Crushing treatment device for recycling medical consumables

A technology for processing devices and consumables, applied in grain processing, cleaning methods using liquids, cleaning methods and utensils, etc., can solve the problems affecting the operation of crushing machines and increase the operation volume, so as to avoid infection and ensure the effect of crushing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

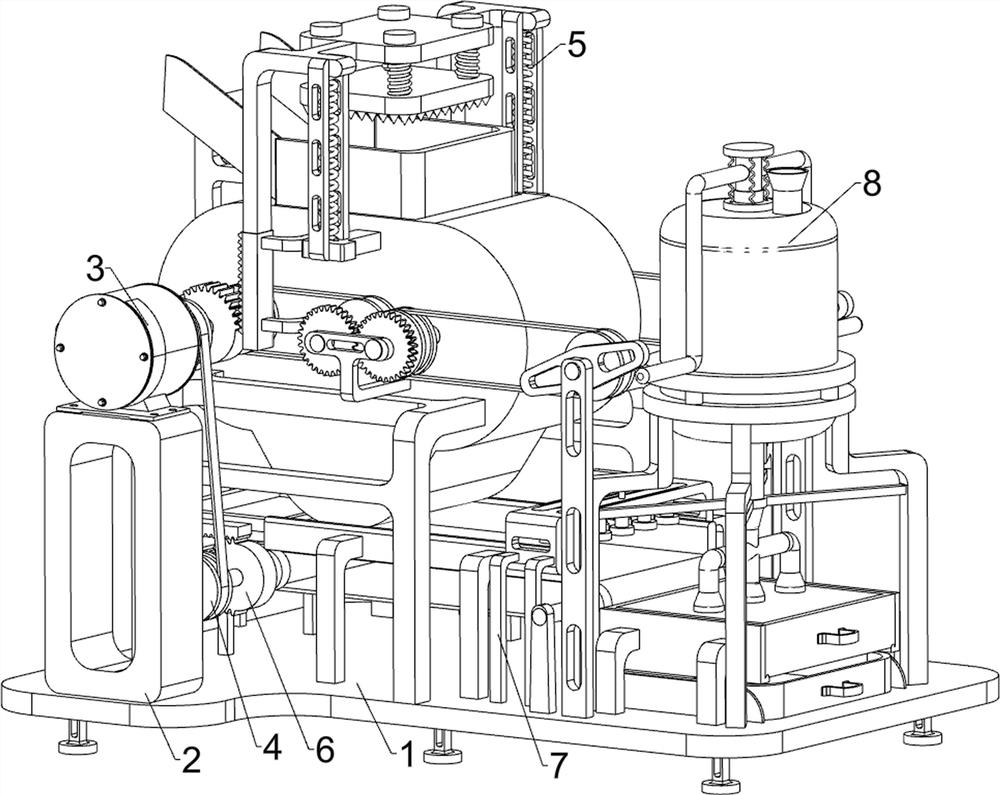

[0058] A crushing device for recycling medical consumables, such as figure 1 As shown, it includes a base 1, an installation seat 2, a crushing mechanism 3, and a transportation and collection mechanism 4. An installation seat 2 is provided on the left front side of the top of the base 1, and a crushing mechanism 3 is connected between the left side of the top of the base 1 and the installation seat 2. A transport collection mechanism 4 is connected between the top and the crushing mechanism 3.

[0059] The staff can place the medical consumables on the crushing mechanism 3, and then start the crushing mechanism 3 to crush the medical consumables, and the broken glass will automatically fall into the transportation collection mechanism 4, and the operation of the crushing mechanism 3 will drive the operation of the transportation collection mechanism 4 to complete the glass. Transport to the right, automatic recovery, all crushing is completed, just stop the operation of the c...

