Grinding device for welding seam in surface of petroleum pipeline

A technology for surface welds and oil pipelines, applied in the direction of grinding drive devices, grinding machines, grinding workpiece supports, etc., can solve the problems of poor control of wiping strength, uneven grinding of weld seams, affecting quality and appearance, etc. Achieve the effect of improving the quality and efficiency of grinding, good appearance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

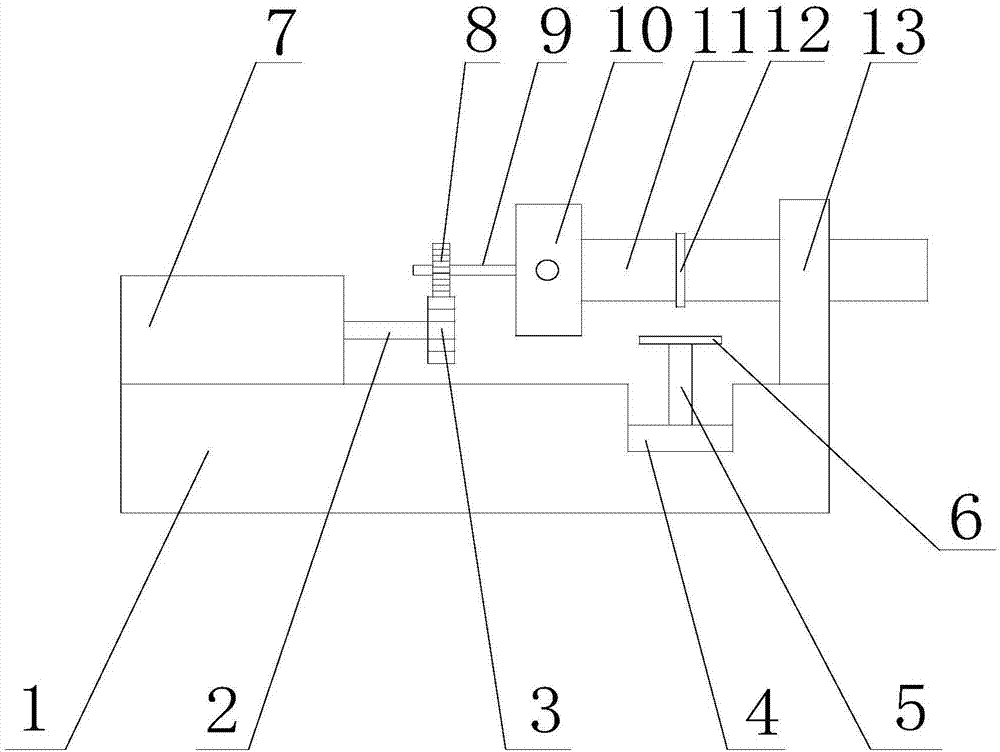

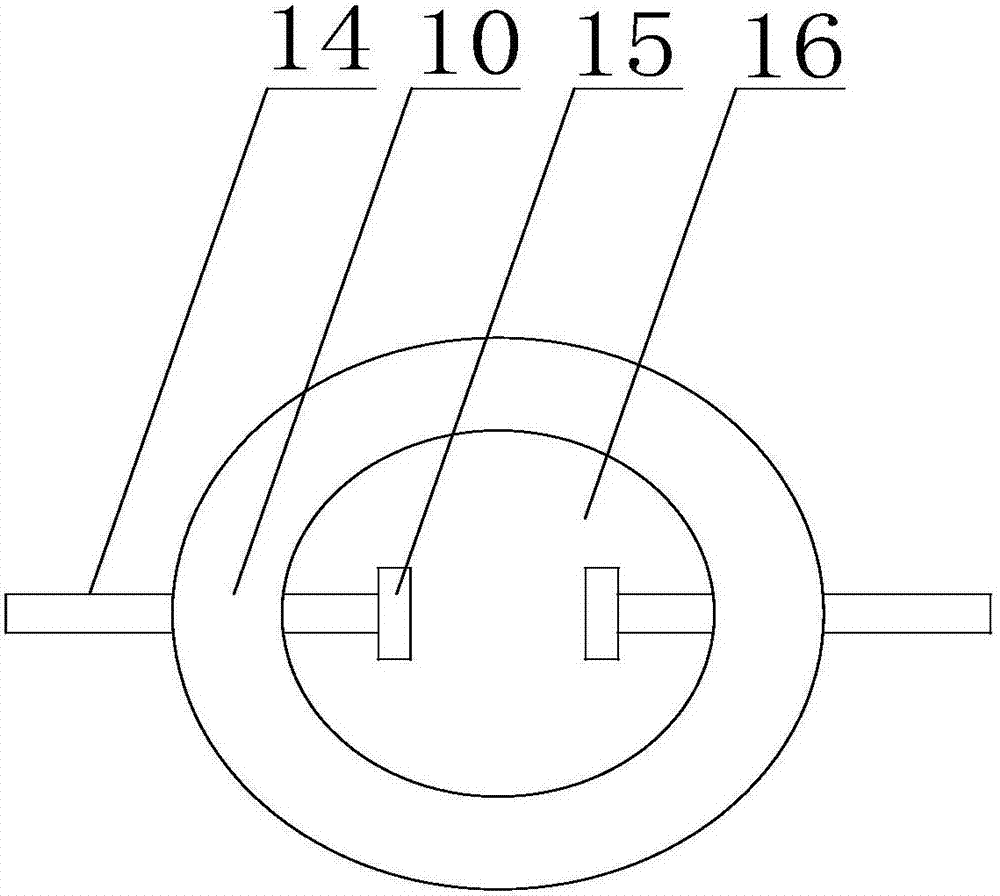

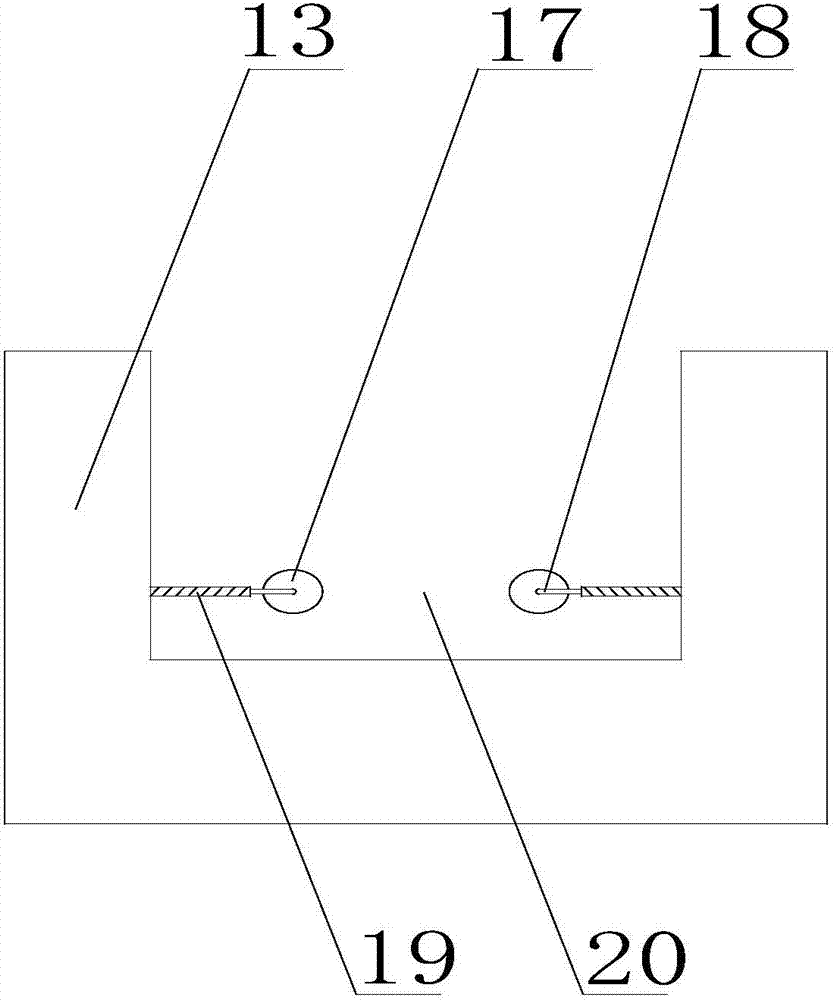

[0024] Such as Figure 1 to Figure 3 As shown, the grinding device of the oil pipeline surface weld seam of the present invention includes a rectangular base 1, the top of the base 1 is provided with a first driving mechanism 7 and a positioning frame 13, and the first driving mechanism 7 and the positioning frame 13 are respectively located Both sides of the axis of the base 1, the first driving mechanism 7 is preferably a motor, the motor is easy to buy in the market, and it is simple to operate and easy to maintain. The first driving mechanism 7 includes a rotating shaft 2, and the extension of the rotating shaft 2 is provided with Driving wheel 3, driving wheel 3 is enclosed within on the rotating shaft 2, when first driving mechanism 7 works, driving wheel 3 will drive rotating shaft 2 to rotate together, and driving wheel 3 is provided with the driven wheel 8 that cooperates with driving wheel 2, When driving wheel 3 rotates, will drive driven wheel 8 to rotate together,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com