Fast transferring method of glass

A glass, fast technology, applied in the directions of transportation and packaging, conveyor objects, furnaces, etc., can solve the problems of glass position deviation, low transmission efficiency, etc., to achieve the effect of rapid transmission, improve transmission efficiency, and reduce damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

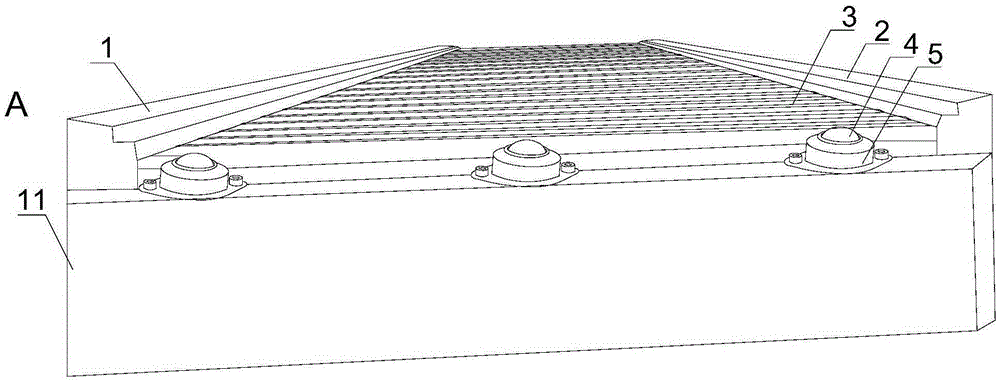

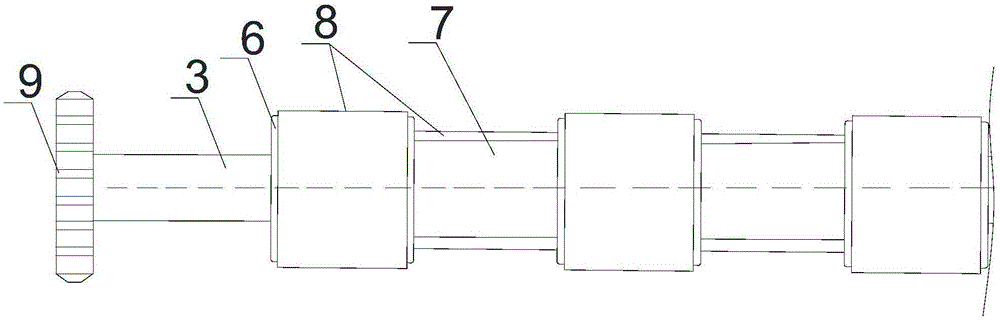

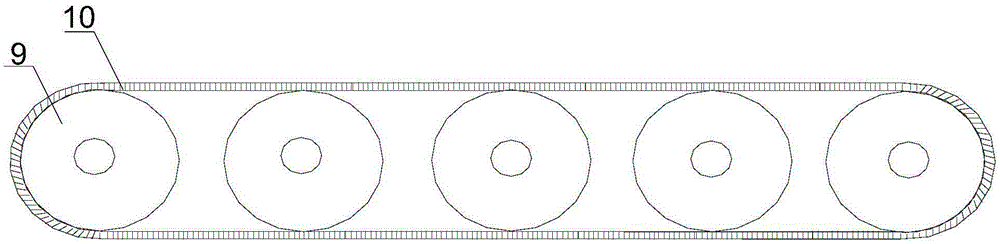

[0022] Such as Figure 1 to Figure 3 As shown, the present invention firstly arranges a left baffle and a right baffle at both ends of the support frame of the transmission mechanism, gears are installed at both ends of the round roller and the output end of the motor, and the motor drives the gear to drive the gear and the left and right baffles. The chain on the plate cooperates to make the round roller support frame rotate, and then start to drive the glass to move; the round roller can make different types of glass be placed stably on the conveying plane to prevent the position of the glass from shifting. The support structure can play a transitional function, which can unify the entrance position of the glass and the processing equipment, and reduce the collision between the glass and the supporting frame or processing equipment; the transmission mechanism includes the supporting frame 11, the motor, the left baffle 1, and the right baffle The plate 2 and the round roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com