Patents

Literature

64results about How to "Reduce transmission speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

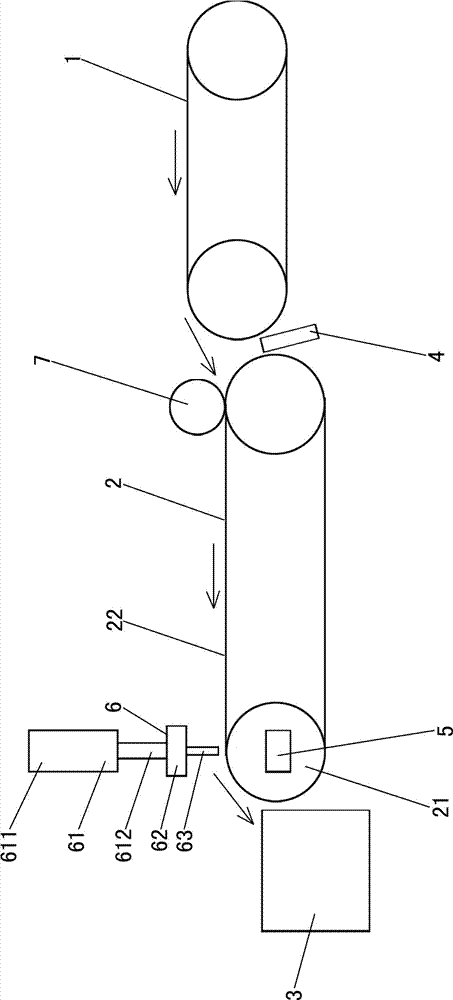

Presswork counting and stacking method

The invention provides a presswork counting and stacking method. A counting sensor is arranged between a fast-speed conveying belt and a slow-speed conveying belt; the counting sensor generates a presswork counting signal and conveys the presswork counting signal to a control device; an encoder is arranged on a belt wheel of the slow-speed conveying belt; a presswork stopping mechanism is arranged above the slow-speed conveying belt; when the accumulated value of the presswork counting signal which is transmitted to the control device by a timing sensor is equal to the pre-set value of the presswork quantity, the control device starts to count pulses to the encoder; when the pulse counting numerical value of the encoder is equal to the encoder pulse pre-set value, the presswork stopping mechanism moves and stops a presswork at the back side; a presswork at the front side is moved to a stacking mechanism to finish the counting and stacking process; and the presswork stopping mechanism is reset. According to the presswork counting and stacking method, the transmission speed of the presswork can be slowed through the slow-speed conveying belt, and the impact force on the presswork is reduced so as to be good for sequentially stacking the presswork; and the encoder and the presswork stopping mechanism are arranged, so that the accurate counting on the presswork can be realized.

Owner:YANBIAN CHANGBAISHAN PRINTING

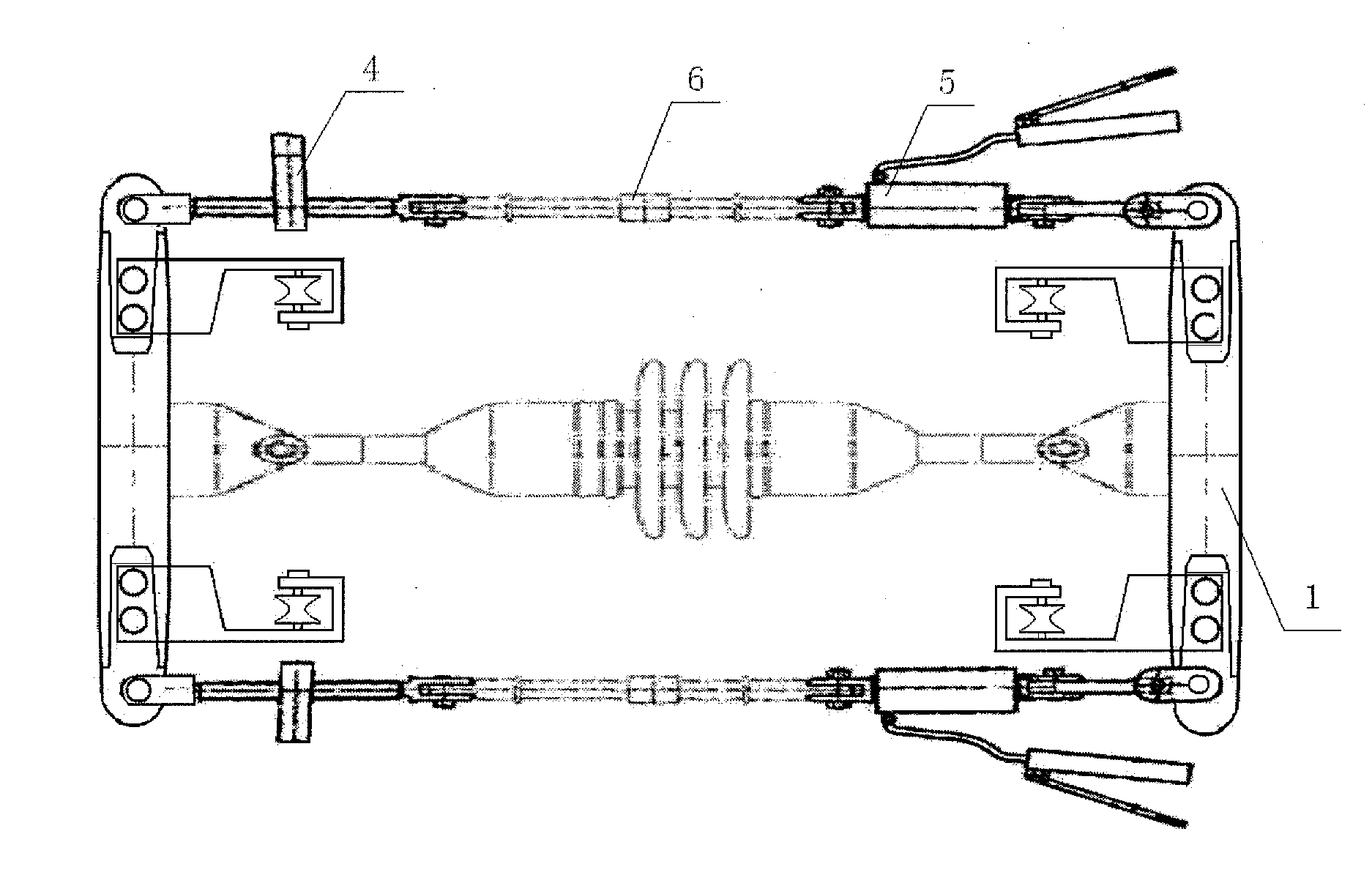

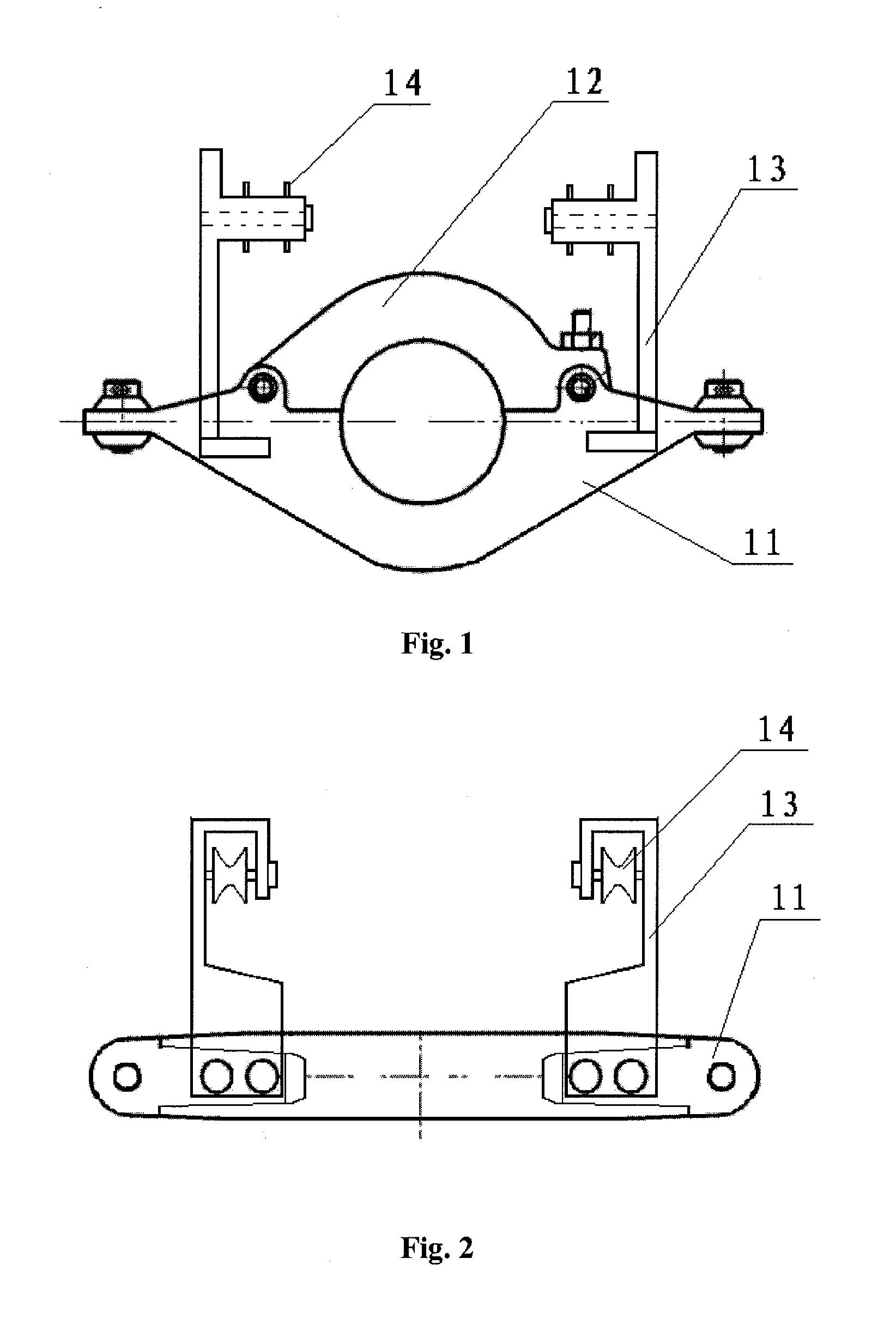

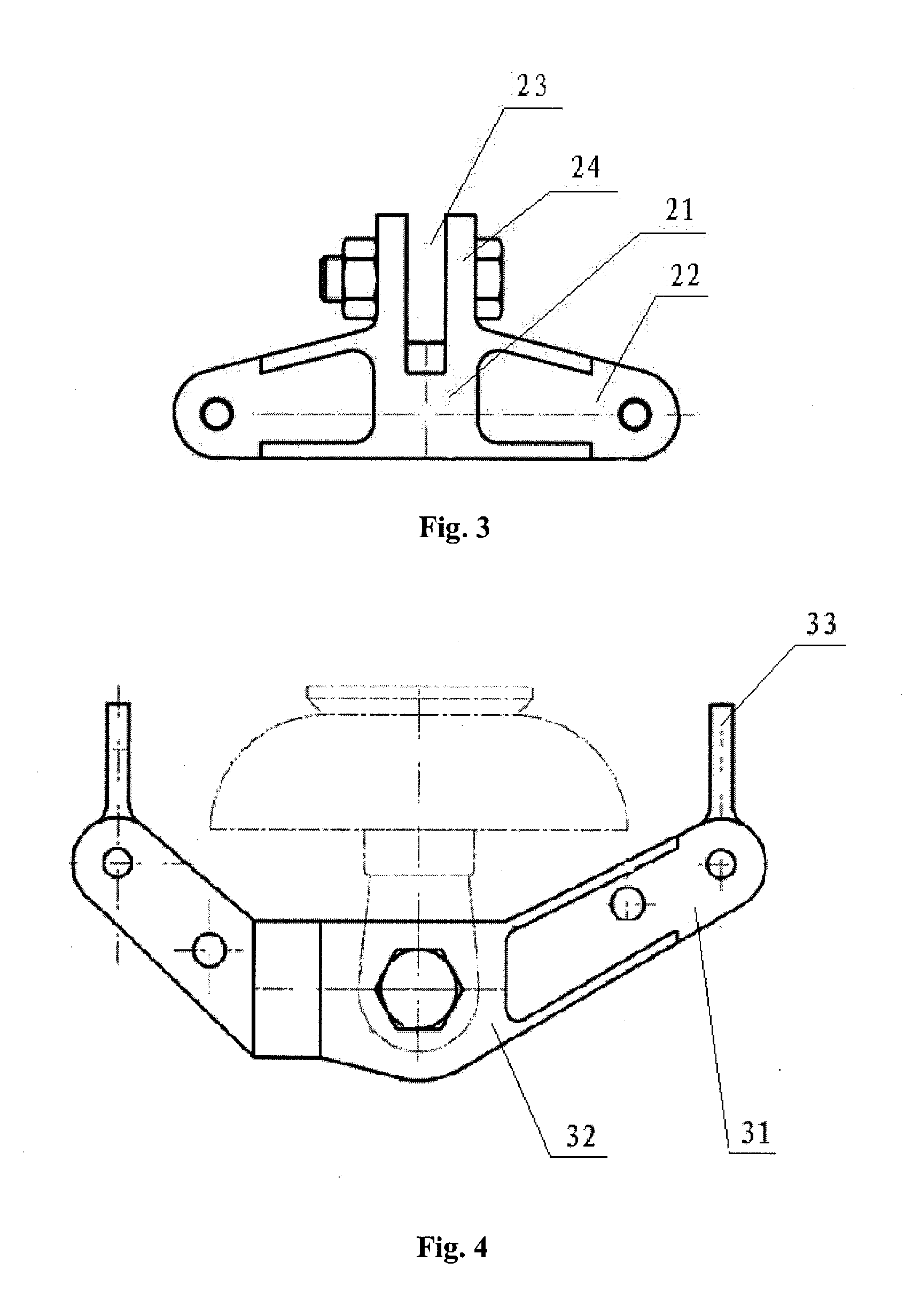

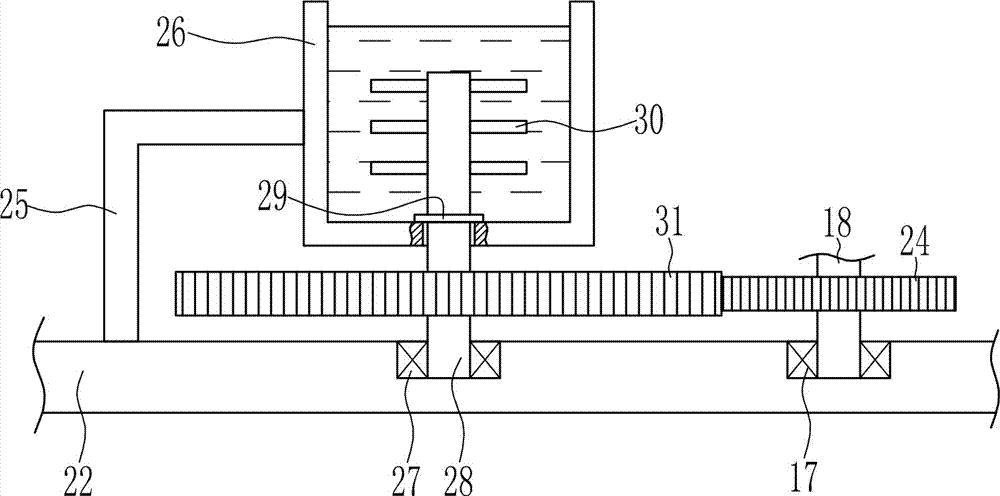

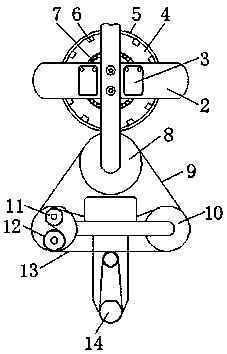

Maintenance tool for insulator of direct current transmission line

InactiveUS20130269180A1High strengthSmall volumeMetal working apparatusApparatus for overhead lines/cablesUltimate tensile strengthDirect current

A maintenance tool for an insulator of a direct current transmission line comprises clamping devices and a tensioning device. The clamping devices are mounted at the two sides of the insulator through clamping, and the tensioning device is connected between the clamping devices. The clamping devices comprise a closed clamp (1), a single serial clamping device (2) and a wire end clamping device (30). The clamping device has advantages such as strong overall strength and bearing capacity, small size, light weight, and reliable working, and can be applied to replacement of various insulators on the direct current transmission line, reliably ensuring safe commissioning and regular maintenance of transmission lines.

Owner:STATE GRID CORP OF CHINA +1

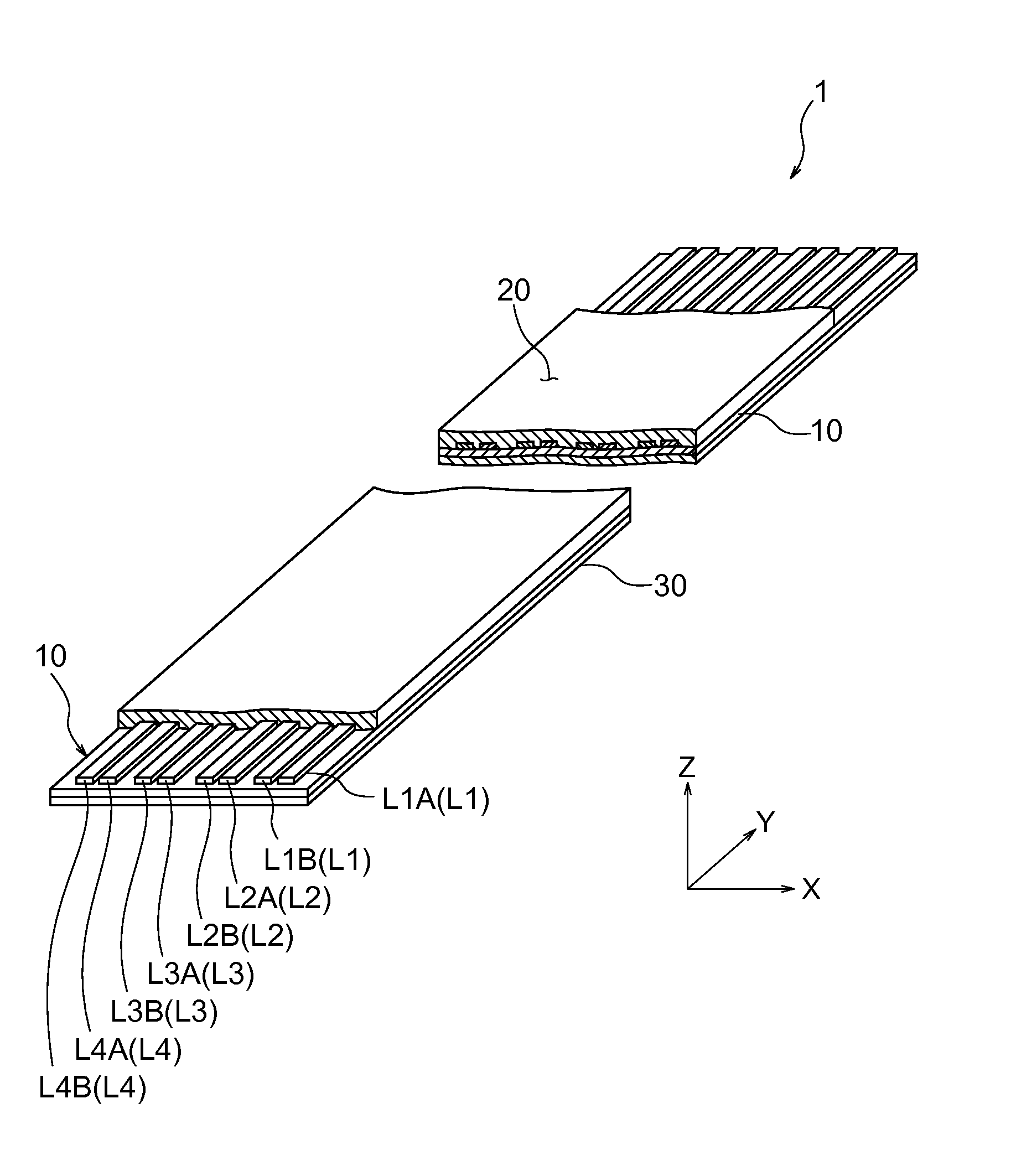

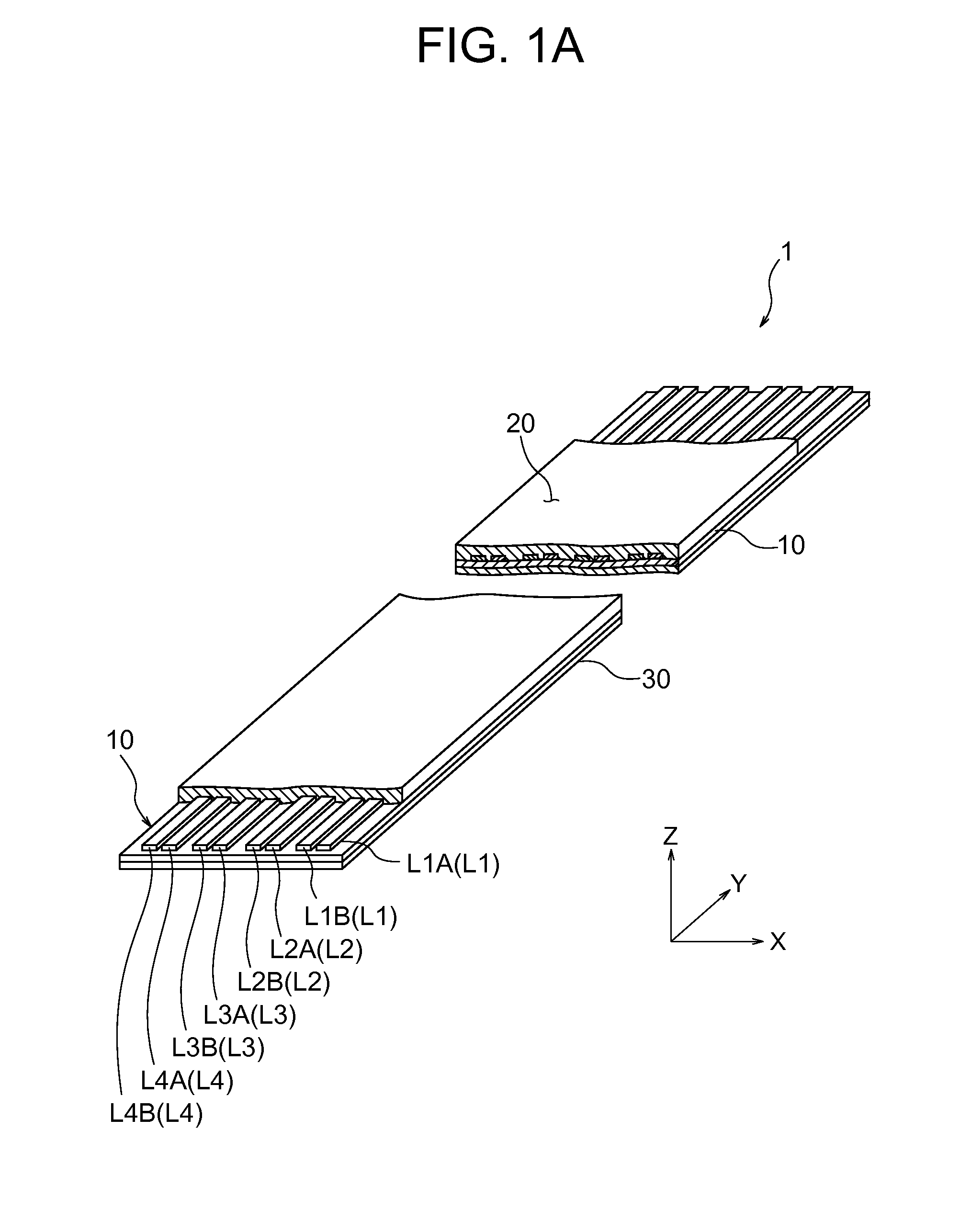

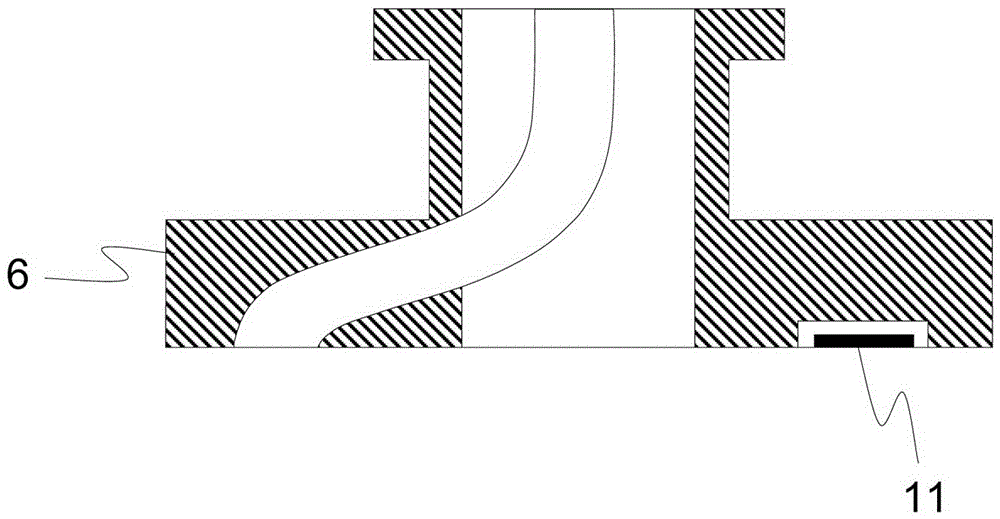

Printed wiring board

InactiveUS20150342030A1Improve transmission qualityLong processCross-talk/noise/interference reductionHigh frequency circuit adaptationsGround planeTransmission time

