Patents

Literature

92results about How to "Guaranteed crushing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Efficient ore pulverizing device

The invention discloses a high-efficiency ore crushing device, which comprises a base. Support plates are arranged on the left and right sides of the base. A top plate is arranged on the top of the support plate. A crushing box is connected to the bottom of the top plate through a bracket. The limit rod is slidingly connected in the position sleeve. The top of the limit rod is connected to the top of the crushing box through a tension spring. The bottom of the limit rod is fixedly connected with a lifting plate. A pressing plate is also provided, and several through holes are evenly arranged on the pressing plate. A crankshaft cooperating with the lifting plate is arranged on the top of the crushing box, and the right end of the crankshaft passes through the right side wall of the crushing box and a second pulley is installed. The invention rotates the crankshaft so that the crushing plate moves downward to perform preliminary crushing of the ore. During the crushing, the ore is initially screened, the smaller particles fall through the through hole of the pressing plate, and the larger ore continues to be crushed. The crushing effect is good and the crushing efficiency is high.

Owner:CHANGSHA KEYUE ENTERPRISE MANAGEMENT CONSULTING CO LTD

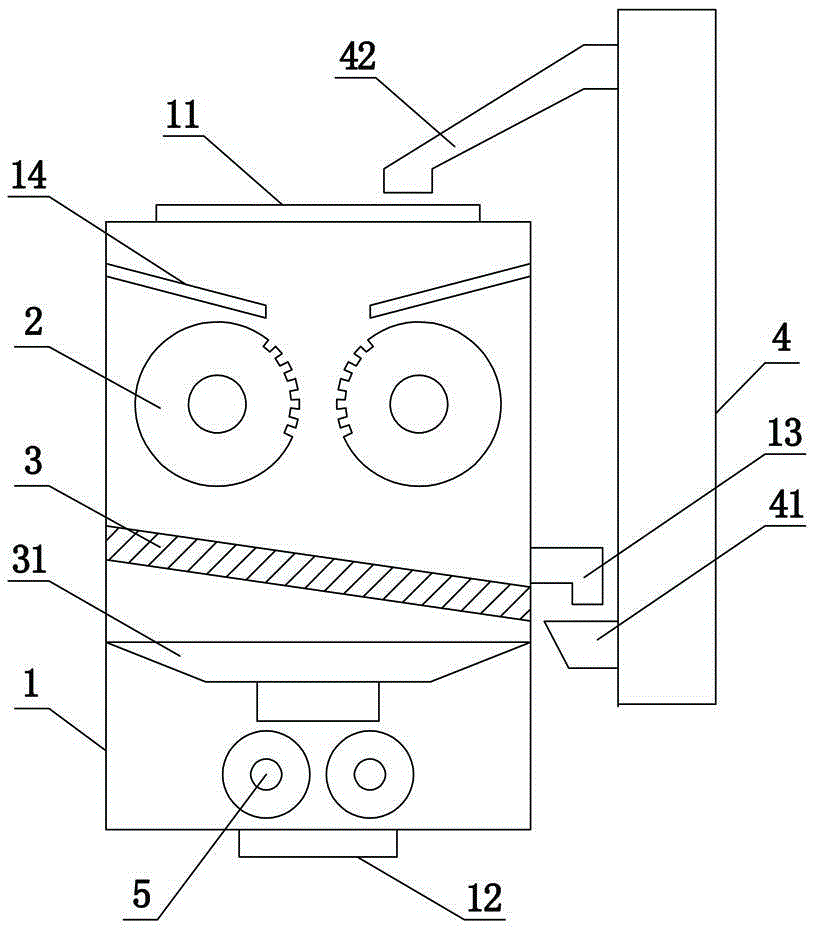

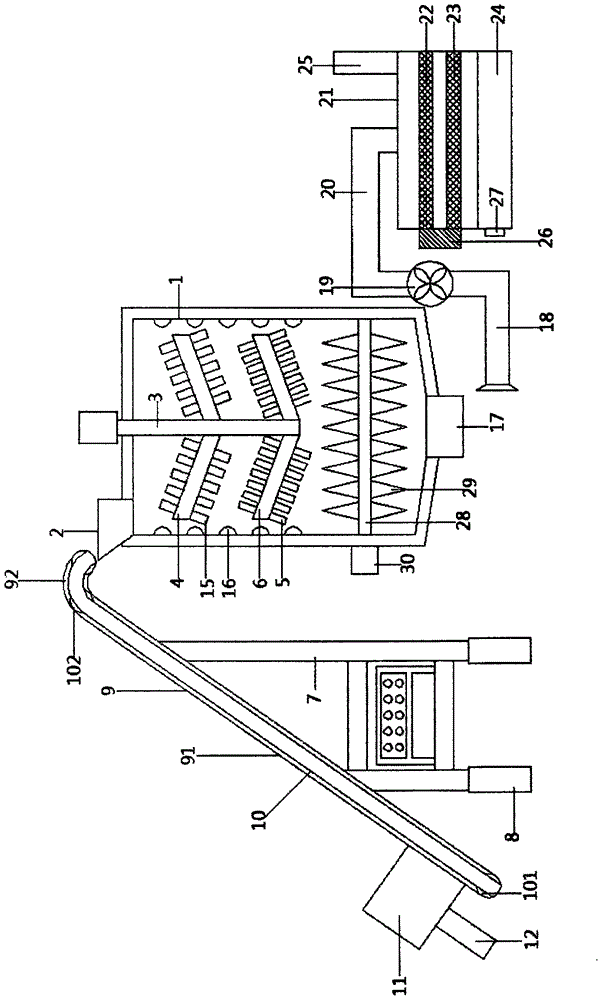

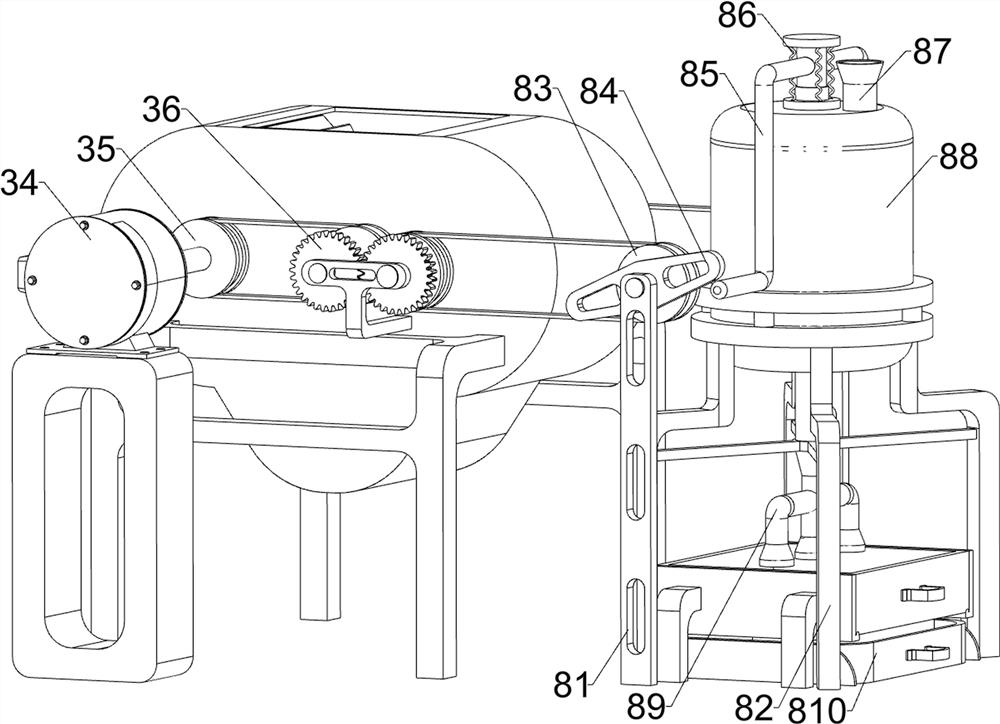

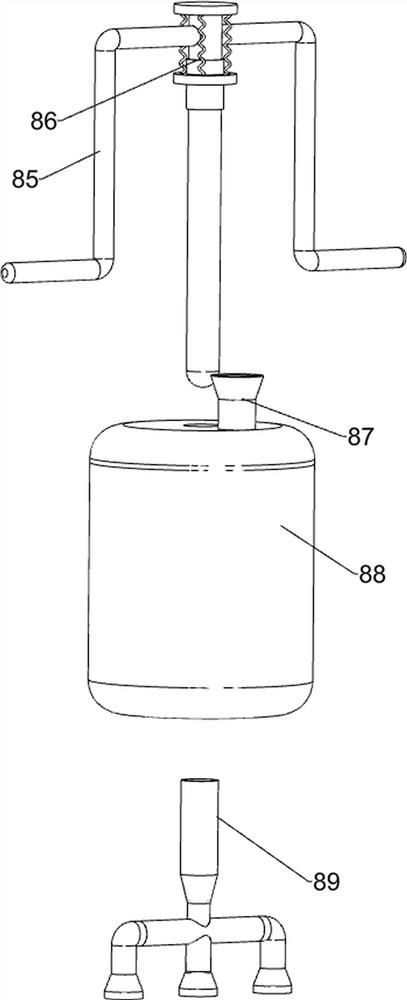

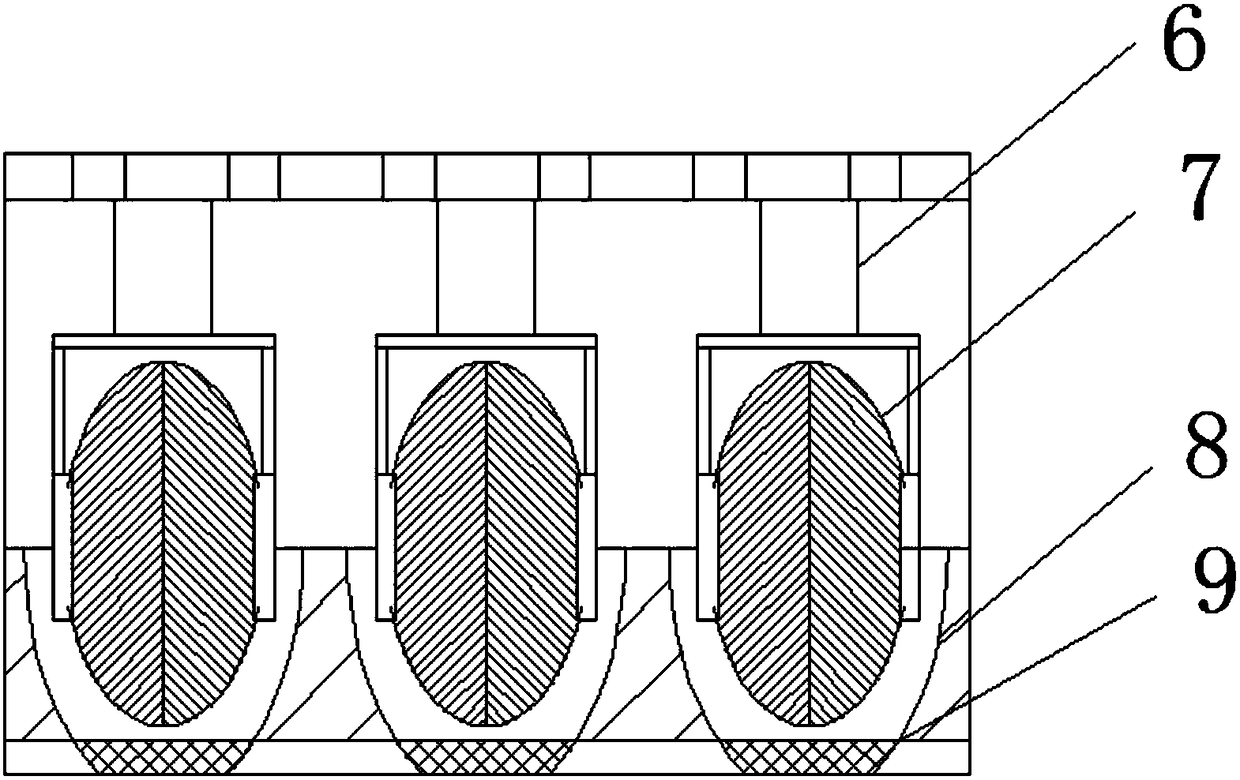

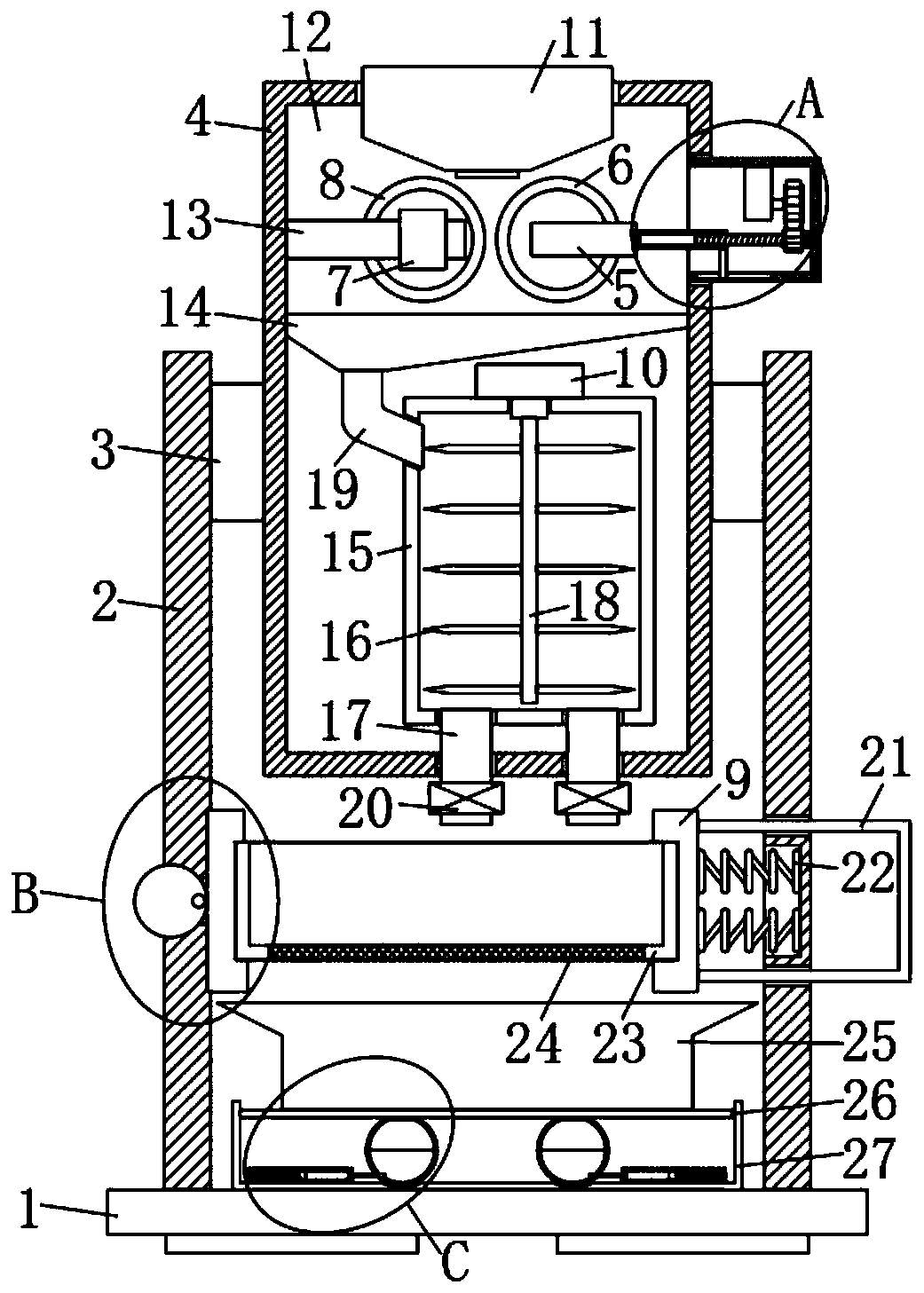

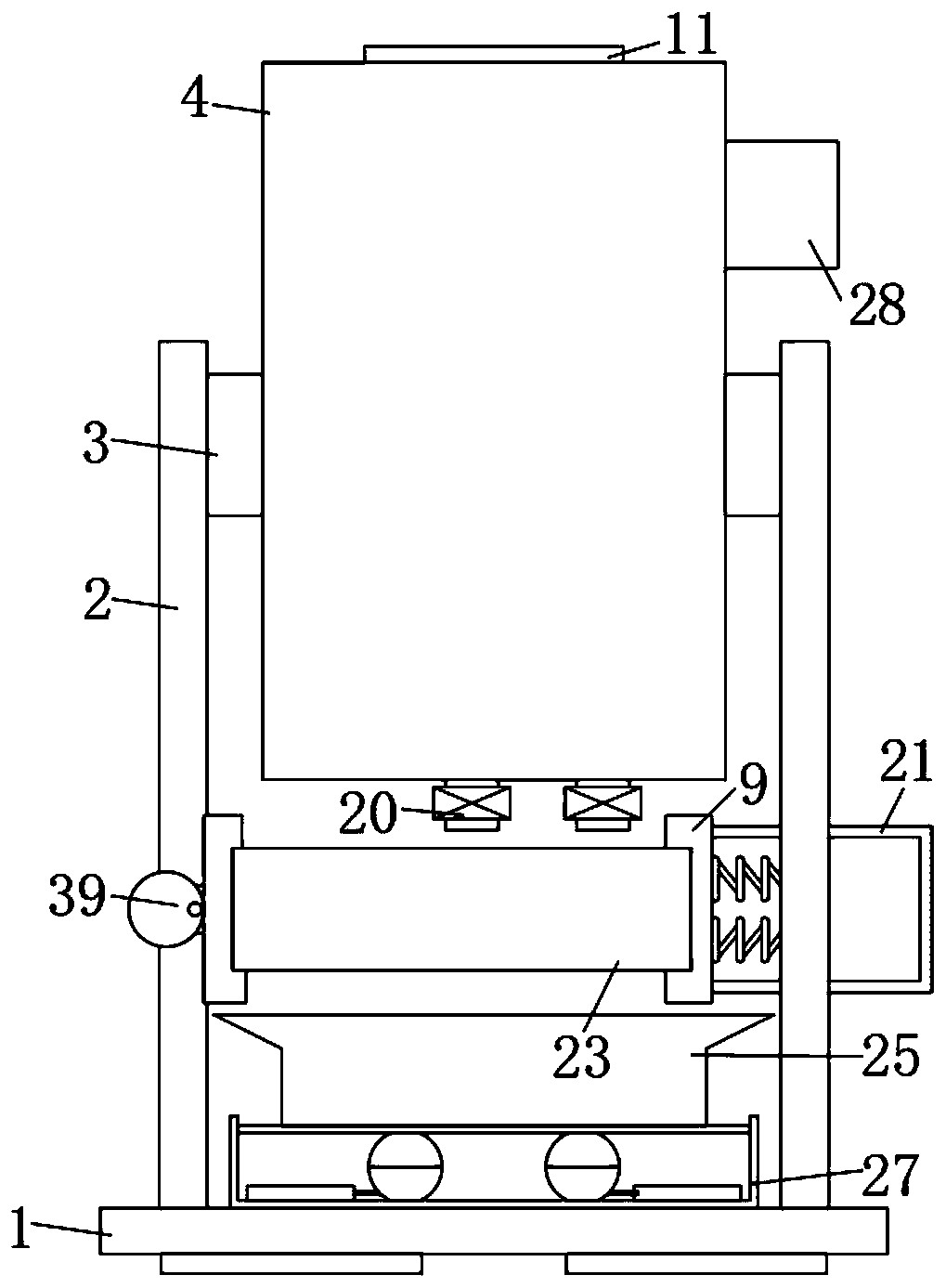

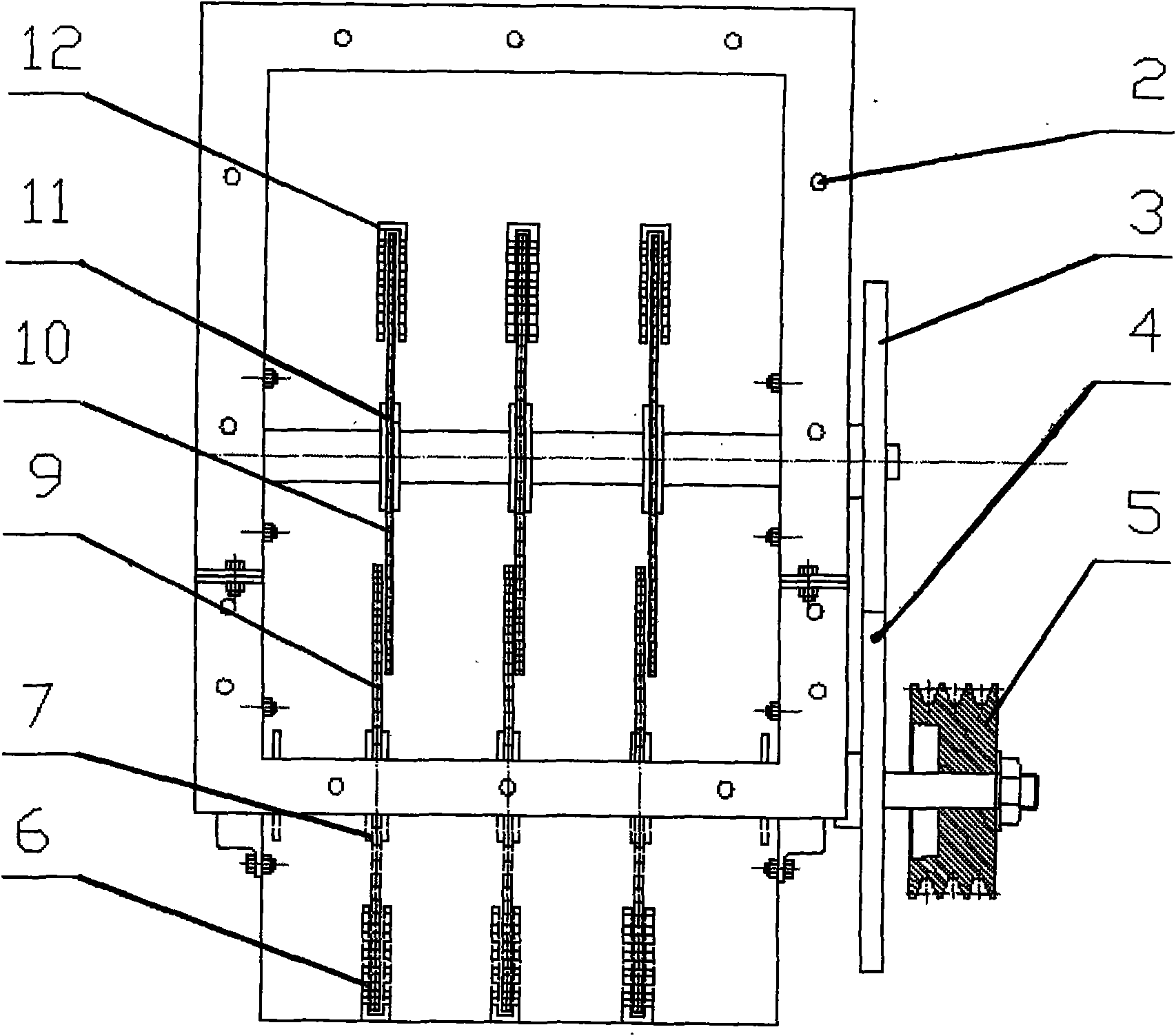

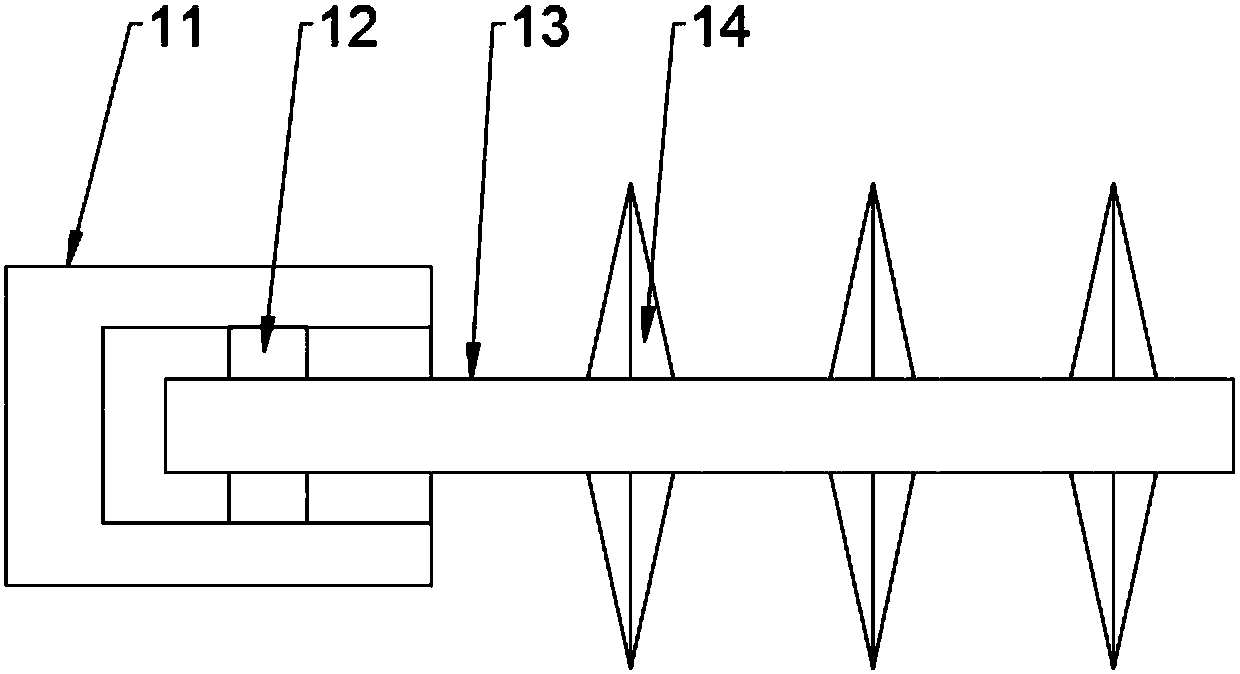

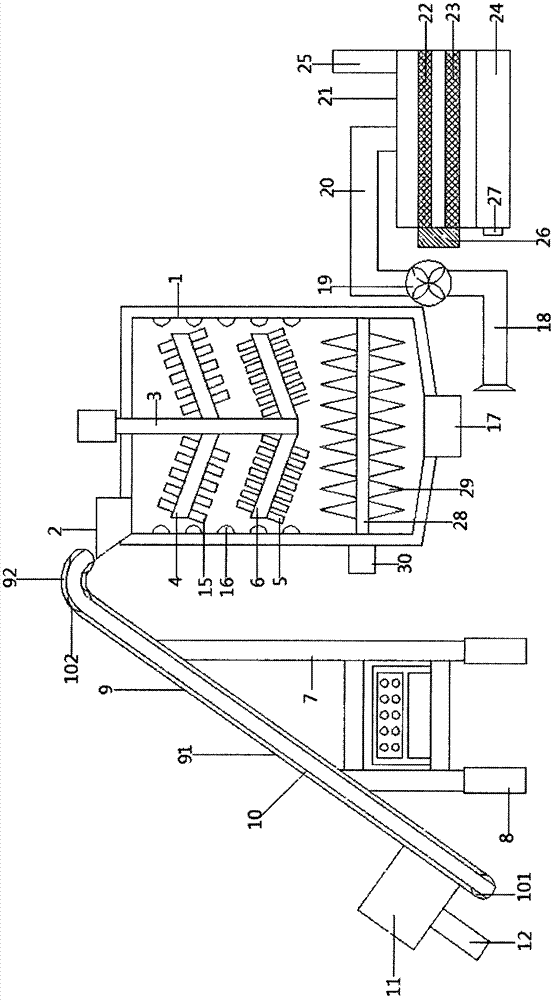

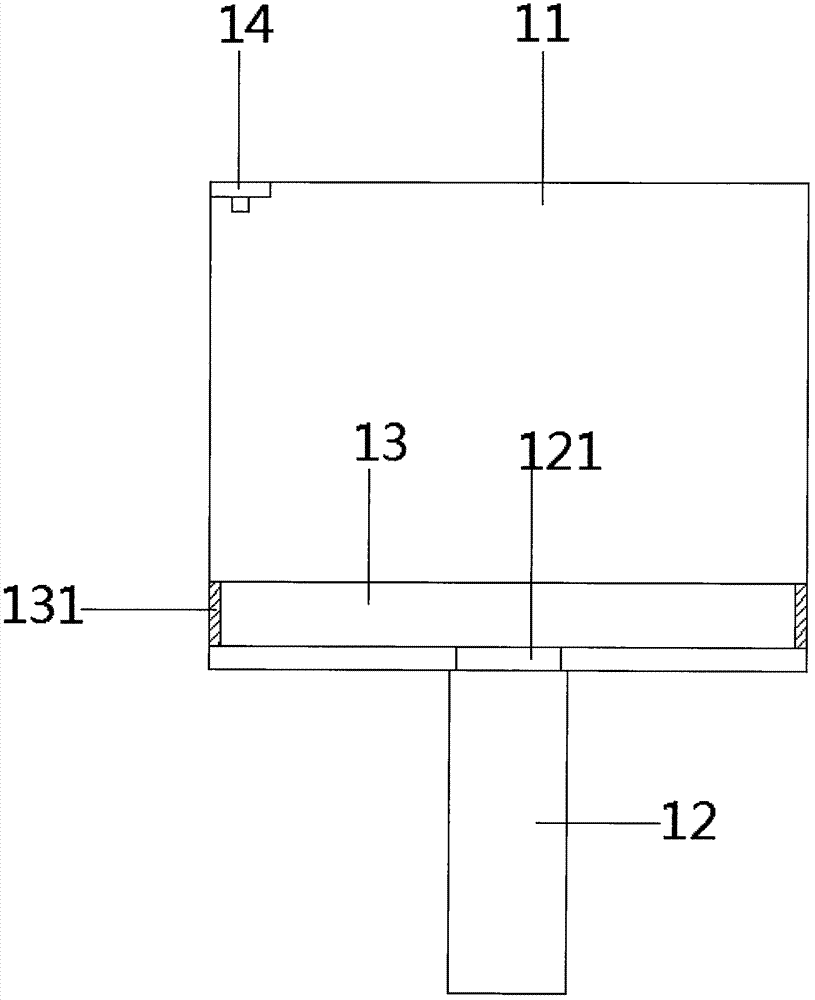

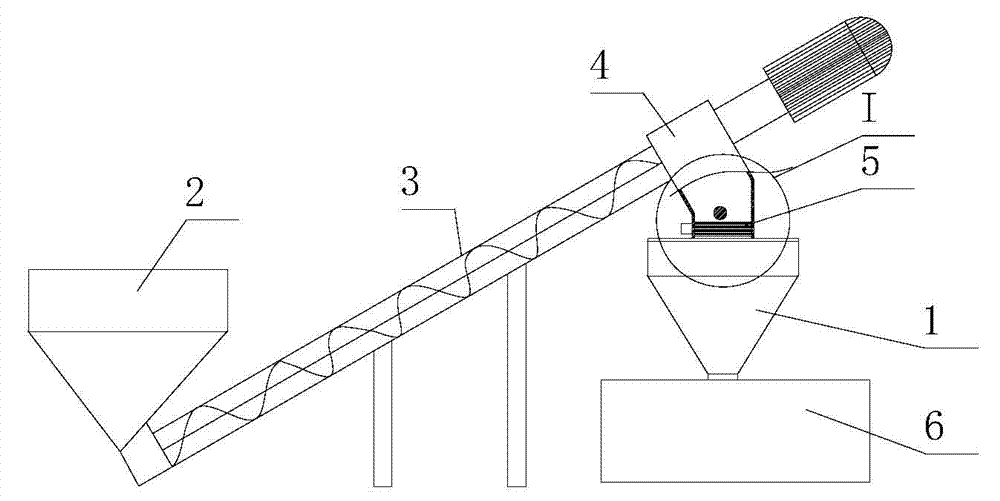

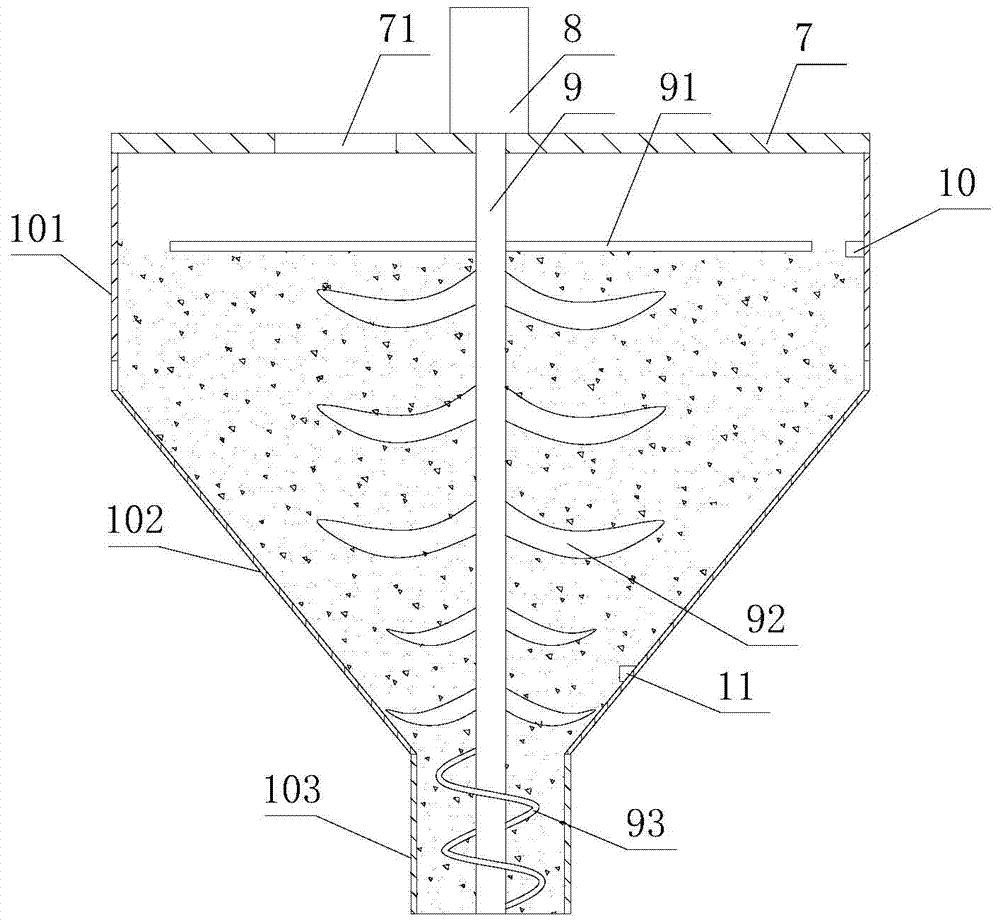

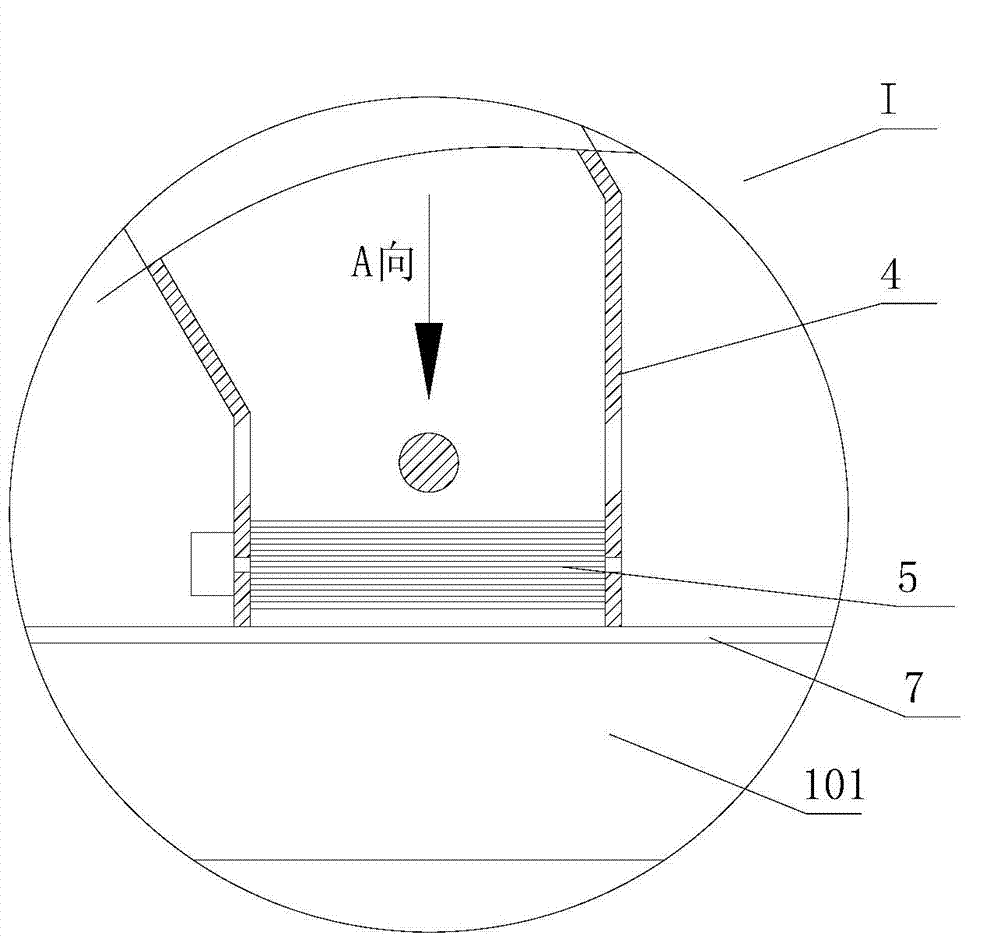

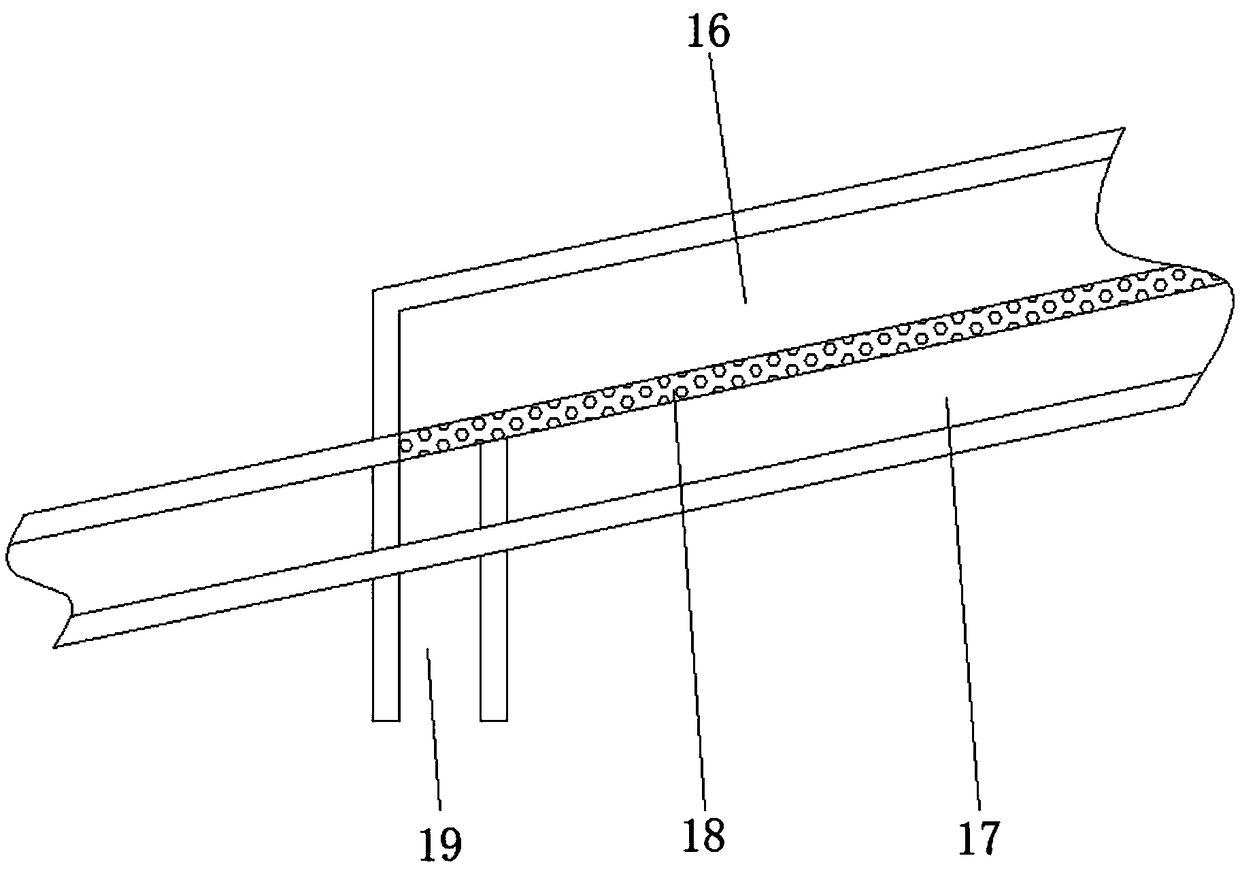

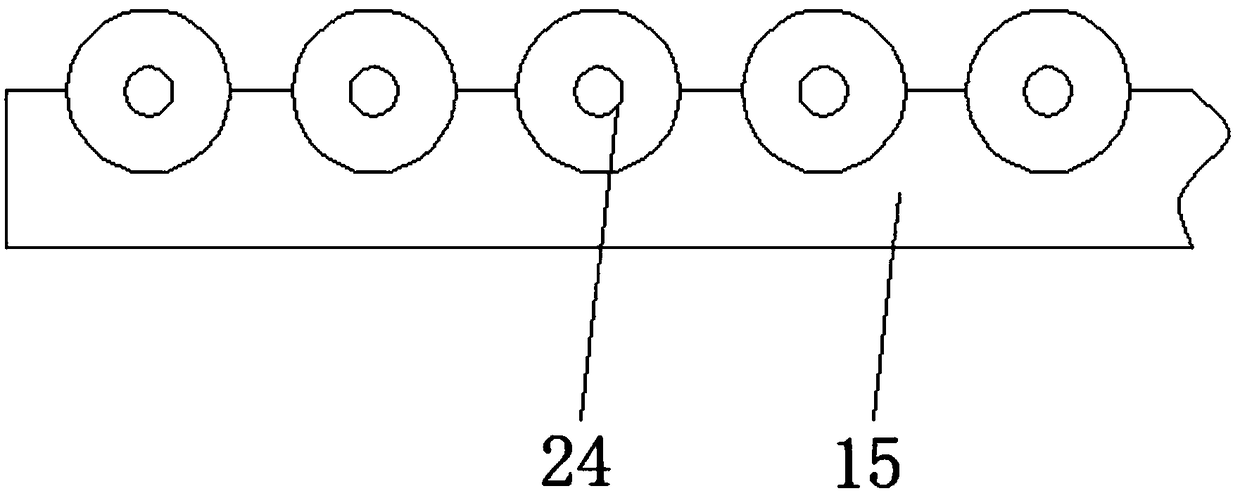

Biomass particle smashing device

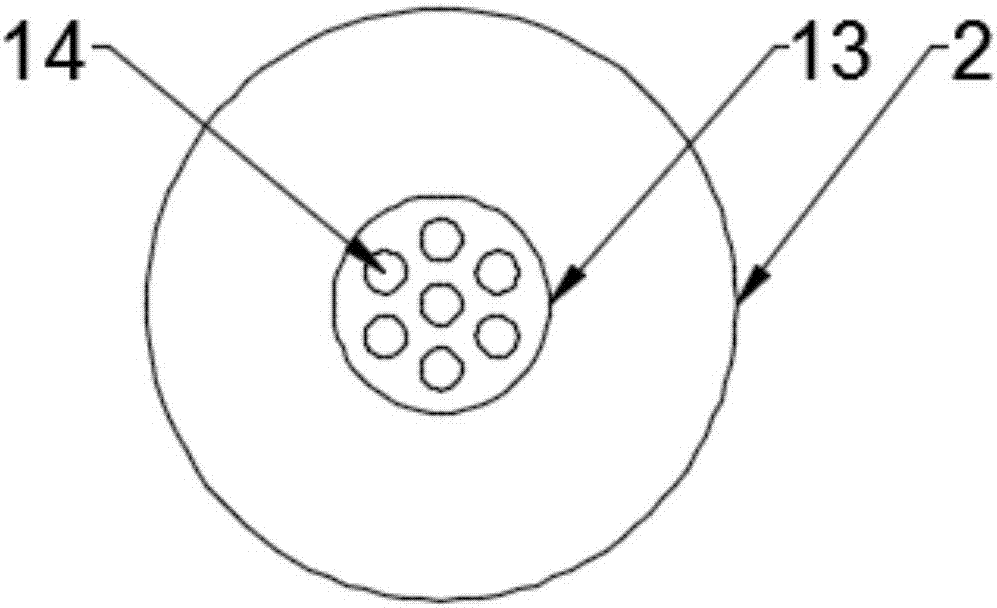

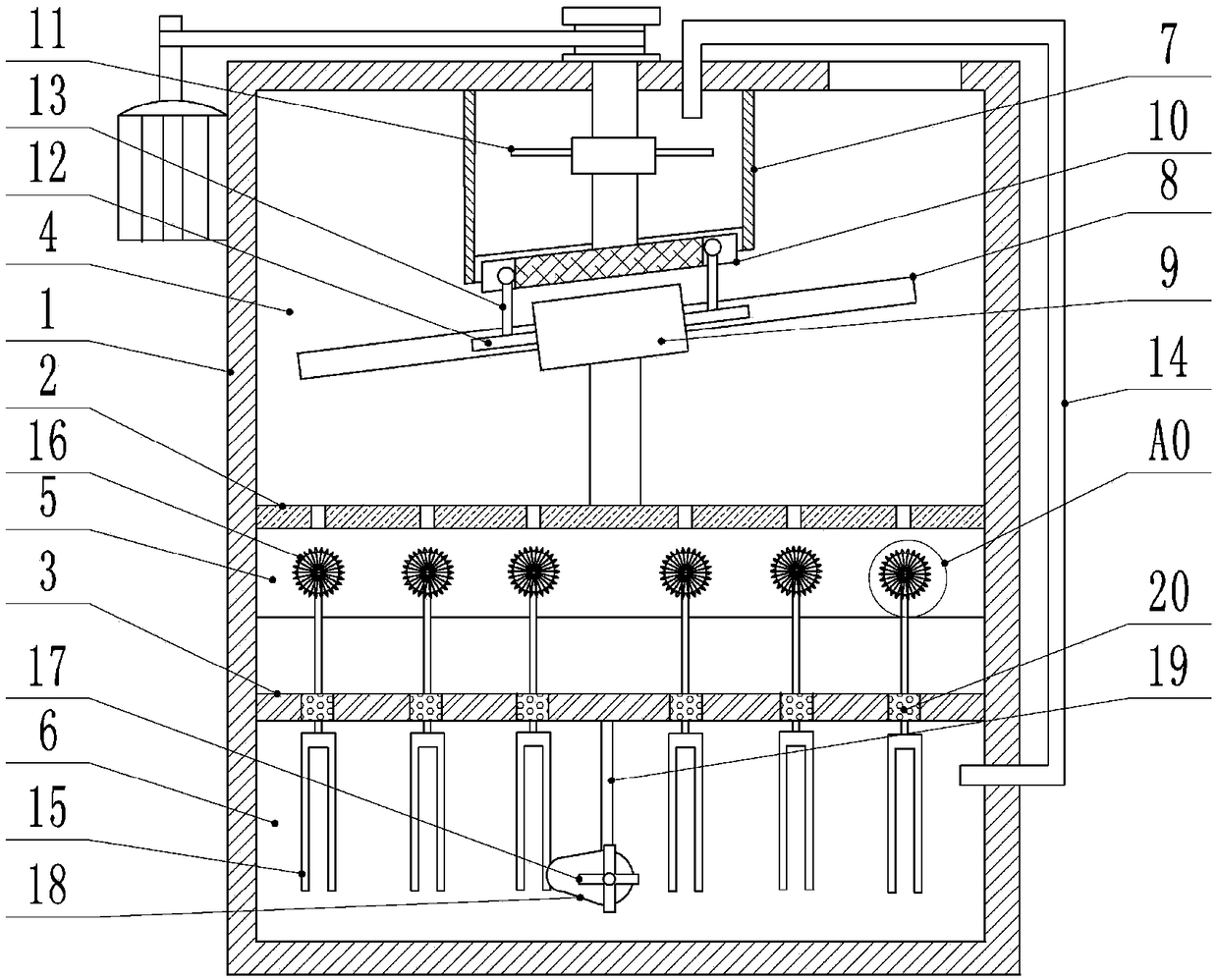

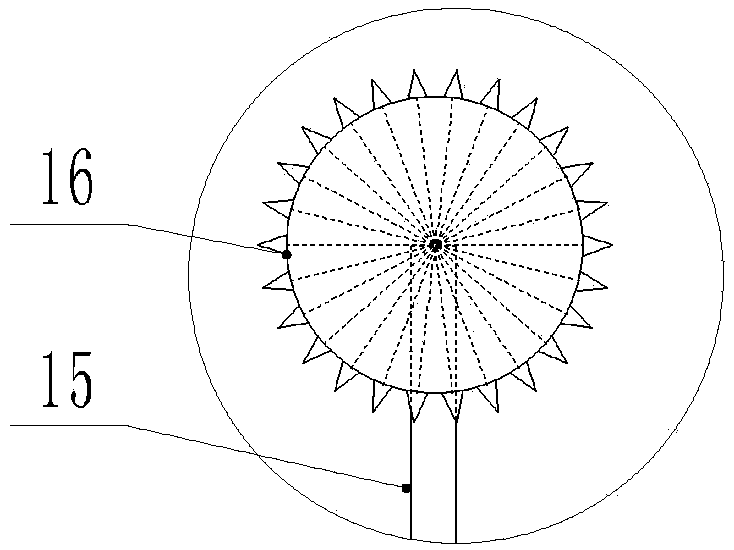

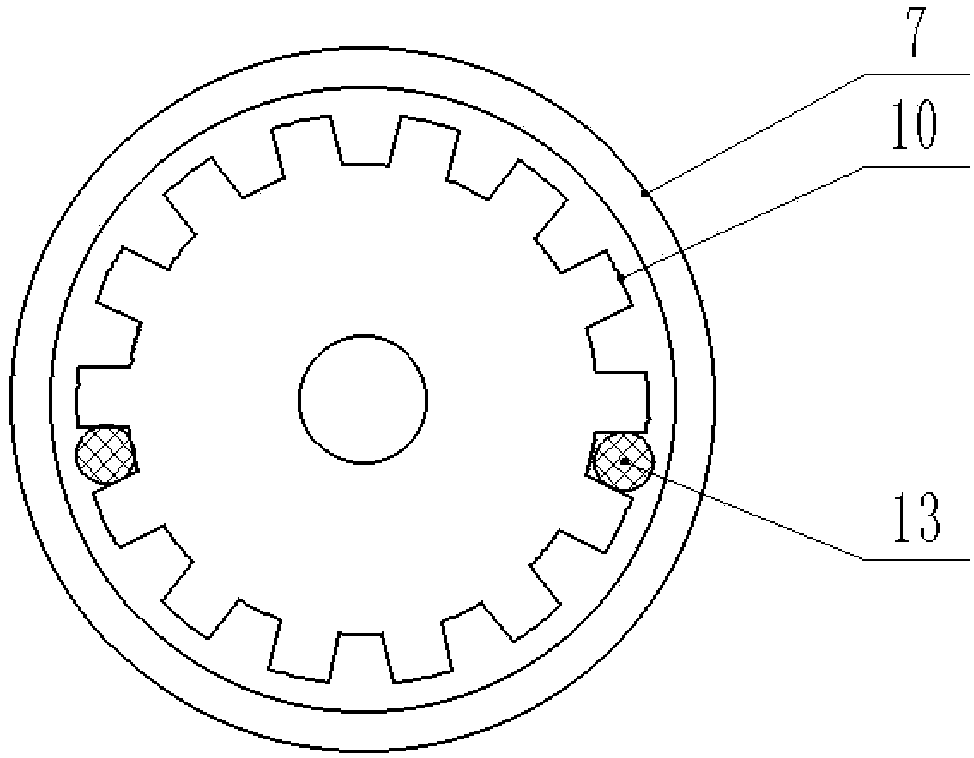

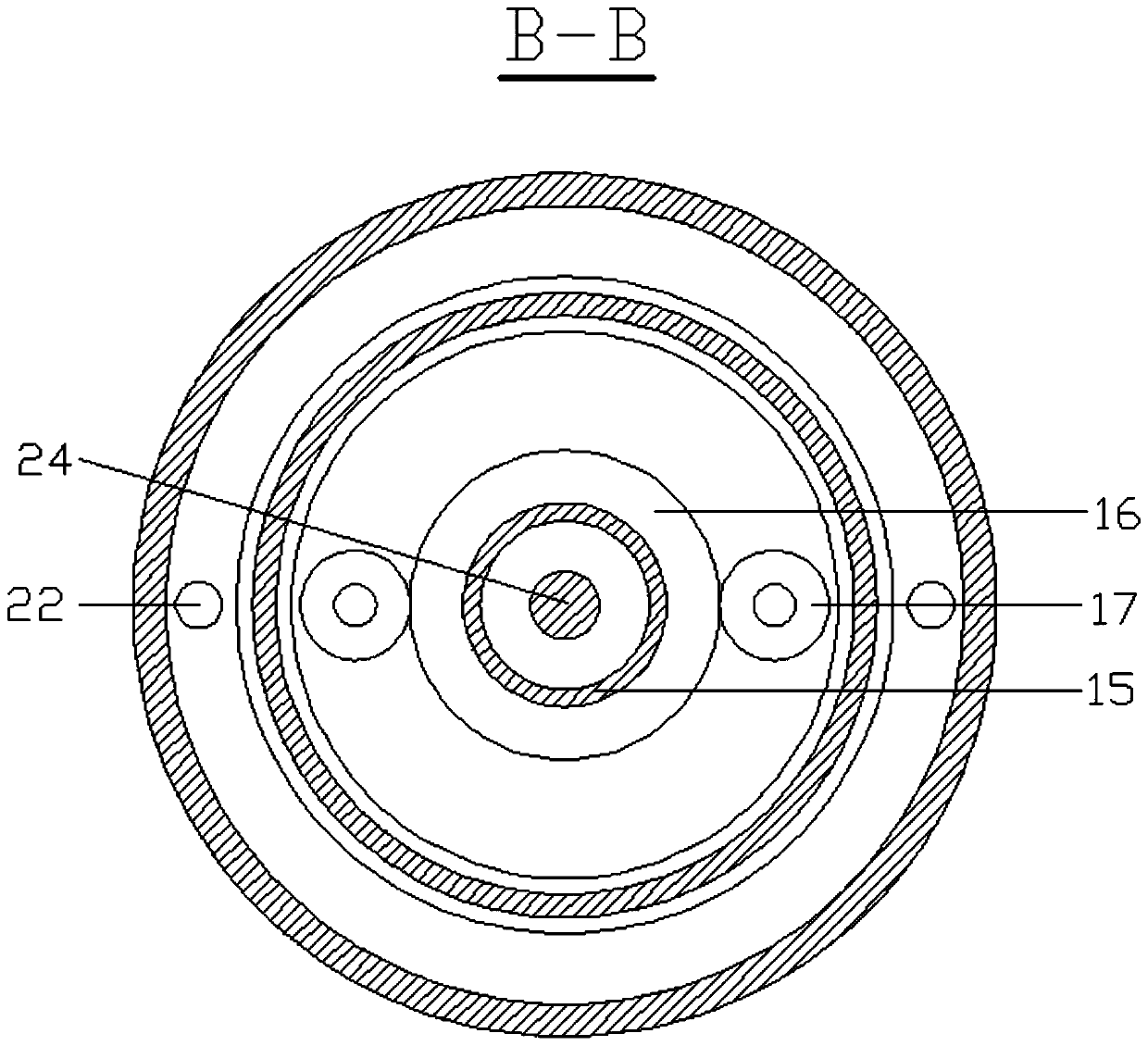

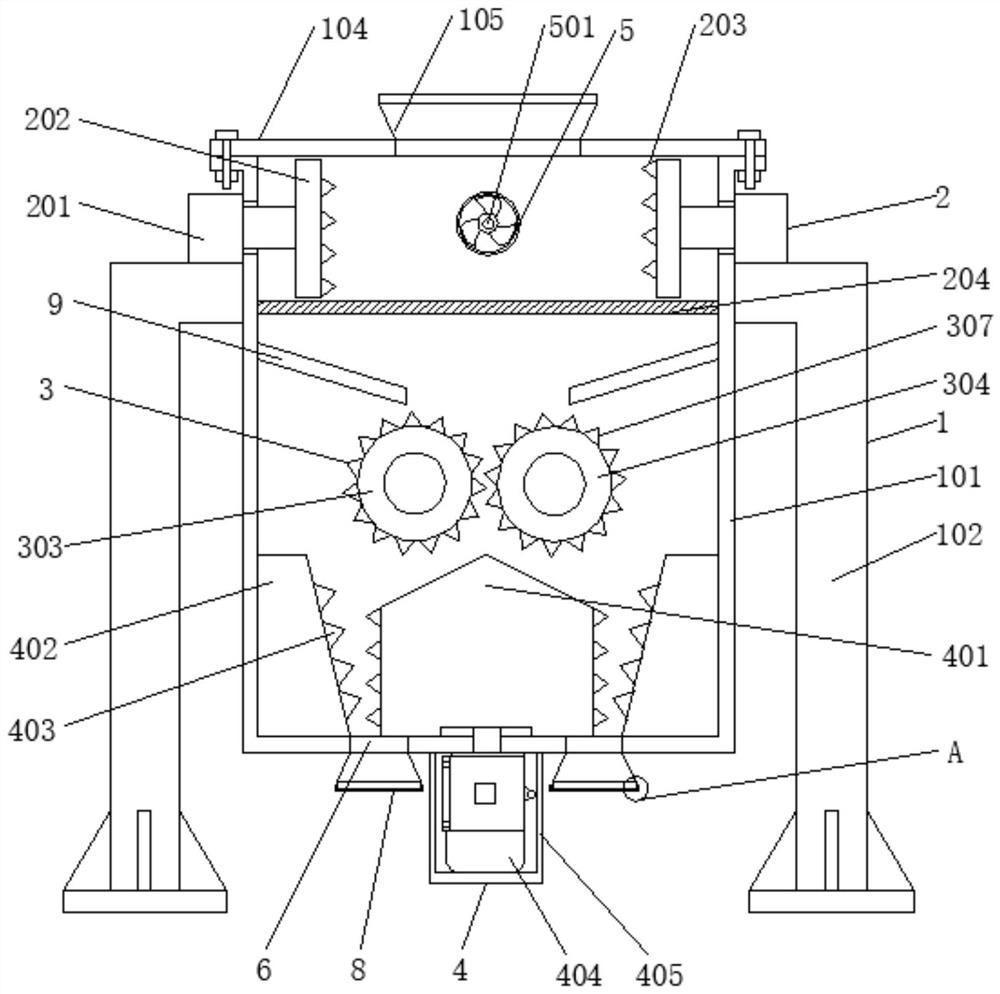

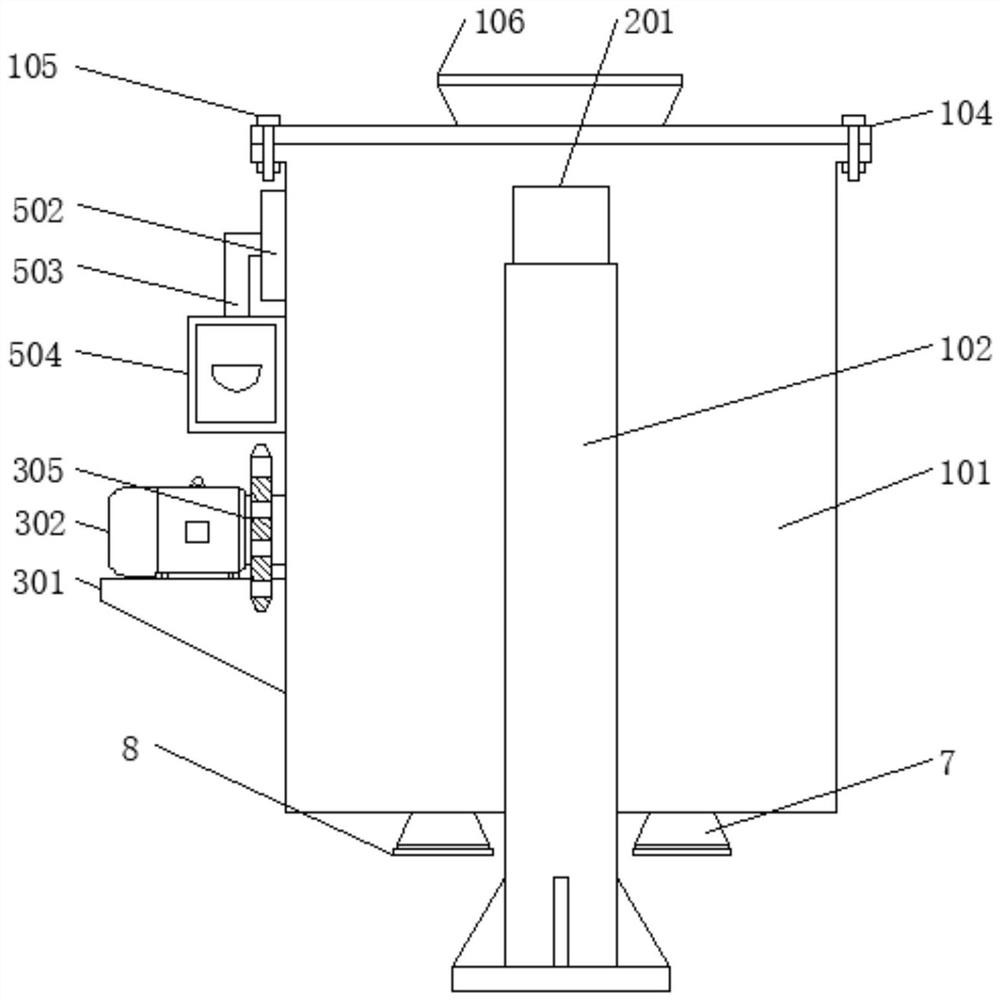

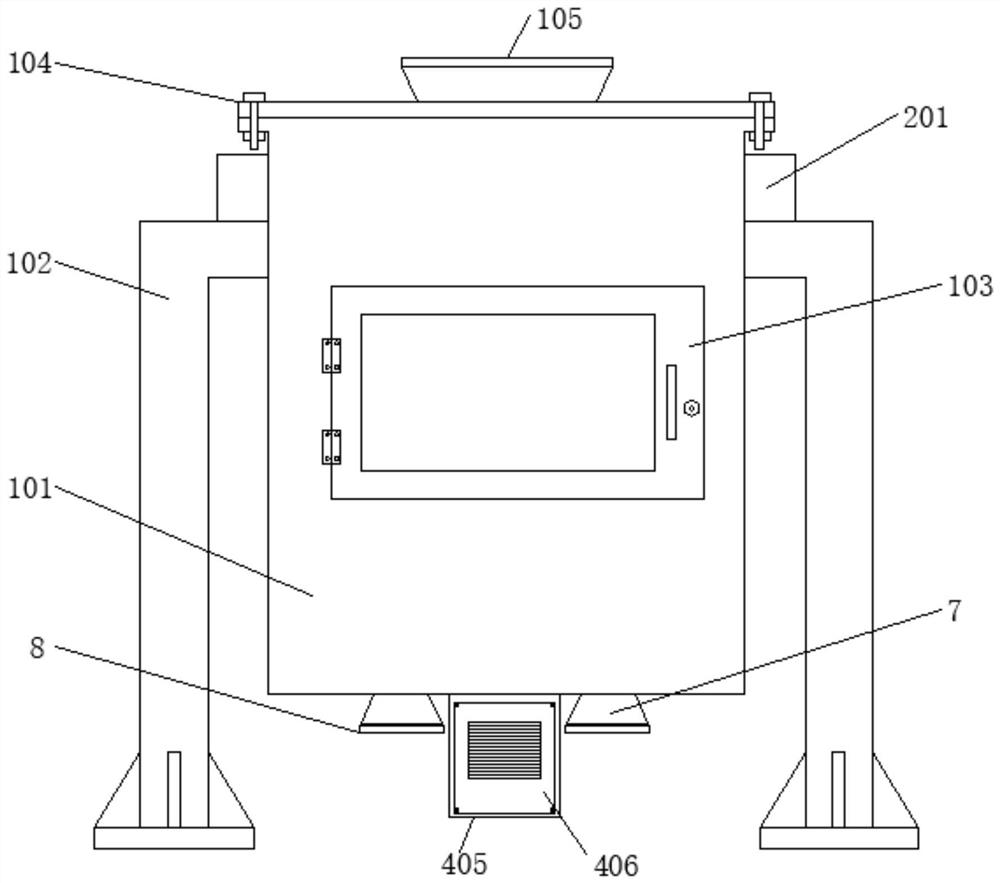

InactiveCN105413797AEasy to cleanGuaranteed crushing qualityGrain treatmentsGear wheelElectric machinery

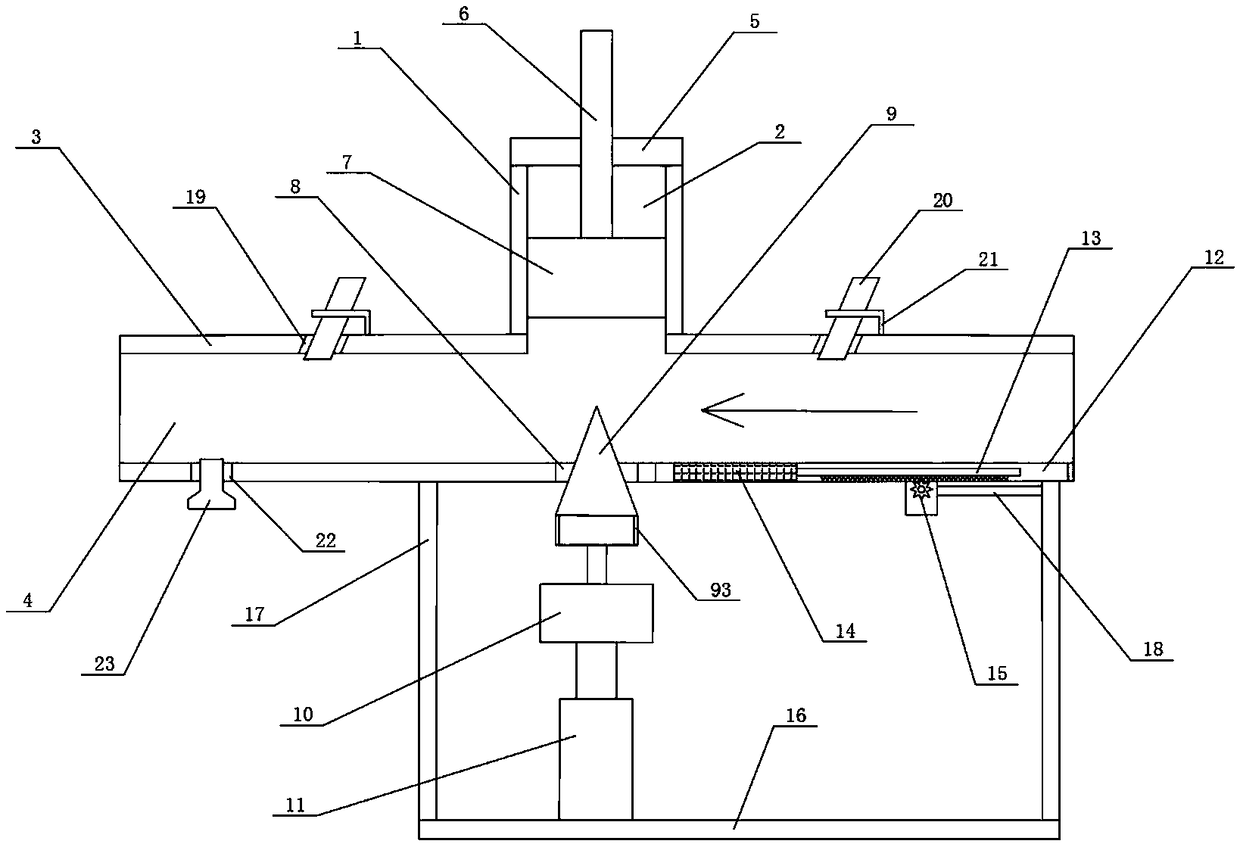