Embodiment 2

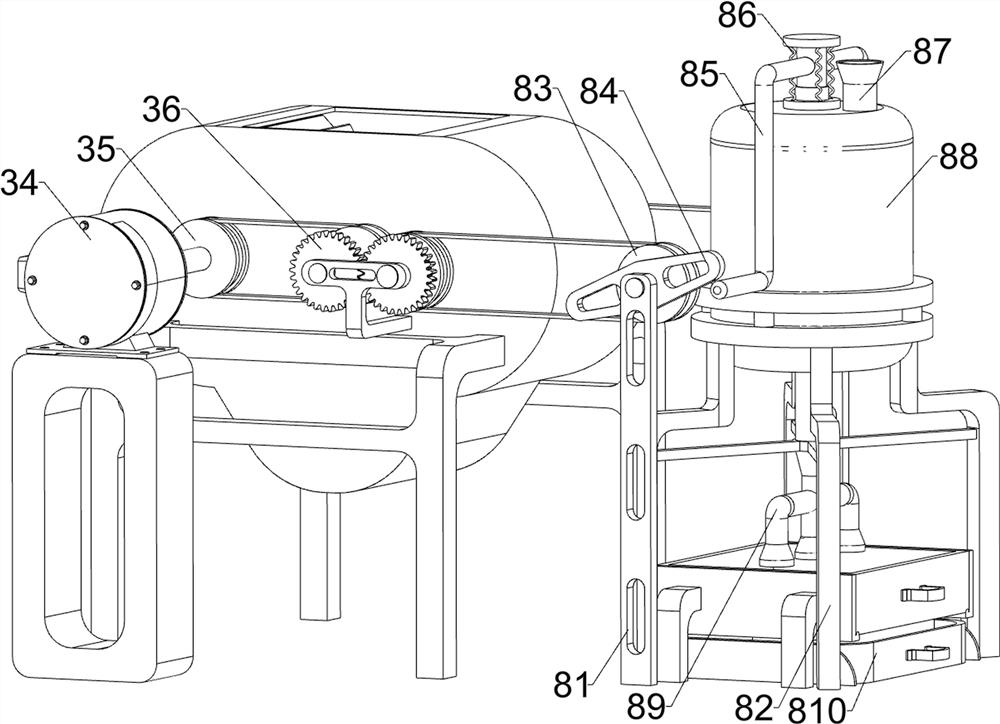

[0061] On the basis of Example 1, such as figure 2 , Figure 4 and Figure 7As shown, the crushing mechanism 3 includes a support base 31, a working chamber 32, a feed chute 33, a servo motor 34, a first pulley assembly 35, a gear set 36 and a crushing cutter 37, and the left side of the top of the base 1 is symmetrically provided with supports Seat 31 is connected with working chamber 32 between the support seat 31 top, and the top of working chamber 32 is provided with feeding port, and the left side of working chamber 32 is connected with feeding chute plate 33, and feeding chute plate 33 cooperates with feeding port, installs The top of the seat 2 is provided with a servo motor 34, and the output shaft of the servo motor 34 is provided with a crushing cutter 37, and the right side of the working chamber 32 is also rotatably connected with a crushing cutter 37, and the front and rear sides of the working chamber 32 are rotatably connected with gears. Group 36, the right ...

Embodiment 3

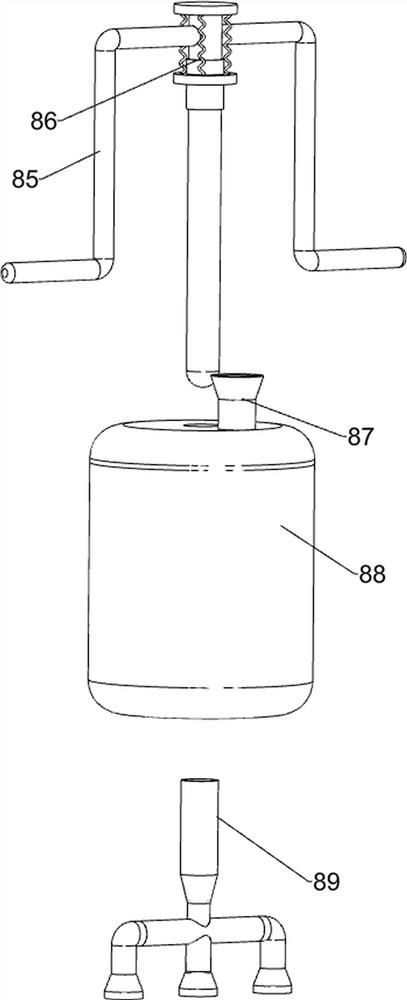

[0065] On the basis of Example 2, such as Figure 3 to Figure 8 As shown, the primary crushing mechanism 5 is also included, and the primary crushing mechanism 5 includes a first sector gear 51, a first rack 52, a connecting frame 53, a crushing block 54, a buffer spring 55, a connecting rod 56, and a first return spring 57 , the mounting frame 58 and the iron scrap feed net 59, the output shaft of the servo motor 34 is connected with the first sector gear 51 on the front and rear sides, the front and rear sides of the working chamber 32 are slidingly connected with the first rack 52, and A rack 52 meshes with the first sector gear 51, a connecting frame 53 is connected between the tops of the first racks 52, four connecting rods 56 are slidably connected to the connecting frame 53, and broken blocks are connected between the bottoms of the connecting rods 56 54, a buffer spring 55 is connected between the top of the broken block 54 and the connecting rod 56, and the front and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com