To suppress occurrence of a difference in transmission time due to a difference in length between signal lines, there is provided a printed wiring board having: an insulating substrate (10); a first signal line (L31A) that constitutes differential signal lines formed on the insulating substrate (10) and includes a curved portion; a second signal line (L31B) provided along the first signal line (L31A) and side by side inside the curved portion; and a ground layer (30) formed for the first signal line (L31A) and the second signal line (L31B) via an insulating material (10). The ground layer (30) includes a first ground layer (G31A) corresponding to a first region (D1) and a second ground layer (G31B) corresponding to a second region (D2). The first region (D1) is defined based on the first signal line (L31A) and has a first predetermined width (W31A). The second region (D2) is defined based on the second signal line (L31B) and has a second predetermined width (W31B). The first ground layer (G31A) has a remaining ratio lower than a remaining ratio of the second ground layer (G31B).

Owner:THE FUJIKURA CABLE WORKS LTD

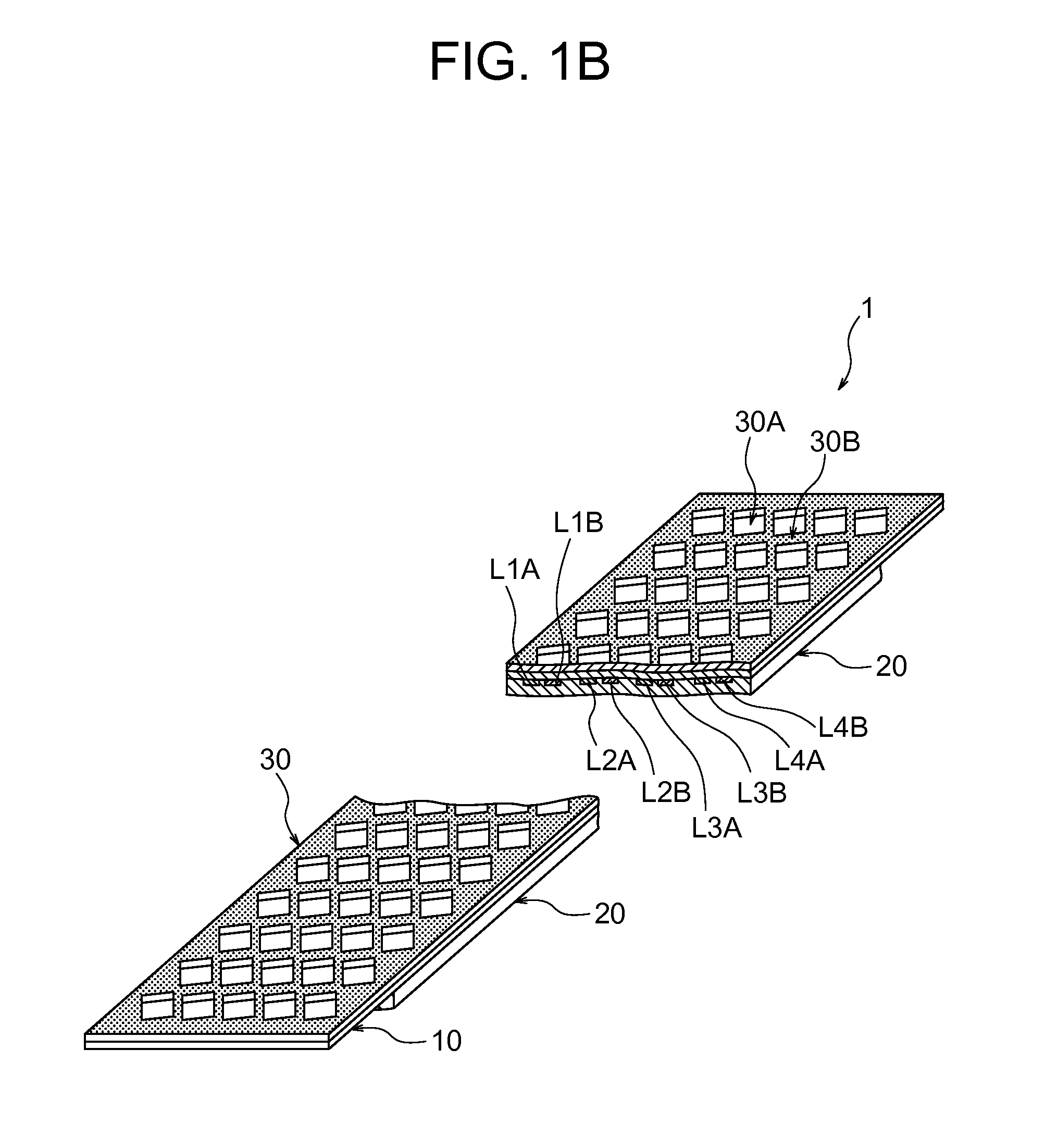

Novel oxygen atomization apparatus for respiratory medicine

InactiveCN108815654ARealize automatic power-off protection functionImprove atomization effectMedical atomisersTransmission beltRespirator

The invention discloses a novel oxygen atomization apparatus for respiratory medicine. The structure of the apparatus comprises a medical breathing mask, an atomization barrel, a supporting foot rack,an automatic regulating box and a connecting breathing tube, wherein the medical breathing mask is fixedly arranged on top of the connecting breathing tube in an embedded manner and is connected to the atomization barrel by connecting the breathing tube in an embedded manner. The novel oxygen atomization apparatus for respiratory medicine can control the air brake mechanism according to the weight change of the water tank to realize the automatic power-off protection function of the ultrasonic control device, drive the transmission belt mechanism through motor brake device to realize fan transmission, and control atomization absorption frequency through hydraulic variable speed transmission mechanism, thereby improving the atomization effect, avoiding hypoxia and protecting the device andthe patient to a large extent.

