Manufacturing method for disposable novel environment-friendly utensil

A production method and a one-time technology, applied in the direction of household appliances, other household appliances, pretreatment of molding materials, etc., can solve the problems of low production efficiency, high cost, and the weight ratio of plant fiber components cannot be reached, and achieve uniform distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

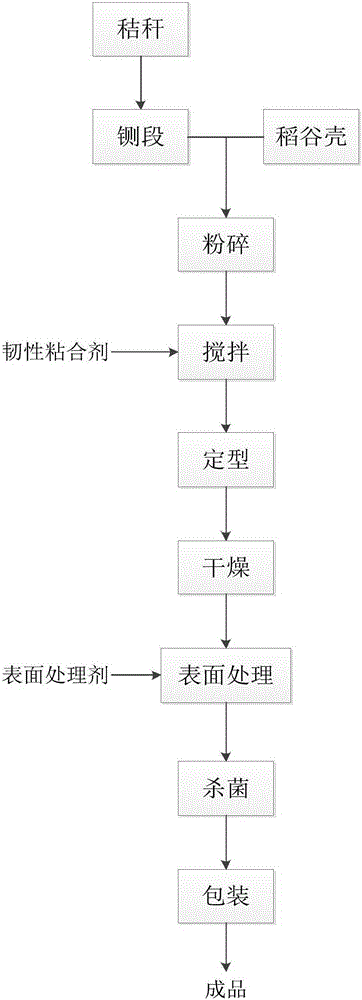

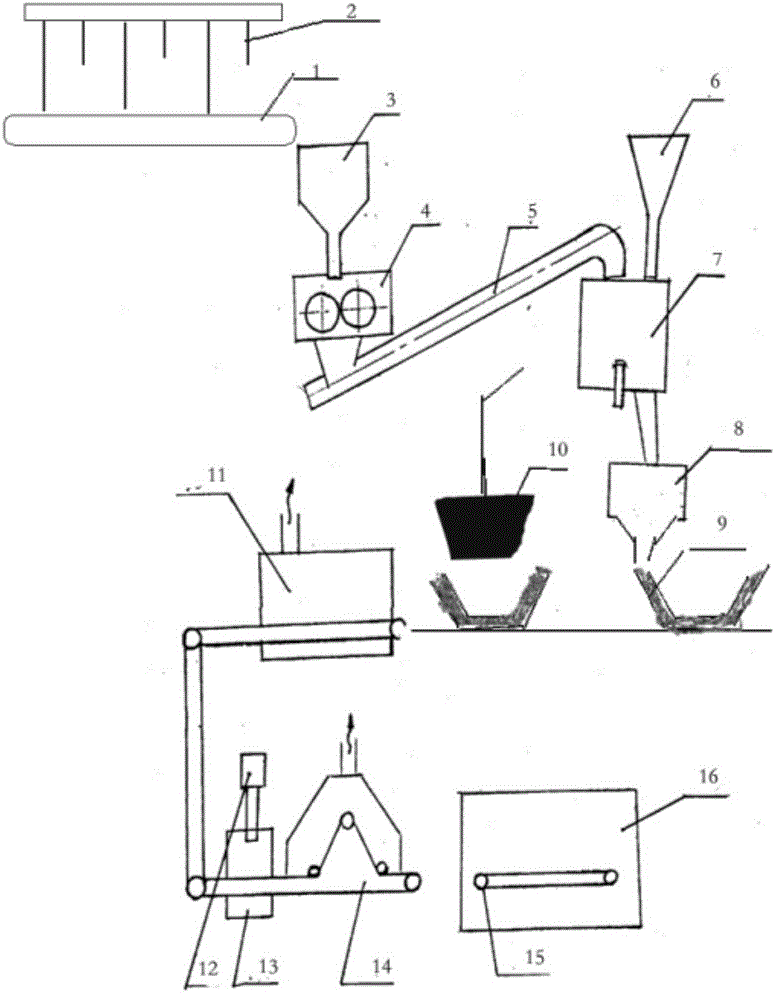

[0029] like Figure 1 ~ Figure 2 Shown, a kind of manufacturing method of disposable novel environmental protection utensil of the present invention, prepares a kind of novel green environmental protection food packaging box with straw, rice husk.

[0030] The facilities and equipment used to prepare a new type of green and environmentally friendly food packaging box include: conveyor belt 1, guillotine 2, mill 4, powder conveying system 5, plant fiber and adhesive mixing mixer 7, control storage tank 8, template 9 , a press 10, a drying box 11, a surface treatment room 12, a drying and curing room 13, a supply system 14, a conveyor belt 15 and a sterilization room 16.

[0031] The steps of preparing a novel green environmental protection food packaging box:

[0032] ① Pre-processing is carried out first, the leaves of the crop straw are removed and the middle part is put on the conveyor belt 1 for sectioning. When sectioning, the sectioning machine 2 is used to evenly cut in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com