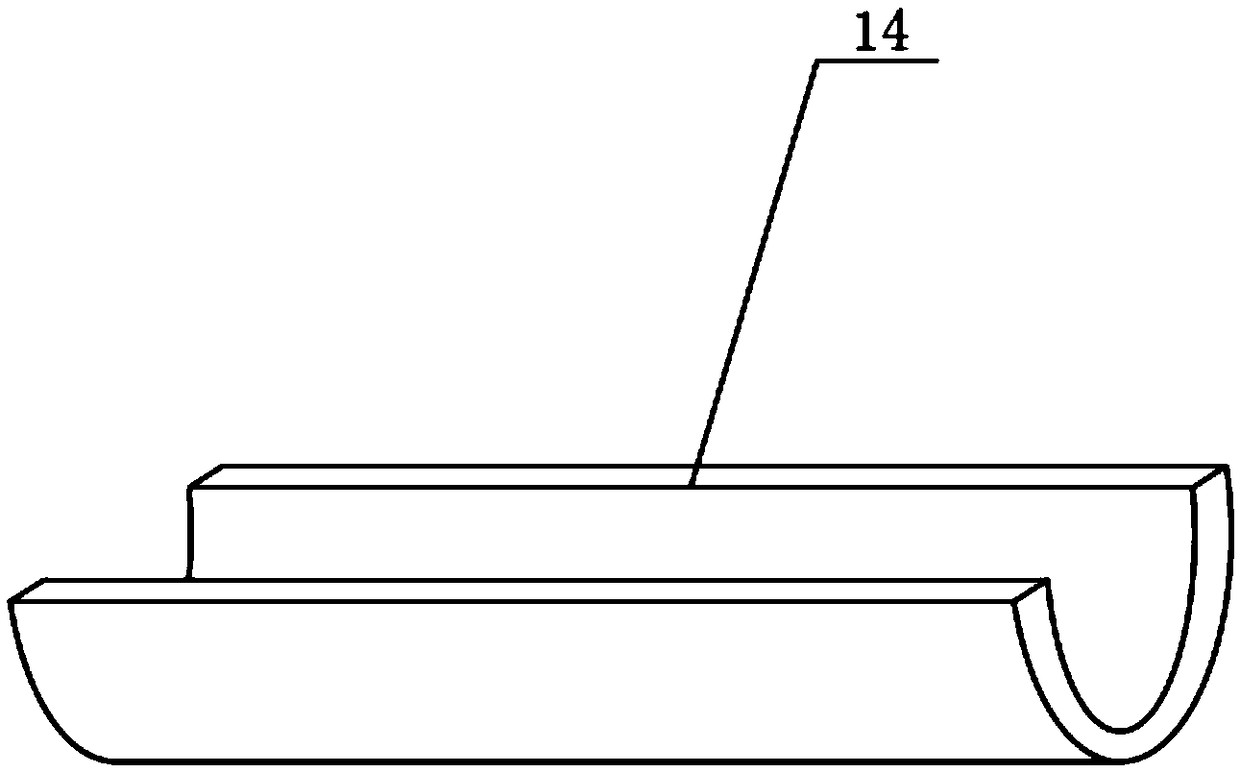

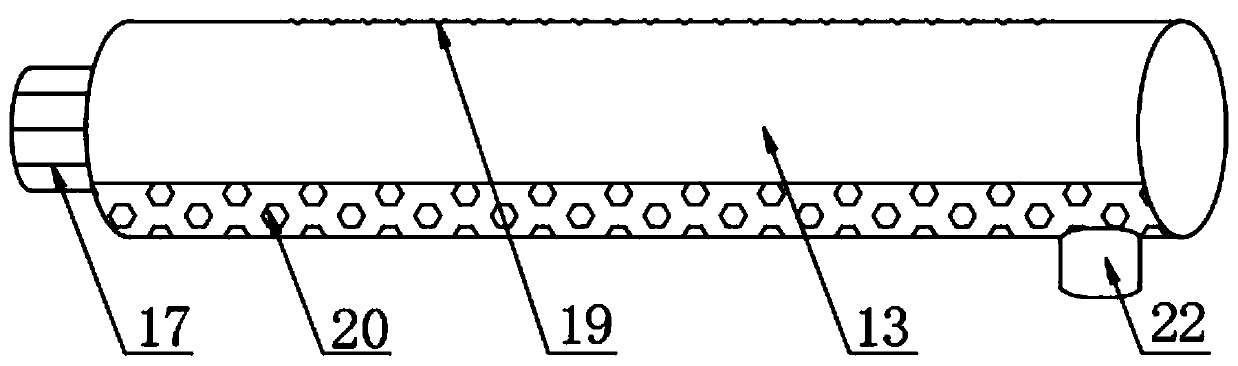

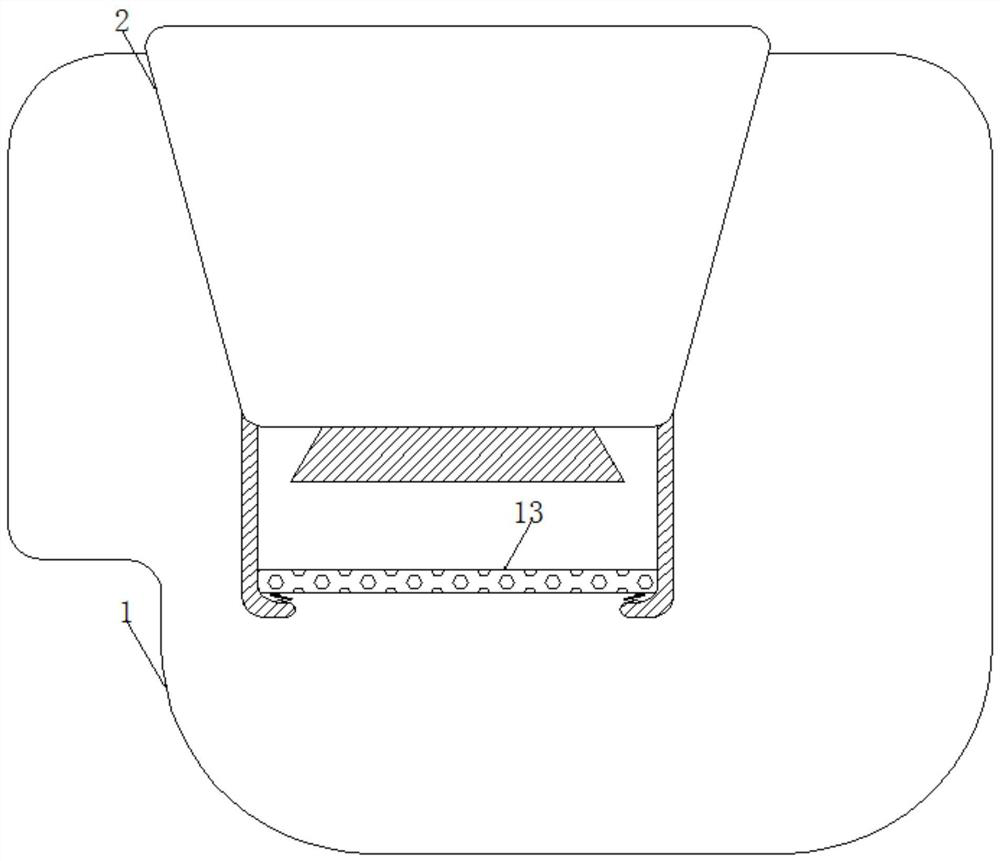

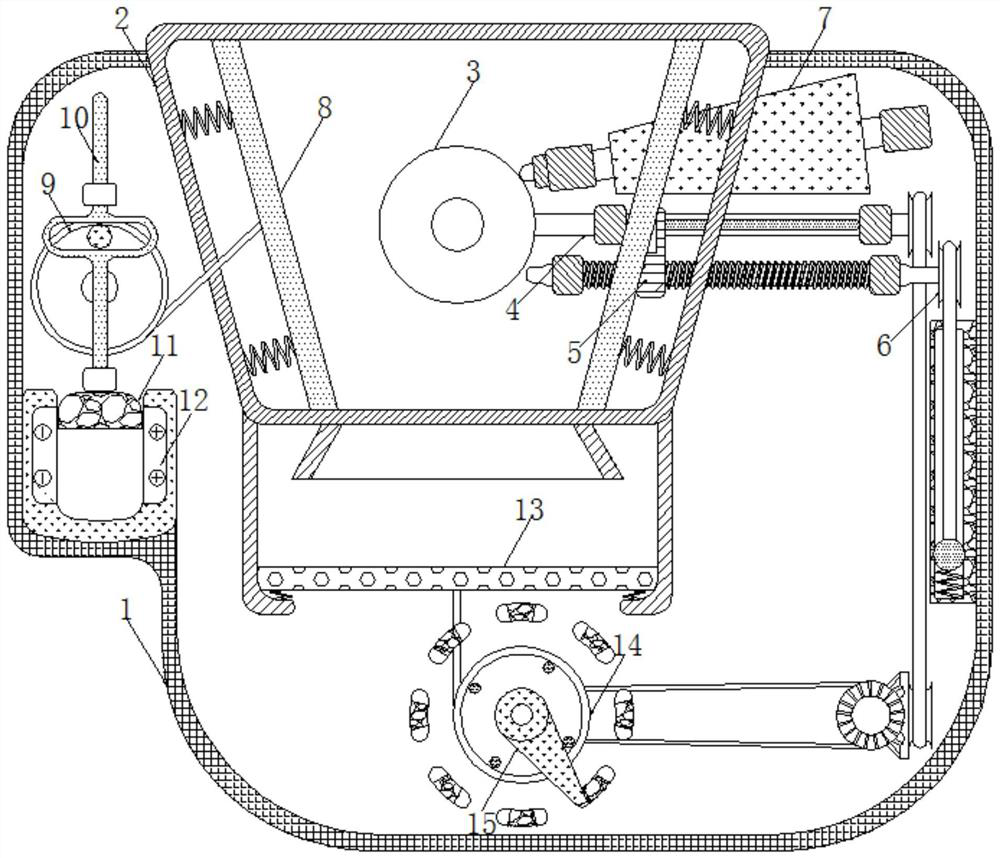

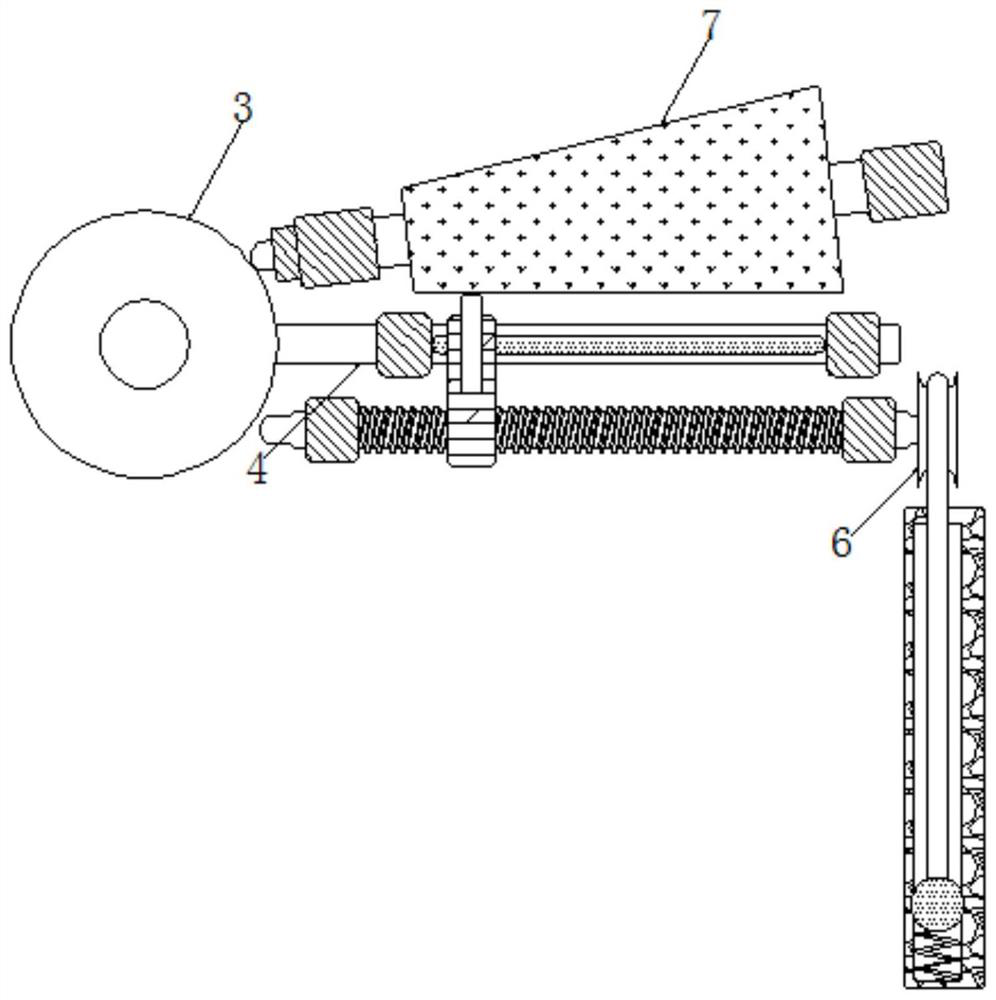

The invention provides a biomass particle smashing device. The biomass particle smashing device comprises a rack, a smashing shell and a smashing motor, wherein the smashing shell and the smashing motor are arranged on the rack. A pair of smashing rollers is horizontally arranged in the smashing shell. Roller shafts of the pair of the smashing rollers are engaged through a gear. An output shaft of the smashing motor is connected with the roller shaft of one smashing roller. A feeding opening is formed in the upper portion of the smashing shell, and a discharging opening is formed in the lower portion of the smashing shell. The smashing shell is provided with a vibration screen obliquely located above the discharging opening. The smashing shell is provided with a circulating discharging opening corresponding to the vibration screen. A lifting auger is arranged at the circulating discharging opening. The biomass particle smashing device has the advantages of being scientific in design, high in practicality, reasonable in structure, high in production efficiency and good in smashing effect.