Owner:张莹

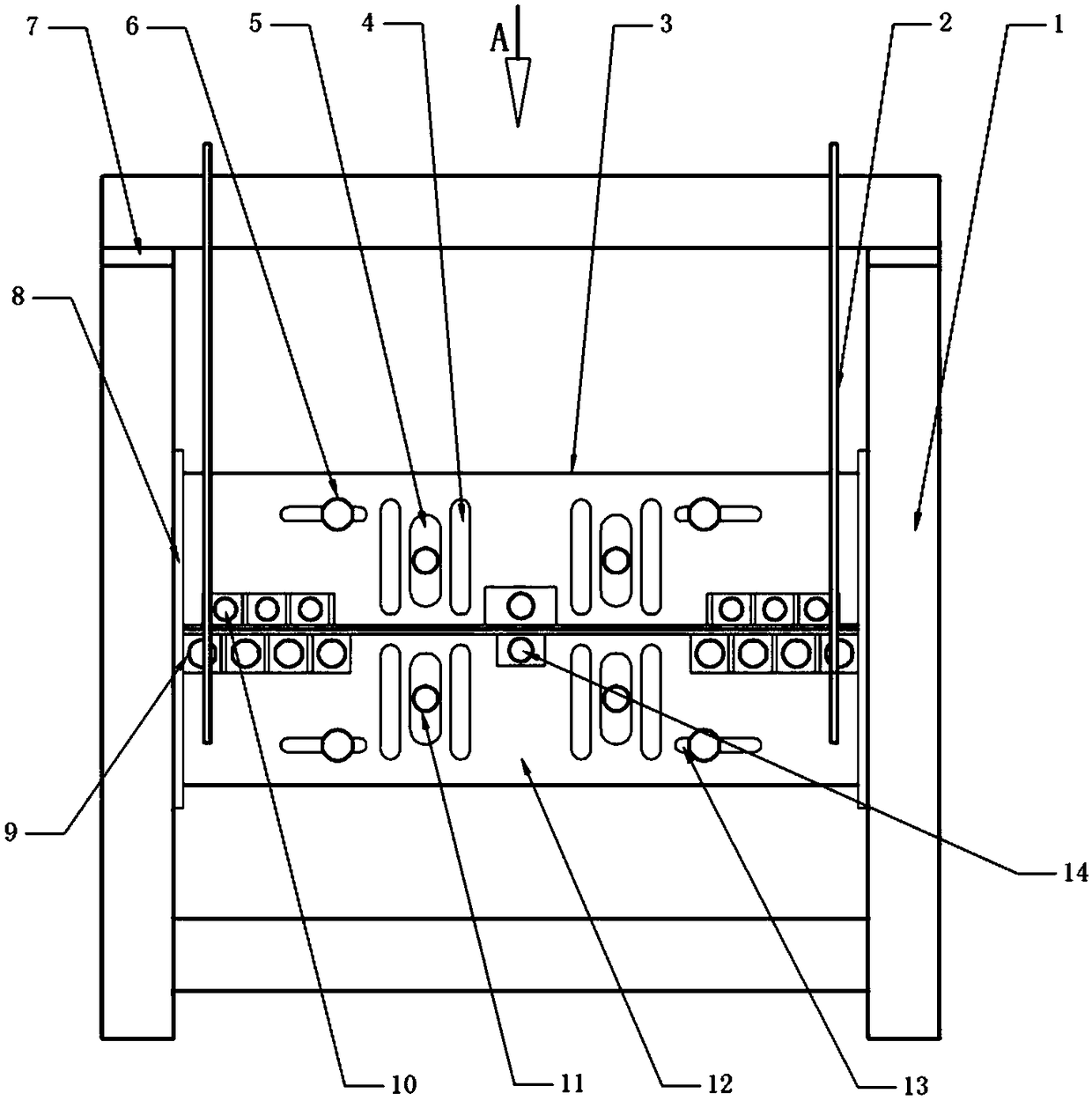

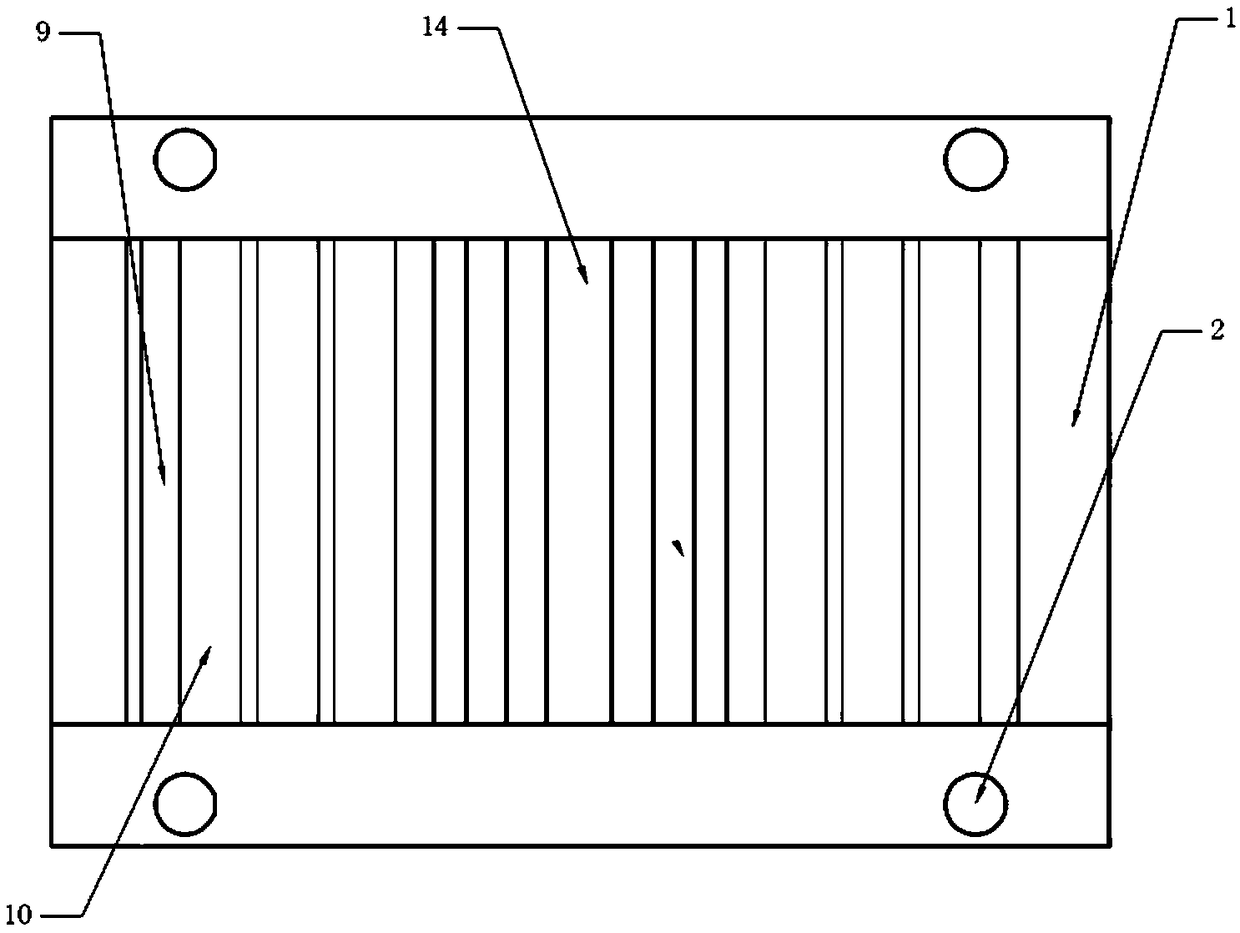

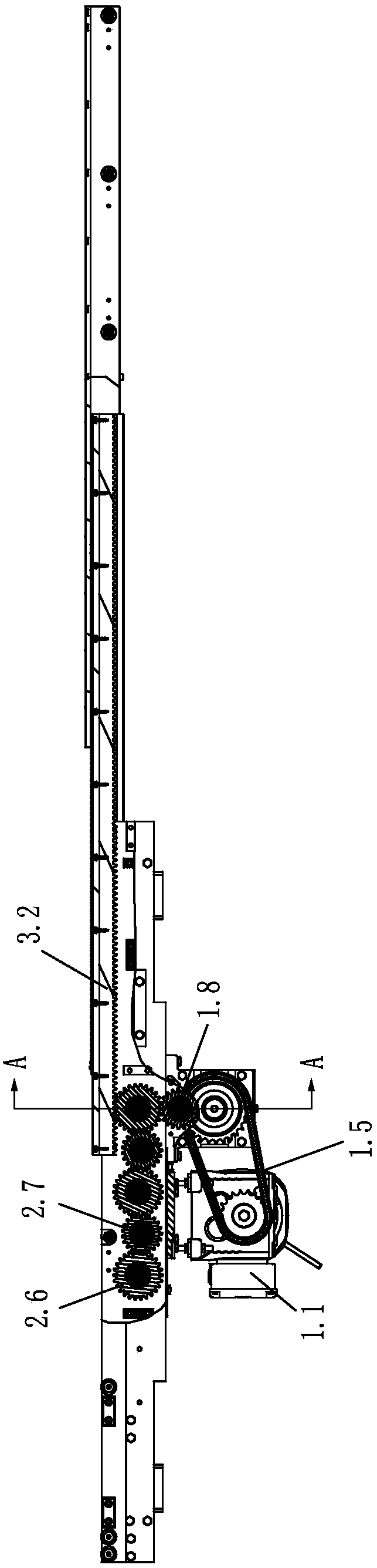

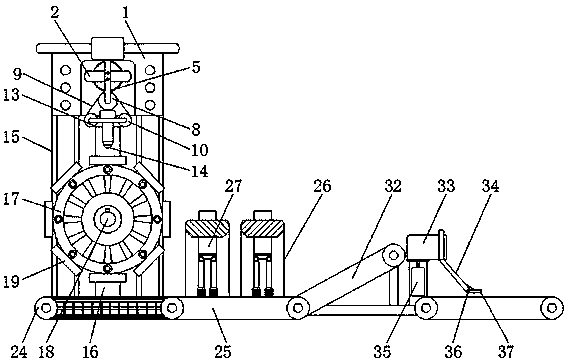

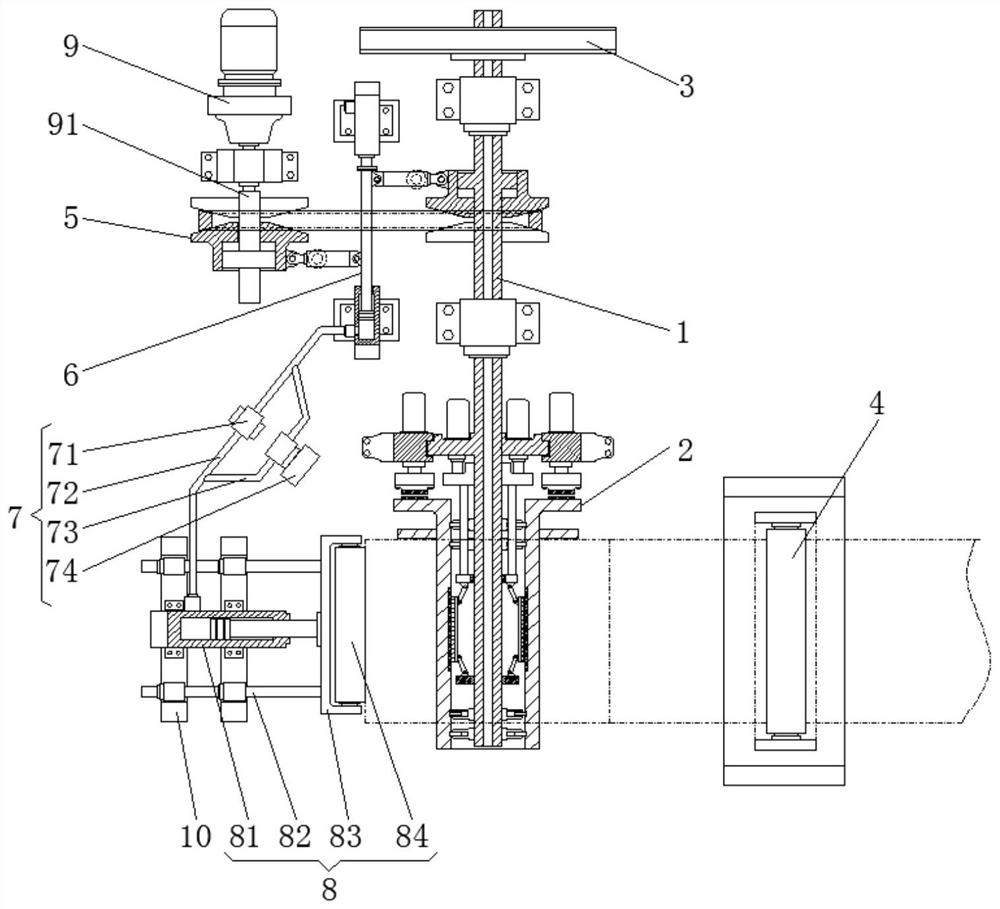

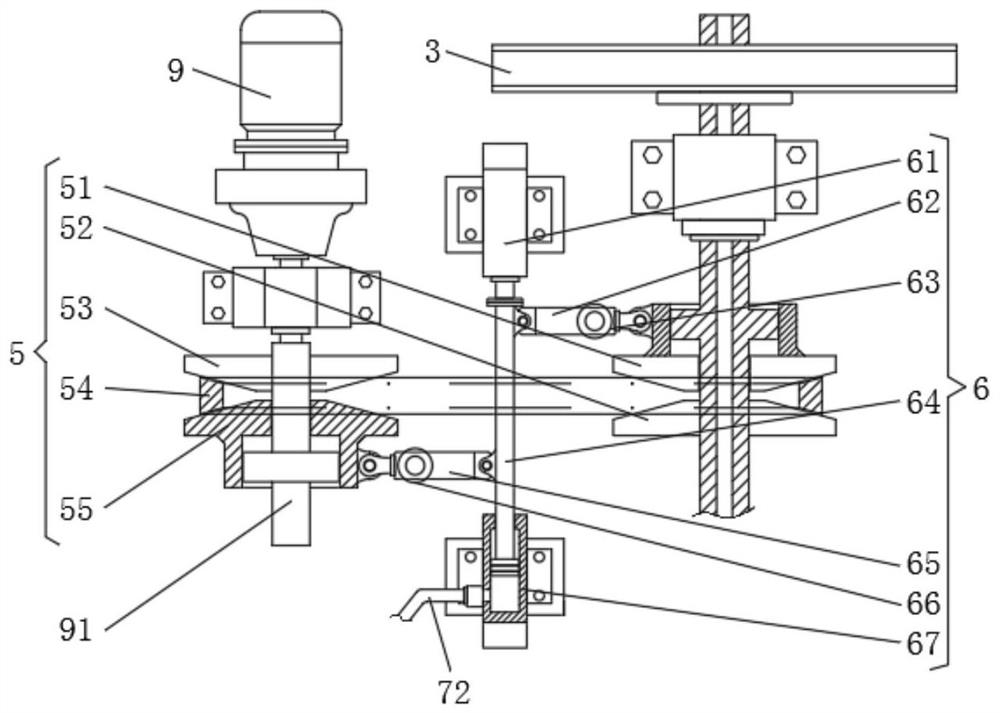

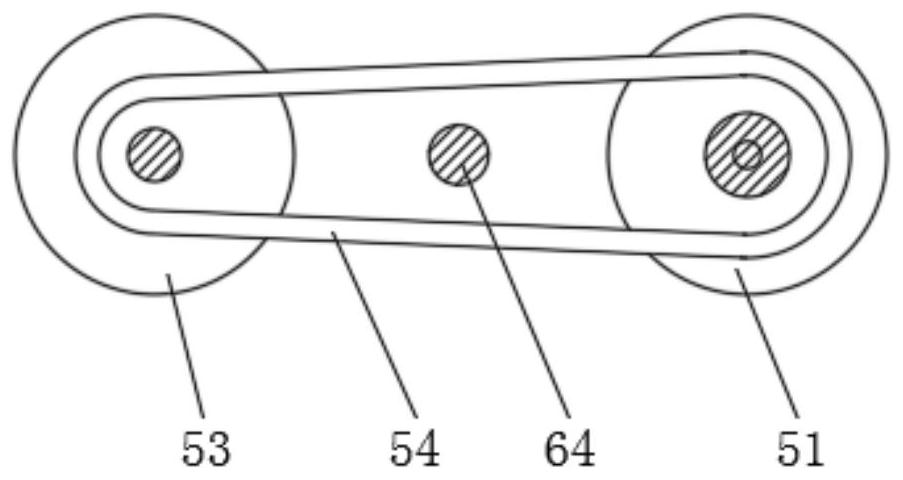

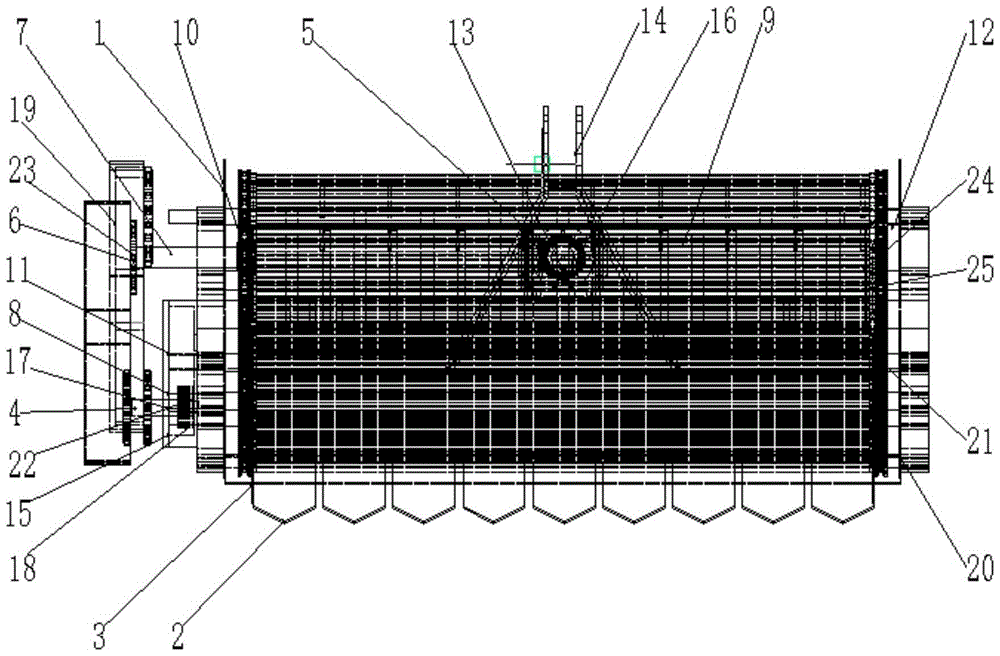

Scaffold screen grinding and leveling machine

ActiveCN109176264AReduce lossImprove work efficiencyGrinding drivesGrinding work supportsEngineeringMachining

The invention relates to the technical field of grinding machining, and discloses a scaffold screen grinding and leveling machine. The scaffold screen grinding and leveling machine comprises a rack. Clamping mechanisms are arranged on the front face and the back face of the rack. Each clamping mechanism comprises an upper clamping plate and a lower clamping plate. Upper leveling roller sets are arranged between the two ends of the two upper clamping plates, an upper buffer roller is arranged between the middles of the two upper clamping plates, and upper grinding rollers are arranged on the two sides of the upper buffer roller correspondingly. A lower buffer roller is arranged between the middles of the two lower clamping plates, lower grinding rollers are arranged on the two sides of thelower buffer roller correspondingly, and the upper grinding rollers and the lower grinding rollers form grinding opposite rollers. A first motor is arranged on the rack, lower leveling rollers at thetwo ends are driven by the first motor, a driving gear is arranged on the lower leveling roller set at one end, and a driven gear is arranged on the upper buffer roller set corresponding to the lowerleveling roller set at the end. Multiple second motors are arranged on the rack. The scaffold screen grinding and leveling machine is simple in structure, screens can be ground well, and the work efficiency of grinding can be improved.

Owner:重庆玖和惠鼎建筑劳务有限公司

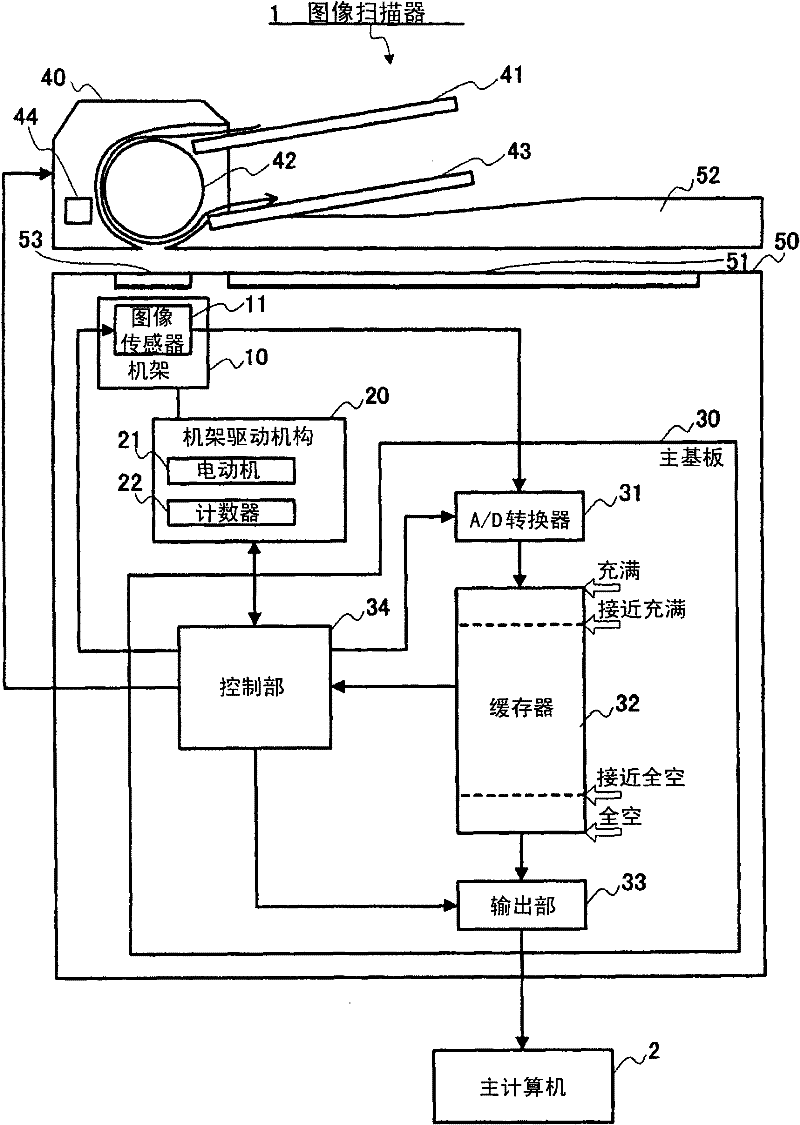

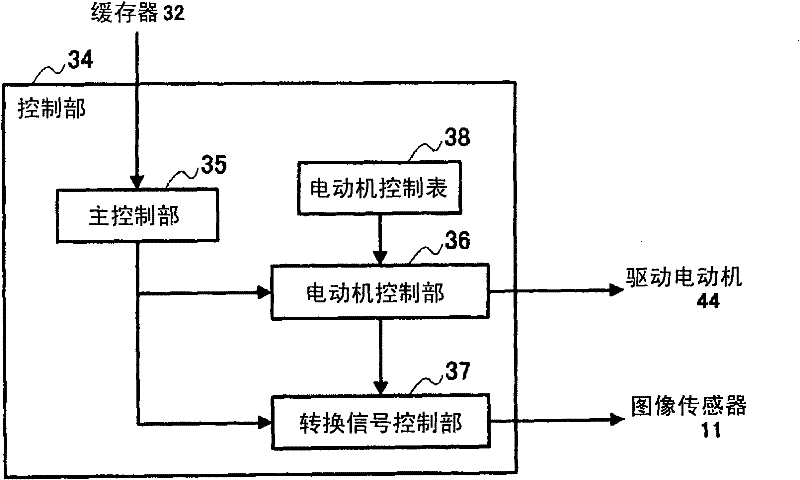

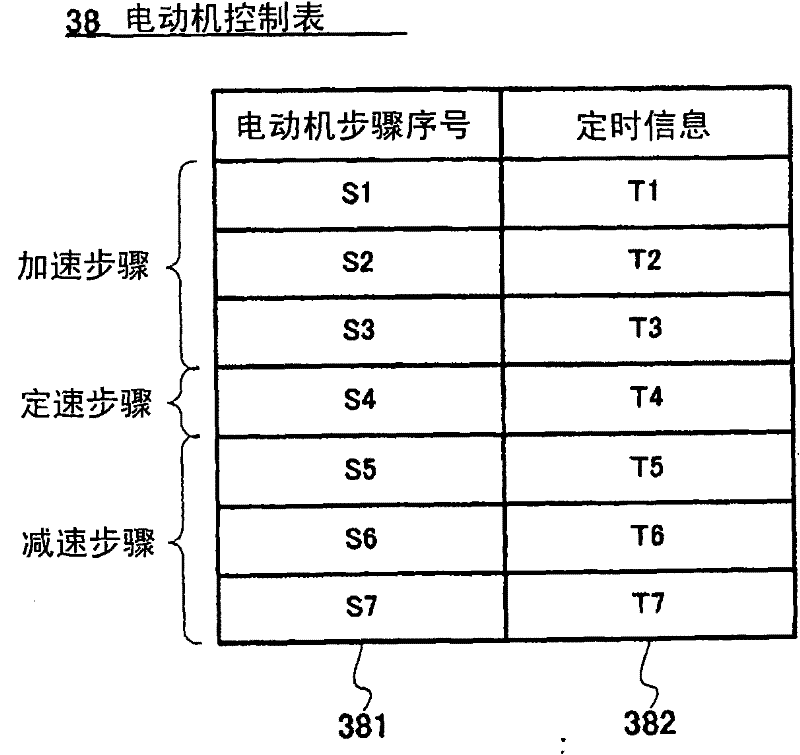

Image reading apparatus, image reading program, and image reading method

ActiveCN101753768AIncrease transmission speedReduce transmission speedPictoral communicationComputer scienceImaging data

The invention provides an image reading apparatus with a sheet feeding device, which can read at high speed with simple structure. In the image reading apparatus, when the monitoring section determines that the volume of the image data is less than a predetermined first threshold value, the sheet feeding control section accelerates the transport of the original document and maintains the transport at a predetermined speed, and the reading control section starts the output of the reading signal when the transport of the original document is started. In addition, when the volume of the image data is over a predetermined second threshold value, the sheet feeding control section reduces the transport of the original document and stops, and transport of the original document stops and the output of the read signal stops. Herein, the image reading apparatus output the read signal every a certain transport distance of the original document in the period of the transport of the original document.

Owner:SEIKO EPSON CORP

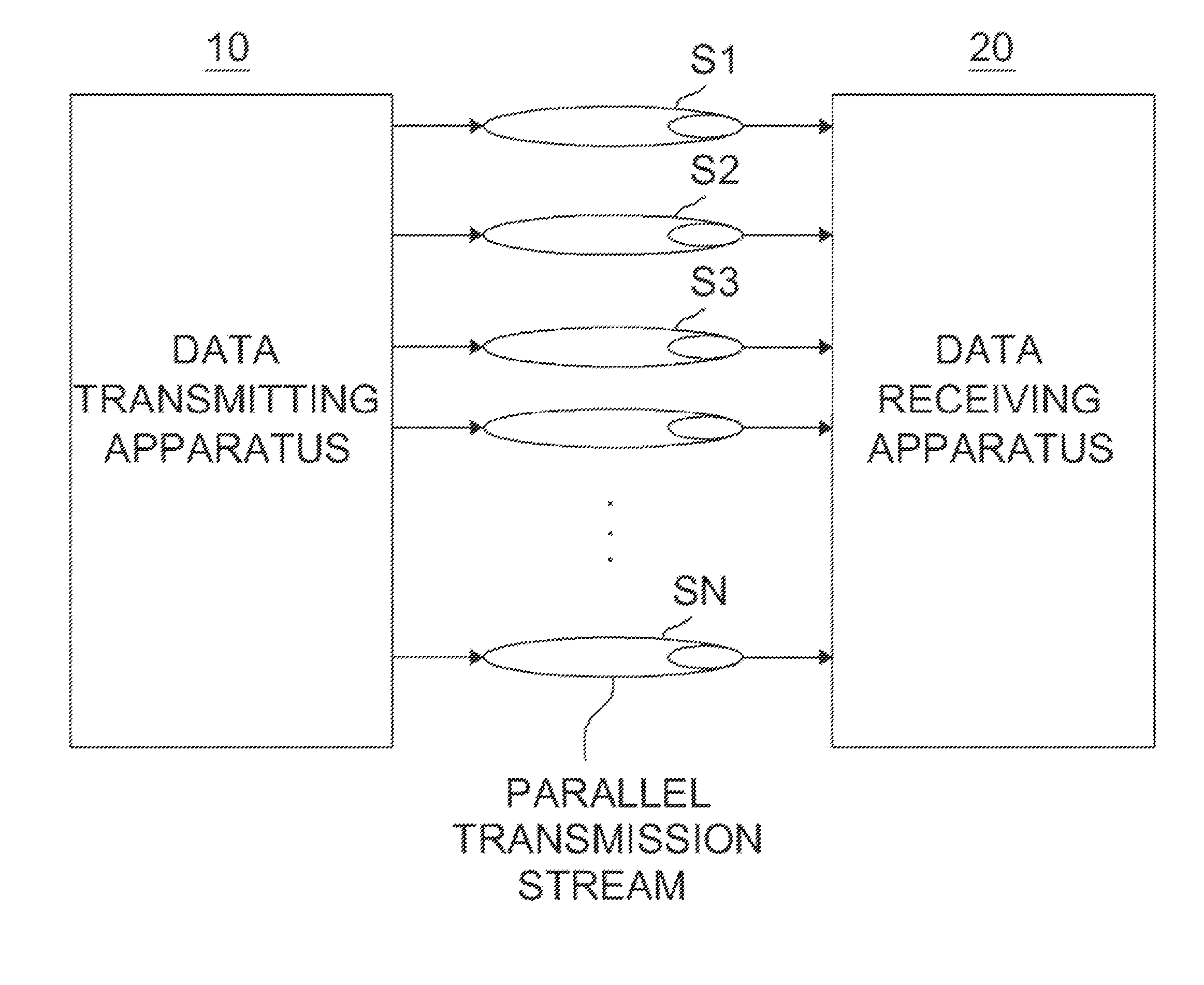

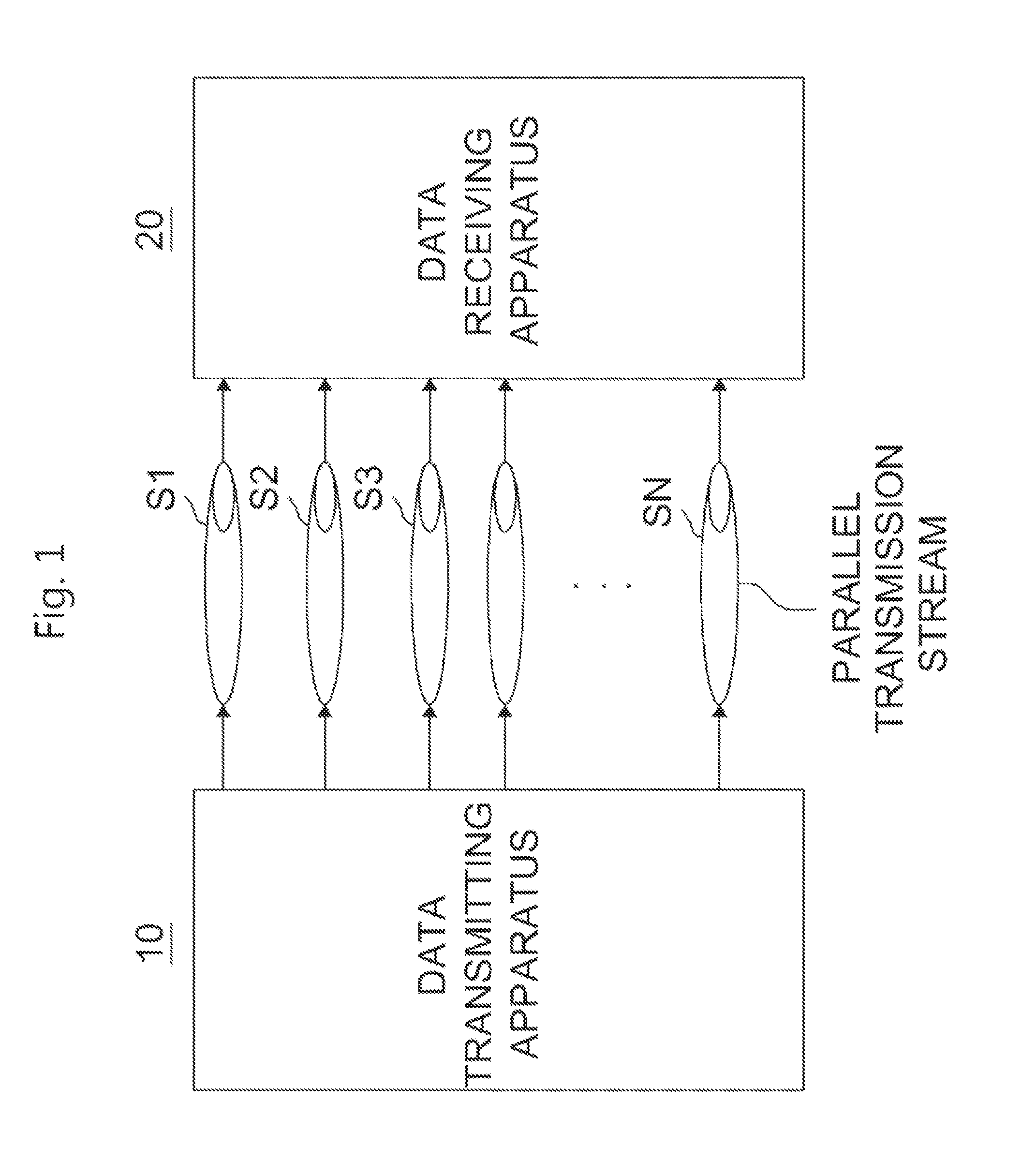

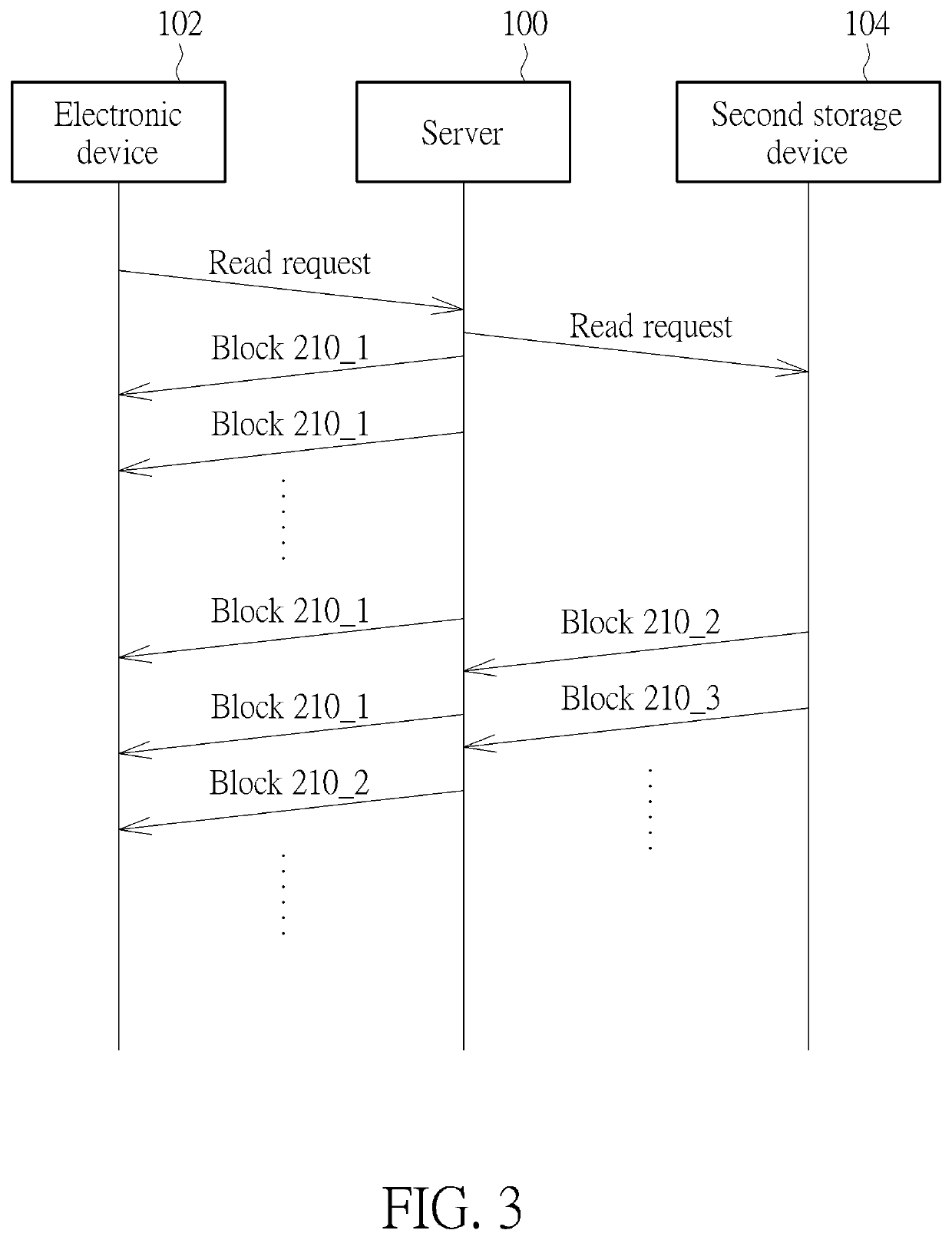

Apparatus and method for transmitting data

InactiveUS20130138771A1Minimize timeImprove TCP efficiencyMultiple digital computer combinationsTransmissionData recordsCommunication unit

Provided are an apparatus and a method for transmitting data and an apparatus and a method for receiving data. The apparatus for transmitting data includes: a disk reader which divides a file block into one or more microblocks, reads data, from the plurality of files, corresponding to sizes of the one or more microblocks, and records the read data in the one or more microblocks in sequence; and a communication unit which, if the read data is recorded in the one or more microblocks included in the file block, transmits the file block to a data receiving apparatus.

