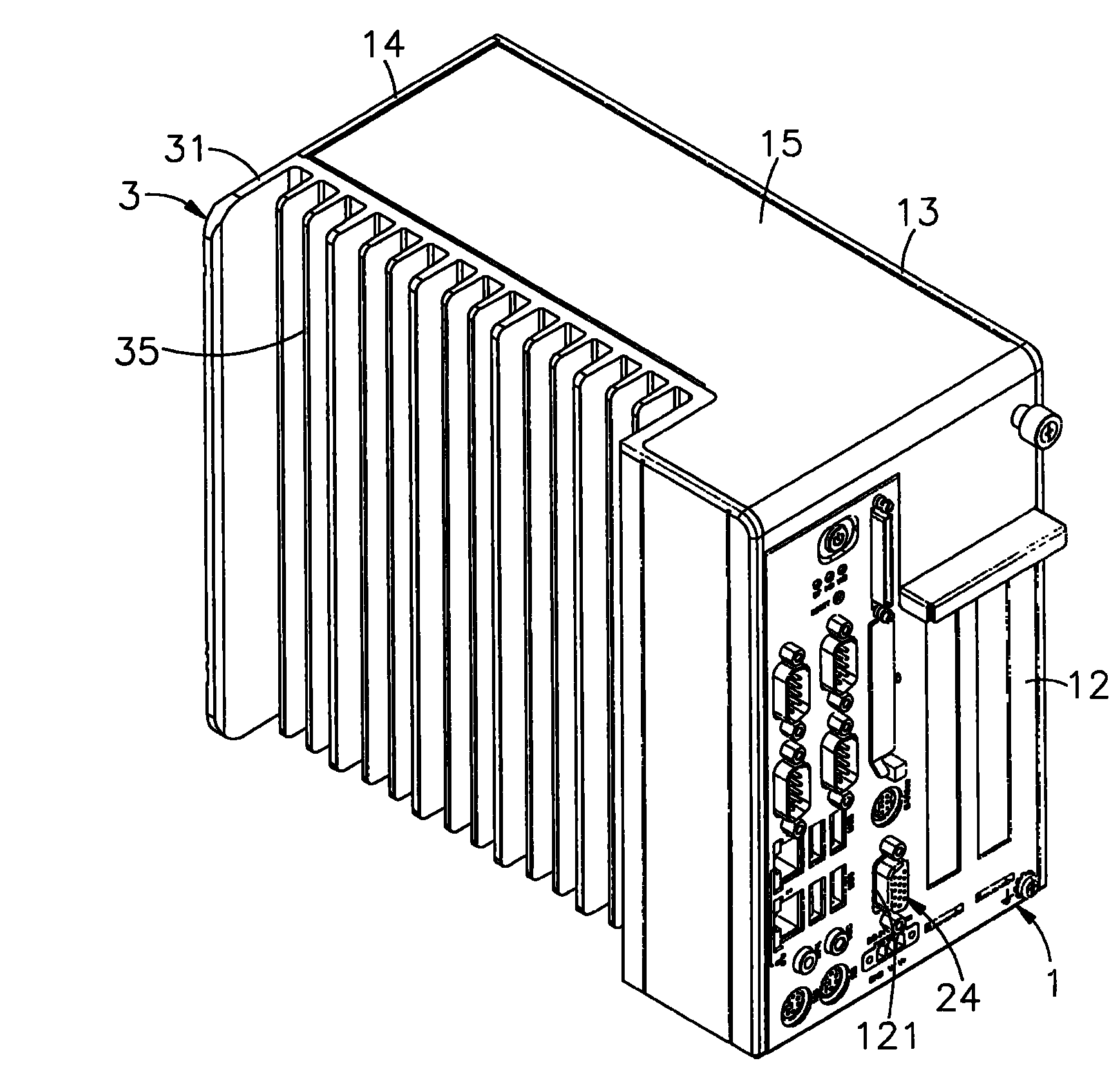

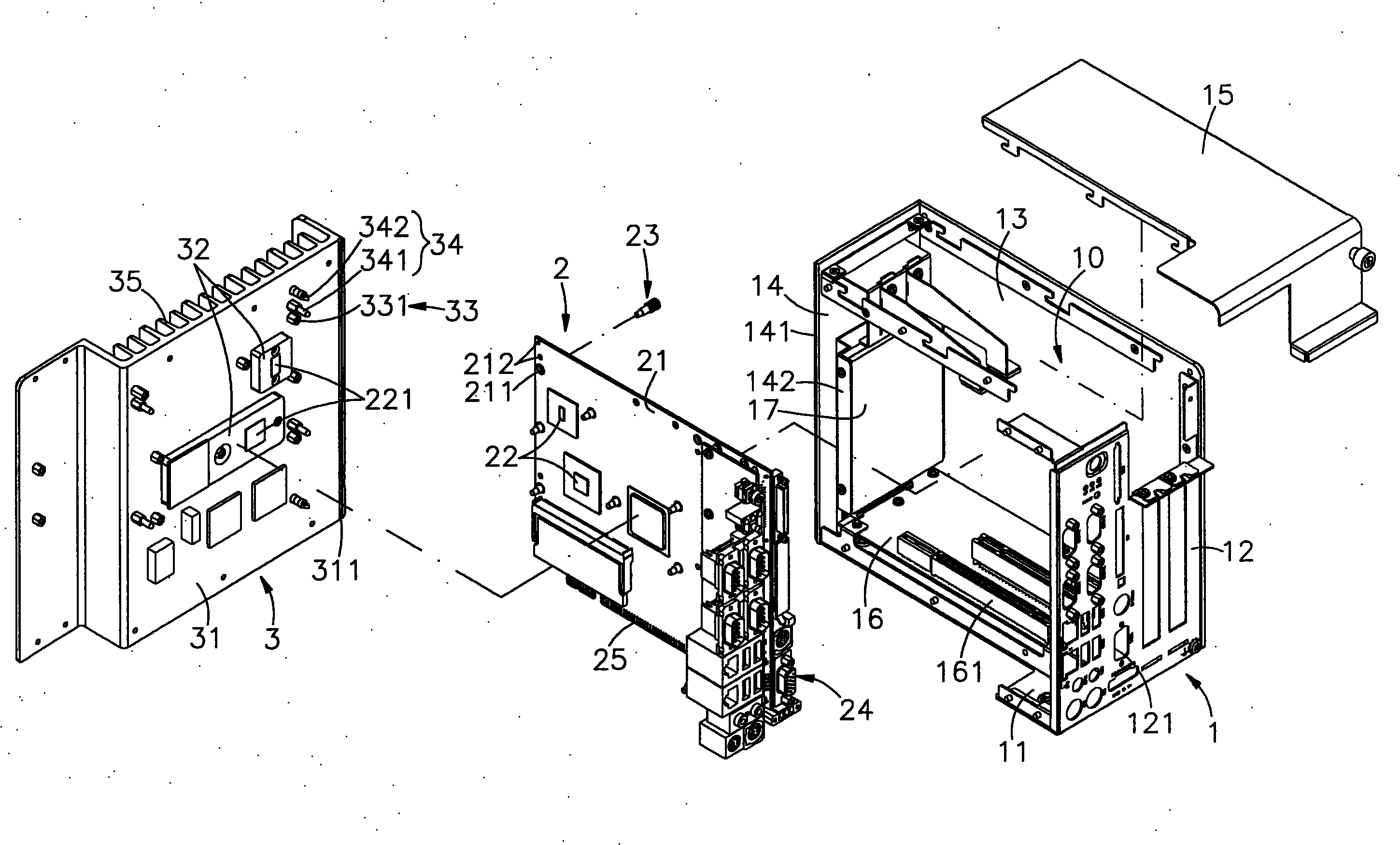

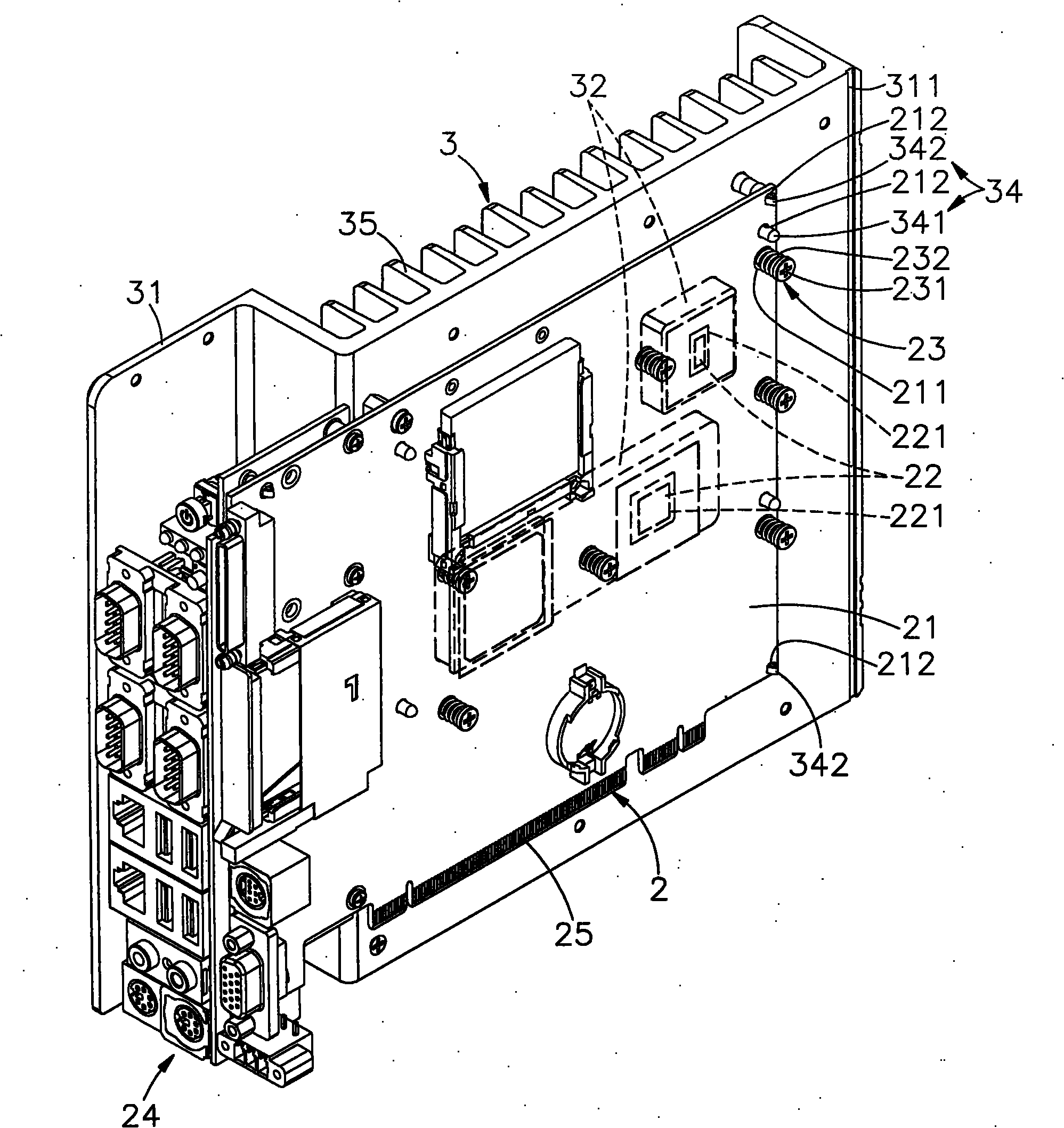

[0037] see figure 1 , 2 , 3, and 4 are respectively the three-dimensional appearance diagram of the present invention, the three-dimensional exploded view, the three-dimensional appearance diagram of the preferred embodiment, and image 3 It can be clearly seen from the partially enlarged diagram that the present invention includes an organic casing 1, a circuit module 2 and an outer casing 3, so the main components and their characteristics of this case are described in detail below, wherein:

[0038] The casing 1 has a base 11, and a docking shell 12 with a plurality of through holes 121 is vertically provided on one side of the base 11, and an outer shell 13 is extended on o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com