Medicinal material pulverizer

A pulverizer and medicinal material technology, applied in grain processing and other directions, can solve the problems of inconvenient dumping of medicinal materials, high labor intensity, low work efficiency, etc., and achieve the effects of good market prospects, reduced labor intensity, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

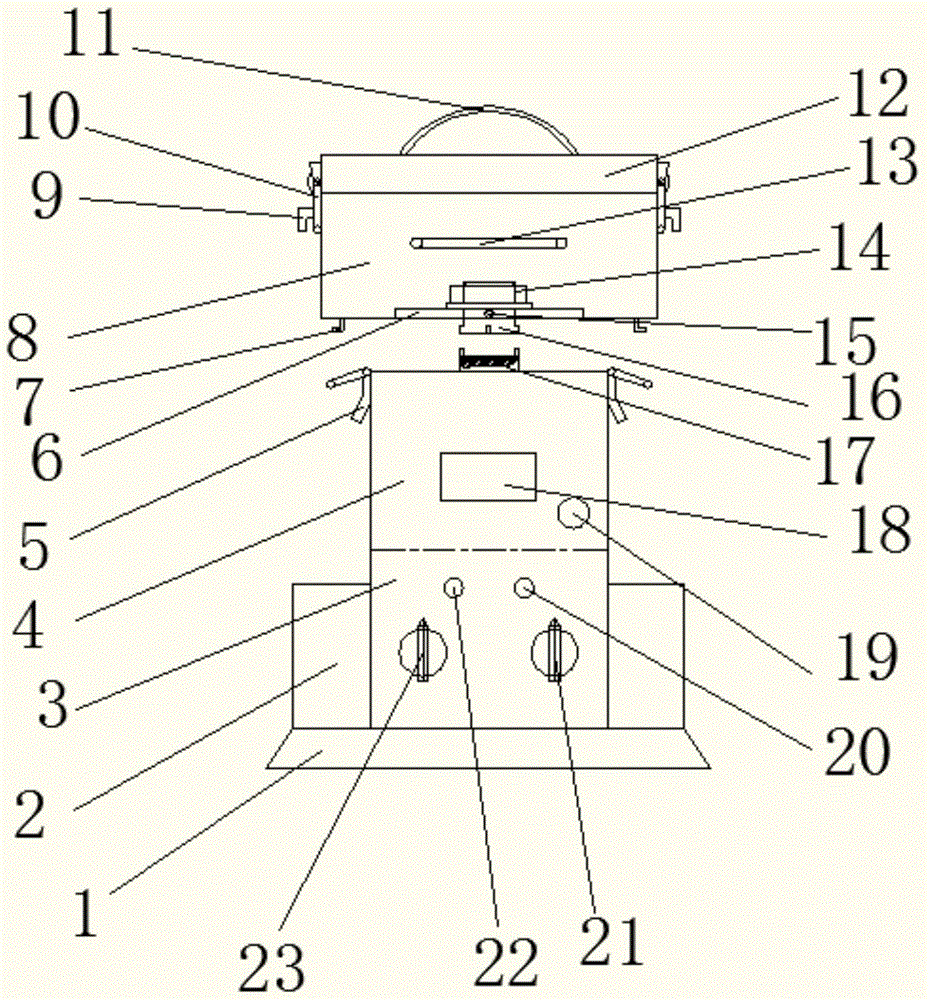

[0021] Such as figure 1 As shown, the present embodiment includes a base 1, the base 1 is provided with a counterweight 2, the counterweight 2 is provided with a casing 4, the inside of the casing 4 is provided with a motor 3, the casing 4 is provided with a crushing cylinder 8, and the crushing cylinder 8 is provided with a A cylinder cover 12 is arranged.

[0022] There is a concave shaft 17 on the top of the shell 4, and a convex shaft 16 on the bottom of the crushing tube 8. The shell 4 and the crushing tube 8 are connected to the convex shaft 16 through the concave shaft 17, which can realize the detachability of the crushing tube 8 and is easy to take The crushing tube 8 dumps the pulverized objects, which greatly improves the work efficiency and reduces the labor intensity of the laborers; there are locking devices A5 on both sides of the upper end of the shell 4, and a locking hook A7 on the bottom of the crushing tube 8, which can ensure the smoothness of the grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com