Owner:SAMSUNG SDS CO LTD

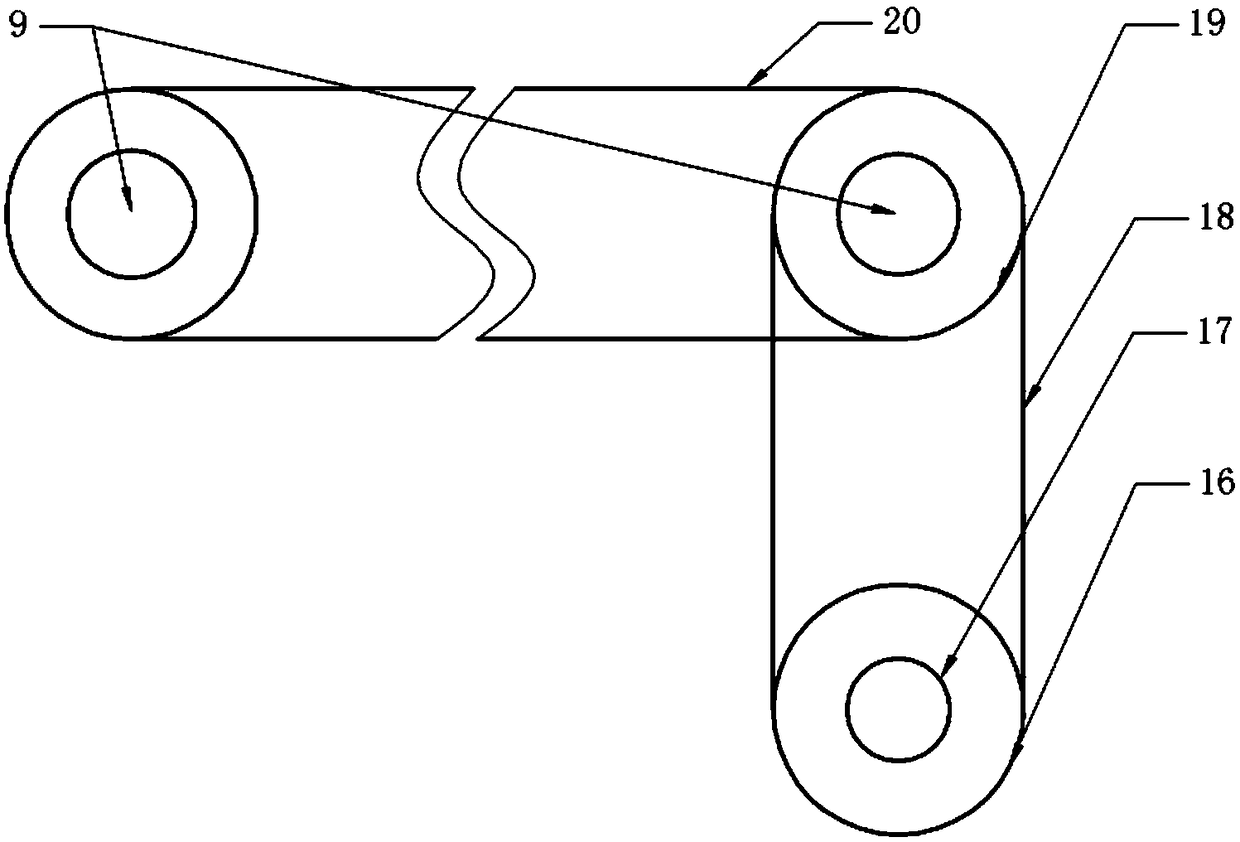

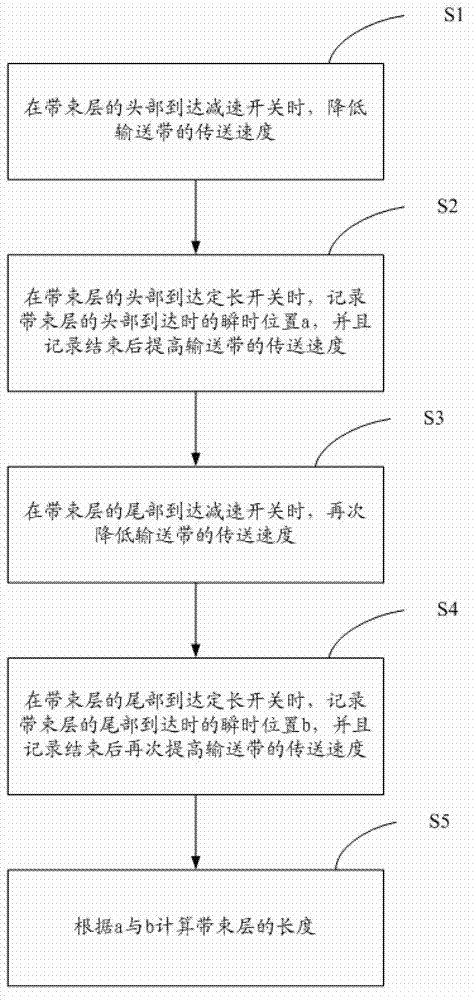

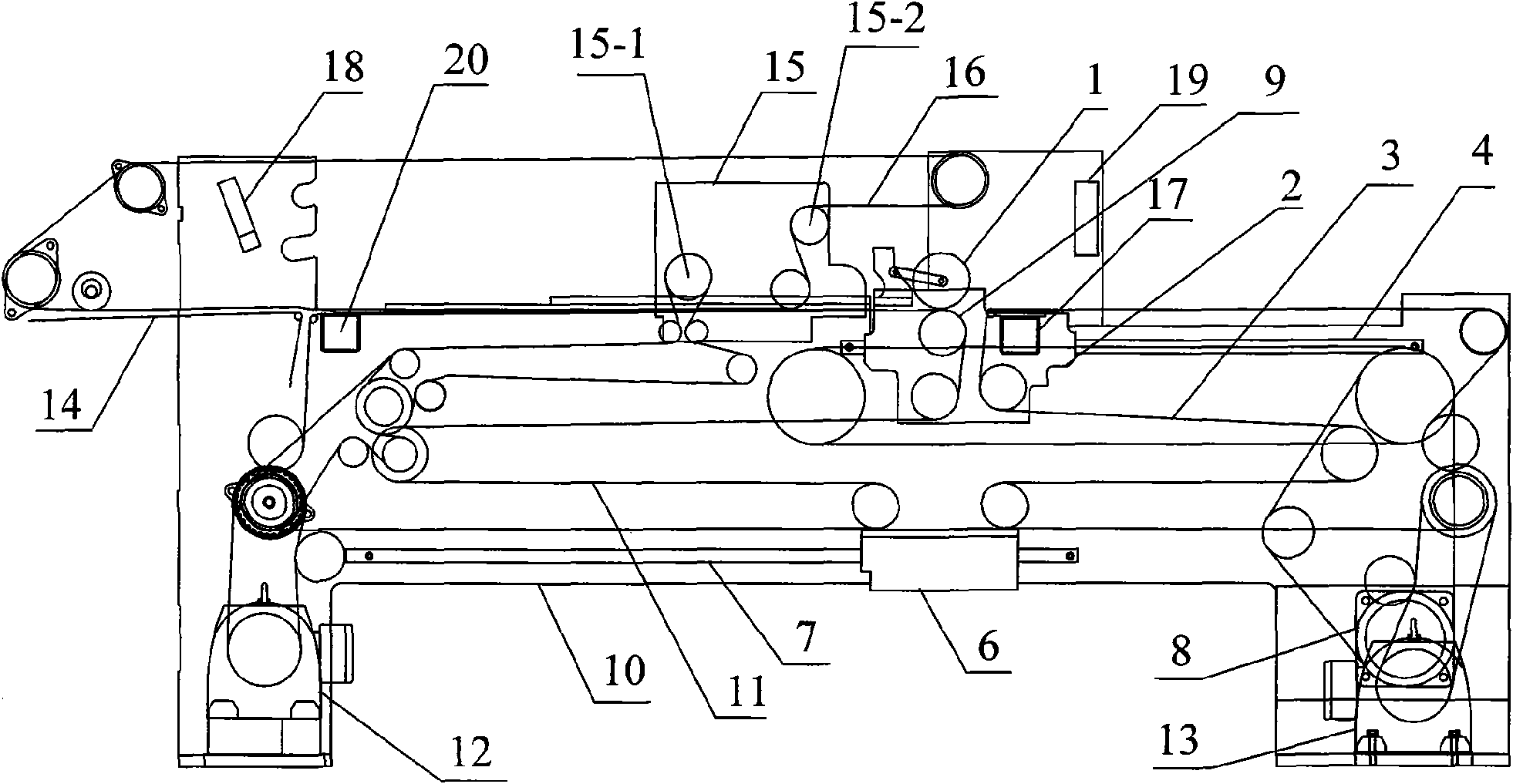

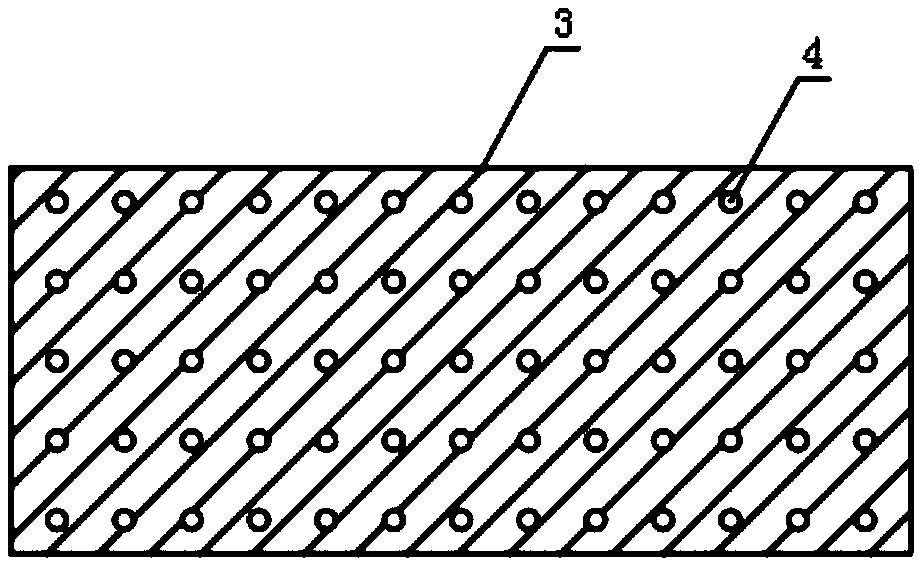

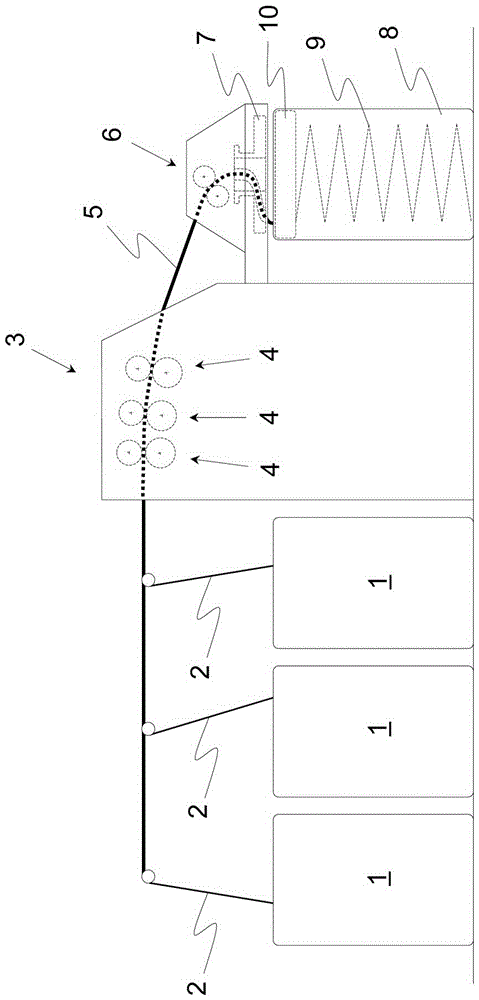

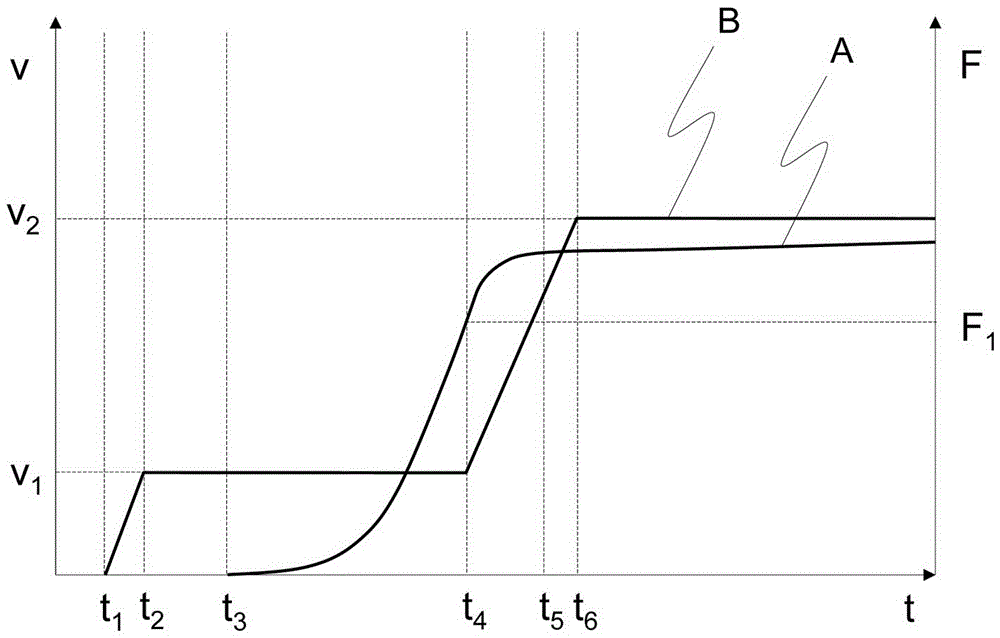

Method and device for length measurement of belt ply

ActiveCN103075985AReduce transmission speedIncrease transmission speedMeasurement devicesArticle feedersLength measurementMechanical engineering

The invention discloses a method and device for length measurement of a belt ply. The method comprises the following steps of: when a head of the belt ply reaches a speed-reducing switch, reducing the transfer speed of a conveyer belt; when the head of the belt ply reaches a fixed length switch, recording an instantaneous position a when the head of the belt ply reaches, improving the transfer speed of the conveyer belt after end of the recording, and when a tail of the belt ply reaches the speed-reducing switch, reducing the transfer speed of the conveyer belt again; when the tail of the belt ply reaches the fixed length switch, recording an instantaneous position b when the tail of the belt ply reaches, and improving the transfer speed of the conveyer belt again after end of the recording; and computing the length of the belt ply according to the a and the b. The moment to cause the head of the belt ply to reach the speed-reducing switch is earlier than the moment to cause the head of the belt ply to reach the fixed length switch.

Owner:SHANDONG JINYU INDUSTRIAL CO LTD

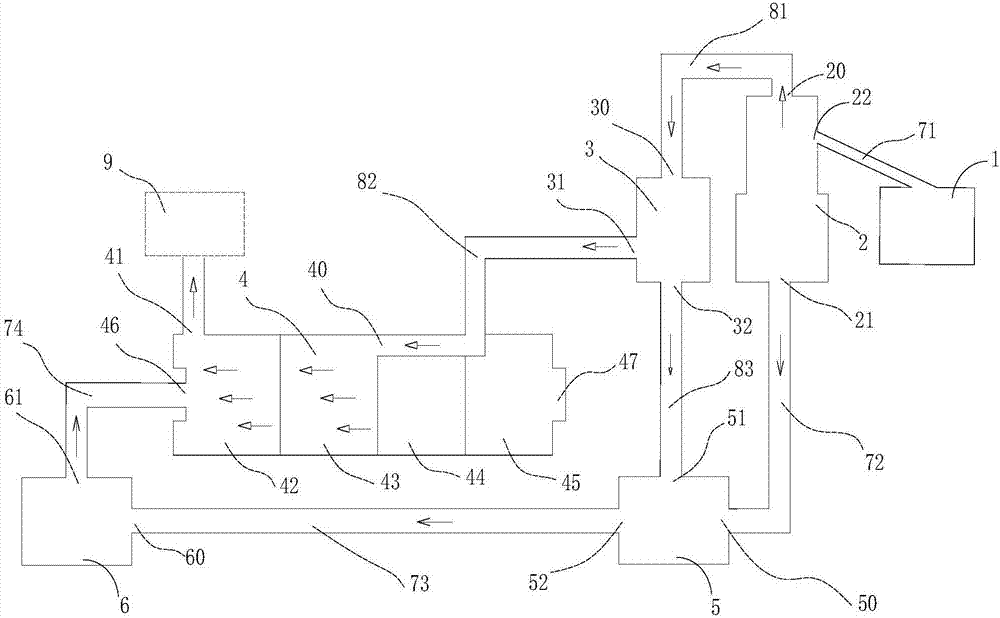

Refuse disposal system

PendingCN106881336ASafe and Efficient DisposalAchieve reuseSolid waste disposalTransportation and packagingCombustionDecomposition

The invention discloses a refuse disposal system. The refuse disposal system comprises a refuse pool, an incinerator, a water disposer and a tunnel brick kiln. The refuse pool conveys refuse to a first feeding opening of the incinerator through a first conveyer belt. A first smoke outlet formed in the incinerator communicates with a first smoke inlet formed in the water disposer through a first pipeline. A second smoke outlet formed in the water disposer communicates with a second smoke inlet formed in the tunnel brick kiln through a second pipeline. A drying section, a combustion section, a heat preservation section and a cooling section are sequentially arranged in the tunnel brick kiln. The second smoke inlet is formed in the combustion section. The second pipeline enters the combustion section via the cooling section and the heat preservation section. A smoke exhaust opening is formed in the drying section. Through the arranged water disposer, smoke enters the tunnel brick kiln for dioxin decomposition after dust and other harmful matter in the smoke are disposed, and dioxin and other harmful matter in the smoke are effectively reduced. The refuse disposal system is wide in application range and low in investment cost.