Owner:LUOYANG KAITUO NEW ENERGY DEV CO LTD

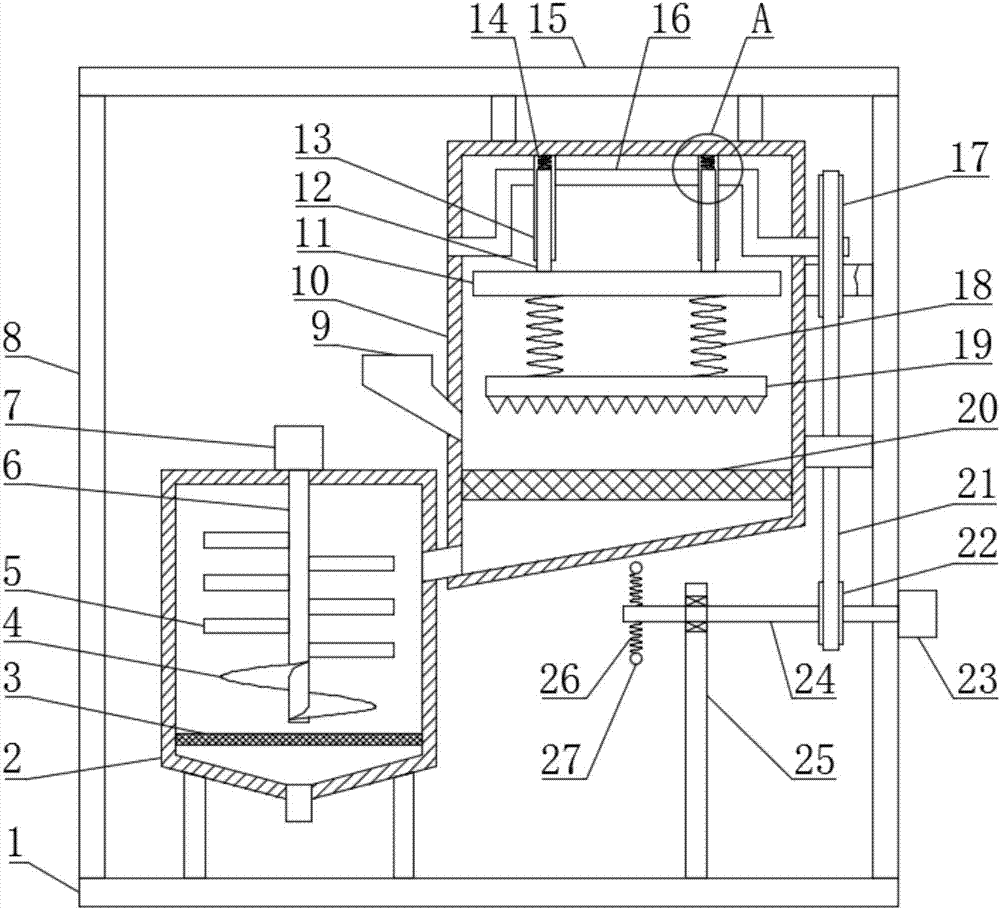

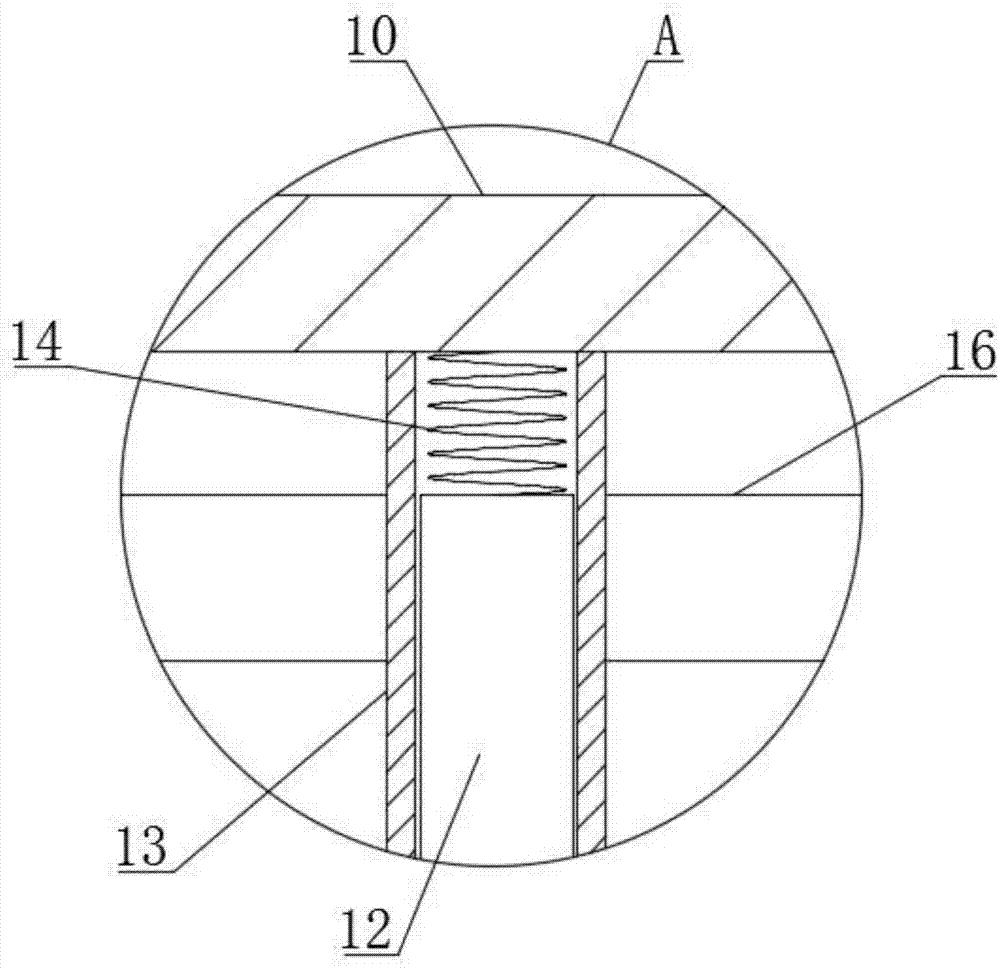

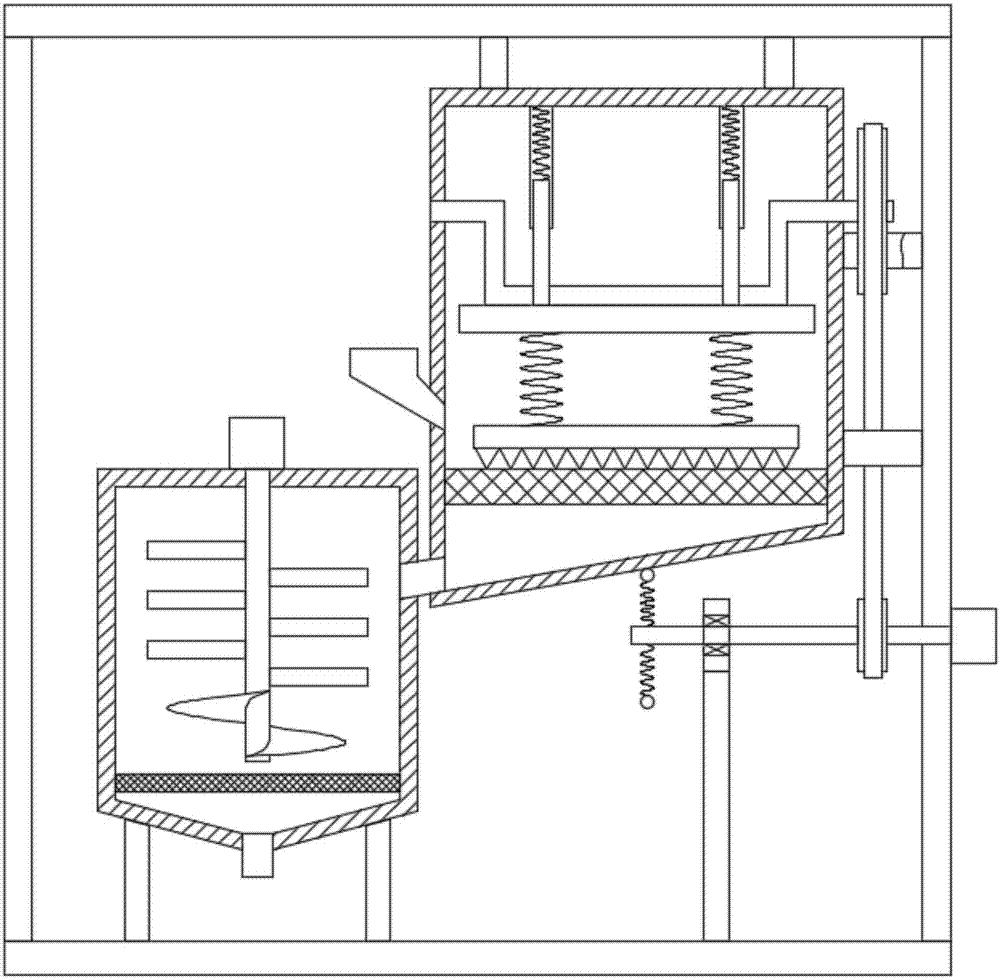

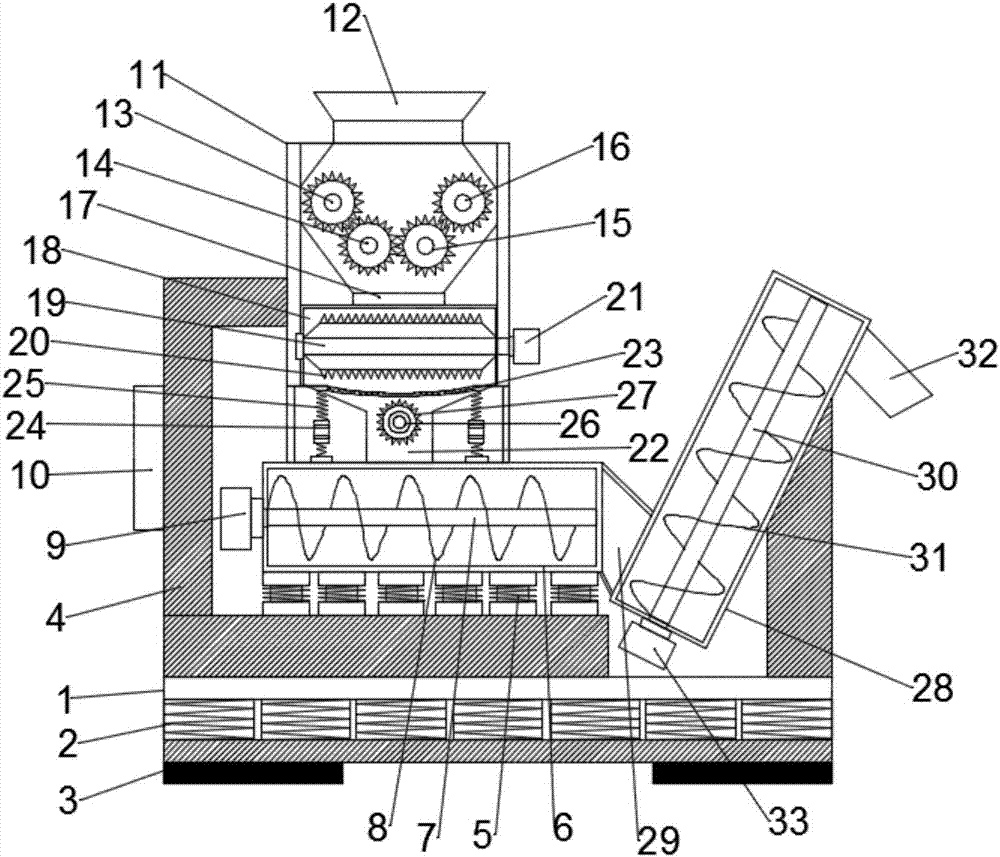

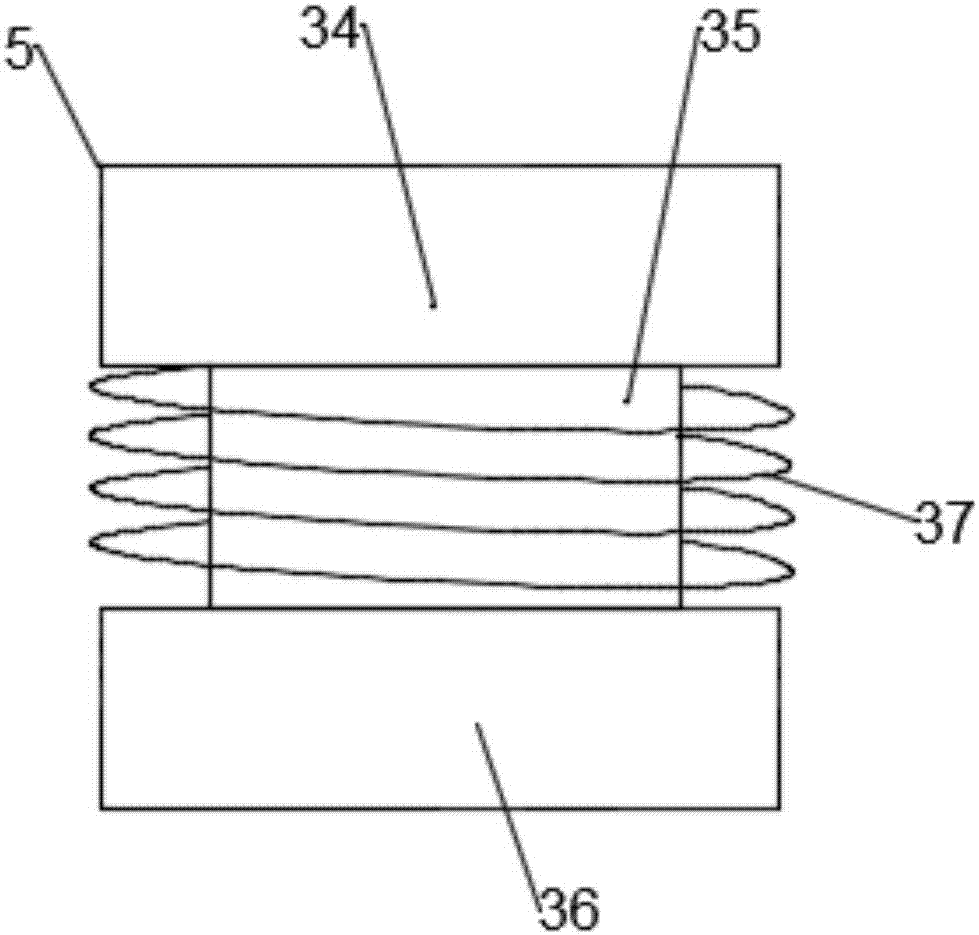

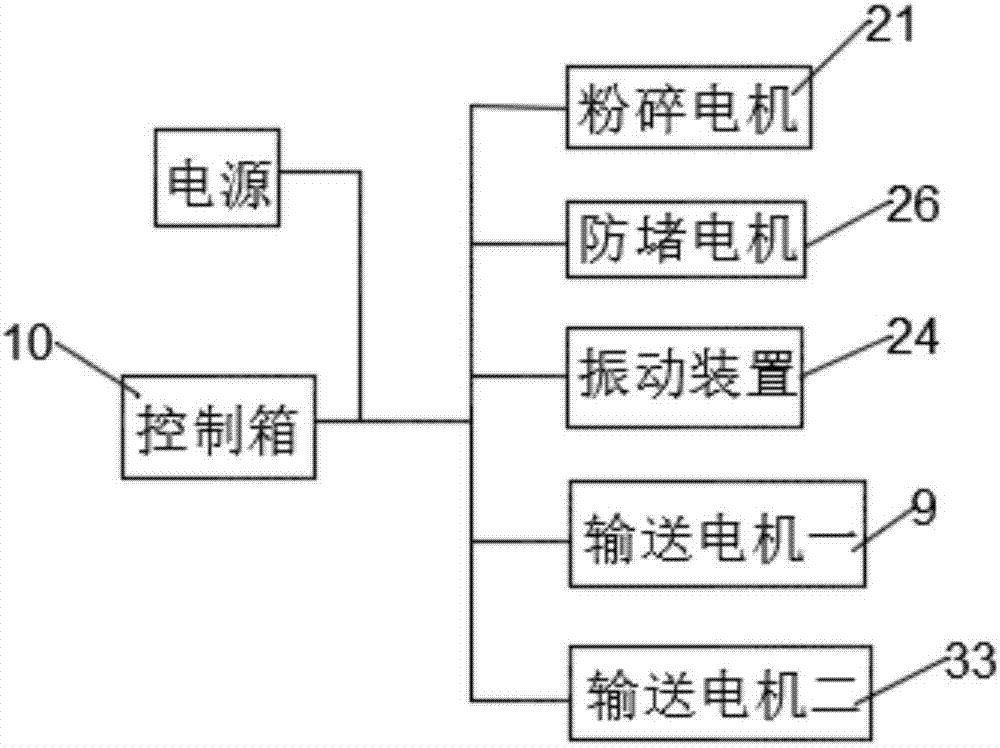

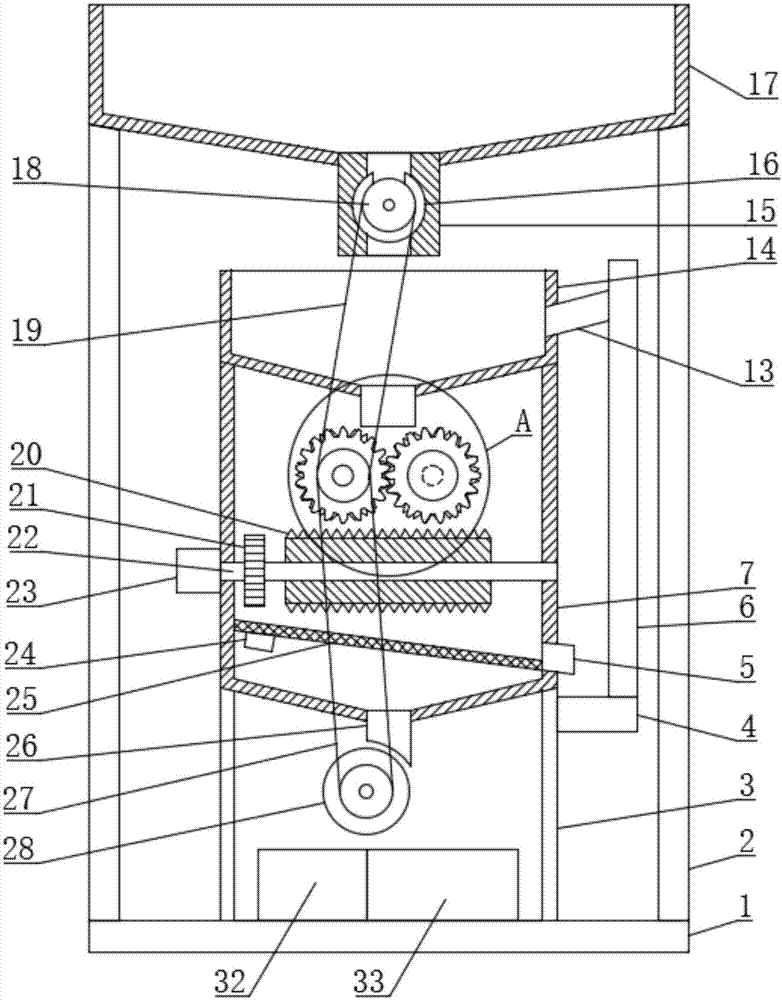

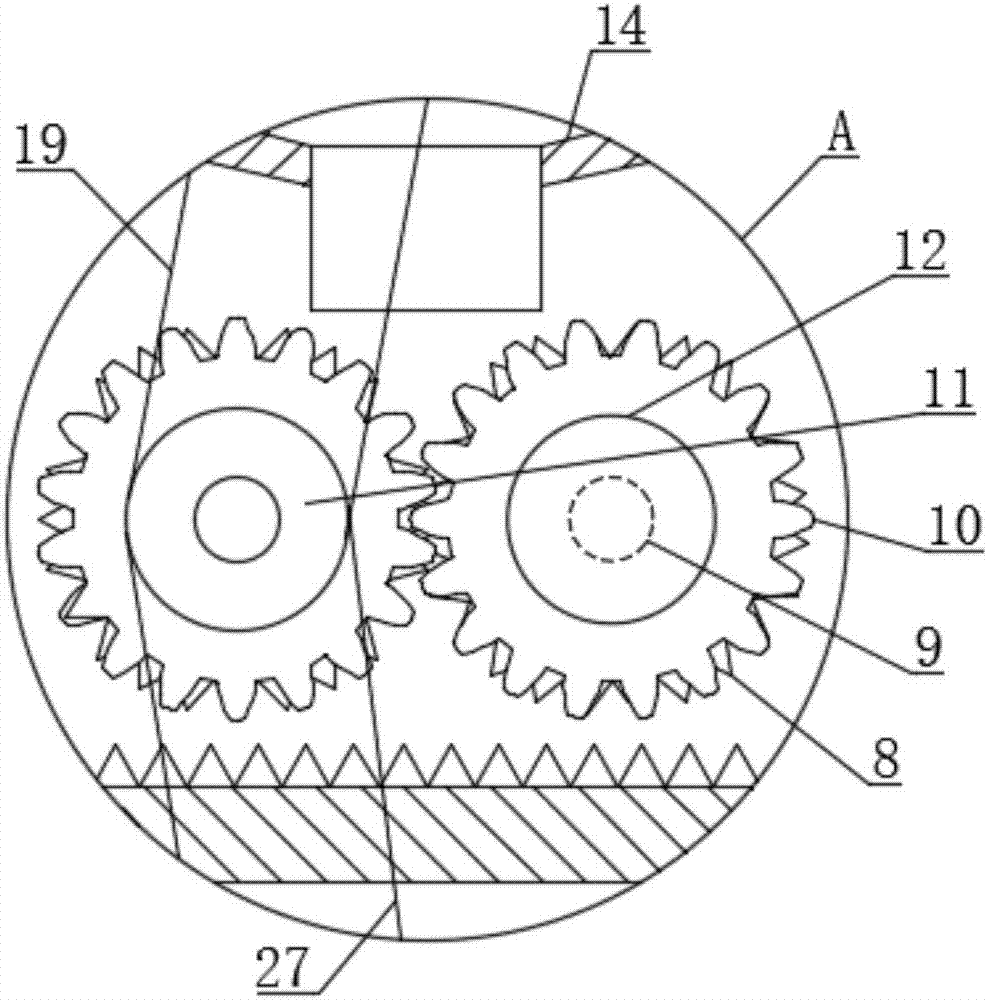

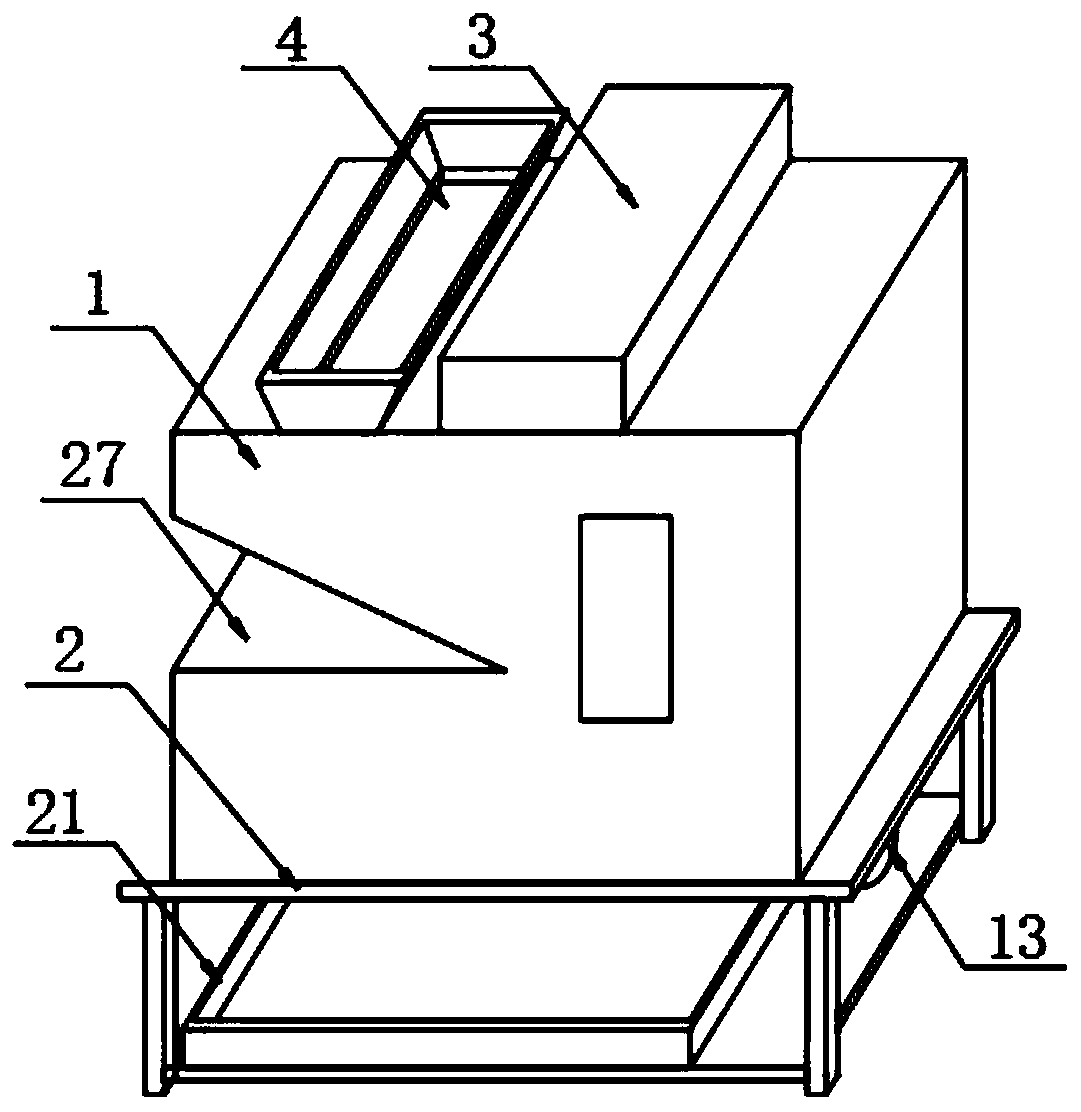

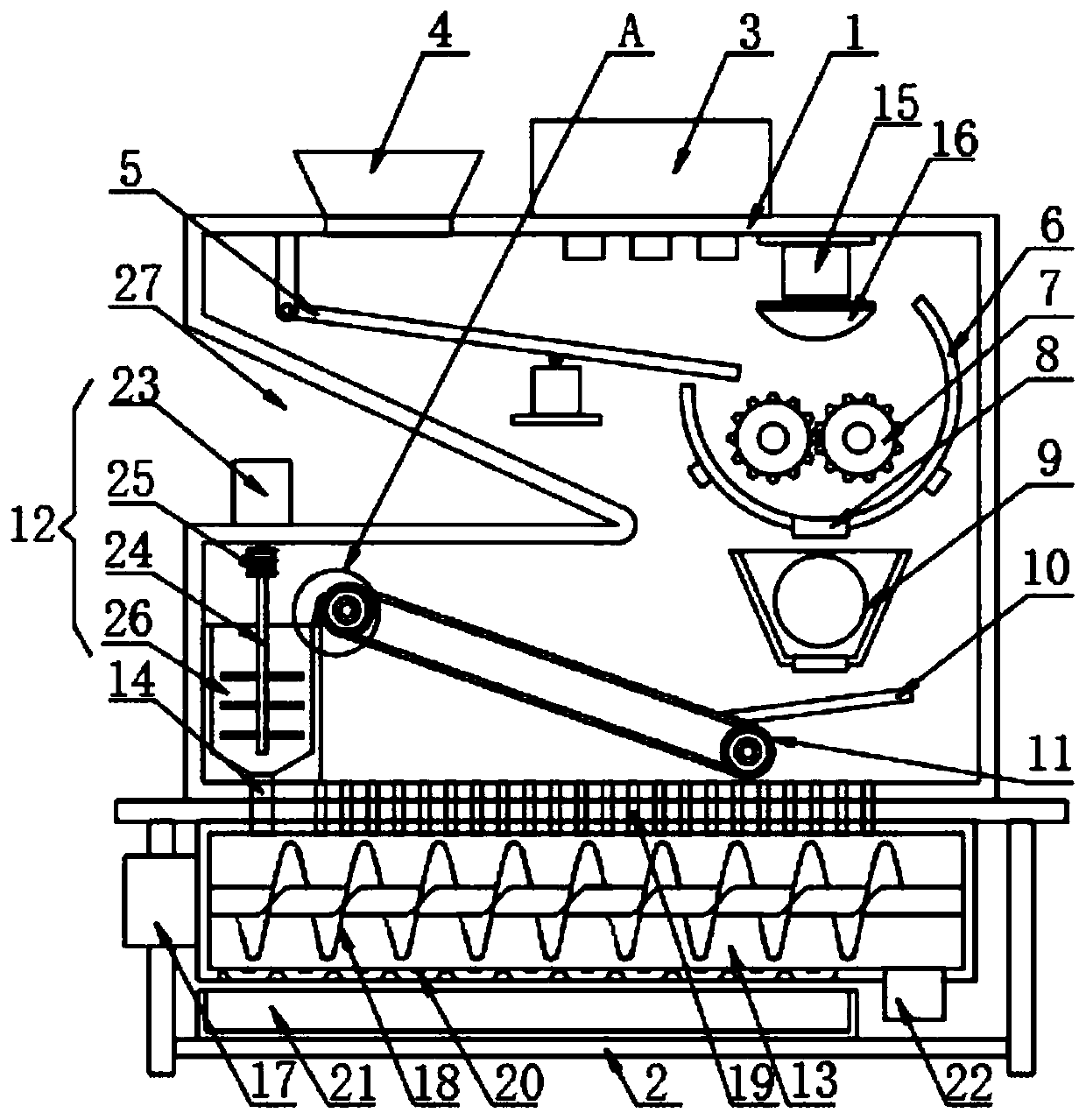

Crushing, stirring and lifting device for construction

InactiveCN107127038ASimple and reasonable designEasy to operatePackagingGrain treatmentsQuality assuranceBuilding material

The invention discloses a crushing and stirring lifting device for building construction, which comprises a bottom frame, a shock-absorbing layer and a base. A second crushing box is provided, the lower end of the second crushing box is provided with a feeding channel, the lower end of the feeding channel is provided with a first conveying cylinder, the right end of the first conveying cylinder is provided with a conveying port, and the lower right end of the conveying port is provided with a second Two delivery cylinders. This device realizes double crushing and mixing of building materials, ensures the quality of material crushing and mixing, and realizes the lifting of materials from low to high, which brings great convenience to construction and can greatly reduce the labor intensity of workers , which is conducive to improving the efficiency of construction. The shock absorbing mechanism and the shock absorbing layer have a good shock absorbing and buffering effect, which can reduce the vibration caused by the equipment during operation, protect the device, and prolong the service life of the device. .

Owner:蔡政伟

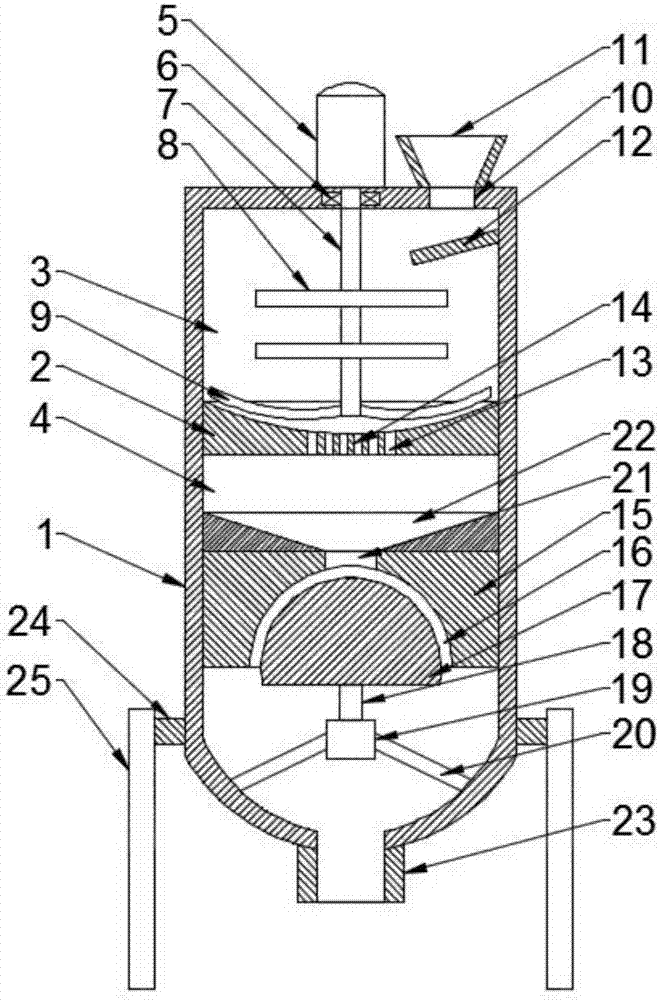

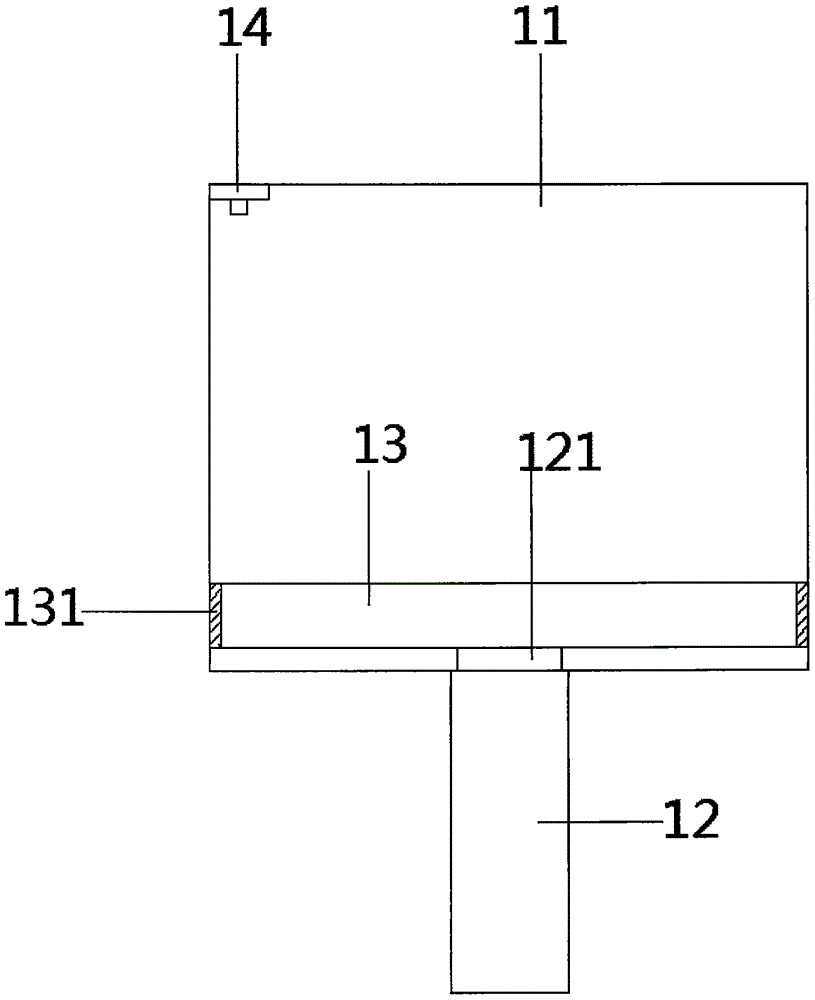

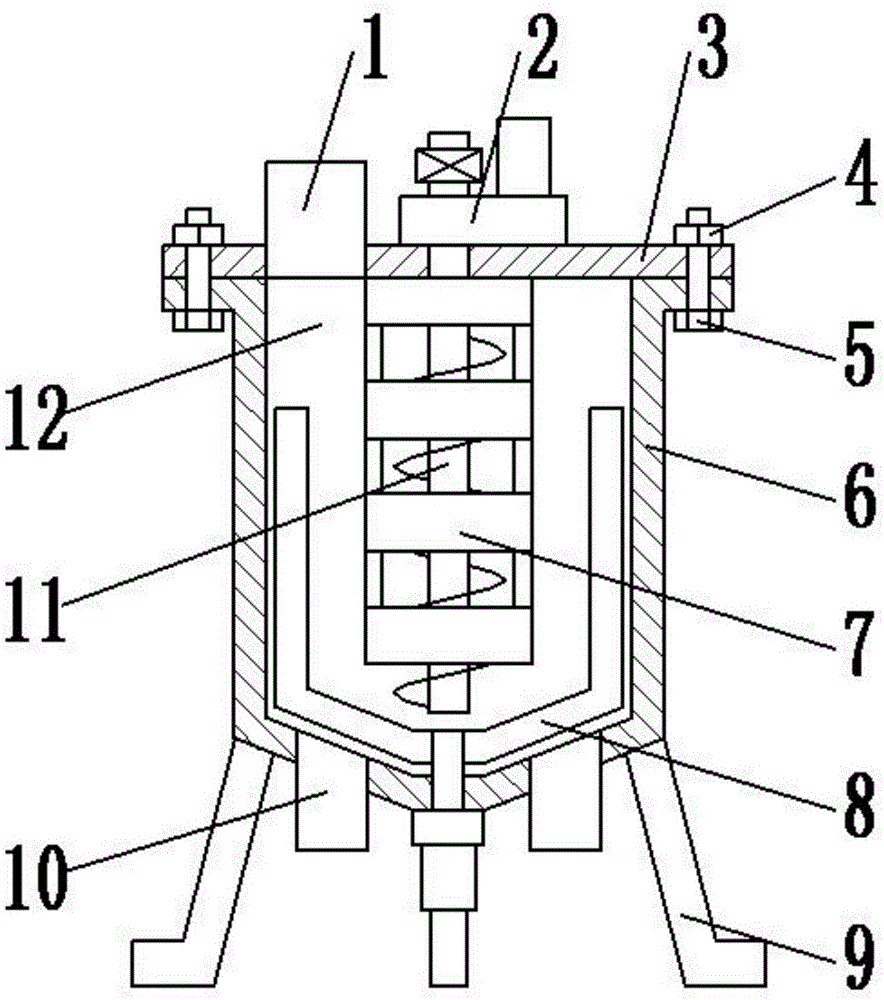

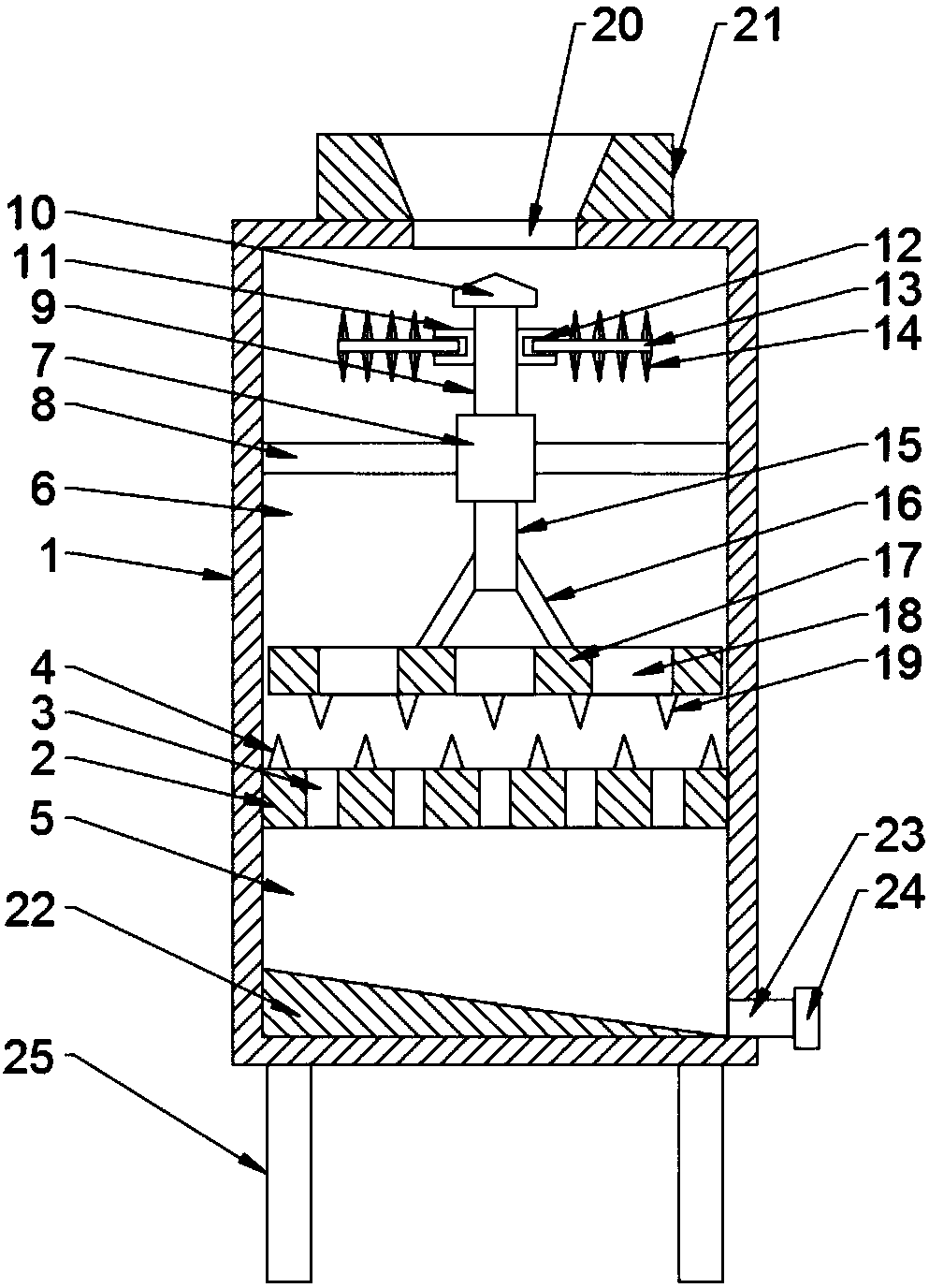

Graded traditional Chinese medicine smashing device

InactiveCN106925395AMeet uniformity requirementsImprove crushing effectGrain treatmentsElectric machineryEngineering

