Road cornerstone

A technology for roadbeds and roads, applied in the field of roadbed stones, can solve problems such as poor effect, unevenness, environmental protection, etc., and achieve the effect of high strength and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

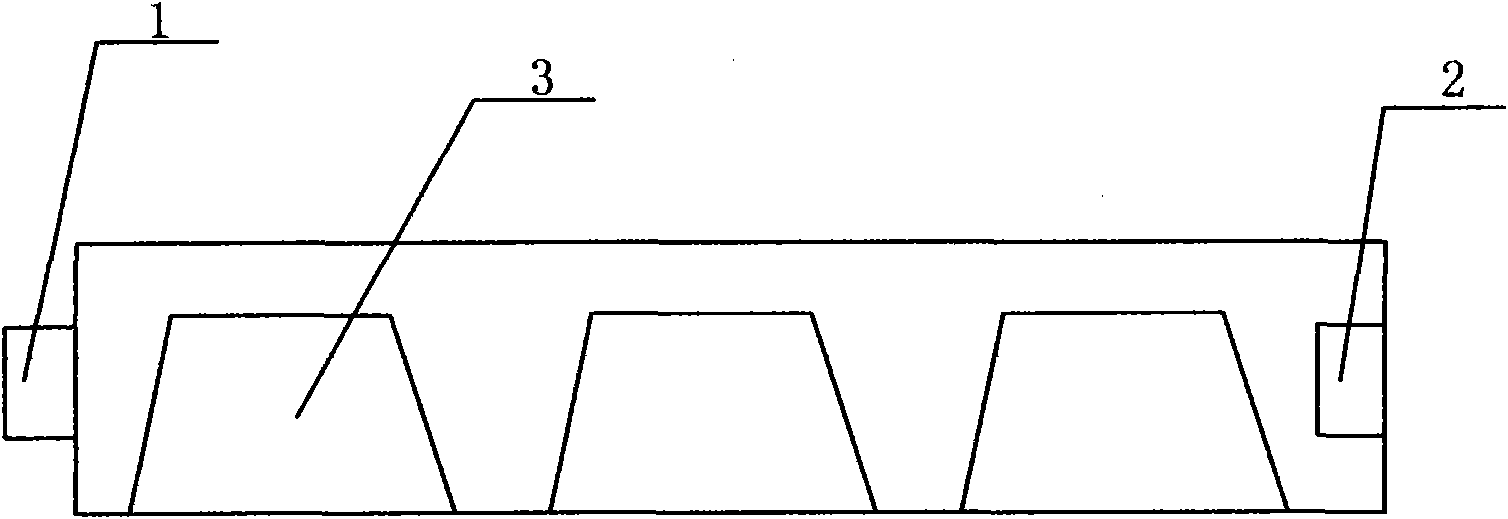

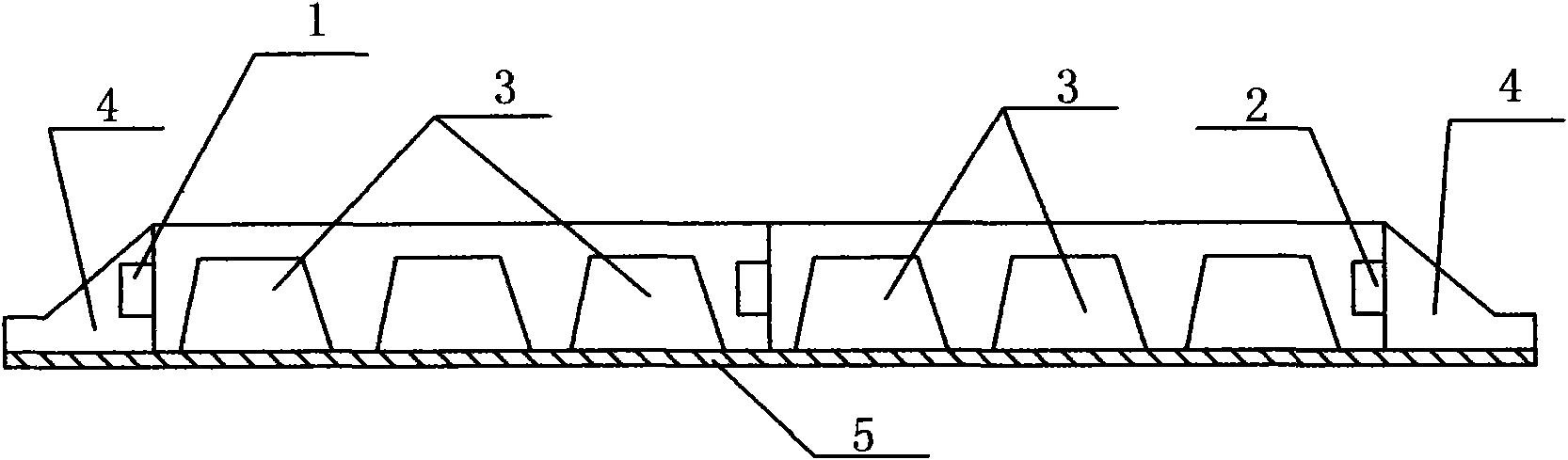

[0009] see Figure 1-2 , the specific embodiment adopts the following technical scheme: it is composed of a plug connector 1, a plug connector 2, a hollow part 3 inside the roadbed stone, a pedestrian part 4 of the roadbed stone opening, and a cement concrete part 5; the plug connector 1 and the plug connector 2 are rectangular , the length and width of the plug joint 1 are slightly smaller than the length and width of the plug joint 2, the hollow part 3 inside the subgrade stone is trapezoidal, and the cement concrete part 5 is 2-3 cm; the plug joint 1 is placed in the plug joint 2, and the subgrade stone opening The pedestrian part 4 is inlaid in the plug joint 1 or the plug joint 2. Each piece is connected in this way, as many as needed can be connected. When the roadbed is pressed to the ground, the hollow part 3 is inlaid in the ground and just poured into the ground. Cement concrete on the ground.

[0010] The invention is non-toxic and harmless, environmentally friendl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com