Owner:重庆秋松环保科技有限公司

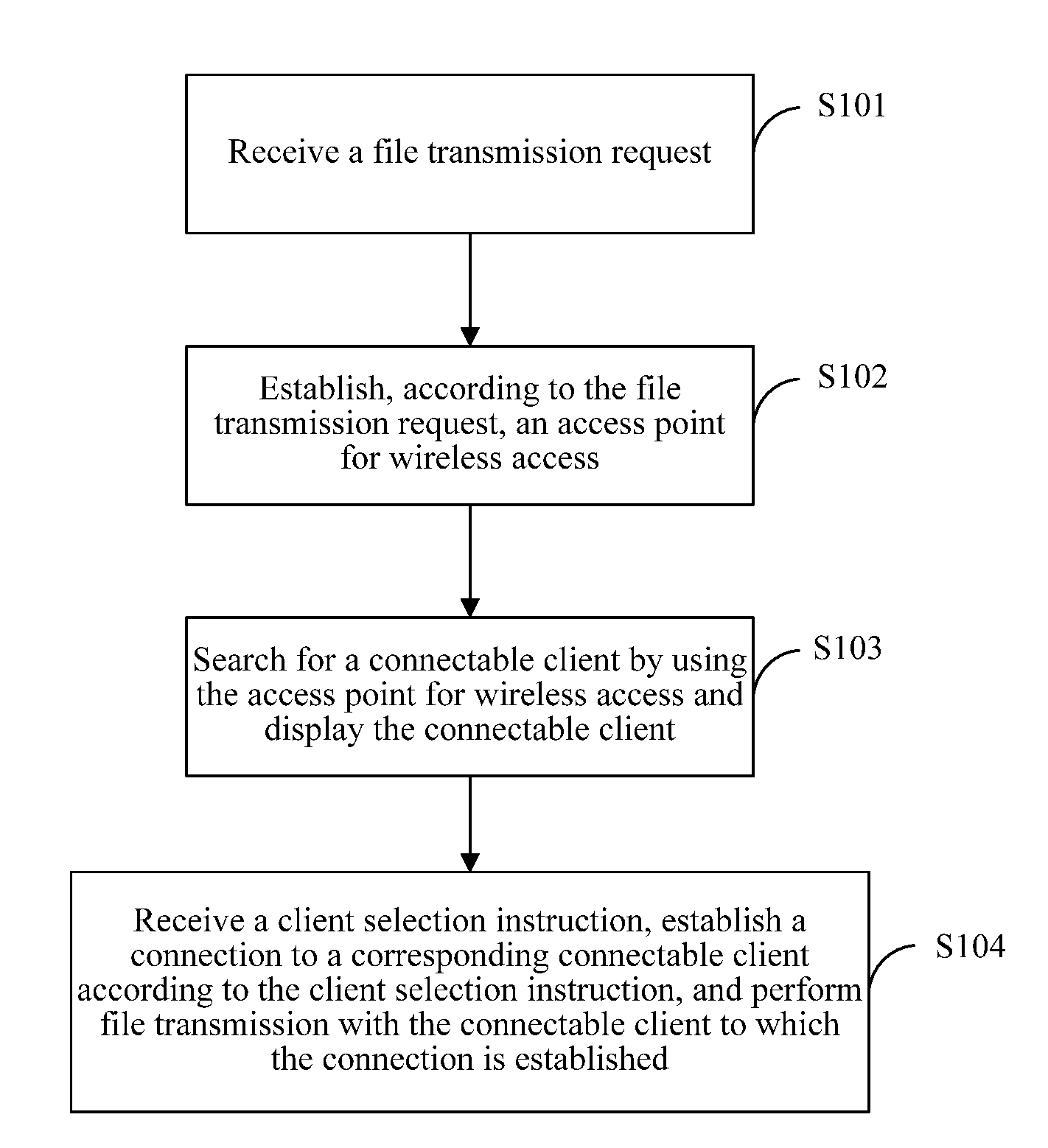

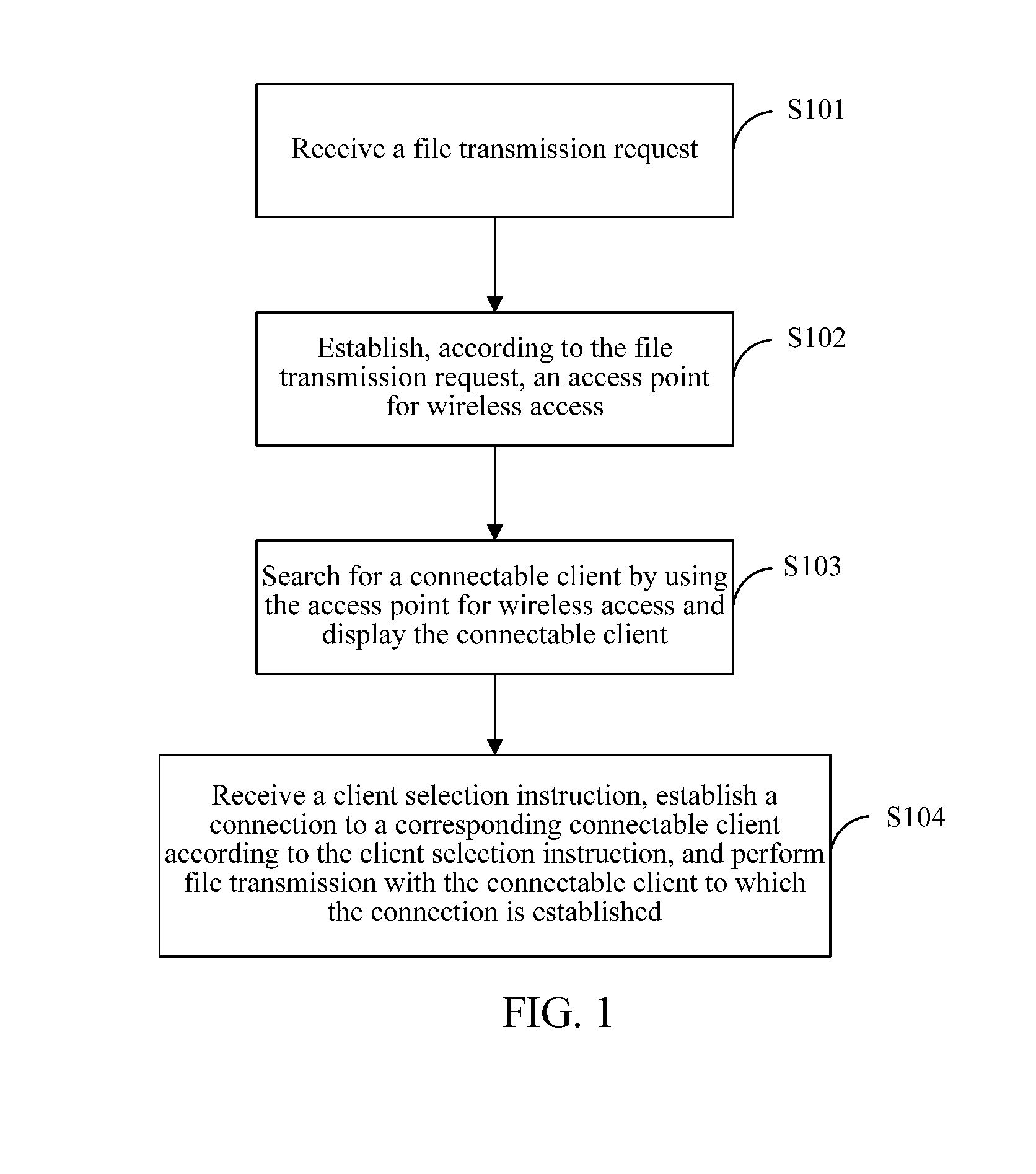

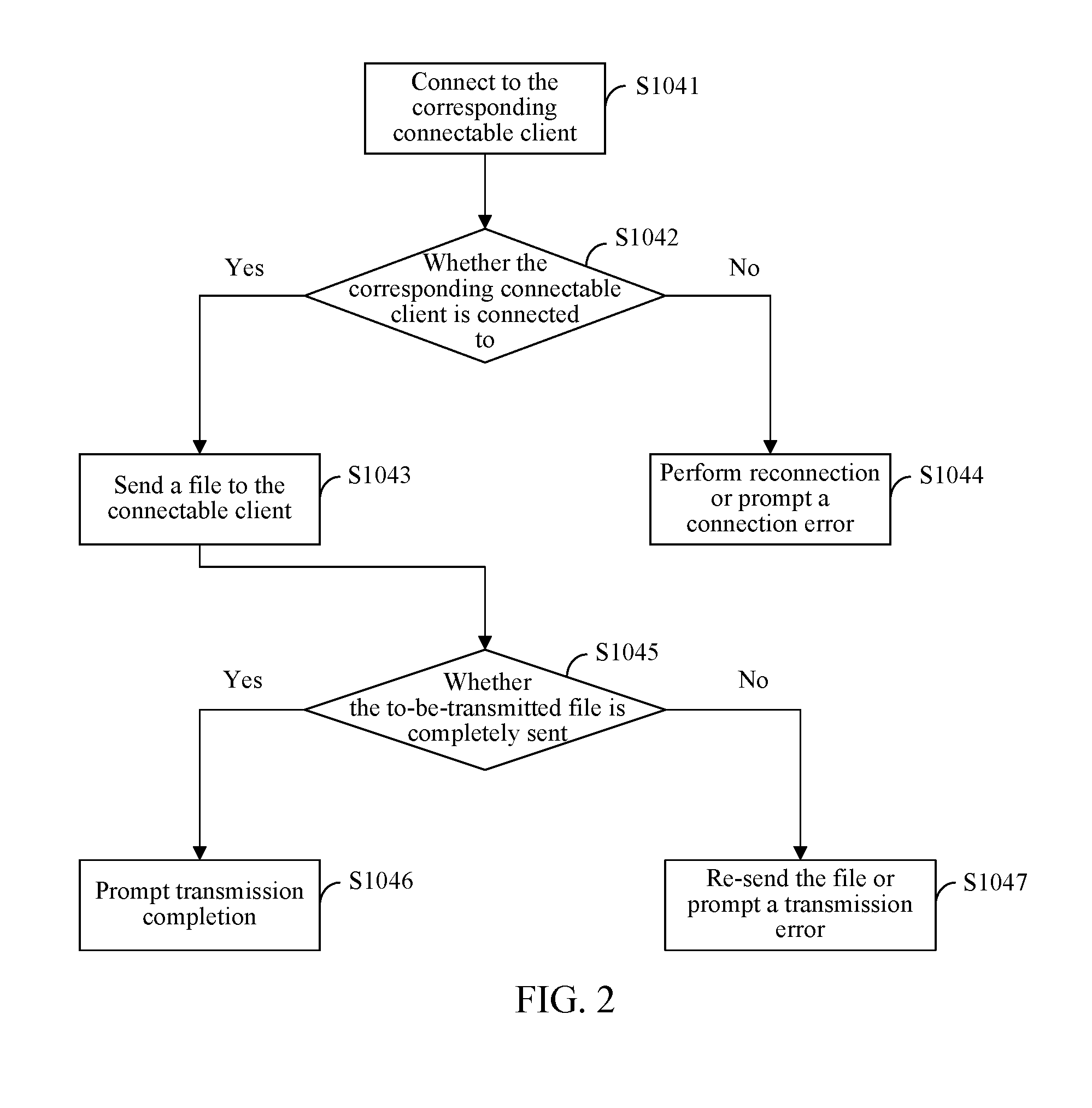

File transmission method, file transmission apparatus, and file transmission system

InactiveUS20170019459A1Reduce transmission speedSolve the real problemError prevention/detection by using return channelAssess restrictionFile transmissionClient-side

A file transmission method, a file transmission apparatus, and a file transmission system are described. The method includes: receiving a file transmission request from an application, where the file transmission request includes a position and a filename of a to-be-transmitted file; establishing, in response to receiving the file transmission request, a wireless access point; searching for at least one connectable client by using the wireless access point; displaying the at least one connectable client in a form of a list; receiving a selection instruction for a connectable client in the list; and establishing a connection to the connectable client corresponding to the selection instruction and sending the to-be-transmitted file having the filename and at the position to the selected connectable client.

Owner:TENCENT TECH (SHENZHEN) CO LTD

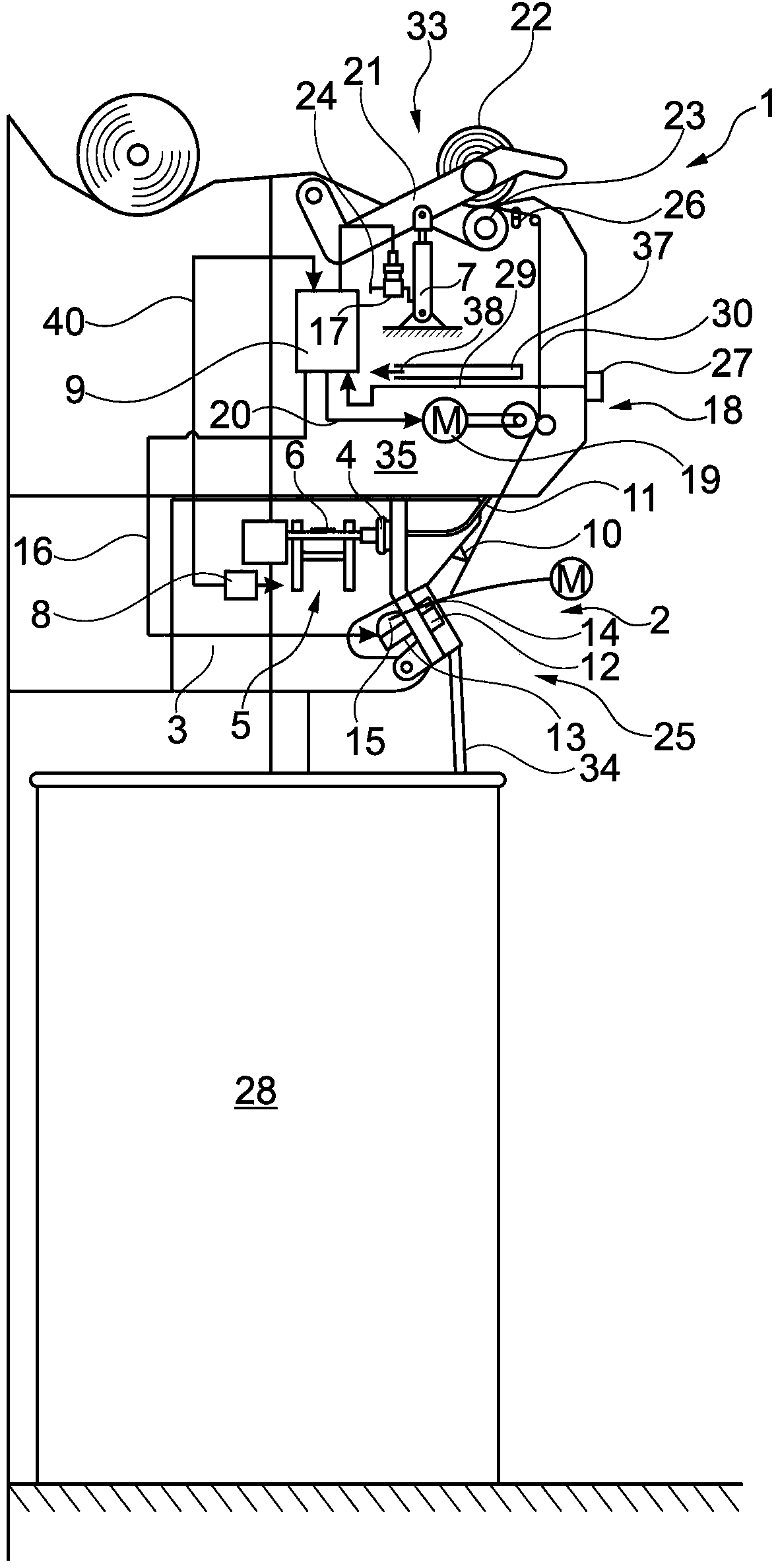

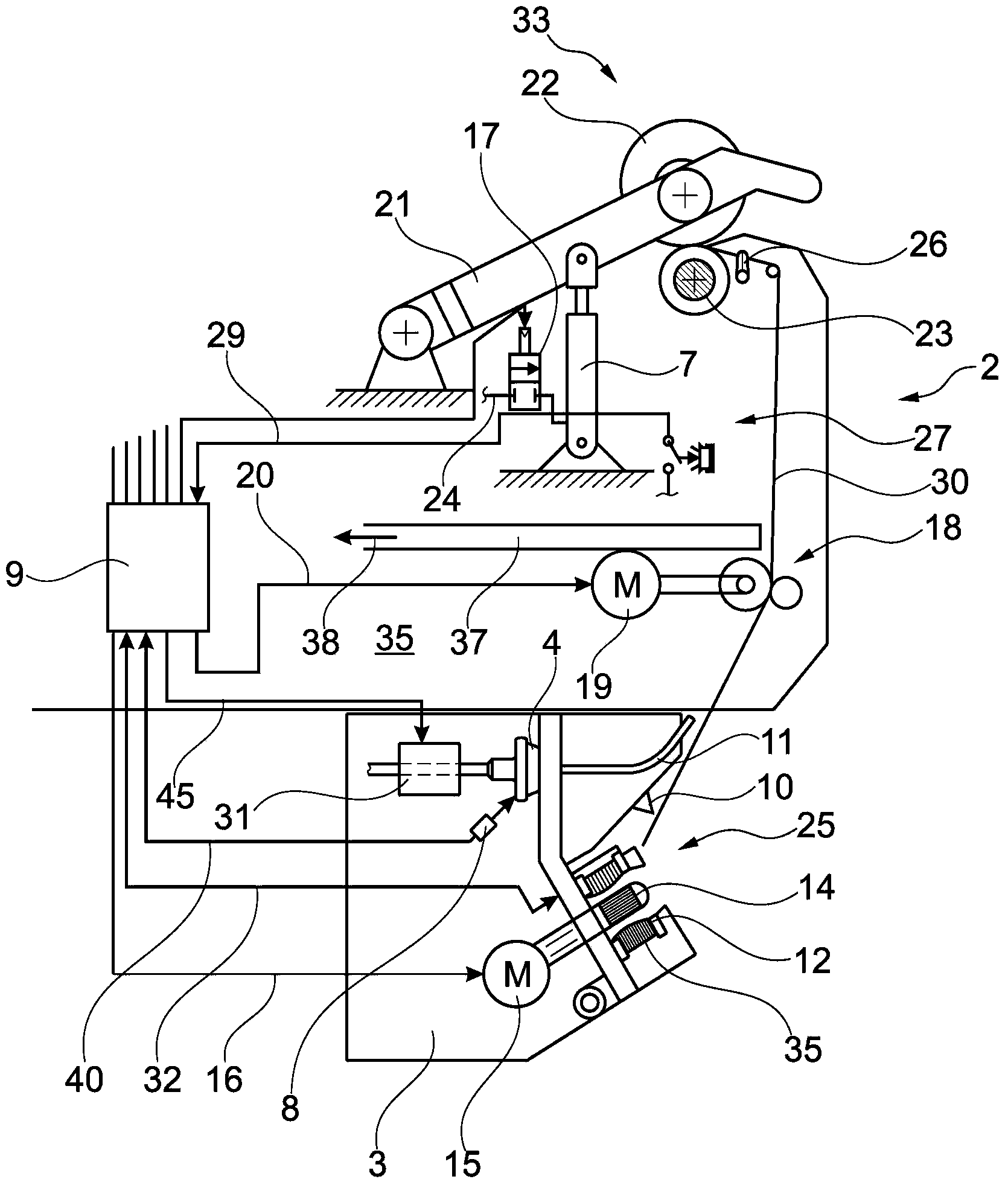

Method for operating a workstation of an open end rotary spinning machine and corresponding workstation

InactiveCN104233531ASmall sizeSmall fluctuationContinuous wound-up machinesOpen-end spinning machinesYarnBobbin

The invention relates to a method for operating a workstation of an open end rotary spinning machine and a corresponding workstation. The workstation is provided with the open end rotary spinning machine having a spinning machine capable of high speed rotation in a rotary cup housing; a fiber ribbon opening mechanism having an opening roller and a fiber ribbon supply drum drivn by a separate motor; a yarn removing mechanism driven by the separate motor to transport finished yarns; a yarn storage mechanism for halfway temporary storage of yarns with a certain length; and a winding device for generating a cross winding bobbin rotatably held in a creel. According to the invention, in the splicing process after the interruption of the winding at the workstation (2), the yarn transport speed of the finished yarns (30) from the yarn removing mechanism (18) is temporarily reduced to such a level lower than a predetermined yarn transport speed at the corresponding workstate in the spinning process.