The invention discloses a graded traditional Chinese medicine crushing device, which comprises a tower body. The inner chamber of the tower is provided with a partition crushing plate. The partition crushing plate divides the tower body cavity into a crushing chamber and a grinding chamber. The top of the rod passes through the tower body and is fixedly connected to the motor shaft of the crushing motor. The middle part of the crushing rod is uniformly equipped with a number of first crushing blades, and the bottom end of the crushing rod is uniformly equipped with a number of second crushing blades in the circumferential direction. The grinding chamber is provided with a grinding plate body, the bottom end of the grinding plate body is provided with a grinding chamber, the grinding chamber is provided with a grinding body, and the grinding body is fixed on the motor shaft of the grinding motor through a rotating shaft; The crushing device grinds and pulverizes the traditional Chinese medicine, and under the screening of the filter screen, it meets the uniformity requirements; the primary pulverized Chinese medicine particles are ground and pulverized under the joint action of the grinding chamber and the grinding body, so that the Chinese medicine particles are further finely crushed, Improve the crushing effect and ensure the crushing quality.

Owner:合肥九州龙腾科技成果转化有限公司

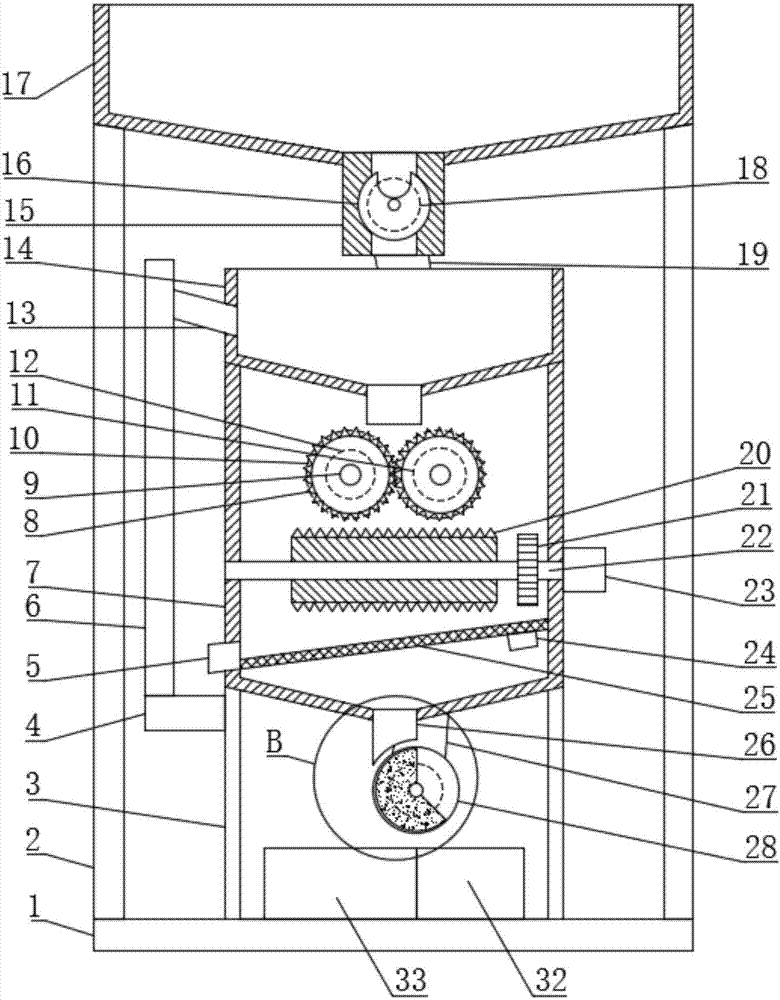

Efficient vertical roll milling machine capable of realizingwith multi-stage crushing

PendingCN109225568AGuaranteed crushing qualityCompact structureGrain treatmentsEngineeringMechanical engineering

The invention discloses an efficient vertical roll milling machine capable of realizingwith multi-stage crushing. The efficient vertical roll milling machine comprises a box body, wherein the left side of the top of the box body is communicated with a feeding pipe; a first motor is fixedly connected onto the top of the box body; the bottom of the output end of the first motor penetrates to the inner cavity of the box body and is fixedly connected with a first rotating rod. The disc matched crushing form of the conventional vertical roll milling machine roller disc matched crushing form is omitted; through the matched use of the first motor, a crushing cutter blade, a fixed cutter blade, a first inclined plate, an electromagnetic valve, support legs, a second motor, a driving gear, a drivengear, a milling roller, a second inclined plate, a conveying case, a third motor, a conveying shaft, a material detection sensor and a processor, the automatic multi-stage crushing on the materials can be realized; the material crushing quality is ensured; the crushing efficiency is improved; in addition, the structure is compact; the technical flow process is simple and safe; the abrasion consumption is low; the production cost is effectively reduced.

Owner:ANHUI UNIV OF SCI & TECH

Vertical environment-friendly smashing machine for building construction

InactiveCN105817303AImprove work efficiencyIncrease the number of cutsDispersed particle filtrationGrain treatmentsArchitectural engineeringRaw material

The invention discloses a vertical environment-friendly smashing machine for building construction. The vertical environment-friendly smashing machine for building construction comprises a machine body. A feeding hopper is arranged at the left end of the upper side of the machine body. A machine frame is arranged on the left side of the machine body. Telescopic columns are connected to the periphery of the bottom of the machine frame, and a sliding rail is arranged on the upper sides of the telescopic columns. The sliding rail comprises an obliquely arranged ascending section and a bent section arranged at the top end of the ascending section, and a transmission chain is arranged on the sliding rail. The two ends of the sliding rail are each provided with a driving chain wheel and a plurality of driven chain wheels. By means of the vertical environment-friendly smashing machine for building construction, automatic feeding can be achieved, feeding is sufficient and thorough, manual operation is not needed, and the working efficiency of the smashing machine is effectively improved; the smashing effect is effectively improved through two V-shaped smashing rods which are arranged with one below the other; materials are further smashed by smashing blades, so that the smashing quality is ensured; and meanwhile, fragments generated in the operating and discharging processes of the smashing machine can be recycled, so that dust pollution is avoided, environmental protection is achieved, and waste of raw materials is reduced.

Owner:姚旺东

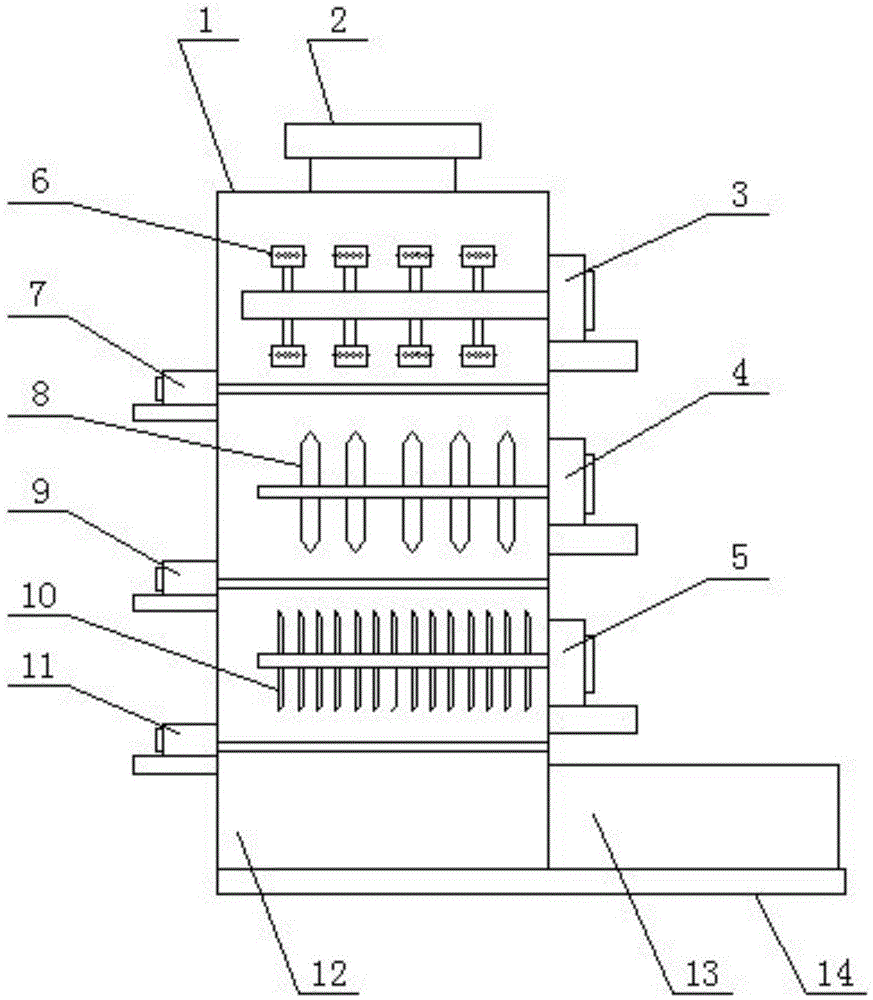

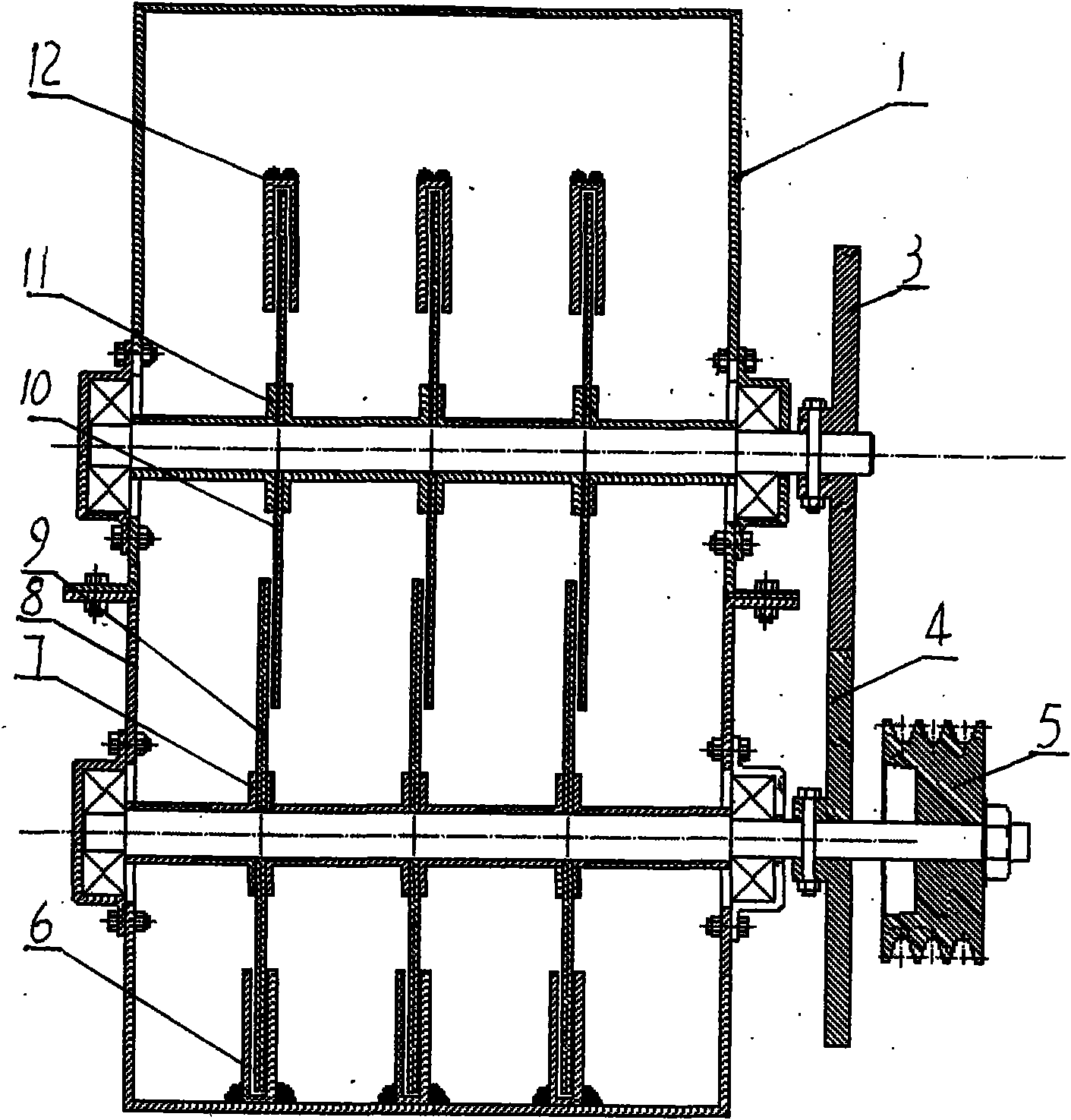

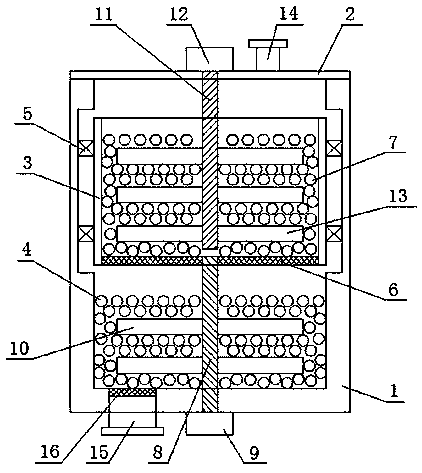

Waste slag classifying and crushing equipment provided with vibratory screening device

The invention relates to the technical field of waste slag crushing equipment and particularly relates to waste slag classifying and crushing equipment provided with a vibratory screening device. The waste slag classifying and crushing equipment comprises a crushing tank; a feeding hole is formed in the top of the crushing tank; a first vibrating screen, a second vibrating screen and a third vibrating screen are sequentially arranged from top to bottom inside the crushing tank; a first crushing chamber, a second crushing chamber, a third crushing chamber and a storage chamber are formed inside the crushing tank; a first vibrating motor, a second vibrating motor and a third vibrating motor are sequentially arranged from top to bottom at the left side surface of the crushing tank and are respectively connected with the first vibrating screen, the second vibrating screen and the third vibrating screen. By adopting multi-layer classified crushing, the waste slag classifying and crushing equipment can be used for simultaneously crushing waste slag different in diameter, so the crushing speed is greatly increased and the crushing quality is guaranteed; the waste slag classifying and crushing equipment has the advantages of high speed, complete crushing, high work efficiency and the like.

Owner:CHONGQING LONGJIAN METAL MFG

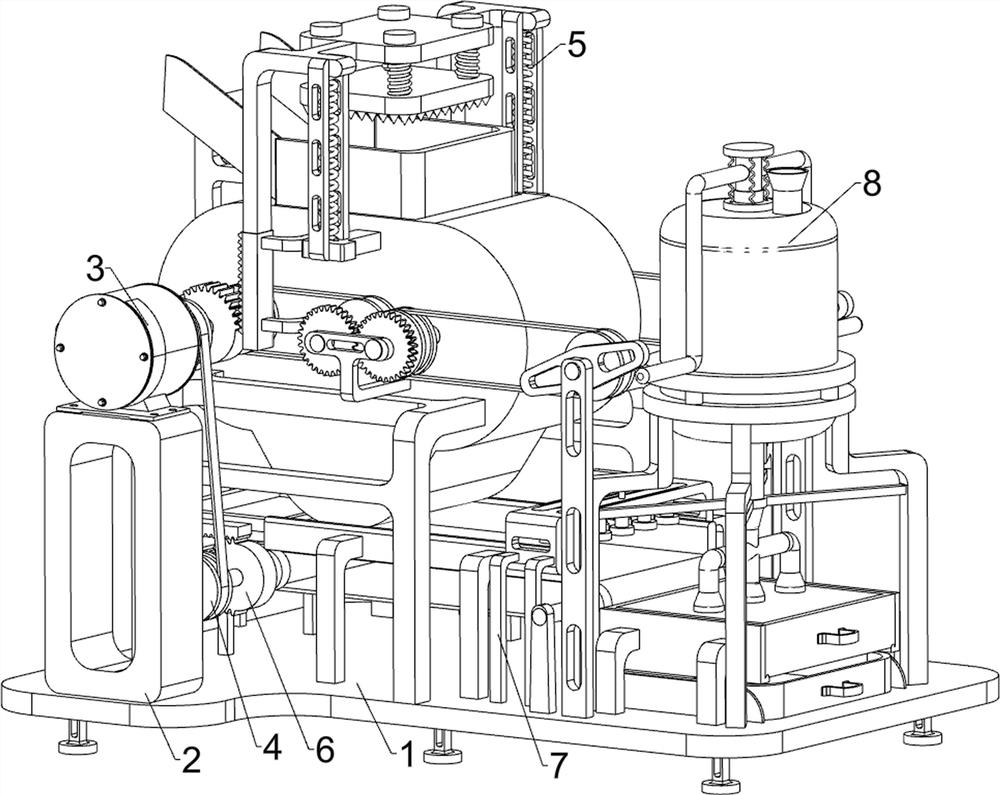

Crushing treatment device for recycling medical consumables

ActiveCN112495482APrevent affecting transmission efficiencyGuaranteed crushing qualityMagnetic separationCleaning using liquidsProcess engineeringMedical treatment

The invention relates to a crushing treatment device, in particular to a crushing treatment device for recycling medical consumables. The crushing treatment device for recycling the medical consumables is mainly used for conducting earlier-stage treatment on the medical consumables and conducting real-time disinfection on the medical consumables after crushing is completed. The crushing treatmentdevice for recycling the medical consumables comprises a base, a crushing mechanism and a transporting and collecting mechanism, wherein a mounting base is arranged on one side of the top of the base;one side of the top of the base is connected with the crushing mechanism; and one side of the top of the base is connected with the transporting and collecting mechanism. By arranging a primary crushing mechanism and the crushing mechanism, secondary crushing is conducted on the medical consumables, and the crushing quality is guaranteed; and by arranging the transporting and collecting mechanismand an accumulation preventing mechanism, the broken glass is automatically conveyed and collected, meanwhile, the glass is smoothened, and the situation that the conveying efficiency is affected dueto the fact that the glass accumulation height is too high is prevented.

Owner:湖南臻和亦康医疗用品有限公司

Environmentally-friendly solid waste treatment device based on cyclic crushing technology

InactiveCN109078721ACrushed fullyGuaranteed crushing qualityGrain treatmentsEngineeringWaste treatment

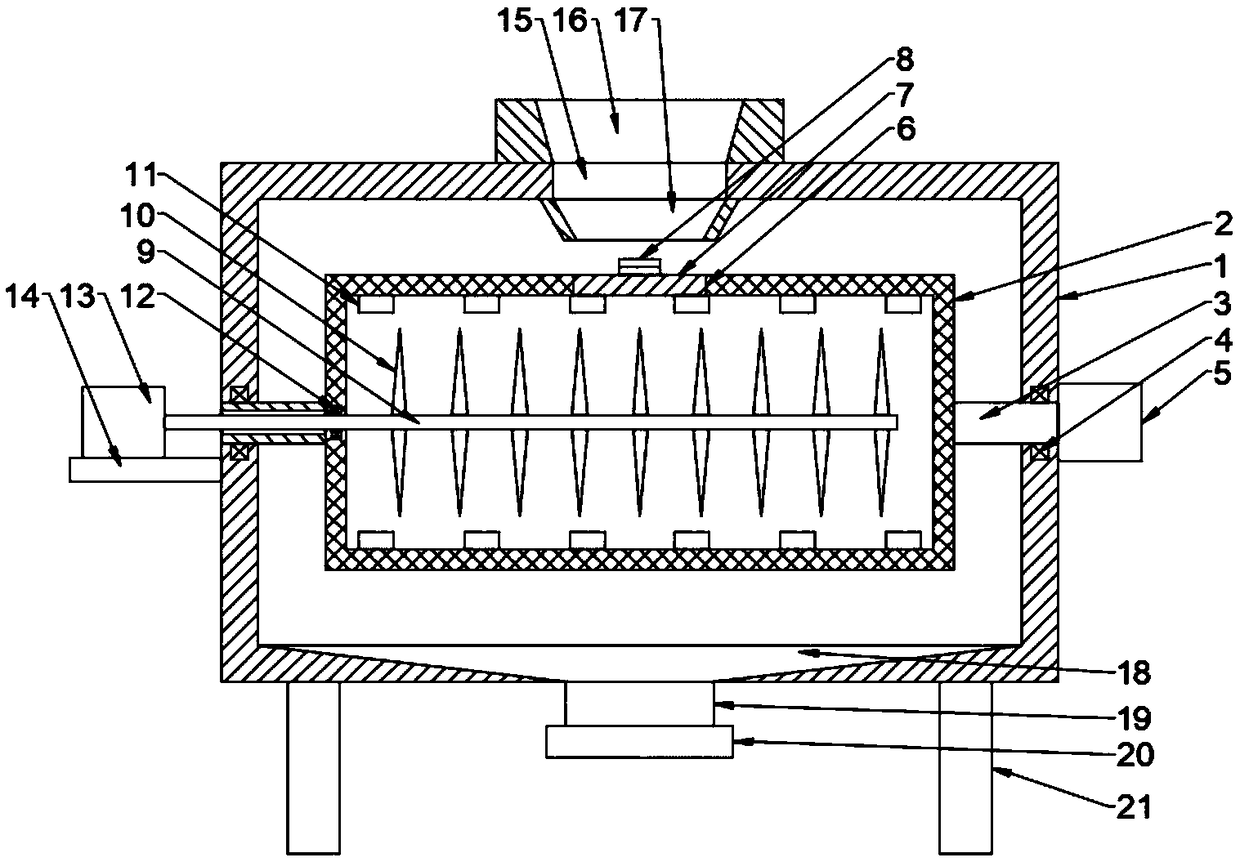

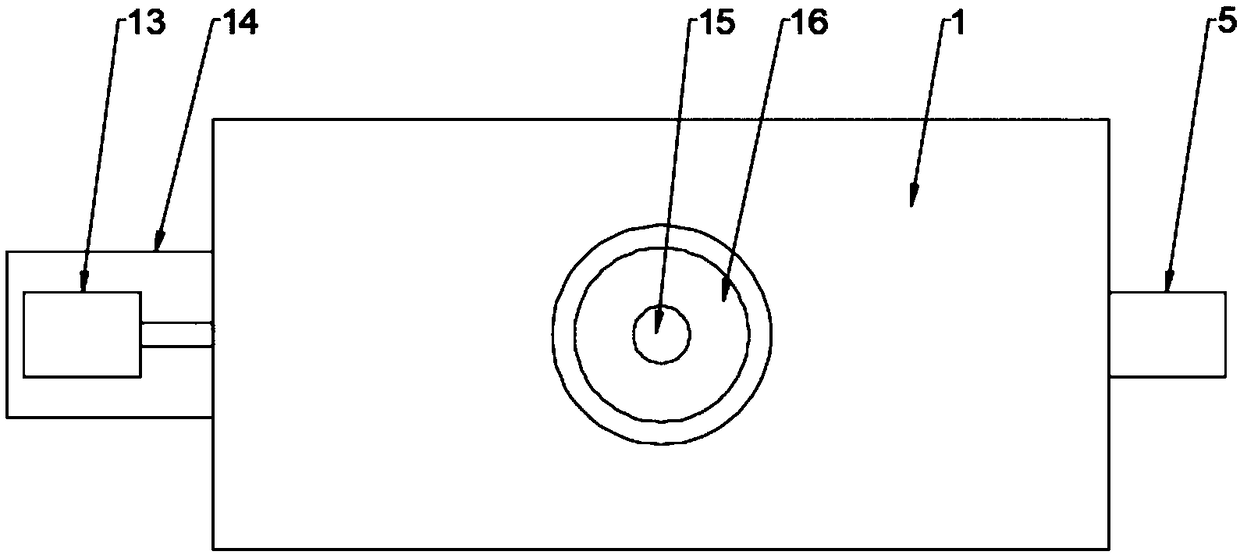

The invention discloses an environmentally-friendly solid waste treatment device based on a cyclic crushing technology. The environmentally-friendly solid waste treatment device comprises an outer casing body and a crushing cylinder, wherein the outer casing body is internally provide with the crushing cylinder; the crushing cylinder is rotationally connected to the outer casing body through a rotating shaft; the right side end of the rotating shaft penetrates through a side wall of the outer casing body and is fixedly connected to a motor shaft of a first motor; the rotating shaft is rotationally connected to the outer casing body through a first bearing; a plurality of material switching plates are uniformly arranged on the wall of an inner cavity of the crushing cylinder; a crushing rodis arranged in the inner cavity of the crushing cylinder; a plurality of crushing blades matched with the material switching plates are uniformly arranged on the outer cylindrical surface of the crushing rod; according to the invention, through the forward rotation of the first motor, the crushing cylinder is driven to rotate in the forward direction, and when the crushing cylinder rotates, materials falling on the bottom wall of the inner cavity of the crushing cylinder are continuously writhed in the inner cavity of the crushing cylinder under the action of the material switching plates; atthe same time, a second motor is utilized to drive the crushing rod to rotate in the reverse direction and drive the crushing blades to rotate in the reverse direction, and the high-speed rotating crushing blades continuously collide with the writhed materials, thereby ensuring that the materials are fully crushed.

