Drying delivery production line structure for lithographed sheet

A production line and iron printing technology, applied in the field of the structure of the printing iron drying and conveying production line, can solve the problems of high labor intensity, collision of iron buffer plates, affecting the processing quality, etc., and achieve low labor intensity, avoid confusion, and good uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

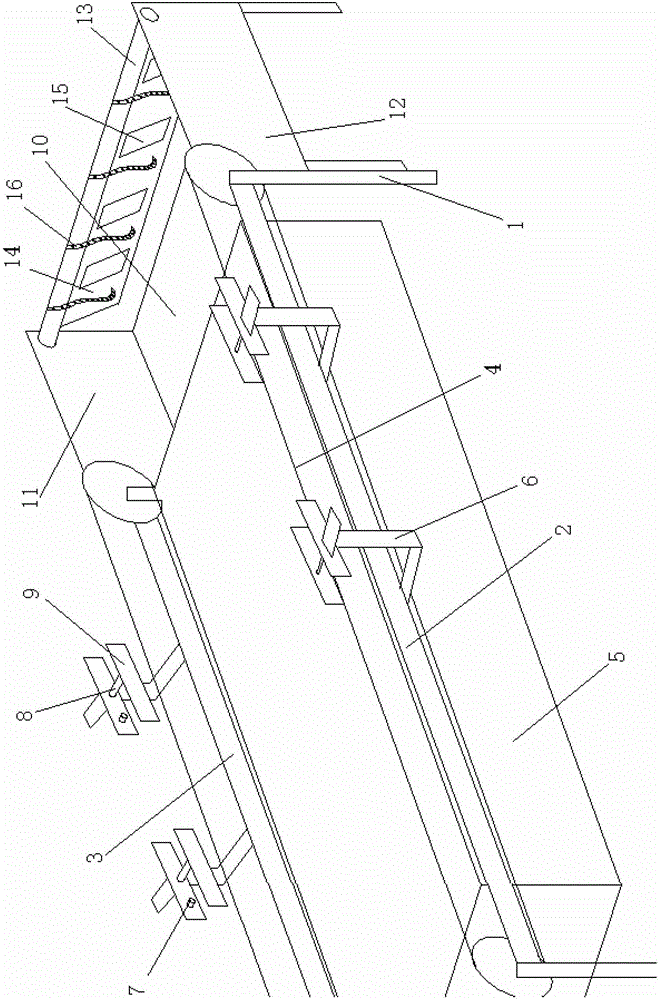

[0017] Referring to the accompanying drawings, a production line for drying and conveying dryers for iron printing includes a bracket 1 on which two parallel beams 2 and 3 are mounted, and a circulating conveyor chain 4 is provided between the beams 2 and 3, and the circulating conveyor chain 4 An oven 5 is arranged below the crossbeam 2 and 3, and fixed mounts 6 are fixedly installed on the outer sides of the beams 2 and 3 respectively, and ultraviolet sensors 7 are respectively installed on the fixed mounts 6, and the ultraviolet sensors 7 face the printing iron on the circulating conveyor chain 4, and the fixed mounts 6 are also installed There is a printed iron push plate 8 facing the circular conveyor chain, and the printed iron push plate 8 is driven by the cylinder piston rod 9, and the ultraviolet sensor 7 transmits the signal to the controller to control the driving of the cylinder; the discharge end of the circular conveyor chain 4 is provided with a Coordinated disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com