Owner:SAURER GERMANY GMBH & CO KG

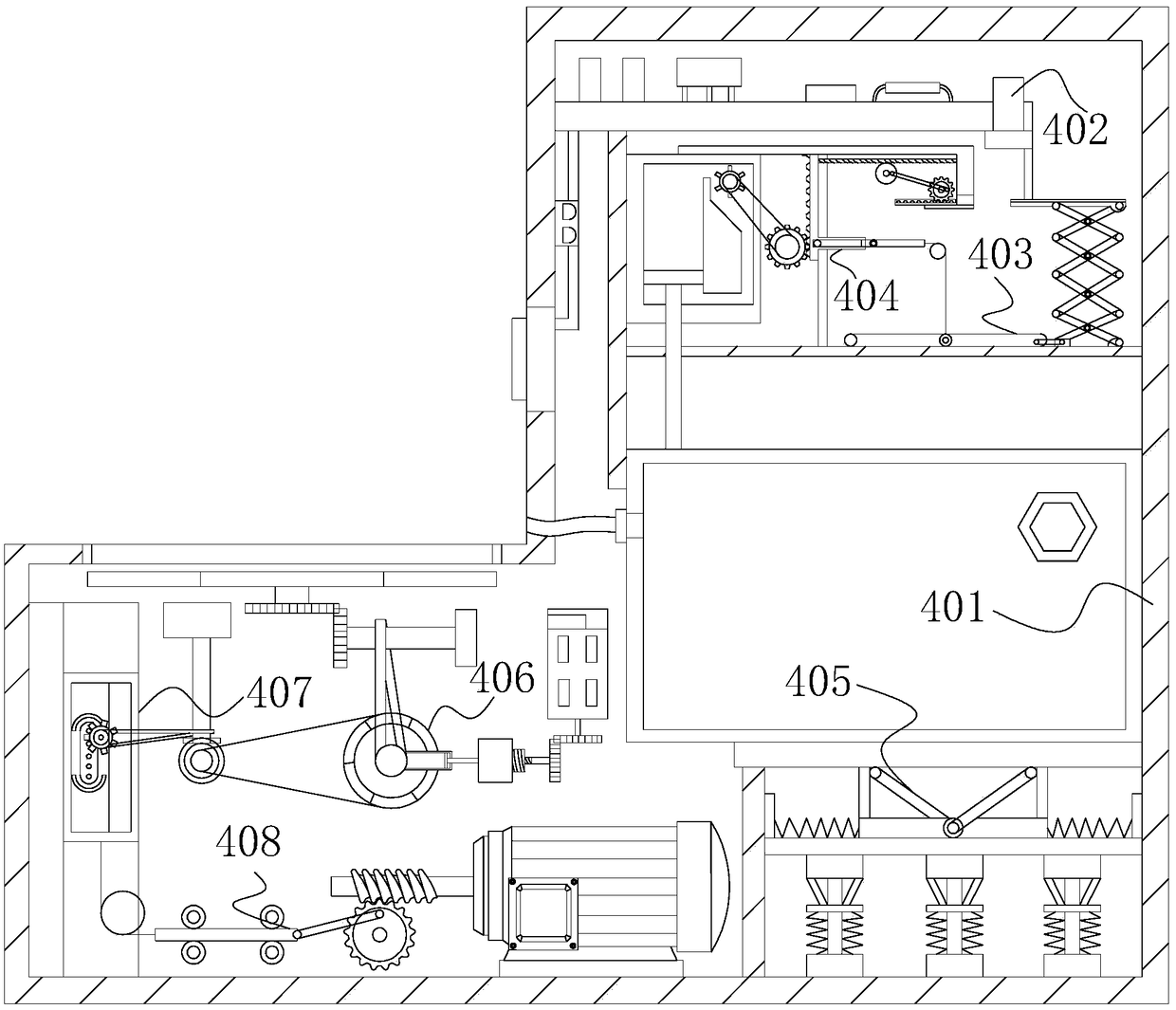

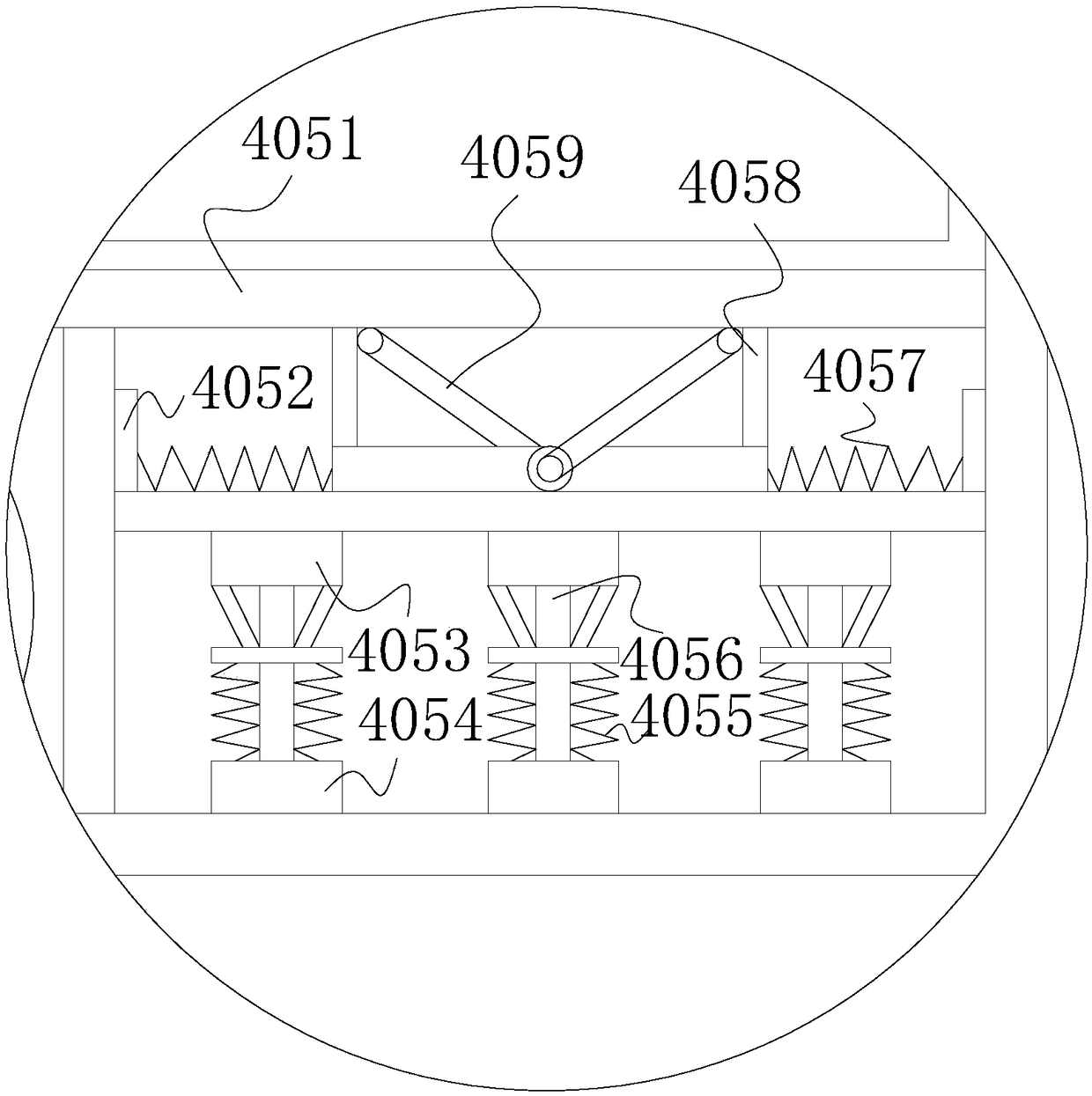

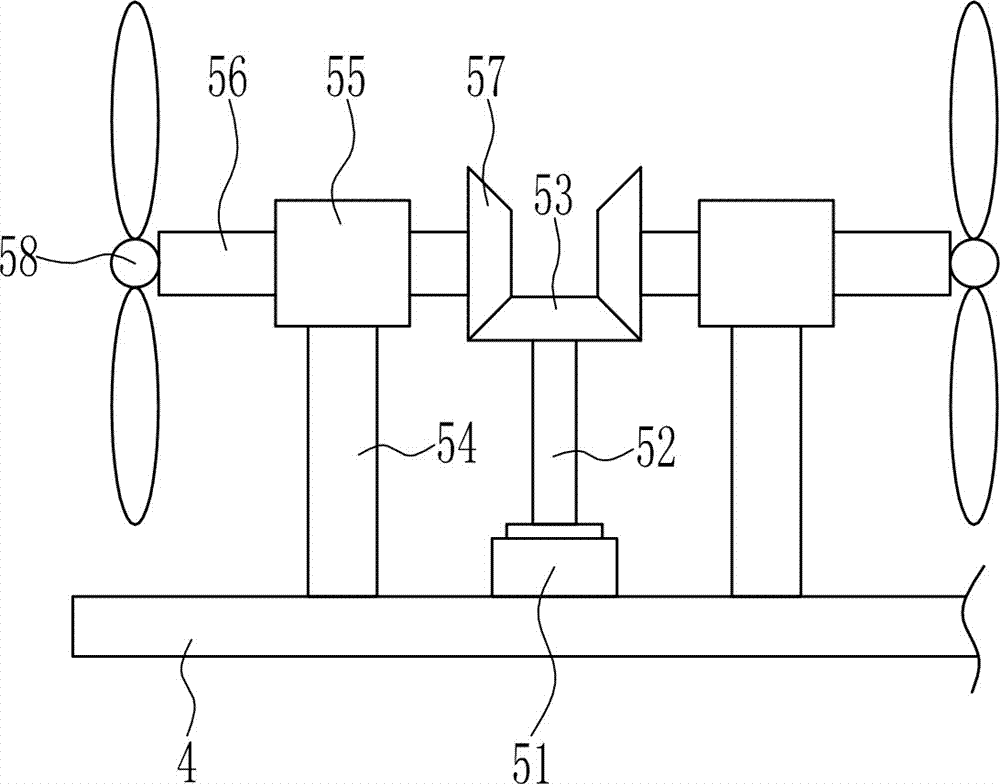

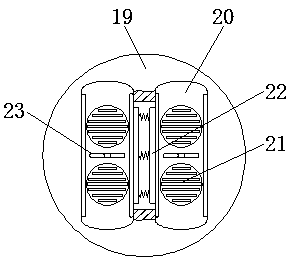

Air rapid cycle device within plant for metallurgical steelmaking

InactiveCN107957107ASpeed up the convection cycleQuick exchangeLighting and heating apparatusFree-cooling systemsSteelmakingAir cycle

The invention relates to a cycle device, in particular to an air rapid cycle device within a plant for metallurgical steelmaking. The air rapid cycle device within the plant for the metallurgical steelmaking can quickly adjust an air convection cycle speed, reasonably adjust the use range of the device, and increase the air humidity. The air rapid cycle device within the plant for the metallurgical steelmaking comprises a first mounting plate, a sliding rail, sliding blocks, a second mounting plate and so on; and the sliding rail is embedded into the left side of the top of the first mountingplate, the top of the sliding rail is symmetrically connected with sliding blocks in a left-right and sliding mode, the top of the sliding blocks at the left and right sides is provided with the second mounting plate, and the top of the second mounting plate is provided with an air cycle device. According to the air rapid cycle device within the plant for the metallurgical steelmaking, first vanesat the left and right sides rotate at a high speed, the air convection cycle speed is accelerated to facilitate a quick exchange of air in the plant and outside air, and a comfortable and safe working environment for workers is created.

Owner:内蒙古禄源联动机械制造有限公司

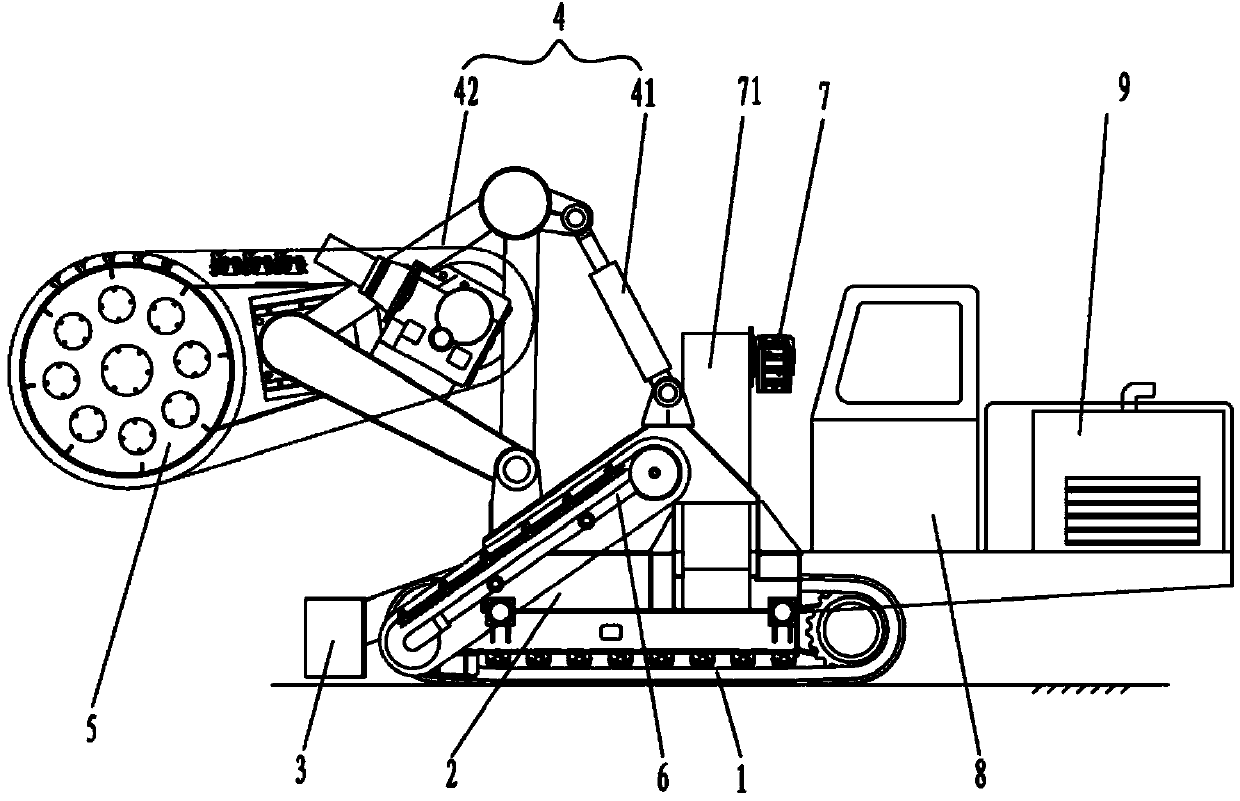

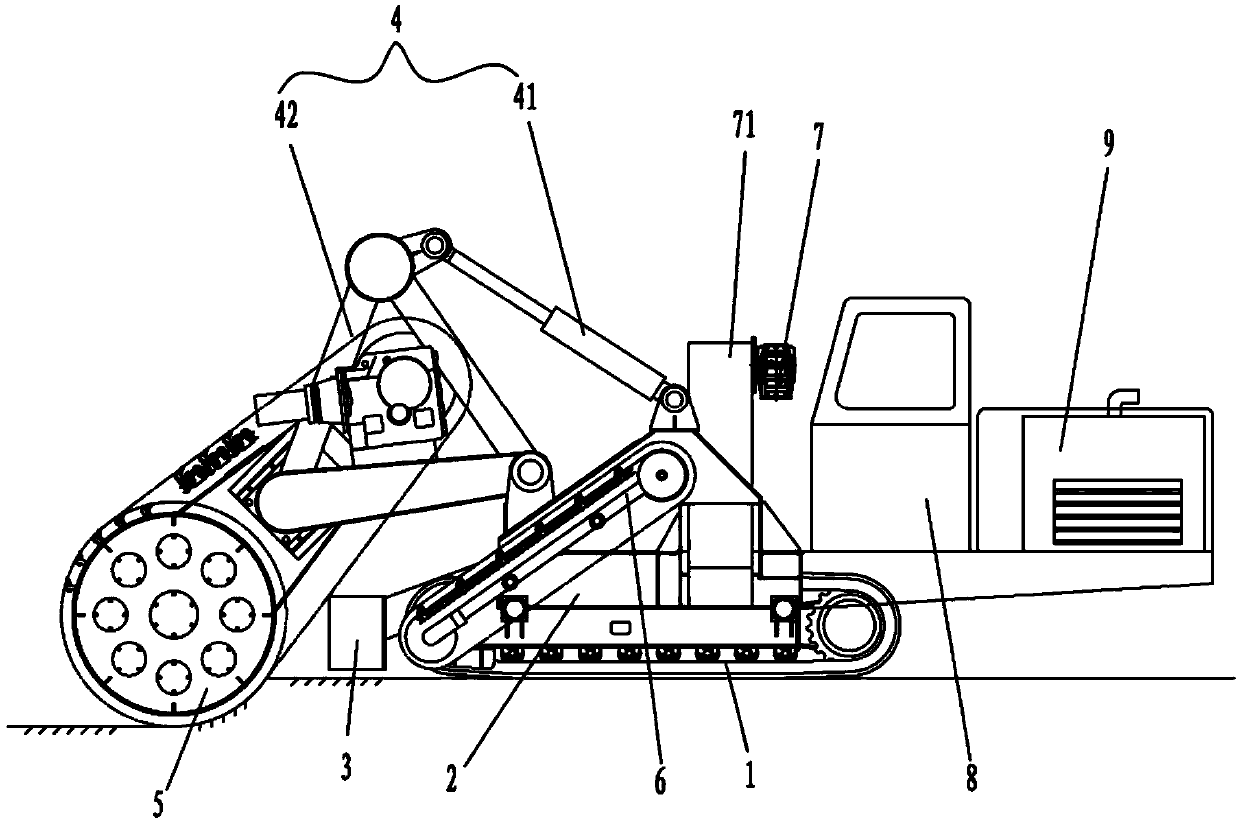

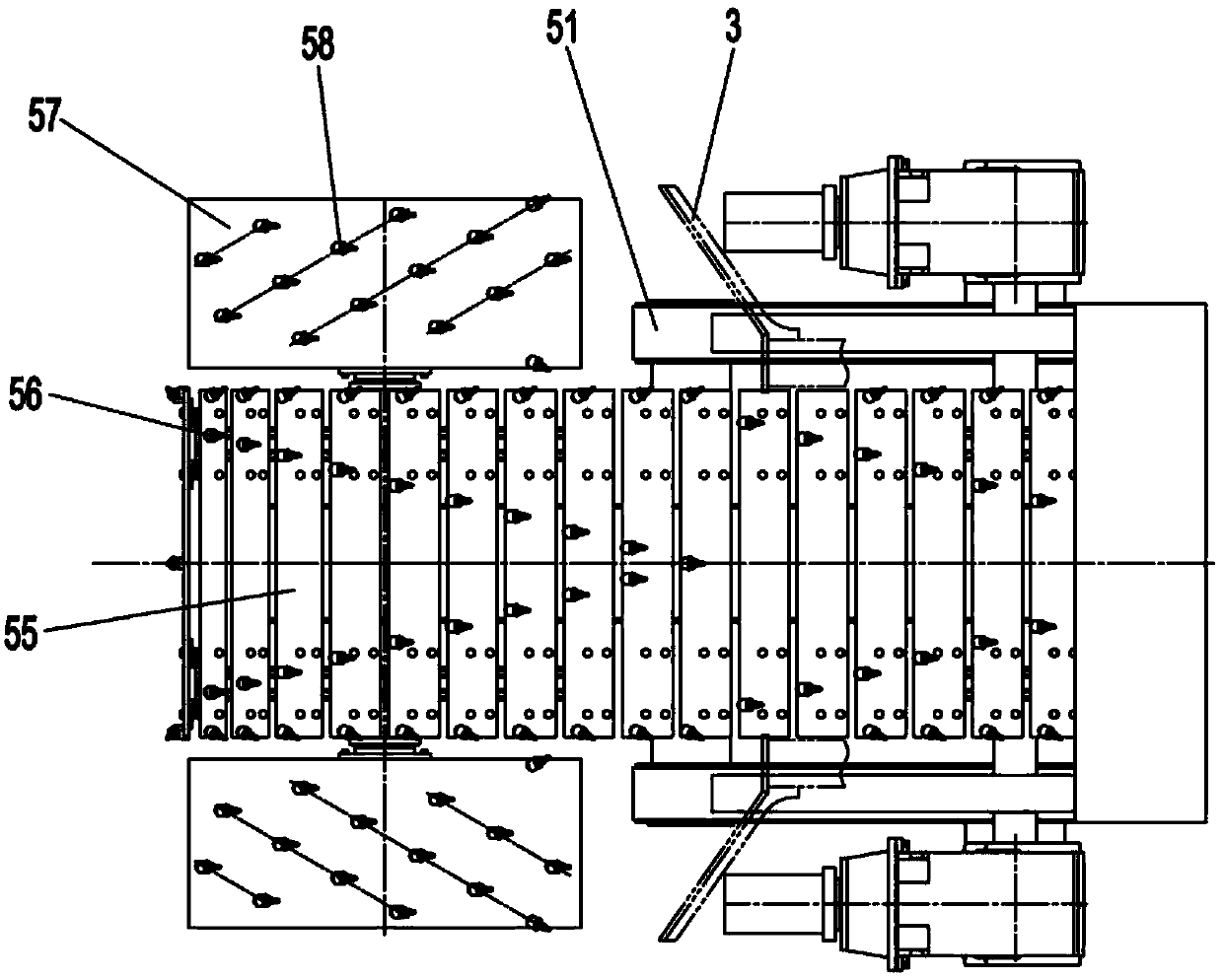

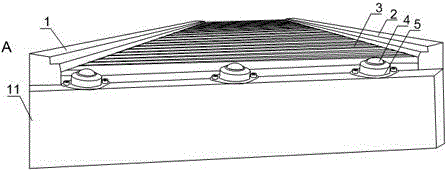

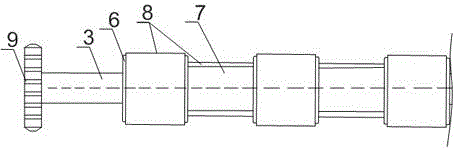

Ditcher

ActiveCN103741742AImprove efficiencyReduce energy consumptionSoil-shifting machines/dredgersIntegrated operationsEngineering

The invention provides a ditcher. The ditcher comprises a cab, a hydraulic transmission system and an action system, wherein the cab is used for monitoring and controlling actions; the hydraulic transmission system is used for supplying a stable power; the action system is used for executing action instructions sent by the cab; the action system comprises a track assembly, a chassis, a depth control device, a milling device, a material collection device and a discharge device. The action system comprised by the ditcher is capable of digging while walking, and realizing the integrated operation from digging to feeding, and the ditcher is a high-efficiency, low-energy-consumption, low-pollution and continuous mechanical device for milling soil and stone (ores), without damages to peripheral earth surface.

Owner:湖北道一专用机械有限公司

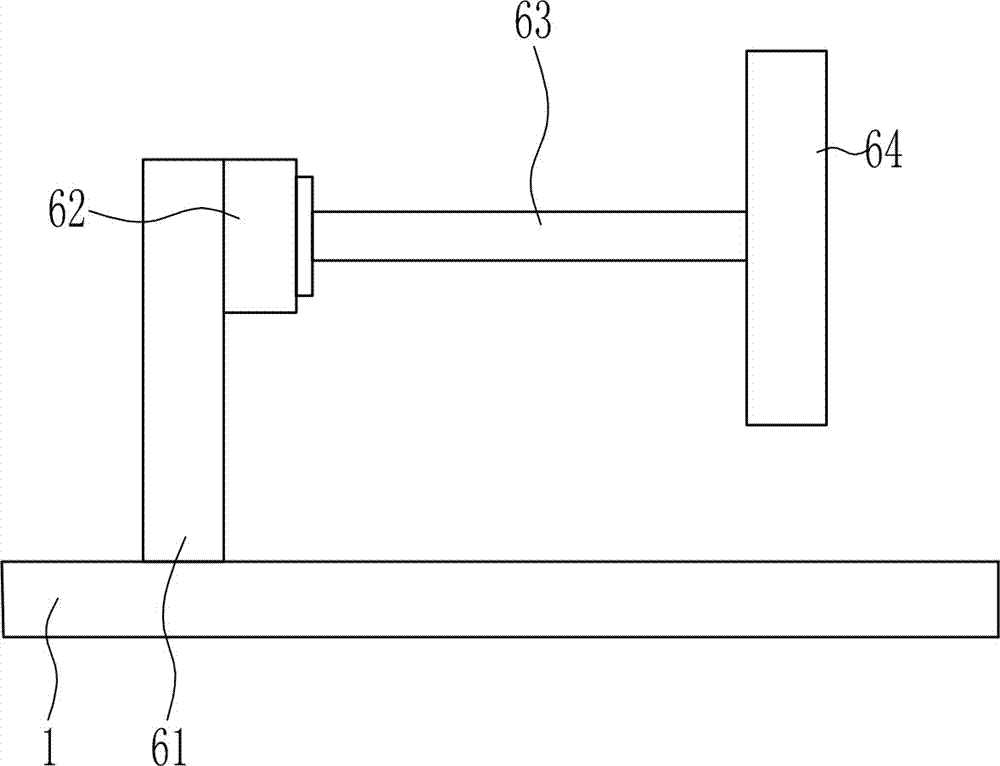

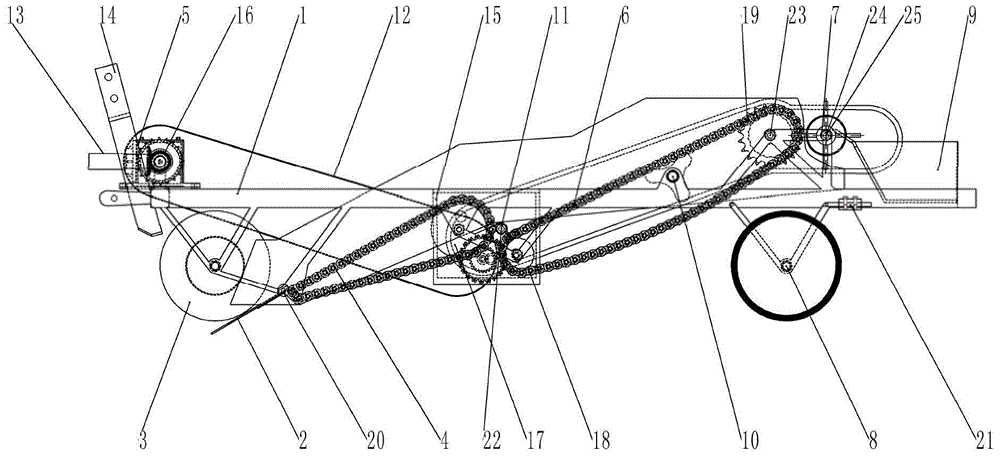

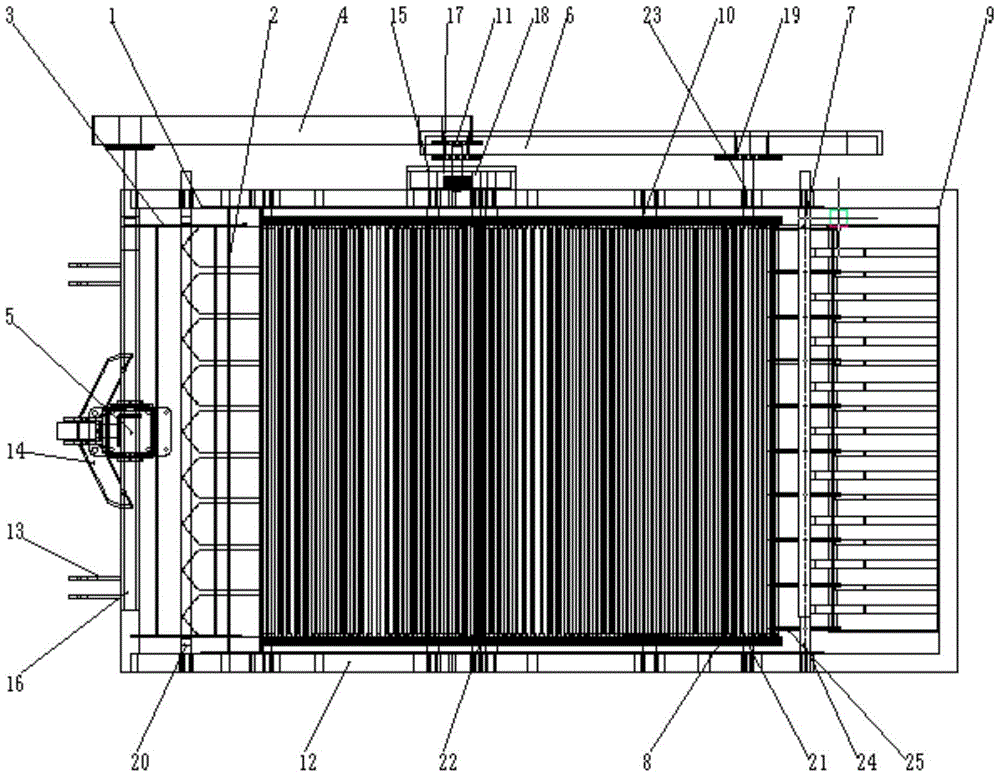

Automotive glass transmission device

InactiveCN103979248AAvoid position shiftReduce the chance of damageRoller-waysTransition functionEngineering

The invention discloses an automotive glass transmission device which comprises a supporting frame, a motor, a left blocking plate, a right blocking plate and a round roller. The motor is arranged in the supporting frame, the left blocking plate and the right blocking plate are arranged at two ends of the supporting frame, the round roller is rotatably arranged between the left blocking plate and the right blocking plate, the left blocking plate and the right blocking plate are provided with chains, and gears are installed at two ends of the round roller and the output end of the motor and matched with the chains. The automotive glass transmission device further comprises an auxiliary supporting structure on the supporting frame. The round roller can enable different varieties of glass to be stably placed on a conveying plane and prevent the glass positions from deviating, the auxiliary supporting structure arranged on the supporting frame can have a transition function, the glass and the inlet position of a processing device can be unified, collision between the glass and the supporting frame or the processing device is reduced, and the glass damage rate is also reduced while the conveying efficiency is improved.