Owner:黄景珍

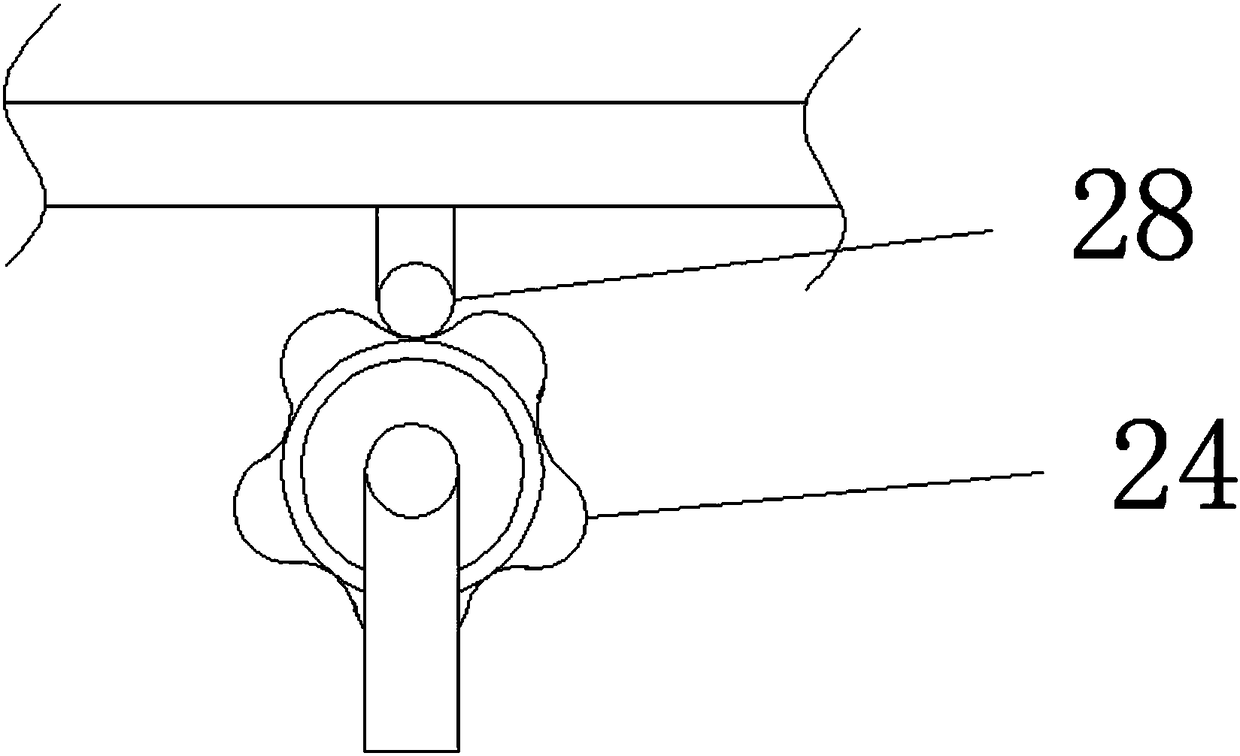

Crank connecting rod type traditional Chinese medicine grinding device

InactiveCN108160275AEffective tilingAvoid uneven crushingGrain treatmentsMoving filtering element filtersWater filterDrive shaft

The invention discloses a crank connecting rod type traditional Chinese medicine grinding device which comprises a crate; an inner cavity of the crate is provided with a grinding tank and a water filter tank; the water filter tank is arranged below the grinding tank; supporting frames are arranged at the front end and the back end of the water filter tank respectively; moving grooves are arrangedon the front side wall and the back side wall of the crate respectively; the supporting frames are installed in the moving grooves through pulleys respectively; a water filter screen is arranged at the middle part of the water filter tank; the bottom end of the water filter screen is provided with a water collection cavity; transmission motors are arranged on the front side and the back side of the bottom end of the crate; a multi-blade cam is installed on each transmission motor through a transmission shaft; an extrusion block is installed at the bottom end of each supporting frame; and a spherical block is installed at the bottom end of each extrusion block and is attached to the corresponding multi-blade cam. By adopting the crank connecting rod type traditional Chinese medicine grinding device provided by the invention, the water filter tank is in a state of moving at an approximate constant speed while jolting, so that the crank connecting rod type traditional Chinese medicine grinding device has very high stability and can effectively and uniformly lay materials on the water filter screen.

Owner:郑州莉迪亚医药科技有限公司

Garbage smashing and treating device for garbage landfills

The invention relates to the technical field of smashing devices, and discloses a garbage smashing and treating device for garbage landfills. The garbage smashing and treating device comprises a tank.A feed inlet and a discharge outlet are formed in the tank, a smashing cutter is rotationally arranged in the tank and is connected with a power mechanism, the power mechanism comprises a cylindricalcam, a gear is rotationally arranged on an oblique plane of the cylindrical cam, the smashing cutter comprises a head and blades, the blades are rotationally arranged on the head, the head is hingedinto the tank, push handles are connected onto blade surfaces of the blades, and ejector rods are hinged onto the push handles, are clamped in tooth spaces of the gear and are butted onto the obliqueplane of the cylindrical cam. The garbage smashing and treating device has the advantage that the problem of influence on the garbage smashing quality due to the fact that garbage sleeves existing smashing cutters can be solved by the aid of the garbage smashing and treating device.

Owner:贵州杉海沿环保科技有限责任公司

Circulating slag crushing and iron separation device

The invention discloses a circulating slag crushing and iron separation device. The circulating slag crushing and iron separation device comprises a base, wherein a crushing box is fixedly arranged on the base through a support plate, a circulating box is fixedly arranged at the top of the crushing box, a sieve screen is arranged slantwise at the bottom in the crushing box, an unloading groove is connected to the left side of the sieve screen, a receiving box is further arranged on the support plate at the left side, a screw elevator is arranged at the upper left side of the receiving box, and a discharge port in the top of the screw elevator is connected to the left side in the circulating box through a circulating pipe; and an unloading pipe is connected to the bottom of the crushing box, a fixed shaft is further fixedly connected to the bottom of the crushing box through a support, a rotary barrel is rotationally connected to the fixed shaft, a cylindrical magnet is further fixedly installed on the fixed shaft, and the cylindrical magnet is located in the rotary barrel. According to the circulating slag crushing and iron separation device disclosed by the invention, the crushed slag is filtered through the arrangement of the sieve screen, and circulating crushing is carried out on the incompletely-crushed ores by the screw elevator, so that the crushing quality for all the slag is ensured; and iron powder is received and reutilized through the arrangement of the rotary barrel and the cylindrical magnet.

Owner:ZHENGZHOU UNIV

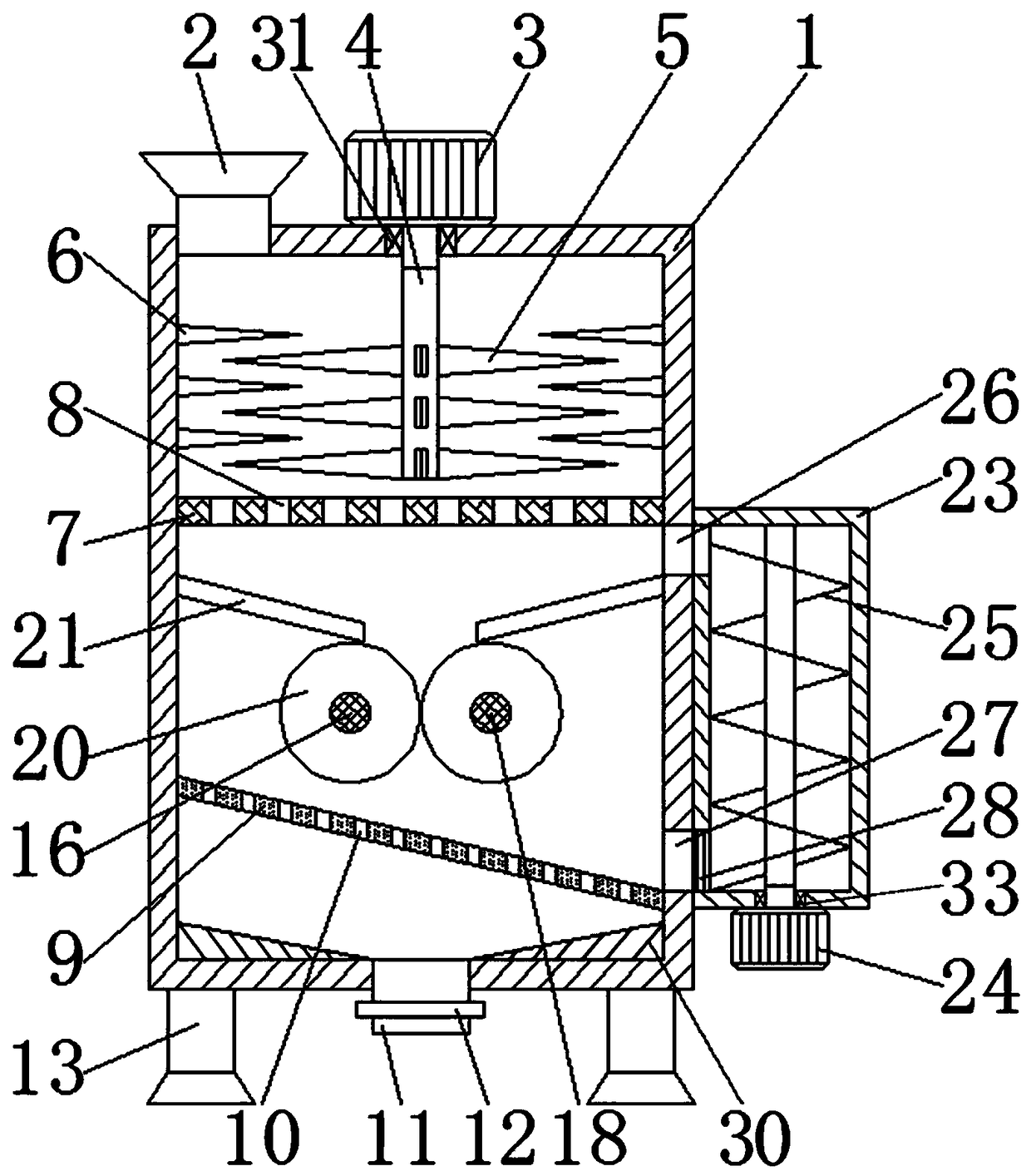

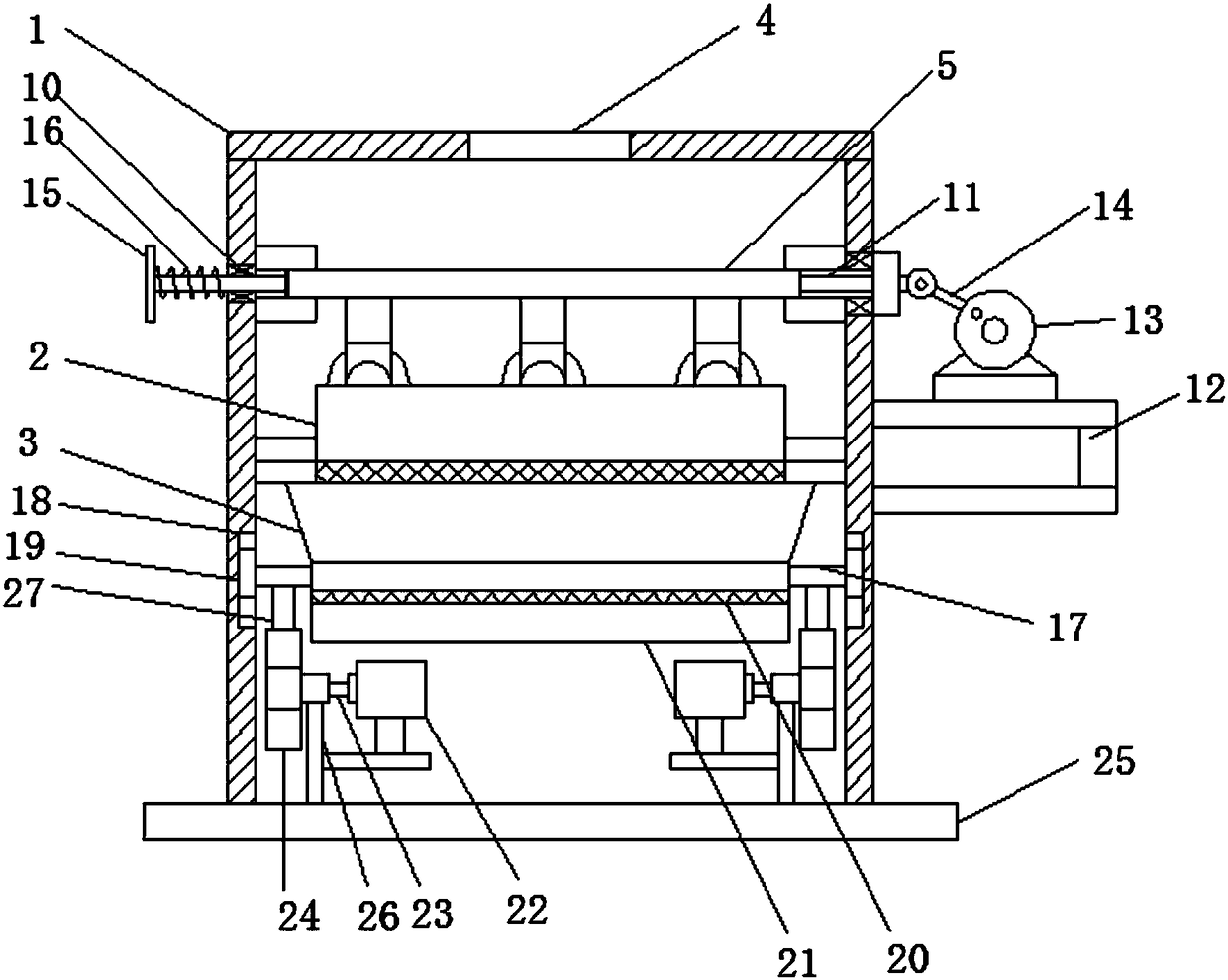

Flour grinding and screening equipment for coarse grains

InactiveCN109909003AAdjust the degree of primary crushing by yourselfIncrease the degree of crushingSievingScreeningElectric machineryEngineering

The invention discloses flour grinding and screening equipment for coarse grains. The flour grinding and screening equipment comprises a base, wherein two support plates are symmetrically arranged atthe upper end of the base; the opposite side walls of the two support plates are fixedly connected with fixed blocks; the opposite side walls of the two fixed blocks are commonly and fixedly connectedwith a first shell; a first hollow cavity is formed in the first shell; a feeding hopper which mutually communicate with the first hollow cavity is arranged at the upper end of the first shell in a penetrating manner; the inner side wall of the first hollow cavity is fixedly connected with a first fixed plate; the side wall of the first fixed plate is fixedly connected with a first motor; an output shaft of the first motor passes through the side wall of the first fixed plate and is fixedly connected with a first press roller; and a mounting plate is arranged on the side wall of the first shell in a penetrating manner. The flour grinding and screening equipment disclosed by the invention is reasonable in structural design, the pulverization degree can be automatically adjusted according to actual demands, and a dedicated material receiving measure is provided while the pulverized rice raw materials are screened at the same time, so that the processing efficiency is further improved.

Owner:李正梅

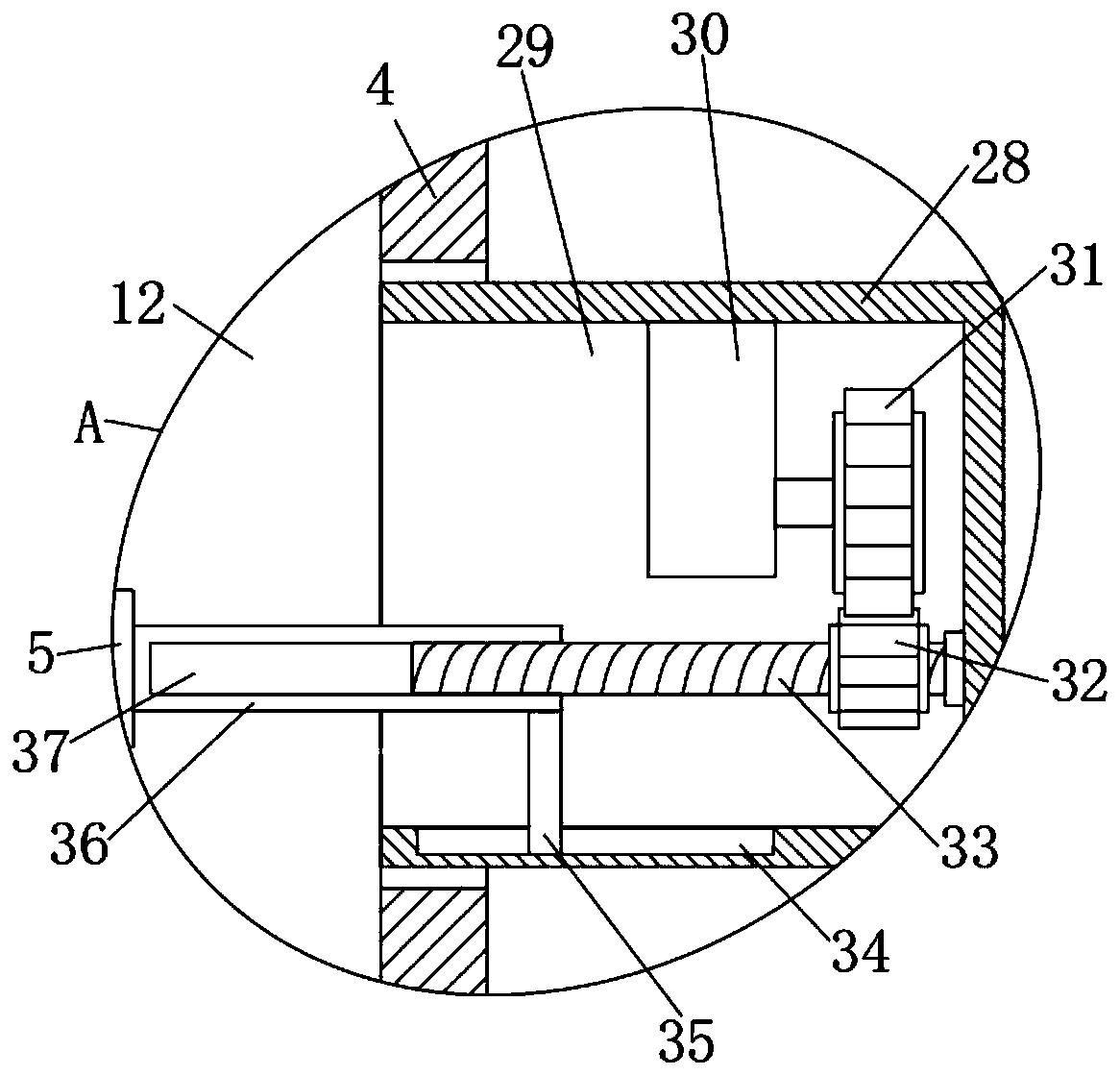

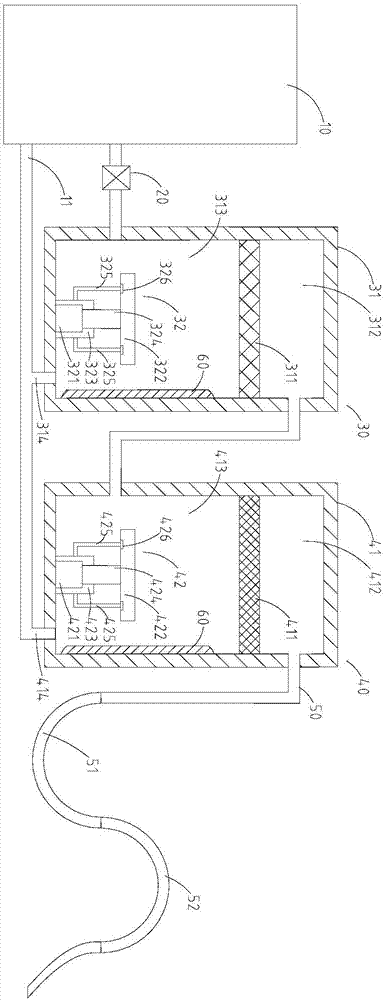

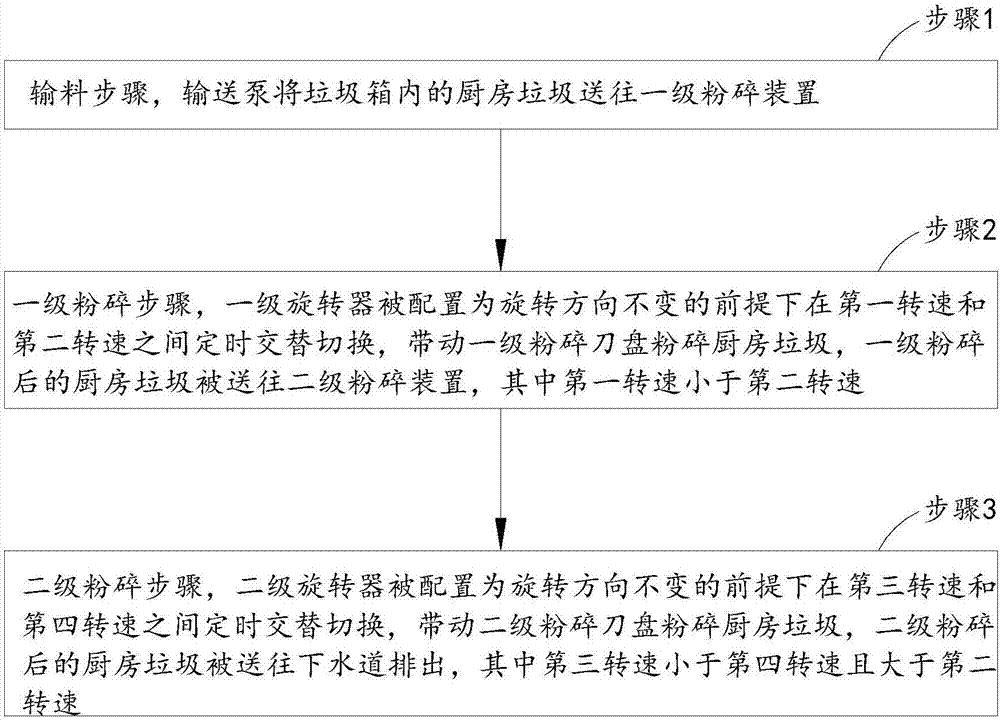

Kitchen waste disposal device

ActiveCN106975551APrevent outflowImprove crushing qualityDomestic plumbingGrain treatmentsLitterEngineering

The invention discloses a kitchen waste disposal device which comprises a waste bin, a conveying pump, a first-stage crushing device and a second-stage crushing device. The first-stage crushing device comprises a first-stage crushing box and a first-stage crushing cutter head assembly; the middle position of the first-stage crushing box is provided with a first-stage filtering piece with a one-way filtering function; the first-stage crushing cutter head assembly comprises a first-stage rotator and a first-stage crushing cutter head; and the first-stage rotator is configured into a timing alternative switching mode between the first rotation speed and the second rotation speed under the premise that the rotation direction is not changed. The second-stage crushing device comprises a second-stage crushing box and a second-stage crushing cutter head assembly; the middle position of the second-stage crushing box is provided with a second-stage filtering piece with a one-way filtering function; the second-stage crushing cutter head assembly comprises a second-stage rotator and a second-stage crushing cutter head; and the second-stage rotator is configured into a timing alternative switching mode between the third rotation speed and the fourth rotation speed under the premise that the rotation direction is not changed. Kitchen waste can be directly discharged into a sewer, and the blocking problem does not occur.

Owner:泰州市海星环保设备安装有限公司

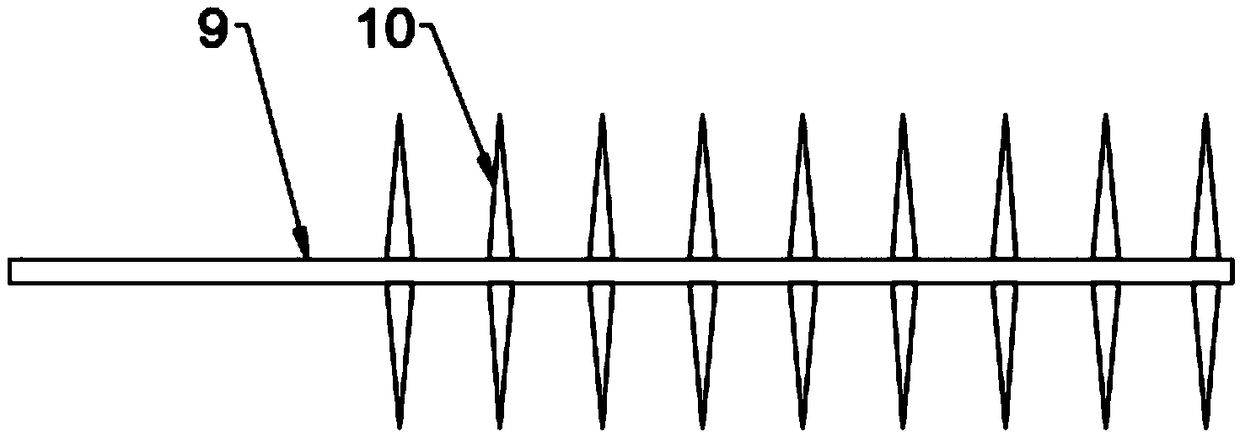

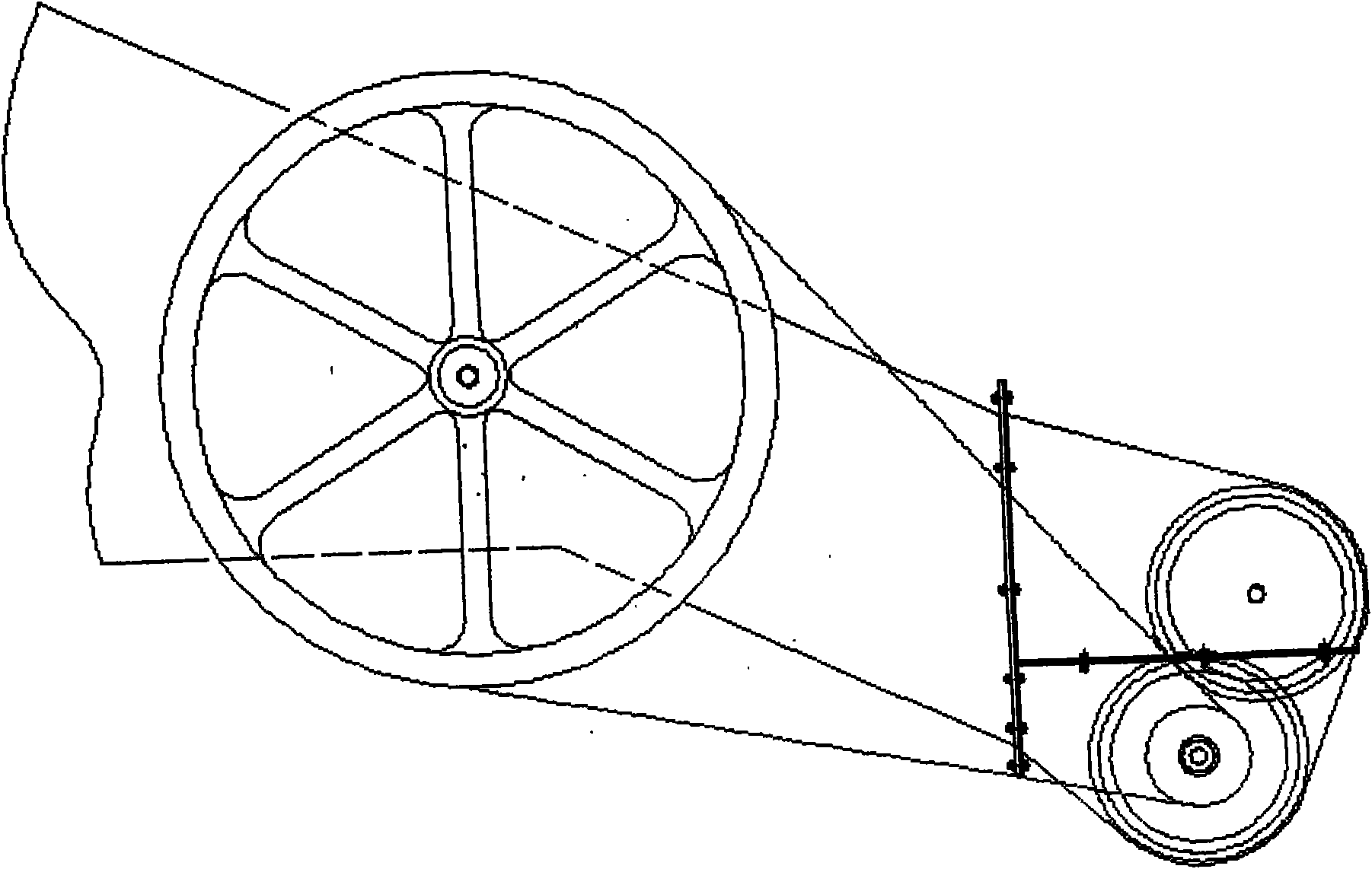

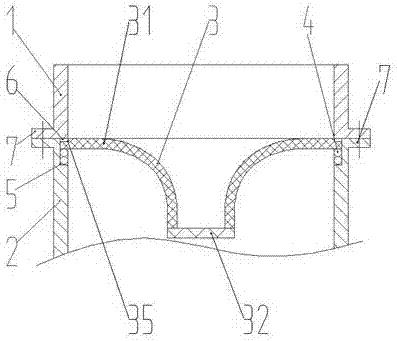

Straw crusher used for whole-feed combine harvester

InactiveCN101558711AConducive to return to fieldNo change in mechanical structureCrop conditionersMowersDrive shaftCrusher

A straw crusher used for a whole-feed combine harvester belongs to the technical field of agricultural tools. The invention aims to provide a straw crusher that is capable of matching with a whole-feed combine harvester for use and has simple structure, little power consumption, good crushing effect and convenient use. The key technical points are as follows: a driven shaft and a driving shaft are respectively fixed with a group of saw bits (10, 9) and respectively composed of three saw bits; an upper cover (1) and a lower cover (8) of an enclosure are respectively correspondingly fixed with an upper cutter tooth (12) and a lower cutter tooth (6) matched with the three saw bits on the driven shaft and the driving shaft, and the ends of the saw bits are arranged in a partially coincident way between the saw bits on the driven shaft and the saw bits on the driven shaft. Two groups of saw bits from three cutting rolls of between the saw bits and the upper cutter tooth, between the saw bits which are opposite in rotary direction and coincident on the driven shaft and the driving shaft, and between the saw bits on the driving shaft and the lower saw tooth. The straw crusher matches with the whole-feed combine harvester domestically used at present for use.

