Automatic chamfering machine

A technology of chamfering machine and chamfering mechanism, which is applied in the direction of grinding frame, grinding feed movement, and machine tools suitable for grinding the edge of workpieces, etc. It can solve the problem that the quality of workpiece chamfering is uneven and cannot be continued for a long time Continuous work, slow chamfering speed and other problems, to achieve the effect of good product quality stability, less artificial factors, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

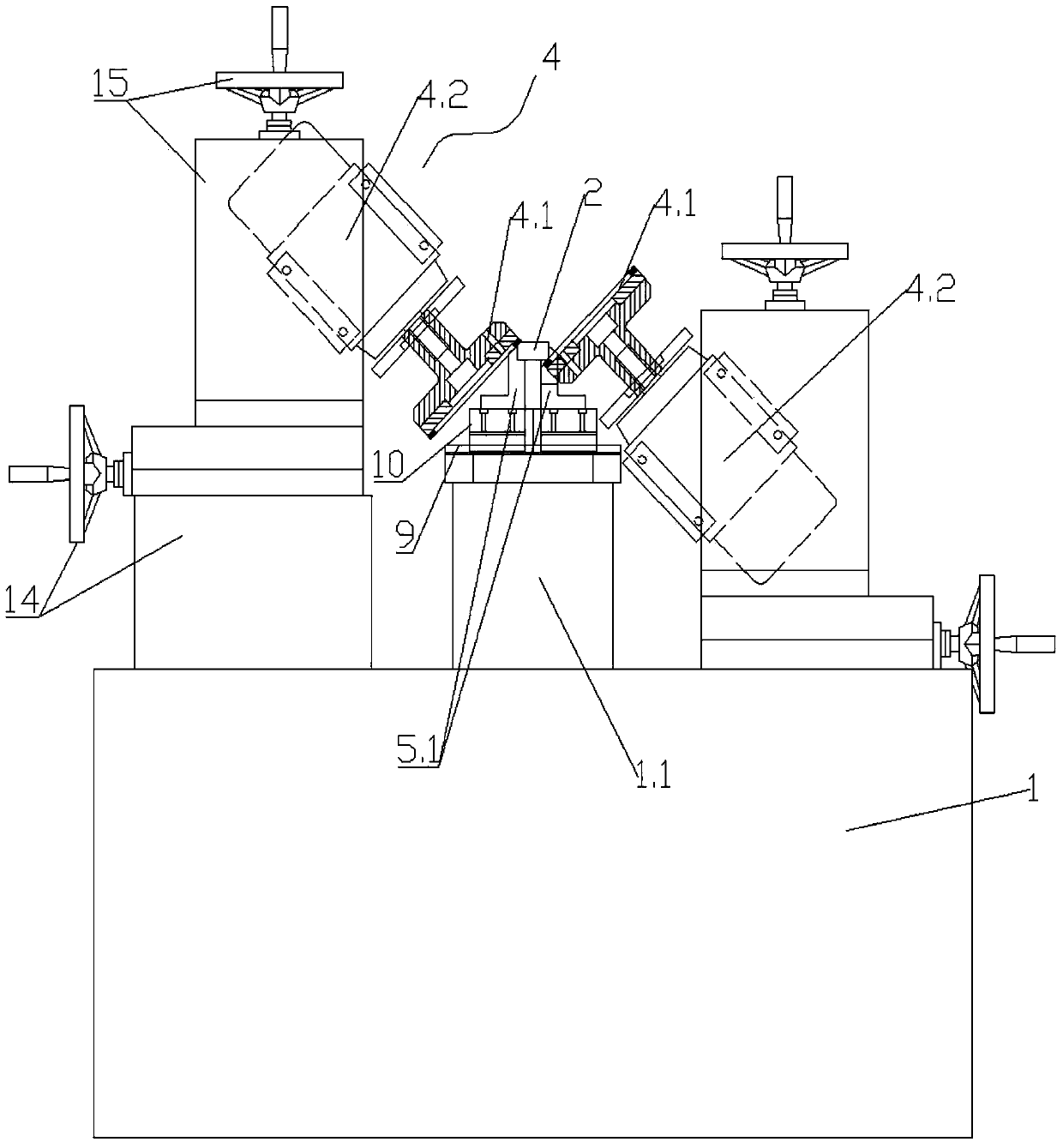

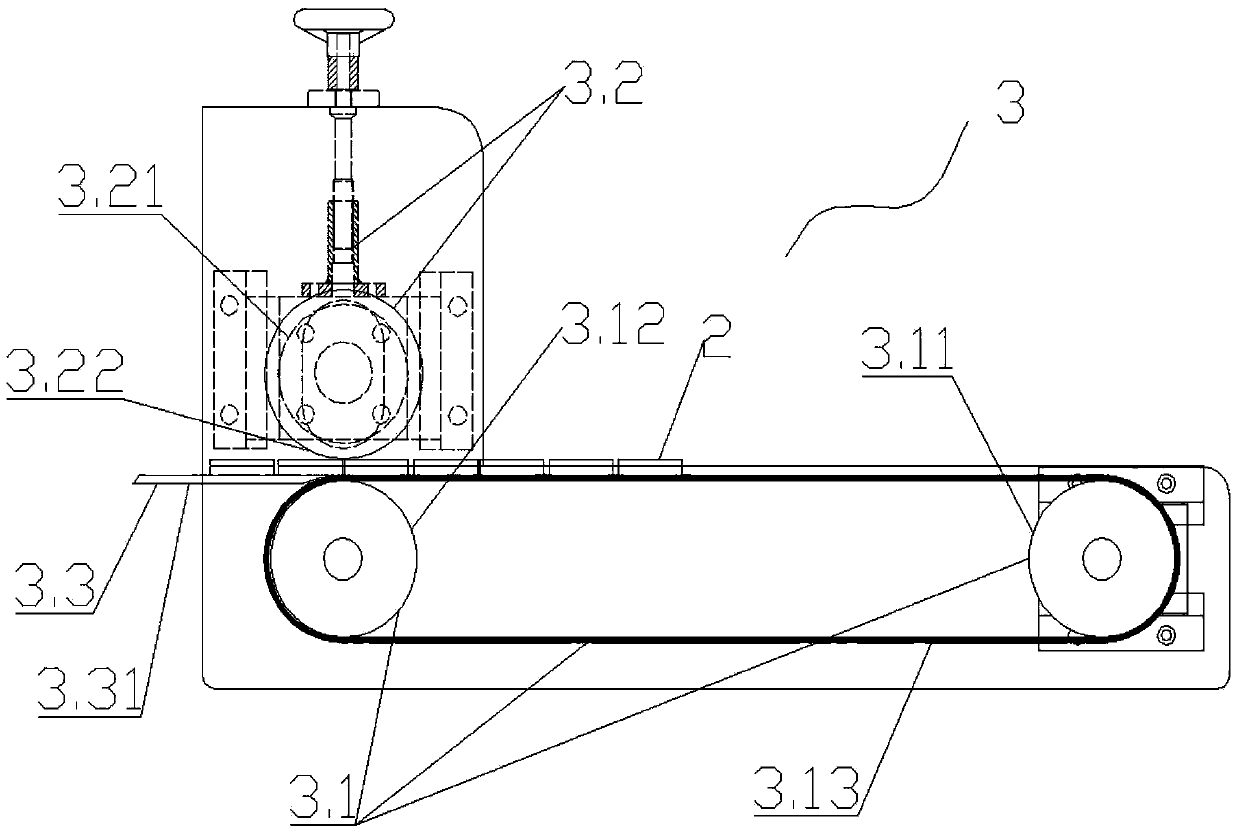

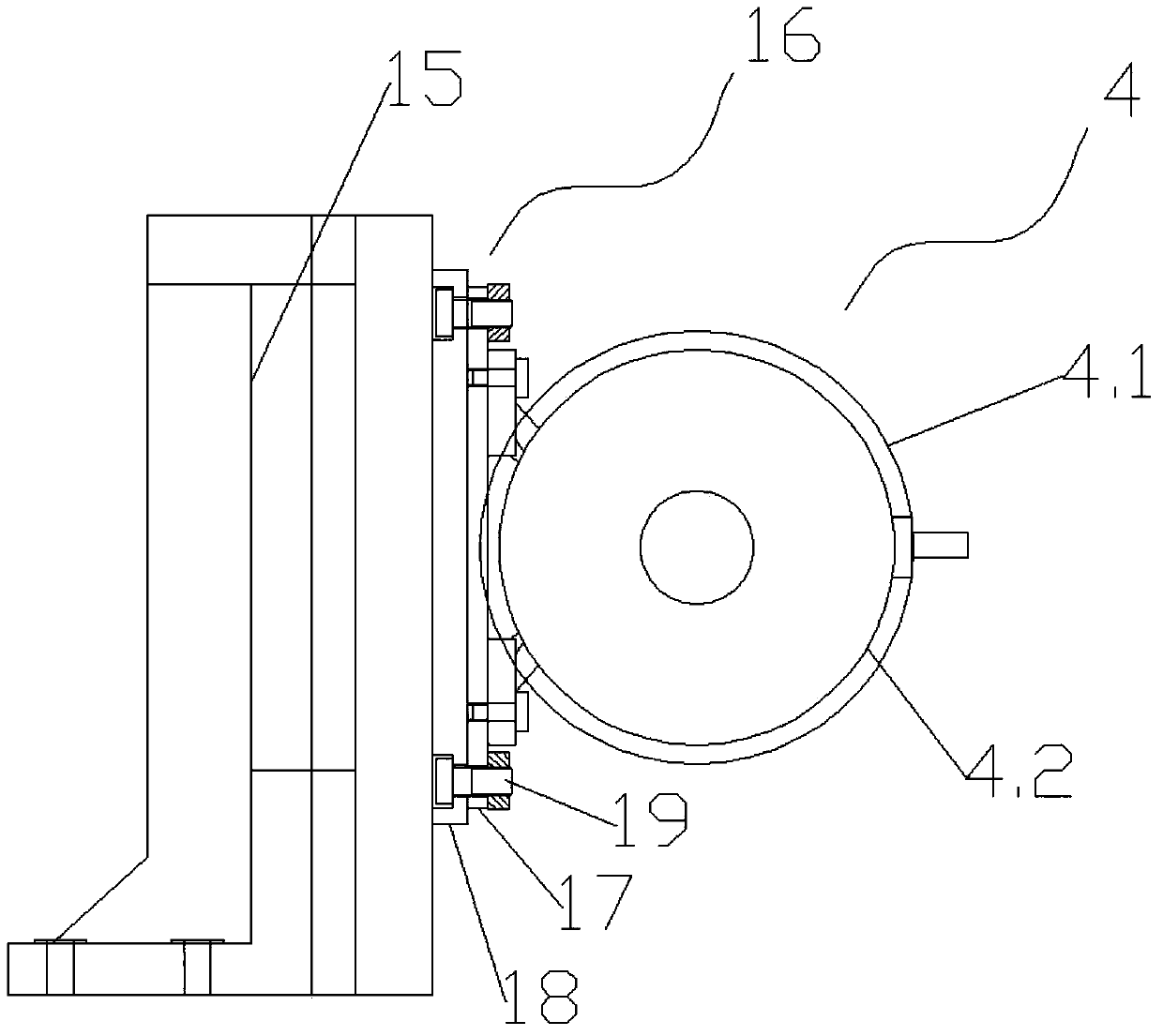

[0031] As shown in the figure, an automatic chamfering machine includes a machine base 1, a conveying mechanism 3 installed on the end of the machine base 1 and used to transport the workpiece 2, and two sets of lengths installed on the machine base 1 for the workpiece 2 Four grinding wheel chamfering mechanisms 4 for simultaneous chamfering of opposite sides 2.1, guide rail clamping mechanism 5 for clamping and smooth movement of workpiece 2 for clamping.

[0032] The guide rail clamping mechanism 5 is installed on the workbench 1.1 of the machine base 1, and the two grinding wheel chamfering mechanisms 4 are respectively located in parallel on both sides of the guide rail clamping mechanism 5 for processing a group of long pairs in the workpiece 2. Side 2.1, the other two grinding wheel chamfering mechanisms 4 are also located parallel to the two sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com