Owner:CHENGDU HAILINGDA MACHINERY

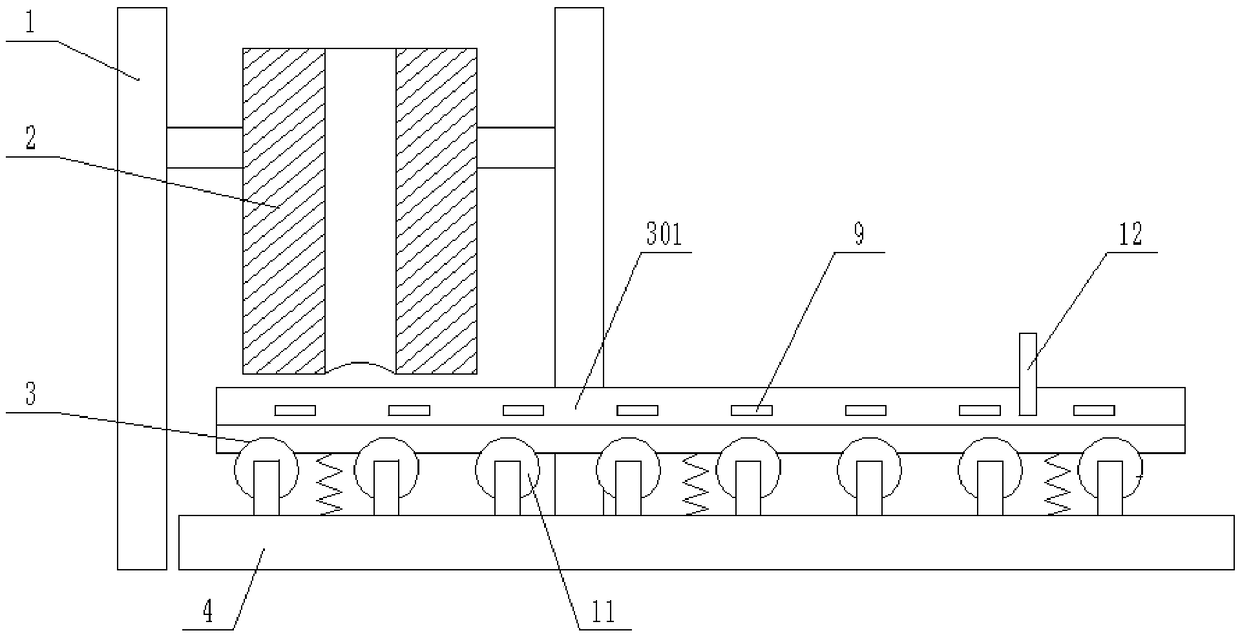

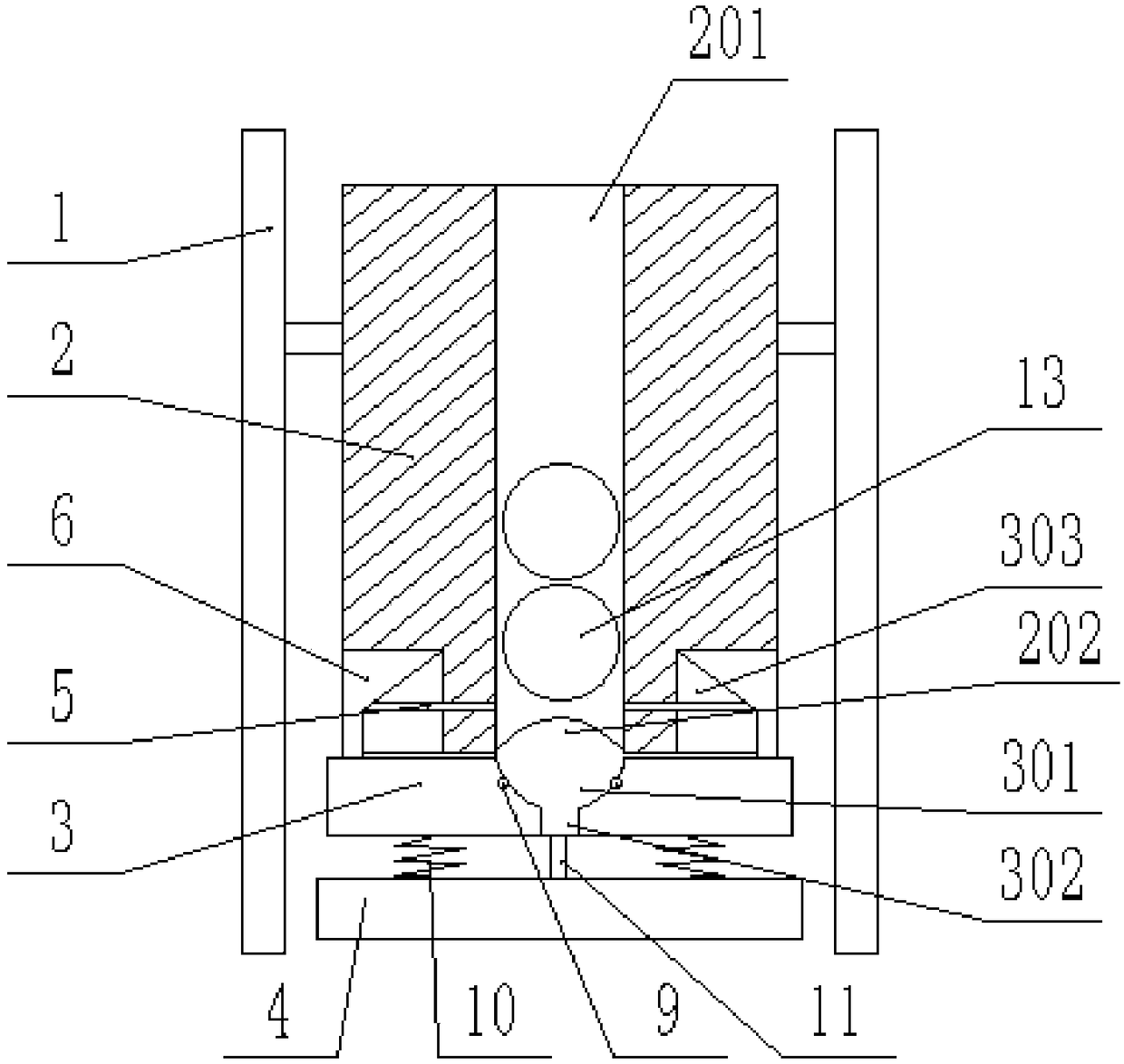

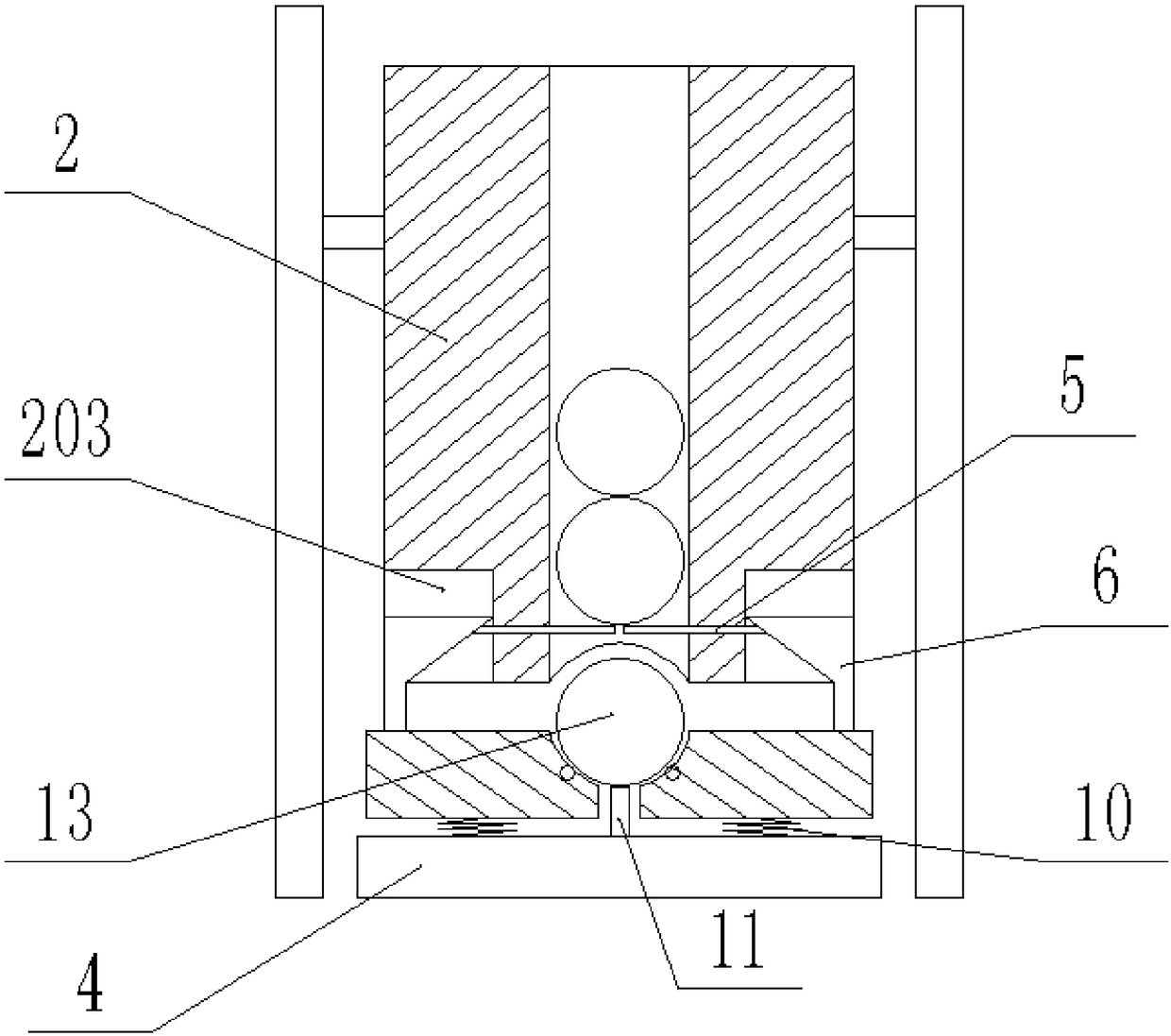

Blocked stack system for sheet positioning and paging and method thereof

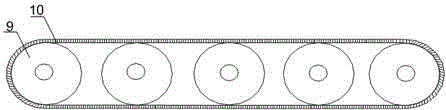

ActiveCN101638192ARealize counting quantitative stackingRealize counting and quantitative stackingArticle deliveryLow speedElectric machinery

The invention discloses a blocked stack system for sheet positioning and paging and a method thereof. The system comprises a frame, a controller, a counter, an upper pressing belt arranged at the upper part of the frame, a low-speed conveying belt 1 and a low-speed conveying belt 2 respectively arranged at the left side and the right side of the frame, and power motors respectively providing powerfor the low-speed conveying belt 1 and the low-speed conveying belt 2; the height of a horizontal section at the upper part of the low-speed conveying belt 1 is lower than that of a high-speed conveying belt of a paper cutter at the left of the low-speed conveying belt 1, and a matched paging part is arranged between horizontal sections at the upper part of the low-speed conveying belt 1 and thelow-speed conveying belt 2. The blocked stack method comprises the following steps: conveying sheets from left to right by the low-speed conveying belt 1 and the low-speed conveying belt 2, paging after arriving sheet stack sizes, quickly conveying following sheets to a stacking part after paging, and conveying the preceding sheets at a low speed. The blocked stack system has the advantages of reasonable design, convenient use and operation and good use effect, and can achieve the functions of no waste discharge and automatic stack change without shutting down machines.

Owner:SHANGHAI ZIDAN FOOD PACKAGING & PRINTING CO LTD +1

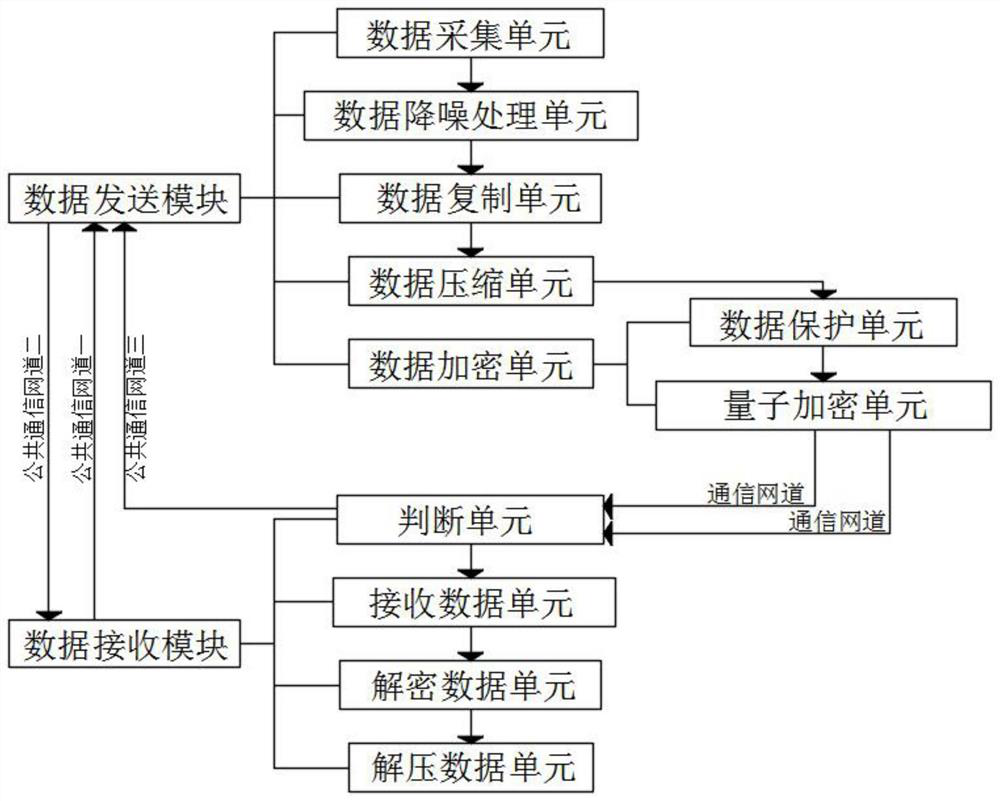

Video monitoring quantum encryption system

PendingCN113596386AAvoid cleavage teleportationIntegrity guaranteedKey distribution for secure communicationAnalogue secracy/subscription systemsVideo monitoringEmbedded system

A video monitoring quantum encryption system disclosed by the present invention comprises a data sending module and a data receiving module, the data sending module comprises a data collection unit, a data noise reduction processing unit, a data copying unit, a data compression unit and a data encryption unit, and the data encryption unit comprises a data protection unit and a quantum encryption unit. The data receiving module comprises a judgment unit, a data receiving unit, a data decryption unit and a data decompression unit. By arranging the data noise reduction processing unit and the data compression unit, the memory size in the data encryption transmission process can be reduced, the transmission speed of the encrypted data is further ensured, the data copying unit is further installed, batch encryption transmission of the data can be achieved, data cracking transmission is avoided. In addition, due to the arrangement of the data protection unit, the corresponding data are destroyed when the data are interfered and intercepted by a third party, and then data leakage is avoided.

Owner:施航

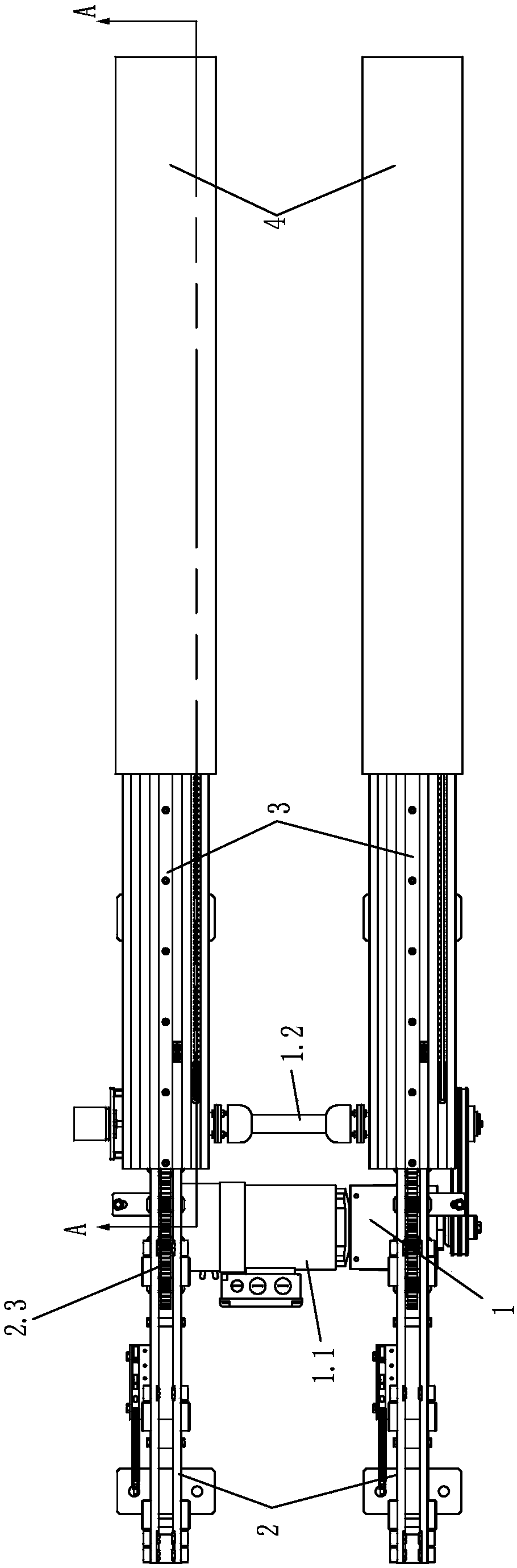

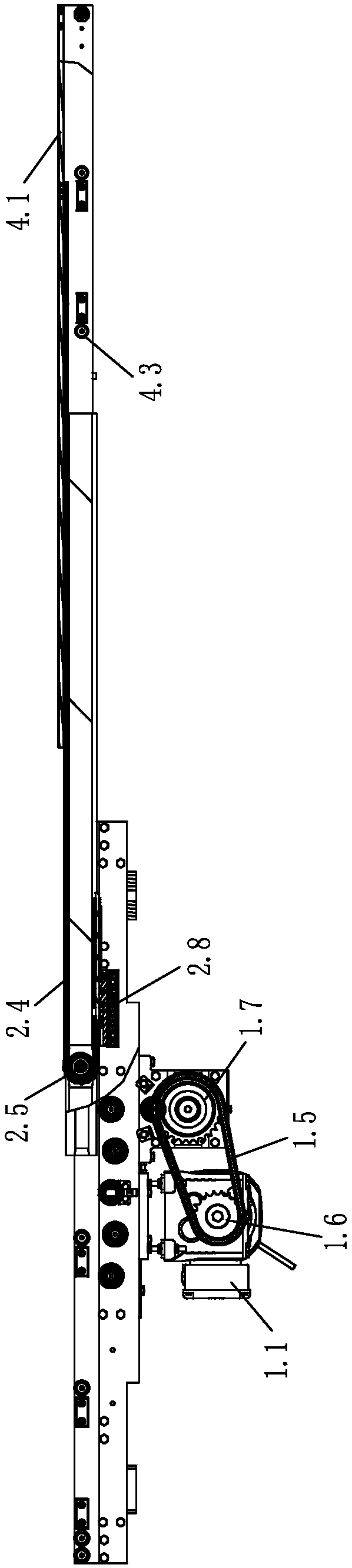

Double-arm large-stroke bidirectional fork device

The invention discloses a double-arm large-stroke bidirectional fork device. The double-arm large-stroke bidirectional fork device comprises a left fork body unit and a right fork body unit. The double-arm large-stroke bidirectional fork device is characterized in that each fork body unit comprises an upper fork body unit, a middle fork body unit and a lower fork body unit; the left fork body unit and the right fork body unit are synchronously driven through a drive unit; the drive unit comprises a motor, a transmission belt, a belt wheel, a drive shaft, a left drive gear and a right drive gear; an output shaft of the motor drives the belt wheel through the transmission belt; the belt wheel is arranged on the drive shaft in a sleeving manner; the left drive gear and the right drive gear are arranged on the drive shaft separately; the left drive gear and the right drive gear are in engagement connection with the transmission gear separately; the transmission gear is engaged with a gear group in the lower fork body unit; and a rack in the middle fork body unit is driven to move by the gear group. According to the double-arm large-stroke bidirectional fork device disclosed by the invention, the drive unit drives the gear group by virtue of the transmission gear, the middle fork body and the upper fork body are driven to synchronously move, and a rotation direction of the gears is changed to control a movement direction of the fork bodies, so that bidirectionally free cargo carrying is realized.