Owner:ANHUI AGRICULTURAL UNIVERSITY

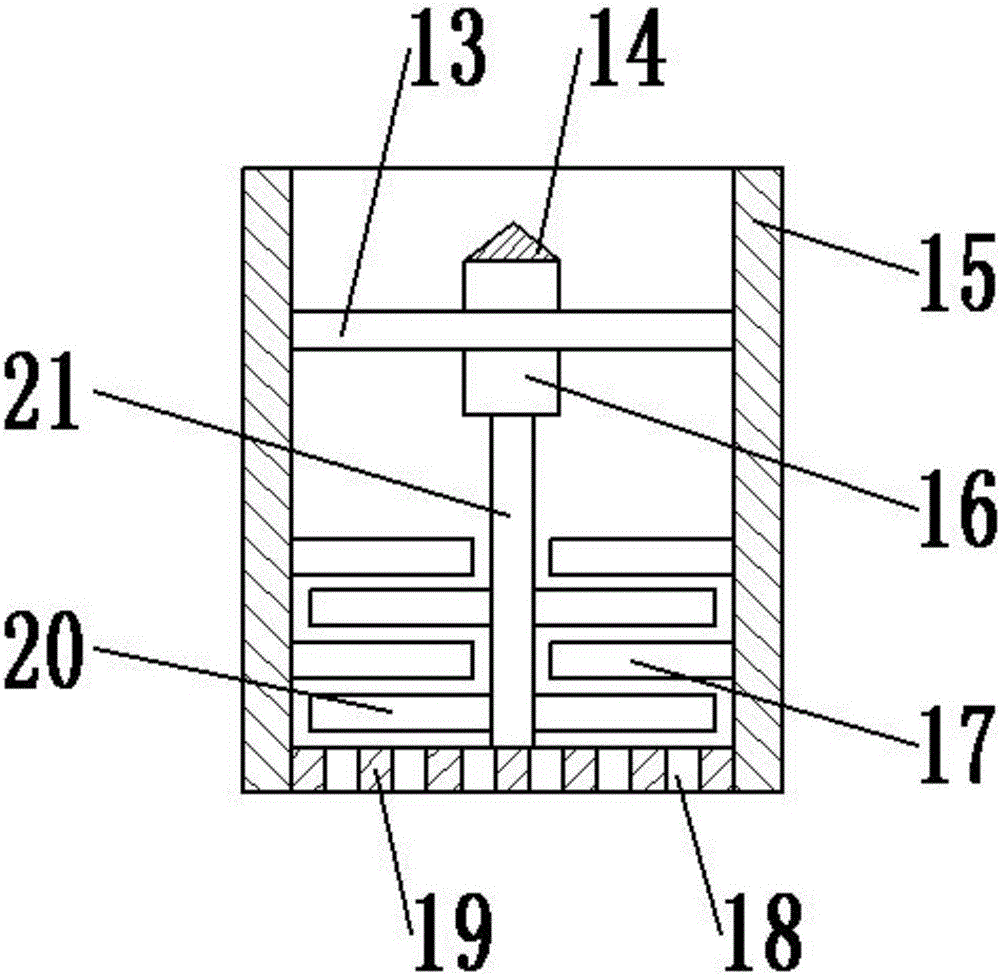

Chemical raw material smashing and stirring tank facilitating complete material discharge

InactiveCN106362636AImprove mix qualityEfficient stirring and mixingRotary stirring mixersTransportation and packagingRotational axisMotor drive

The invention provides a chemical raw material smashing and stirring tank facilitating complete material discharge. The tank comprises a tank body and an upper cover. A stirring cavity is formed in the tank body. The upper cover is provided with a feeding device and a water adding and driving device. The feeding device is composed of a feeding pipe, a smashing motor, a smashing rotary shaft, a fixed blade and a rotary blade. The water adding and driving device is composed of a transmission box, a first motor and a water inflow pipe. A material guiding pipe, a spiral stirrer and a scraping device are arranged in the stirring cavity. The spiral stirrer is composed of a stirring shaft and a spiral stirring blade. The scraping device is composed of a second motor, a rotary shaft and a scraper plate. The smashing motor drives the smashing rotary shaft to rotate, the smashing rotary shaft drives the rotary blade and the fixed blade to relatively rotate, and caked chemical raw materials are smashed. Through the arrangement of the water adding and driving device, the mixing quality of raw materials can be improved. Through the arrangement of the scraping device, the quality of products is improved, and complete material discharge is promoted during material discharge.

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

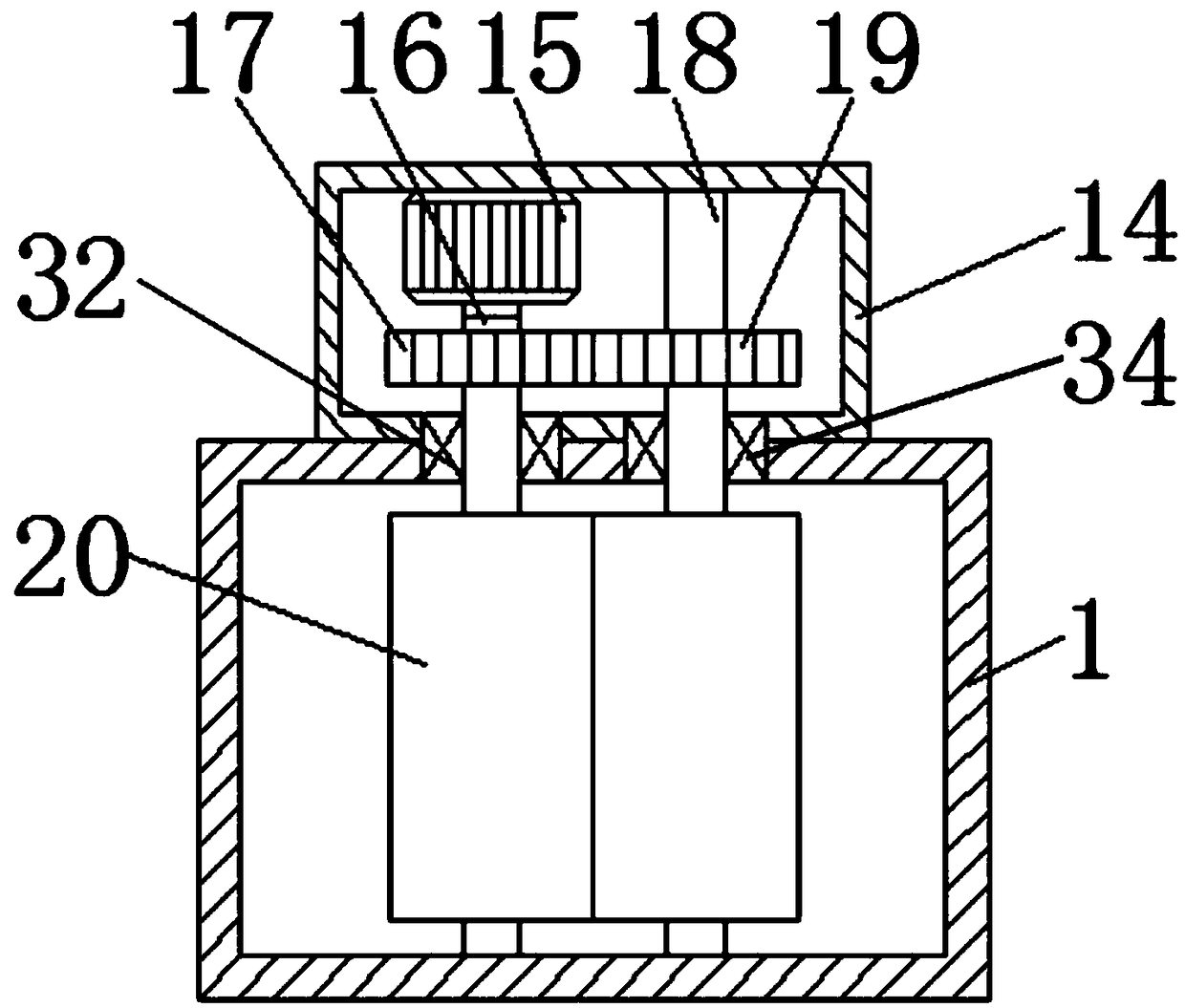

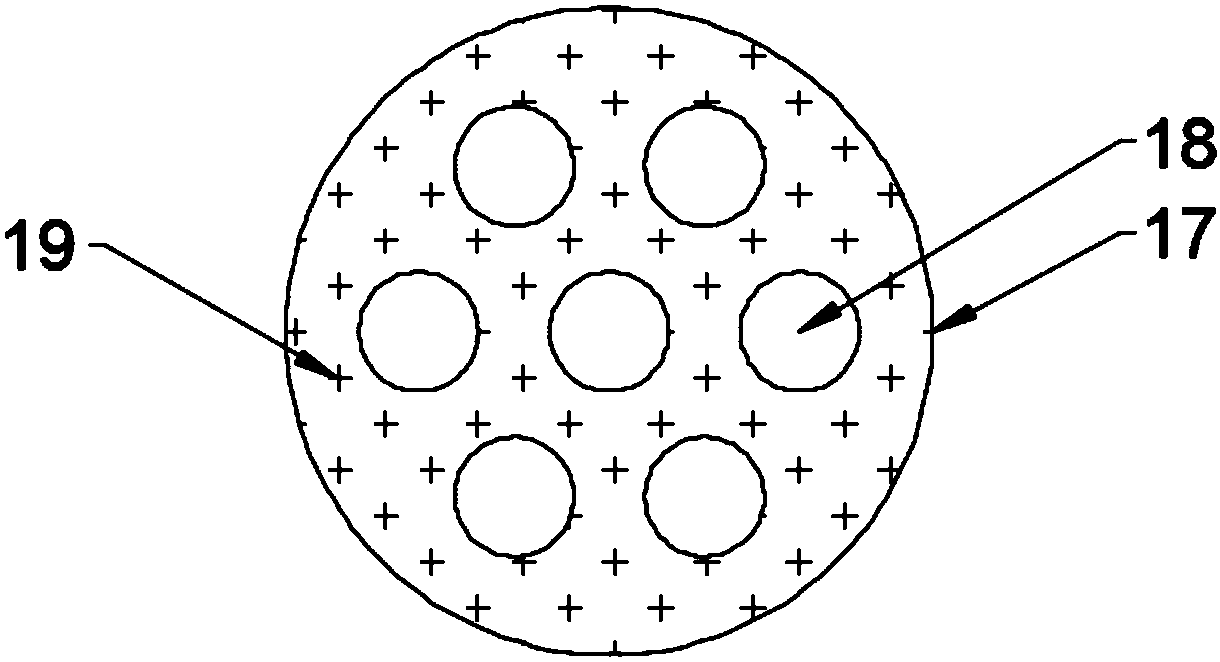

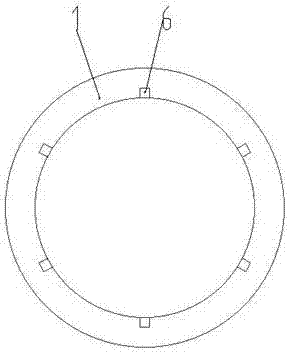

Grinding device with pre-grinding function for processing traditional Chinese medicines

InactiveCN110152816AGuaranteed crushing qualityImprove cleanlinessCocoaGrain treatmentsMotor shaftEngineering

The invention discloses a grinding device with a pre-grinding function for processing traditional Chinese medicines. The grinding device comprises a cylinder body, wherein the top end of the cylinderbody communicates with a feeding hole; a grinding screening plate is arranged on the bottom wall of an inner cavity of the cylinder body; a plurality of screening holes are uniformly formed in the grinding screening plate; a plurality of fixing teeth are uniformly arranged on the top end surface of the grinding screening plate; the inner cavity of the cylinder body is divided by the grinding screening plate into a grinding cavity and a discharging cavity; a motor is arranged in the grinding cavity; an upper motor shaft of the motor is fixedly connected with an upper rotating shaft; a lower motor shaft of the motor is fixedly connected with a lower rotating shaft; a plurality of connecting pins are uniformly arranged on the outer circular surface of the upper rotating shaft; a grinding rodis arranged in an inner cavity of each connecting pin; a plurality of fixing rods are uniformly arranged at the bottom end of the outer circular surface of the lower rotating shaft; and the other endof each fixing rod is fixedly connected with a grinding plate matched with the grinding screening plate. The whole grinding process is automatically completed, the labor intensity is greatly reduced,the grinding time is reduced, and the grinding effect is greatly improved; and in addition, the whole grinding process is completed mechanically and independently, people and the medicines are isolated, and the cleanness of the medicines is guaranteed.

Owner:连云港励尚信息科技有限公司

Anti-blocking mud pump valve

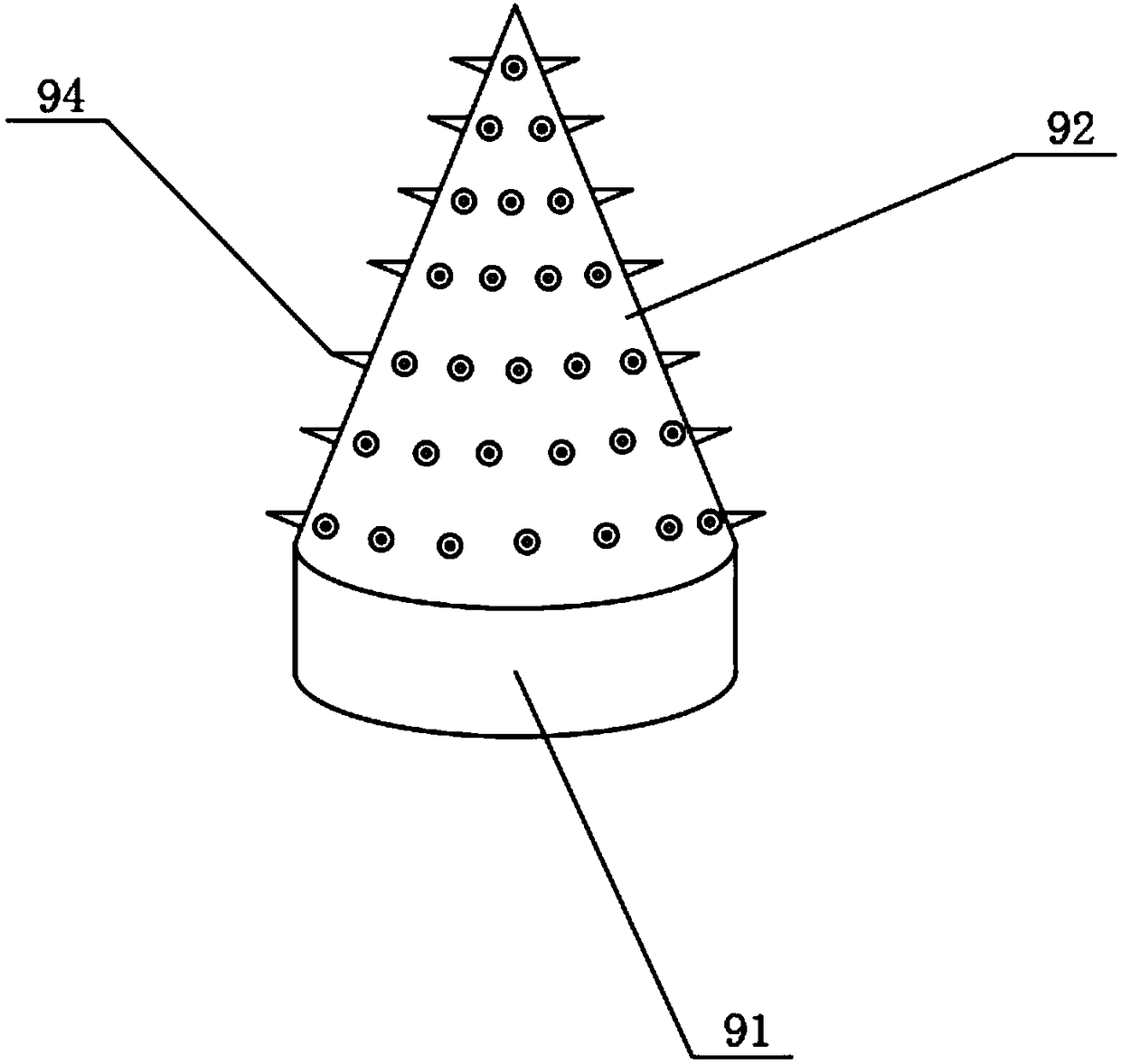

ActiveCN108825808AAvoid cloggingGuaranteed circulation spaceSlide valveGrain treatmentsMotor driveEngineering

The invention discloses an anti-blocking mud pump valve. The anti-blocking mud pump valve comprises a valve body in an inverted T-type, and an adjustment cavity is formed in the vertical portion of the valve body. A circulation cavity which communicates with the adjustment cavity is formed in the horizontal portion of the valve body. A valve cover is disposed at the top of the vertical portion ofthe valve body, and a valve stem penetrating the valve cover is disposed in the vertical portion of the valve body. An adjustment block is disposed at one end in the vertical portion of the valve stem, and a cleaning hole is formed in the inner wall, located below the vertical portion, of the circulation cavity, A cone-shaped cleaning head for crushing mud is disposed in the cleaning hole, and a movable groove is formed in the side wall of the circulation cavity. A rack is disposed in the movable groove, and one end of the rack is connected with a baffle for blocking the cleaning hole. Saw blades of the rack are disposed downwards, and the saw blades mesh with a gear of the end portion of a second motor drive shaft. The purposes that hardened mud is broken, the valve body is prevented fromblockage, the circulation space of the circulation cavity is ensured, and the normal use of the mud pump valve is ensured are achieved.

Owner:YANCHENG RUIDE PETROCHEM MACHINERY CO LTD

Multifunctional feeding device for vertical sieving and vibrating sand making machine

PendingCN107282276AAvoid easy cloggingBroken evenly and fullySievingScreeningBreaking strengthEffective solution

The invention discloses a multifunctional feeding device for a vertical screen vibrating sand making machine, which comprises a feeding box body, a material distribution plate and elastic parts; the upper end of the feeding box body is an incompletely closed feeding The lower end surface is a fully-opened discharge port; in the feed box, a distribution plate is arranged transversely relative to its axis; an elastic member is axially arranged between the distribution plate and the feed box; The feed box is located on the square of the impeller of the sand making machine, and the material distribution plate, the impeller, the feed pipe of the sand making machine, and the vibrating mechanism of the sand making machine are arranged correspondingly on the same axis from top to bottom; The material distributing mechanism and the vibrating mechanism on the vertical vibrating vibrating machine work together to make the material make full use of the collision force, and the crushing strength is greater. The above structure can effectively solve the problem of unsmooth discharge of materials in the vibrating vibrating vertical vibrating mechanism and sand making. The problem of low crushing efficiency and insufficient crushing of materials has greatly improved the crushing efficiency and quality of materials, and reduced the energy consumption of crushing.

Owner:尹国祥

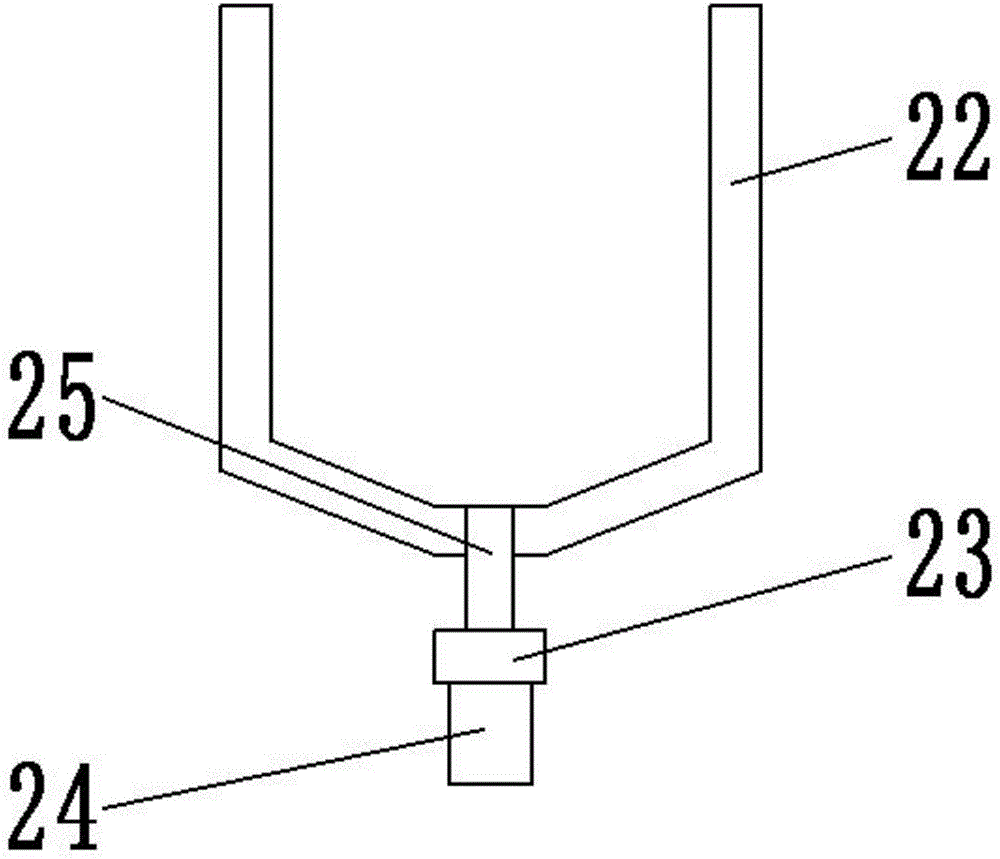

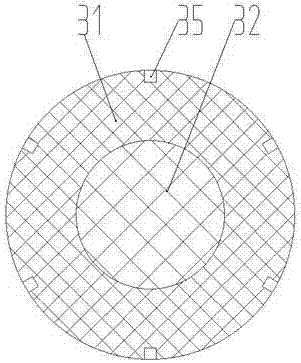

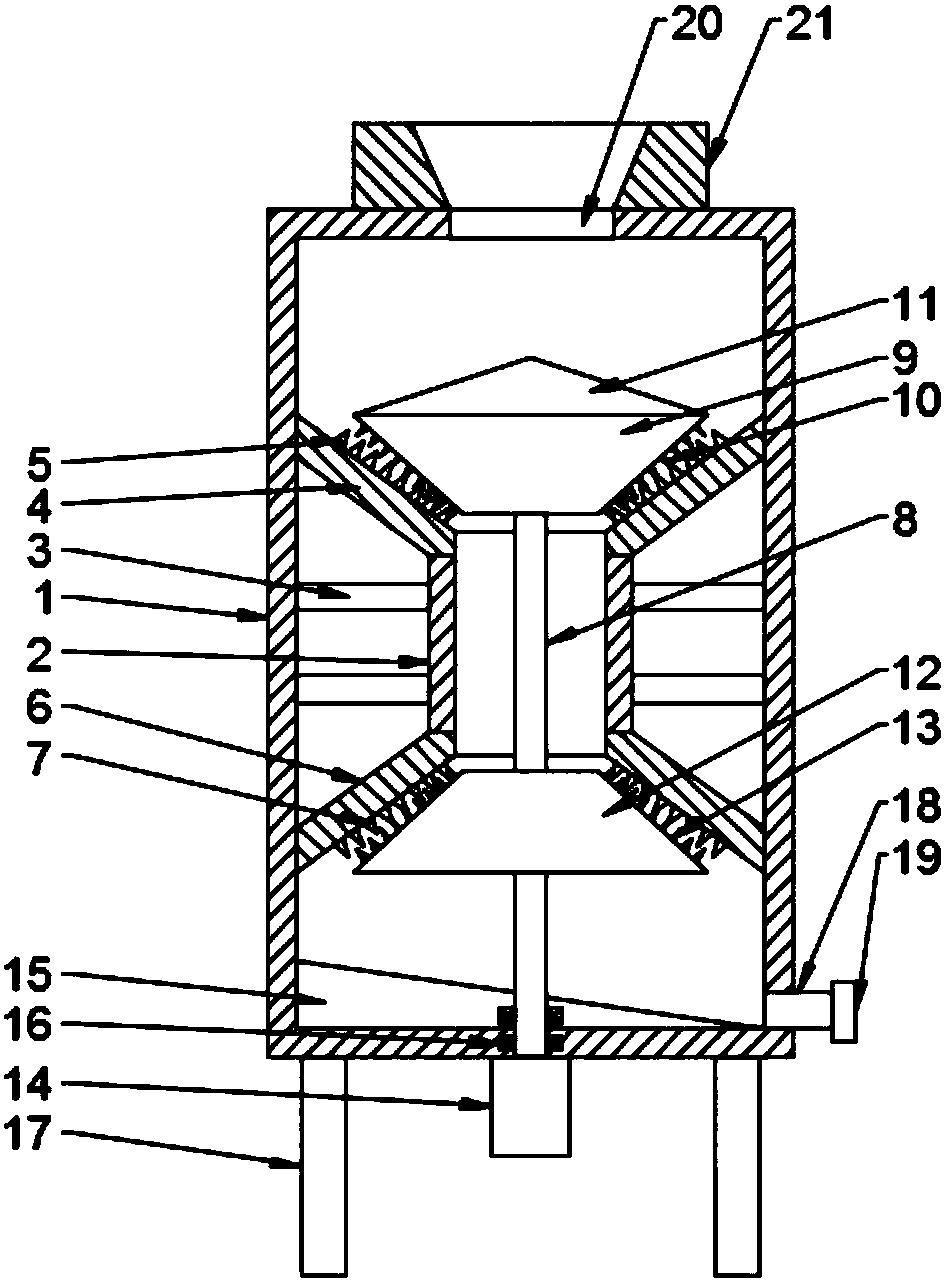

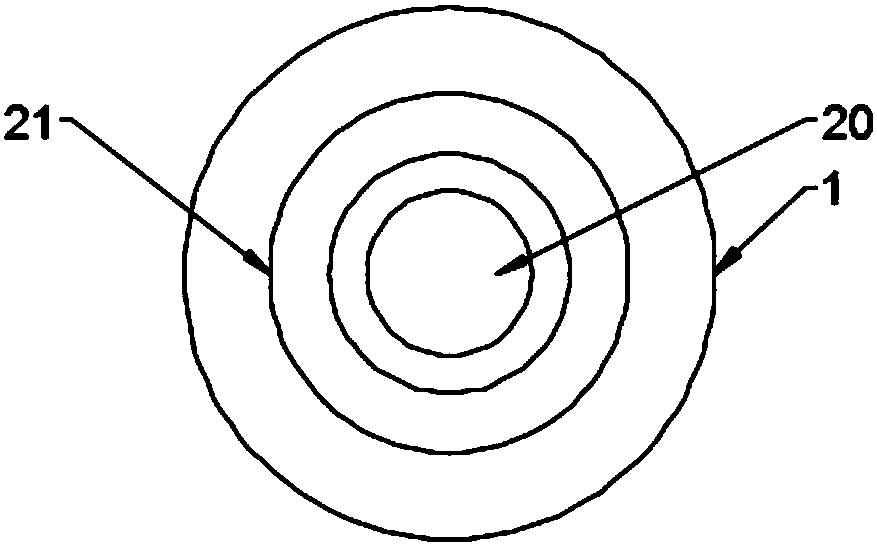

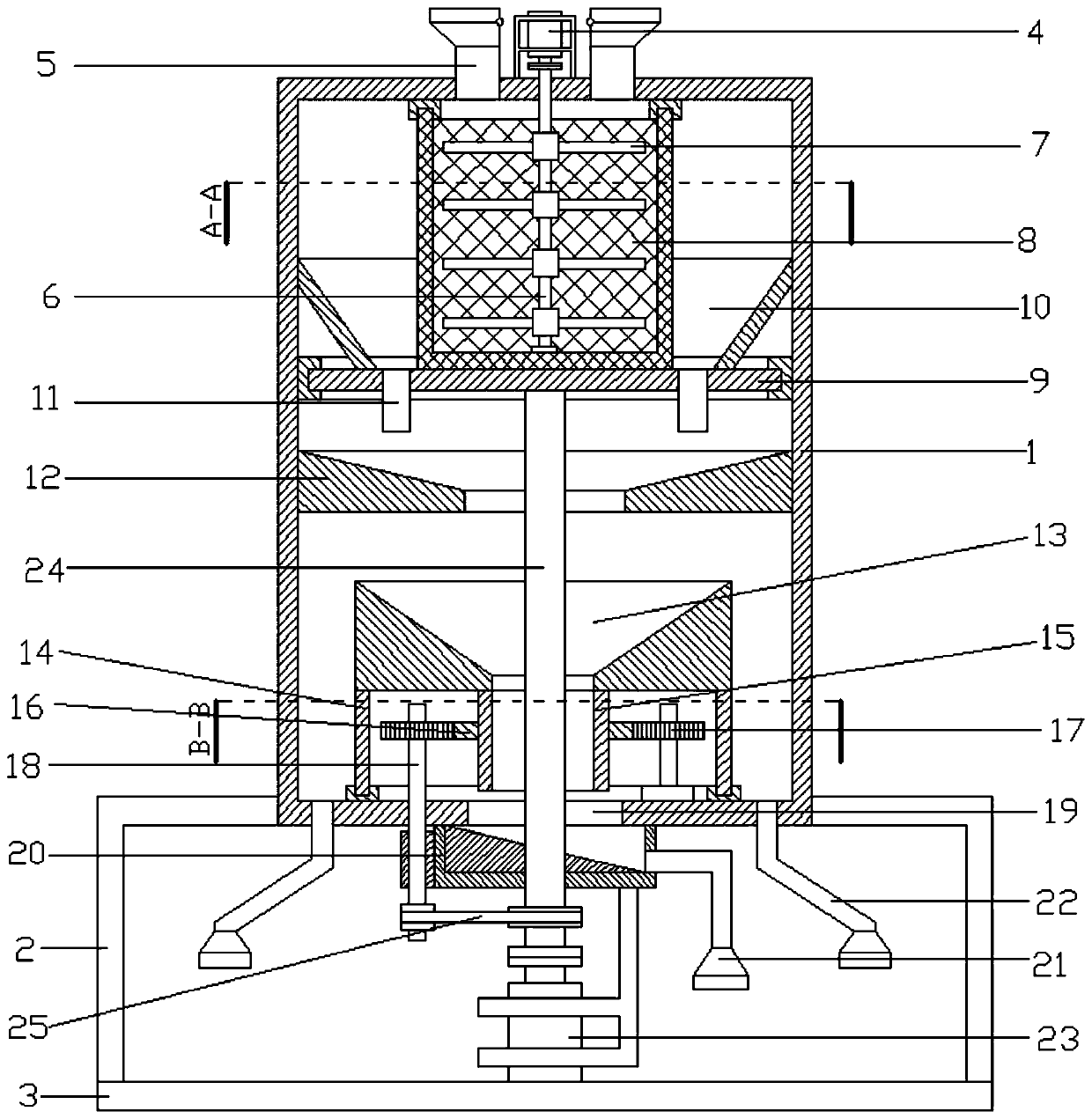

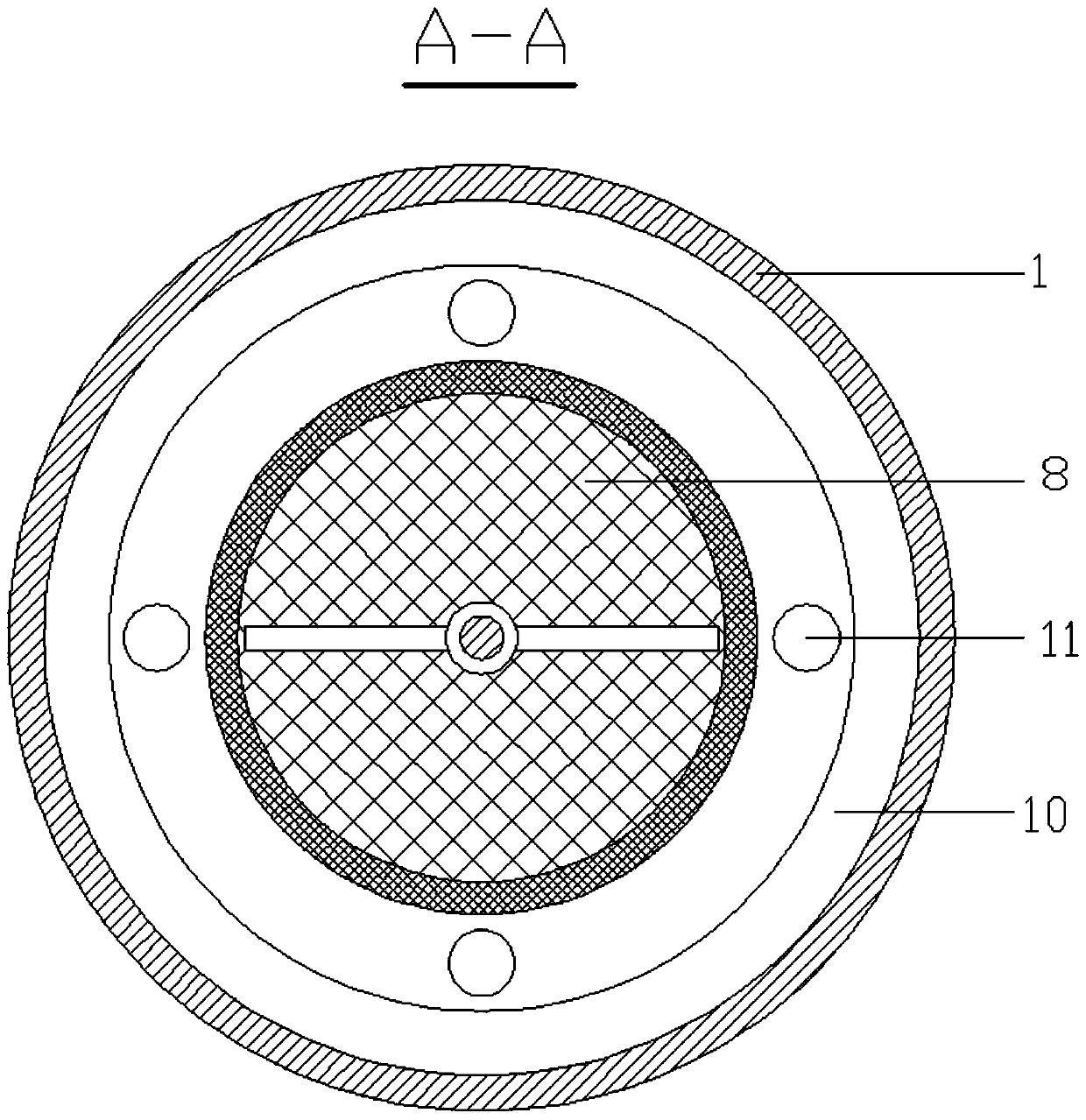

Grinding device for processing traditional Chinese medicine based on step-by-step grinding technology

InactiveCN110152790AGuarantee the quality of drug crushingReduce labor intensityCocoaGrain treatmentsEngineeringCircular surface

The invention discloses a grinding device for processing traditional Chinese medicine based on a step-by-step grinding technology. The grinding device comprises a cylinder body, wherein the top end ofthe cylinder body is provided with a feeding hole; the inner cavity of the cylinder body is provided with a connecting cylinder; the outer circular surface of the connecting cylinder is uniformly provided with a plurality of connecting rods; the top end of the connecting cylinder is connected with an upper grinding hopper in a penetrating manner; the bottom end of the connecting cylinder is connected with a lower grinding hopper in a penetrating manner; a rotating shaft is arranged in the connecting cylinder; the top end of the rotating shaft is fixedly connected with an upper grinding disc matched with the upper grinding hopper; a lower grinding disc matched with the lower grinding hopper is arranged on the lower part of the outer circular surface of the rotating shaft in a sleeving mode; and a plurality of supporting legs are uniformly arranged at the bottom end of the cylinder body. According to the grinding device, the medicine is grinded and crushed twice under the action of theupper grinding disc and the lower grinding disc, so that the medicine is completely grinded and crushed; the medicine crushing quality is guaranteed, the whole grinding process is automatically completed, the labor intensity is greatly reduced, the grinding time is shortened, and the grinding effect is greatly improved; in addition, the whole grinding process is completed by the grinding device independently, humans are isolated from the medicine, and cleanness and safety of the medicine are guaranteed.

Owner:连云港励尚信息科技有限公司

Medicinal material pulverizer

The invention belongs to the technical field of pulverizing equipment, and in particular, relates to a medicinal material pulverizer; the medicinal material pulverizer is characterized by comprising a base; the base is provided with a balance weight, the balance weight is provided with an outer shell, the outer shell is internally provided with a motor, the outer shell is provided with a pulverizing cylinder, and the pulverizing cylinder is provided with a cylinder cover; the top of the outer shell is provided with a concave shaft, and the bottom of the pulverizing cylinder is provided with a convex shaft; the outer shell and the pulverizing cylinder are connected through the concave shaft and the convex shaft; both sides of the upper end of the outer shell are each provided with a locking device A, and the bottom of the pulverizing cylinder is provided with locking hooks A; the convex shaft is provided with a blade, a positioning screw is arranged between the blade and the convex shaft, and the blade is provided with a locking nut; the outer side of the pulverizing cylinder is provided with a pulverizing cylinder handle, and the upper part of the pulverizing cylinder is provided with lock hooks B; the cylinder cover is provided with locking devices B, and the top of the cylinder cover is provided with a cylinder cover handle; the upper part of the front side of the outer shell is provided with a display screen, one side of the display screen is provided with a timekeeping knob, and the lower part of the front side of the outer shell is provided with a warning light and a running light; the lower side of the running light is provided with a power supply switch knob and a speed adjusting knob.

Owner:阳光森林(天津)生物科技有限公司

Gangue crushing and screening device for mine production

The invention relates to the field of mineral products, in particular to a gangue crushing and screening device for mine production. The gangue crushing and screening device comprises a machining cavity, the middle of the upper side of the machining cavity is connected with a first motor through a connecting piece, and the lower side of the first motor is connected with a crushing shaft through acoupler, the left end and the right end of the lower side of the crushing shaft are provided with crushing blades through installation sleeves, the outer side of the crushing blades is provided with ascreening cylinder, and the lower side of the screening cylinder is provided with a rotating plate, the lower side of the rotating plate is provided with a second flow guide groove, and the lower side of the second flow guide groove is provided with a screening hopper, discharging pipes are welded to the middle of the lower side of the screening hopper, outer gears are welded on the outer side ofthe discharging pipes, and connecting gears are meshed on the left side and the right side of the outer gears, connecting shafts are arranged in the connecting gears, and a discharging port is formedin the machining cavity located on the lower side of the discharging pipes, a discharging cavity is formed in the lower side of the discharging port, and a second motor is arranged on the lower sideof the discharging cavity through a mounting piece. According to the device, the crushed gangue can be effectively screened and separated, so that the waste of coal resources can be effectively reduced.

Owner:李洋洋

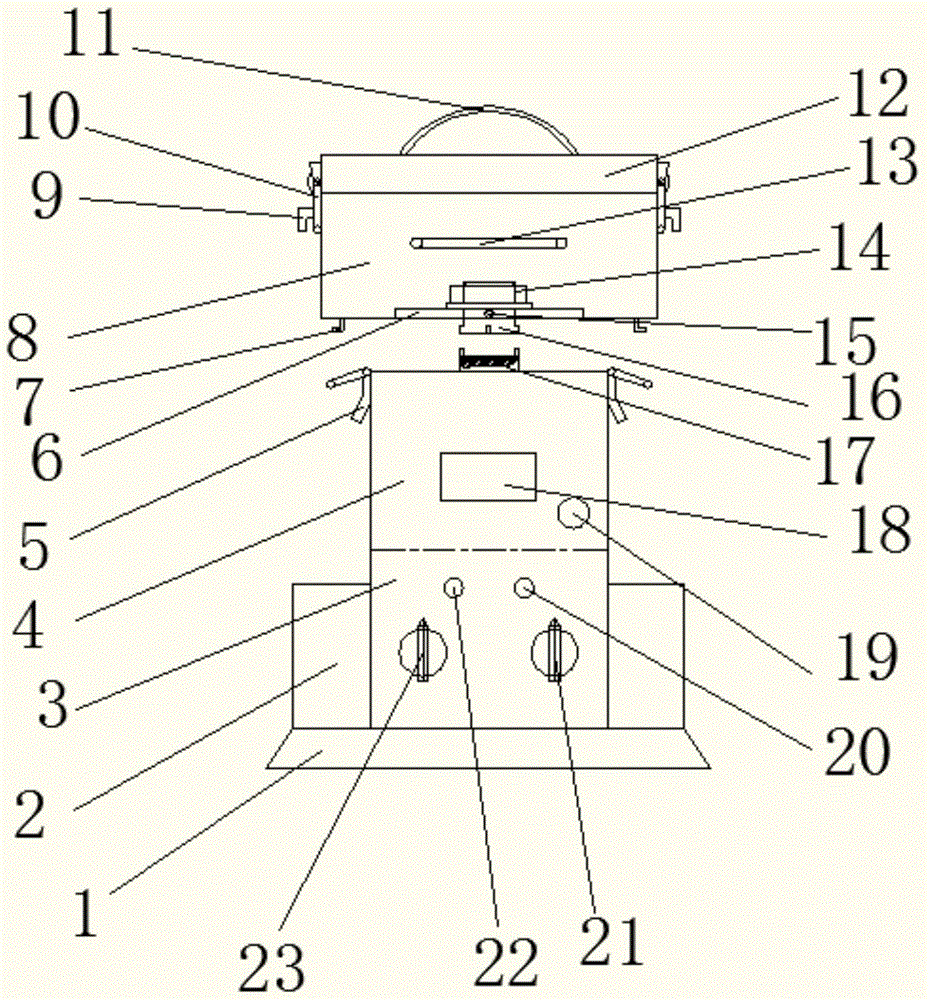

Natural graphite crushing device for lithium battery processing

InactiveCN112246310AEasy to GrindGuaranteed crushing qualityDirt cleaningGrain treatmentsHydraulic cylinderEngineering

The invention discloses a natural graphite crushing device for lithium battery processing. The natural graphite crushing device comprises a supporting mechanism, an extrusion mechanism, a first crushing mechanism and a discharging port, wherein the supporting mechanism comprises a crushing box, supporting legs, a sealing door, a top cover and a feeding port, the front side of the crushing box is rotationally connected with the sealing door, the top cover is arranged at the top of the crushing box, the outer sides of extrusion plates are connected with hydraulic cylinders, the hydraulic cylinders are arranged at the tops of the supporting legs, the first crushing mechanism is arranged below the extrusion mechanism, and a second crushing mechanism is arranged below the first crushing mechanism. According to the natural graphite crushing device for lithium battery processing, the hydraulic cylinders are arranged, the hydraulic cylinders can drive crushing cutters on the extrusion plates to extrude and crush graphite in a circulating and reciprocating mode, meanwhile, a screening net is arranged, the screening net can filter graphite particles crushed for the first time, and the graphite blocks with overlarge sizes remain on the screening net and are extruded by the crushing cutters again, so that the crushing uniformity can be ensured to a certain extent.

Owner:江苏英能新能源科技有限公司

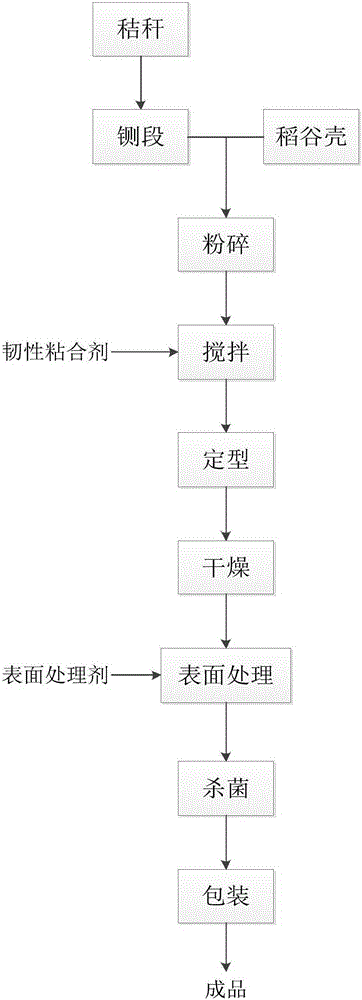

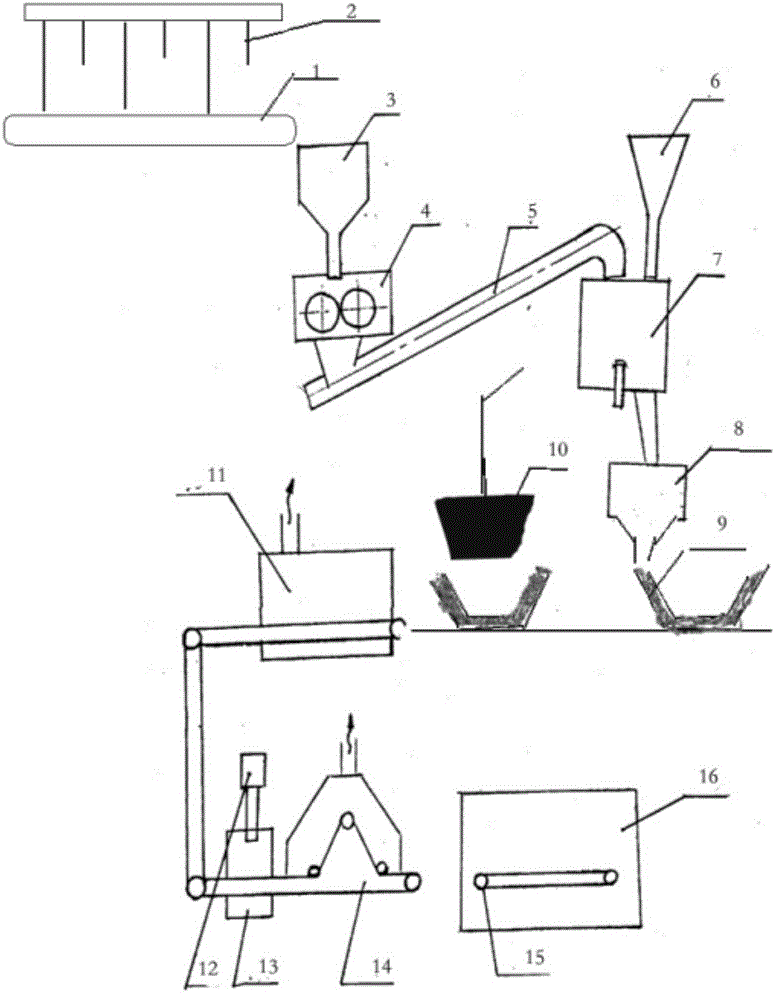

Manufacturing method for disposable novel environment-friendly utensil

InactiveCN105216087AThere will be no unevennessGuaranteed crushing efficiencyDomestic articlesHollow articlesFiberAdhesive

The invention discloses a manufacturing method for a disposable novel environment-friendly utensil. Adopted facilities and equipment comprise a conveyer belt, a straw chopper, a pulverizer, a powder conveying system, a plant fiber and adhesive mixing and stirring machine, a control storage tank, templates, a pressing machine, a drying box, a surface treatment chamber, a drying solidification chamber, an agent supplying system, a conveyer belt and a sterilizing chamber. Straw and rice hulls serve as raw materials and are subjected to section chopping through the straw chopper, pulverizing and grinding are conducted in the pulverizer, the materials are blended with a flexible adhesive for stirring, a disposable non-toxic environment-friendly and easily-degradable material is obtained, and then the material is subjected to forming, drying, surface treatment with a homemade surface treatment agent, and sterilization to be made into the environment-friendly utensil.

Owner:CHANGZHOU UNIV

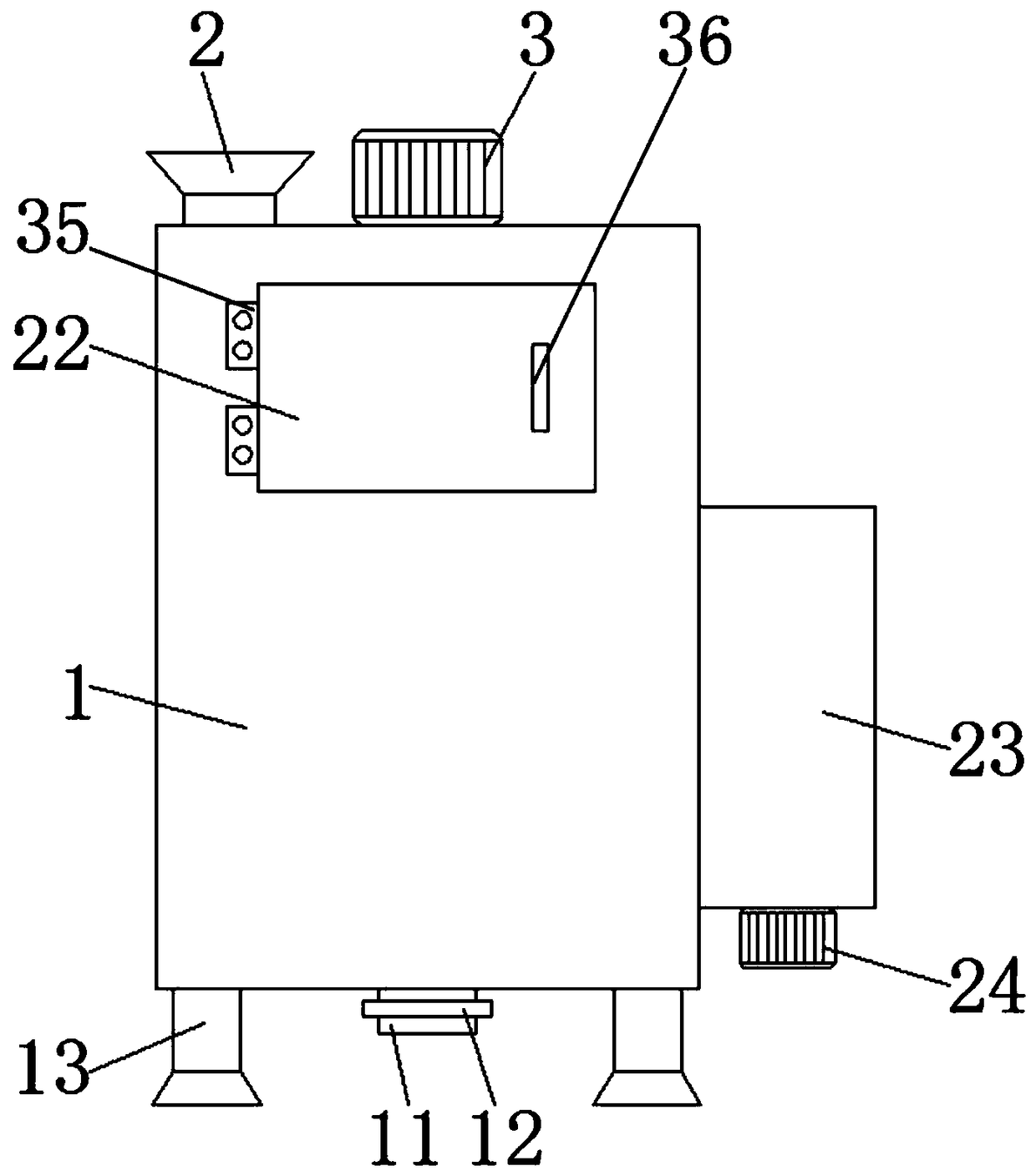

Environment-friendly smashing device for building construction

InactiveCN107185674AImprove work efficiencyIncrease the number of cutsGrain treatmentsEngineeringDust pollution

Owner:金柯楠

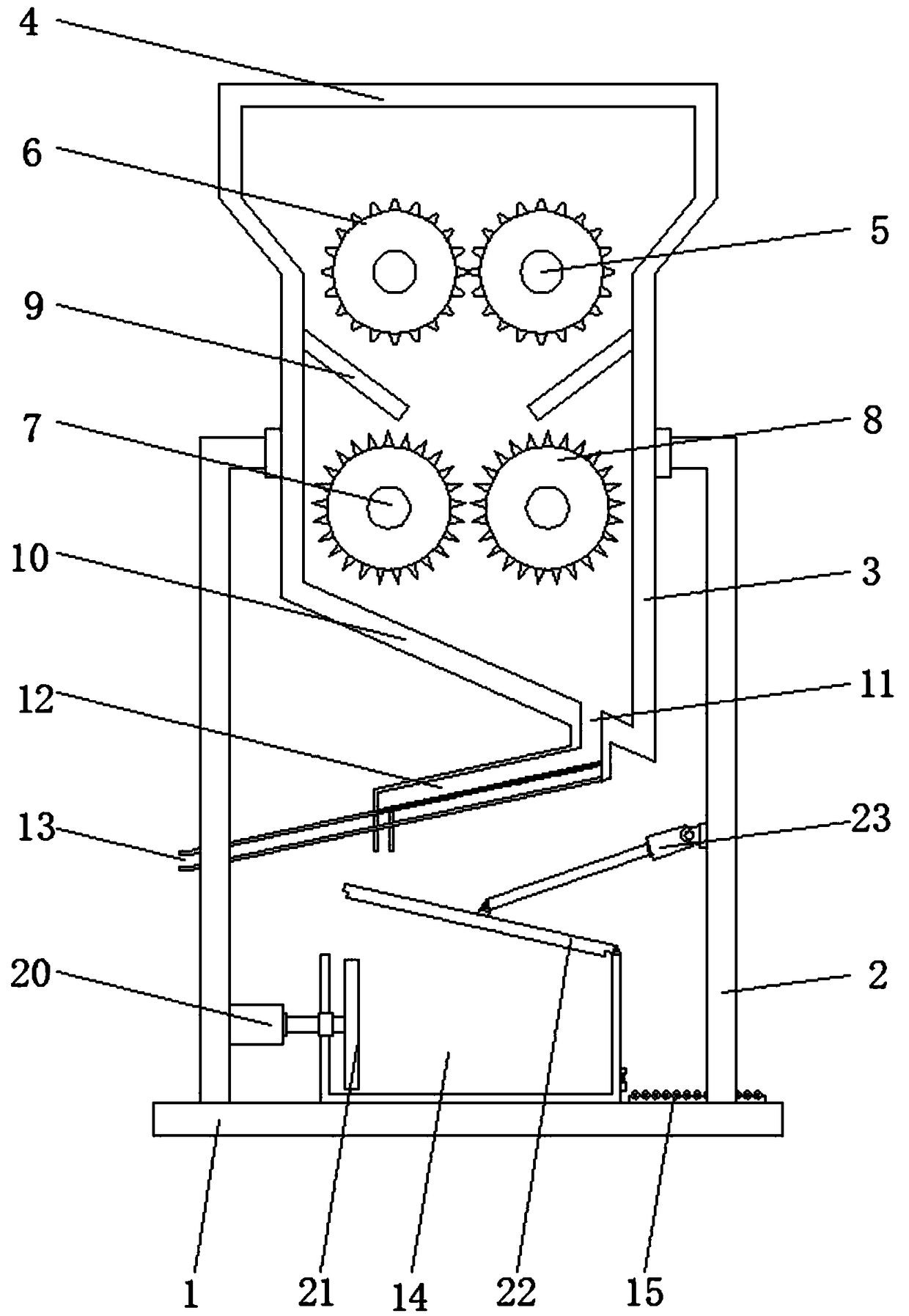

Loading device of extruder

The invention discloses a loading device of an extruder. The loading device comprises a feeding hopper, a material storage box and a spiral loading mechanism which is connected between the feeding hopper and the material storage box, wherein one end of the spiral loading mechanism is arranged on the bottom of the material storage box; the other end of the spiral loading mechanism is arranged above the feeding hopper; a discharging tube is connected between a spiral conveying mechanism and the feeding hopper; two crushing devices are arranged in a cross manner in the discharging tube, wherein one crushing device is arranged above the other crushing device; each crushing device comprises a first roller and a second roller which are engaged with each other, wherein the first roller and the second roller are arranged at the same height and are rotatably connected with the discharging tube, and one end of the first roller is connected with a drive device; bristles are arranged inside the discharging tube; and the bristles are matched with the first rollers and the second rollers. The loading device of the extruder disclosed by the invention can be used for crushing materials, and is beneficial to extrusion forming of materials in the extruder.

Owner:昆山市华浦塑业有限公司

Environment-friendly construction waste molding packer

InactiveCN109225427AGuaranteed crushing qualityAvoid damageGrain treatmentsPressesSlagArchitectural engineering

The invention discloses an environment-friendly construction waste molding packer which comprises a base plate; a rough grinding idler wheel is fixedly connected with the axis of a first support shaft; a fine grinding idler wheel is fixedly connected with the axis of a second support shaft; an inclined bottom plate is fixedly connected with the bottom end of a milling processing tank; a dischargehole is formed on the right side of the bottom end of the inclined bottom plate; a screening plate is connected with one end of the discharge hole on the exterior of the milling processing tank; a slag outlet is formed on the left side of the screening plate; a compression slot is fixedly connected with the middle position of the top of the base plate. The invention relates to the technical fieldof environment-friendly construction. The environment-friendly construction waste molding packer can achieve the purposes of grading, refining and smashing construction waste, guaranteeing smashing quality, preventing the fine grinding wheel from being damaged by heavy construction waste, reducing the space occupied by construction waste in the manner of smashing treatment, increasing the use rateof construction waste, guaranteeing quality while reducing the cost of flood-proof sandbag filler.

Owner:廖祥菊

Gravel crushing device for architectural engineering

ActiveCN111420781AGrinding fineness can be adjusted quickly and accuratelyReduce subsequent processesDirt cleaningGrain treatmentsArchitectural engineeringDust control

The invention discloses a gravel crushing device for architectural engineering. The gravel crushing device comprises a processing box and a supporting base, wherein the bottom of the processing box isfixedly connected to the top of the supporting base; the right side of the top of the processing box is fixedly connected to a dust removal mechanism; the left side of the top of the processing box is provided with a charge hopper; the left side of the top of the inner cavity of the processing box is rotatably connected to a first material conveying plate through a connecting rod; and a curved frame is fixedly connected on a position, below the output end of the first material conveying plate, between front and rear walls of the inner cavity of the processing box. The invention relates to thetechnical field of gravel crushing. According to the gravel crushing device for architectural engineering disclosed by the invention, conveying space is lengthened by the first material conveying plate, so that an area with generated dust is reduced; multiple grinding processes are directly set in the processing box, and are matched with the dust removal mechanism for adsorbing and treating, so that diffusion of crushing dust is effectively reduced, and gravels with mass smaller than standard mass are screened in a crushing process, and therefore, follow-up processes are saved, and processingquality of the device is effectively guaranteed.

Owner:程志求

Speed-up rubber crushing device based on centrifugal force and capacitance principle

The invention relates to the technical field of rubber, and discloses a speed-up rubber crushing device based on centrifugal force and a capacitance principle. The speed-up rubber crushing device comprises a shell, wherein a cutting bin is fixedly connected into the shell. According to the centrifugal force generated by rubber in the actual process, the capacitance principle is utilized, the variable speed cutting and variable speed screening operation are triggered to improve the linkage between structures, through the joint action of a cutting disc, a linkage rod, a moving block, a first rotating disc and a rotating column, the cutting speed is automatically increased, the situation that the cutting speed is weakened due to the change of current is compensated, the crushing quality problem caused by the reduction of cutting speed is avoided, so that the crushing quality of the rubber is ensured, through the joint action of the linkage rod, the moving block, the rotating column, a screening plate, a third rotating disc and a rotating plate, and the screening speed is automatically increased to avoid the situation that the screening frequency is reduced due to the weakening of current, resulting in rubber accumulation and reduction of the screening efficiency of the rubber.

Owner:赵艳花

Smashing device used for domperidone bulk drugs

InactiveCN108906240AIncrease the frequency of collisionsIncrease agitation rateGrain treatmentsSteel ballEngineering

The invention provides a smashing device used for domperidone bulk drugs. The device comprises a smashing body, a top cover is arranged at the top end of the smashing body, a rotation cylinder is arranged on the upper portion of an inner cavity, second steel balls are contained in the lower portion of the inner cavity, the lower end of the rotating cylinder is provided with a filter net plate, first steel balls are contained in the rotating cylinder, a lower rotating shaft is arranged below the filter net plate, a lower stirring paddle set is distributed on the lower segment of the lower rotating shaft, an upper rotating shaft is arranged below the top cover, and an upper stirring paddle set is distributed on the lower segment of the upper rotating shaft. The device has the beneficial effects that upper stirring paddles can stir the first steel balls in the rotating cylinder, the collision frequency of the first steel balls and the bulk drugs can be improved, the primary and rapid smashing is achieved, in addition, the rotating cylinder and the upper stirring paddles are controlled to be opposite in the rotating direction, the stirring rate of the upper stirring paddles for the first steel balls is improved, the smashing rate of the first steel balls for the bulk drugs is improved, the lower stirring paddles stir the second steel balls, secondary smashing of the bulk drugs is achieved, the smashing efficiency is effectively improved, and the smashing quality is ensured.

Owner:江苏又一城智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com