Owner:太仓爱致递机器人自动化有限公司

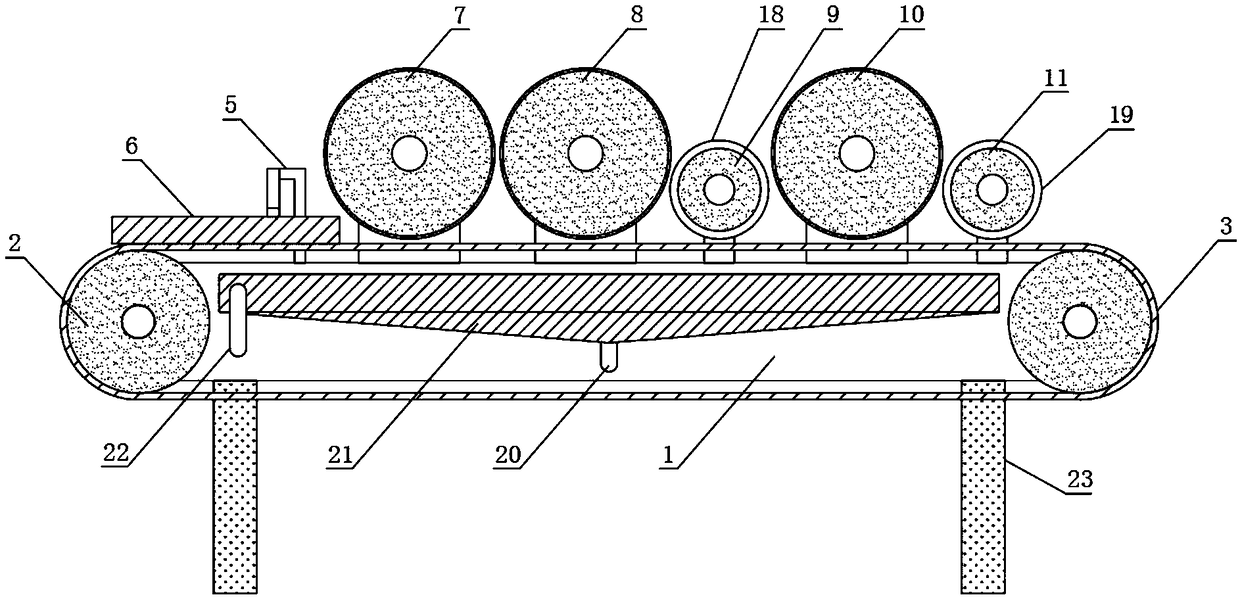

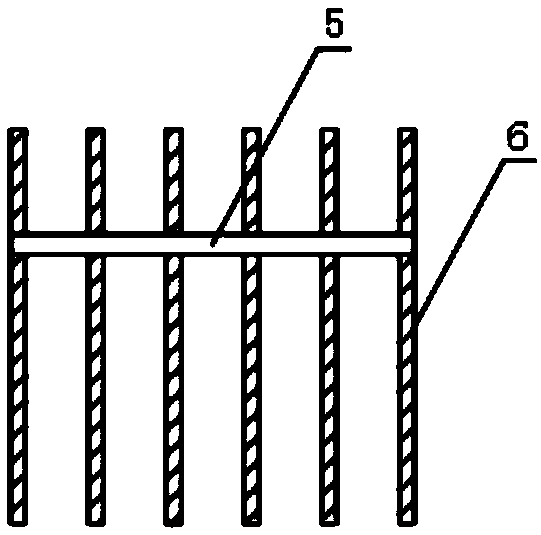

Stripping device of wicker stripping machine

The invention discloses a stripping device of a wicker stripping machine. The stripping device comprises lathe bodies, a conveying roller set is arranged between the lathe bodies, the outer side of the conveying roller set is sleeved with a conveying belt in a connected manner, a slag outlet hole penetrates the conveying belt, an installing support is fixedly arranged on the tops of the lathe bodies, a plurality of separating plates are fixedly arranged on the bottom end of the installing support, a first grinding roller is arranged on one side of the installing support, a second grinding roller is arranged on one side of the first grinding roller, a skin removing roller is arranged on one side of the second grinding roller, a third grinding roller is arranged on one side of the skin removing roller, and a polishing roller is arranged on one side of the third grinding roller. By means of the stripping device, wickers roll back and forth on the conveying belt, and therefore wicker surface layer fiber looseness and cracking are facilitated; and meanwhile, it can be guaranteed that the wicker outer surfaces can be in contact with a steel brush layer, and therefor the good surface layer removing effect is achieved, the polishing effect can be more even, and the quality of the polished wickers is guaranteed.

Owner:霍邱县淮美奇工艺品有限公司

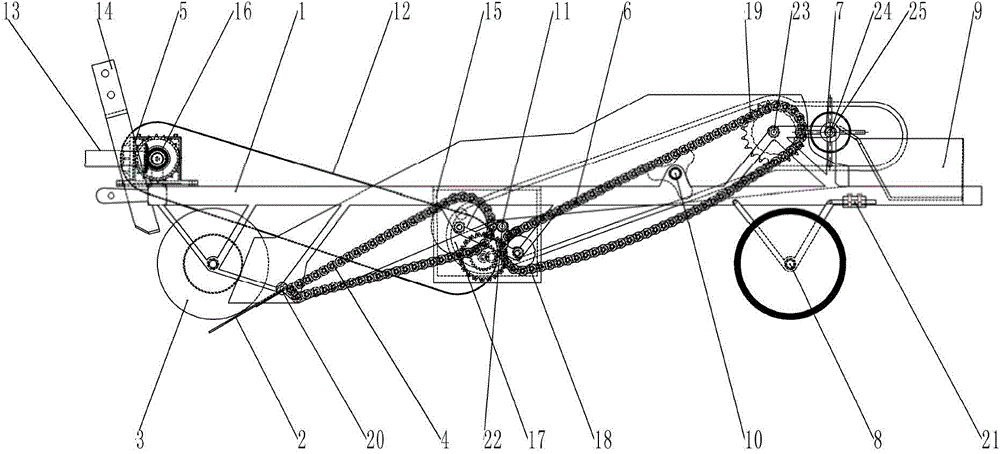

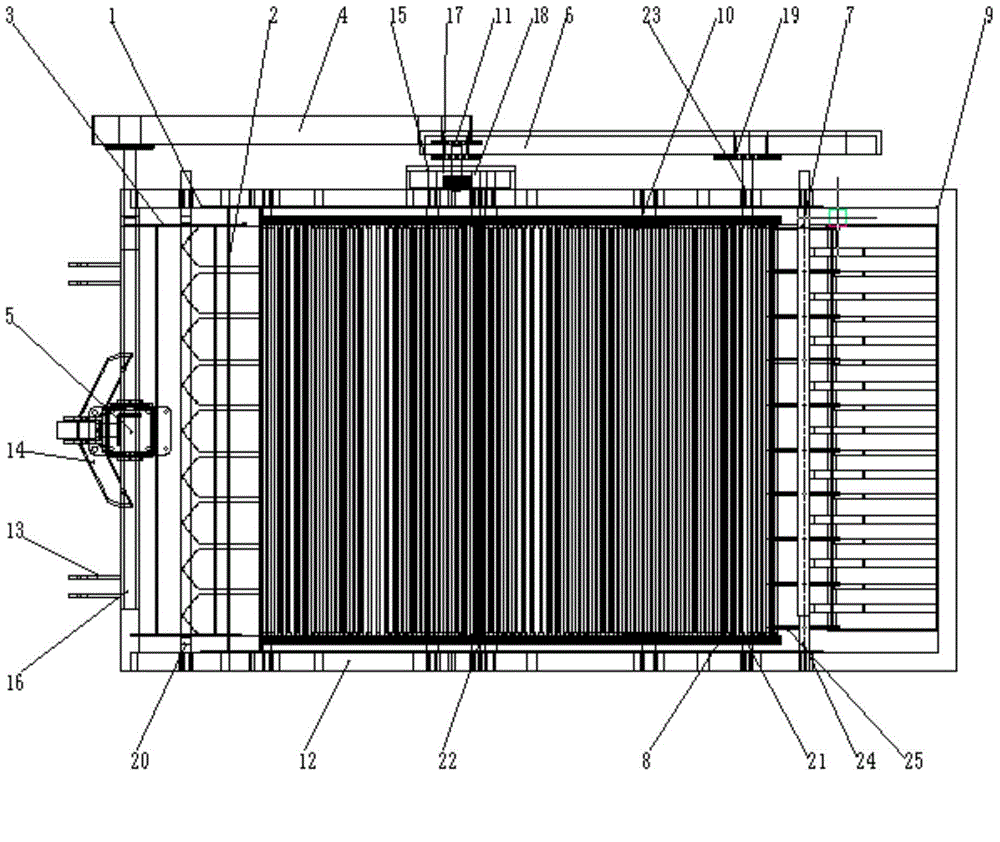

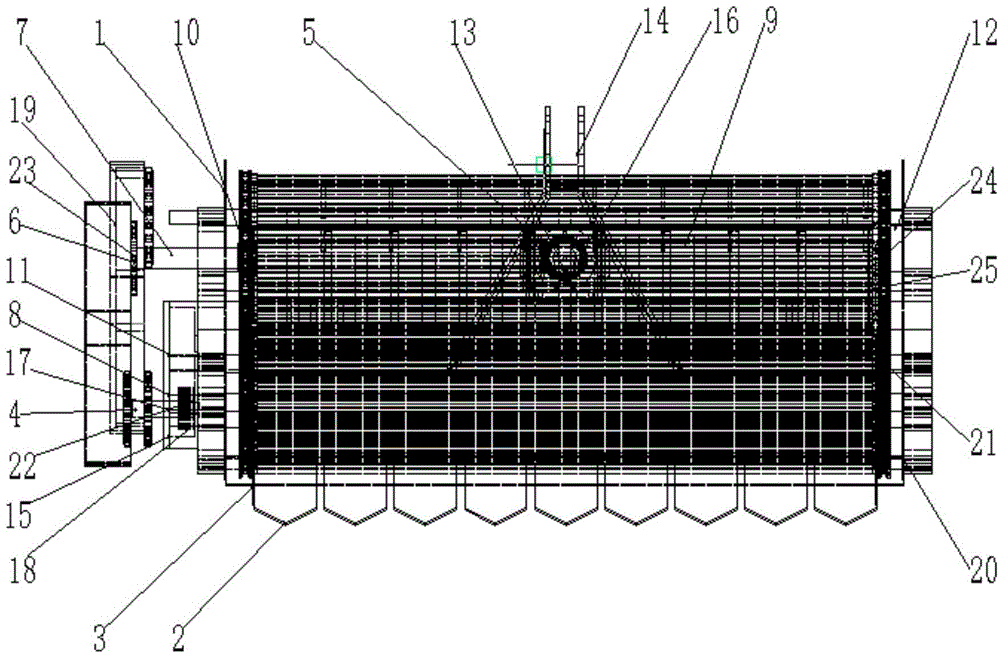

Potato multi-stage conveying and separation excavator

InactiveCN104855033AExtension of timeHigh transmission speedDiggersAgricultural engineeringExcavator

The invention relates to the technical field of potato harvest equipment in agricultural machinery, in particular to a potato multi-stage conveying and separation excavator. The excavator includes a machine frame and is characterized in that digging shovels are arranged at the lower front part of the machine frame; cutting discs and penetrating angle adjusting mechanisms are arranged on the two sides of the digging shovels; a conveying chain is arranged at the rear part of the digging shovels; a lifting-transporting type conveying separating chain is arranged at the rear part of the conveying chain; a vibrating roller is arranged in the middle of the lifting-transporting type conveying separating chain; a membrane and stem residual separating device is arranged at a corresponding position at the rear part of the lifting-transporting type conveying separating chain; a collecting box is arranged at the rear part of the membrane and stem residual separating device; a gearbox and a hanging rack are mounted at the upper front part of the machine frame; travelling support wheels are arranged at the lower rear part of the machine frame; a depth adjusting plate is arranged at a corresponding position on the machine frame at the upper end of the support wheels. According to the invention, the transmission speed of the conveying chain is higher than that of the separating chain, so that the probability of digging shovel blockage caused by the soil and potato mixture is reduced, and conditions are provided for the separating chain to further separate soil from potatoes; the separating effect is good without blockage, and defects in the prior art are effectively overcome.

Owner:GANSU AGRI UNIV

Automatic trademark-printing and packaging device for slipper production

The invention discloses an automatic trademark-printing and packaging device for slipper production. The automatic trademark-printing and packaging device comprises a printing frame, a conveying roller and arrangement frames. A protecting frame is mounted in the middle of the printing frame, and lubricating oil boxes are fixed to the left side and the right side of the protecting frame correspondingly; a rotating disc is mounted on the rear side of the protecting frame, a steel ruler pressing wheel is arranged on the outer side of the rotating disc and is in matched connection with the rotating disc through buckle plates, and balls are inlaid on the surface of the rotating disc; a preparation roller is mounted on the lower portion of the steel ruler pressing wheel, and an engraving conveying belt is arranged on the outer side of the preparation roller; a central shaft penetrates through the middle of the conveying roller, and the conveying roller is located below a trademark-printing roller; and crossbeams are fixed to the inner sides of the arrangement frames, and the arrangement frames are located on the second conveying belt. According to the automatic trademark-printing and packaging device for slipper production, trademarks are labeled orderly and accurately, finished slipper products are stably conveyed, position offset on a large extent is avoided during transporting ofthe finished slipper products, and the whole process is high in automation degree.

Owner:云和县东泽阀门有限公司

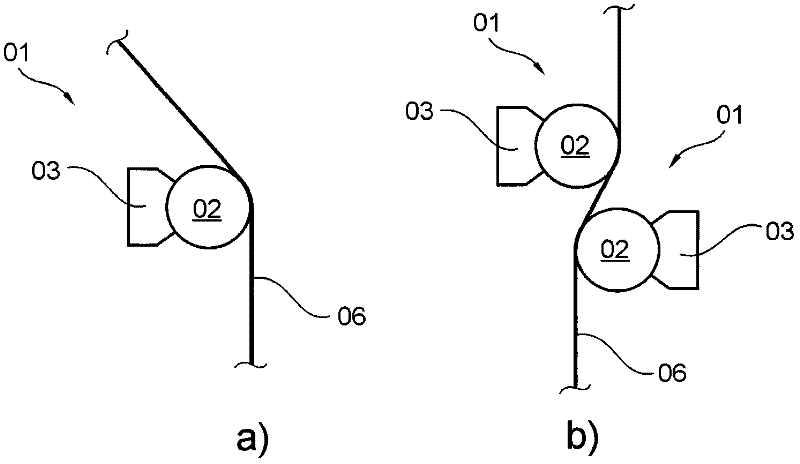

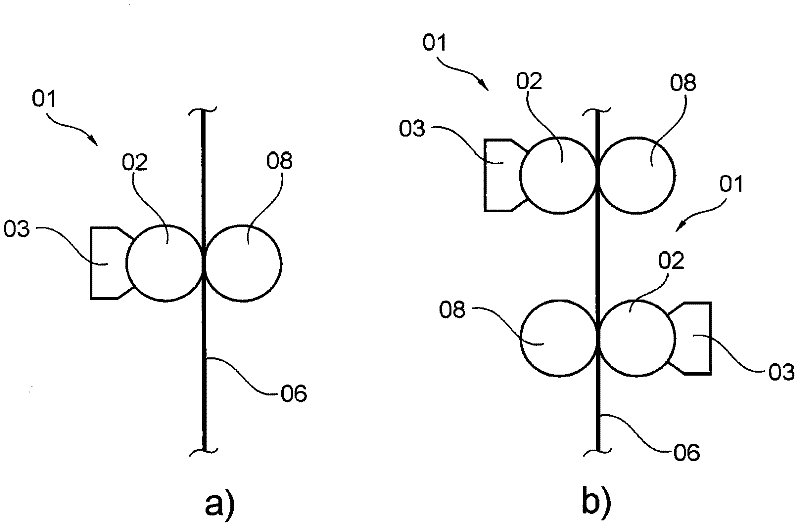

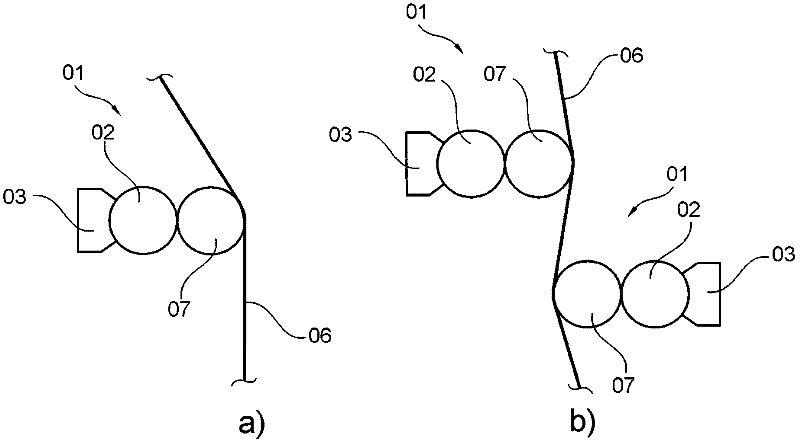

Roller rotary offset printing press having at least one coating unit with a chamber blade and an anilox roller

The invention relates to a roller rotary offset printing press having at least one coating unit (01) and at least one printing unit (11), wherein the coating unit comprises at least one chamber blade (03) comprising a water-based coating and at least one anilox roller (02), wherein the coating unit is arranged along a transport path of a print stock downstream of the at least one printing unit of the roller rotary offset printing press and wherein at least one pair of two rollers is arranged that together form a coating gap and wherein at least one roller of said at least one pair is in contact with the at least one anilox roller and wherein the conveyed volume at least on one part of the shell surface of the at least one anilox roller is filled by an amount of coating, the mass of which based on this part of the shell surface of the at least one anilox roller, minus a water portion, equals on average a maximum of 4 g / m2. A blanket having several layers can be placed or is placed on at least one roller of the coating unit.

Owner:KOENIG & BAUER AG

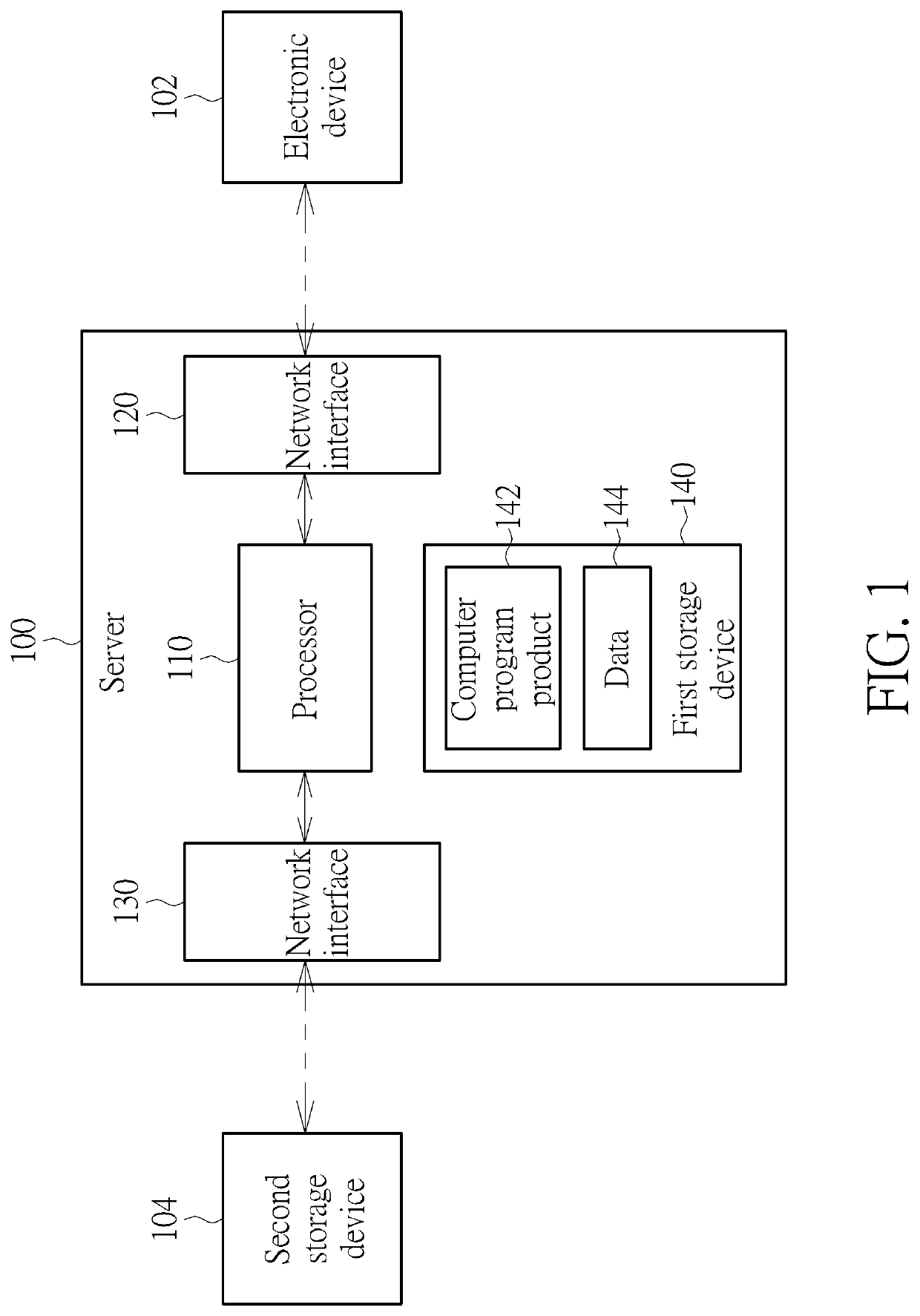

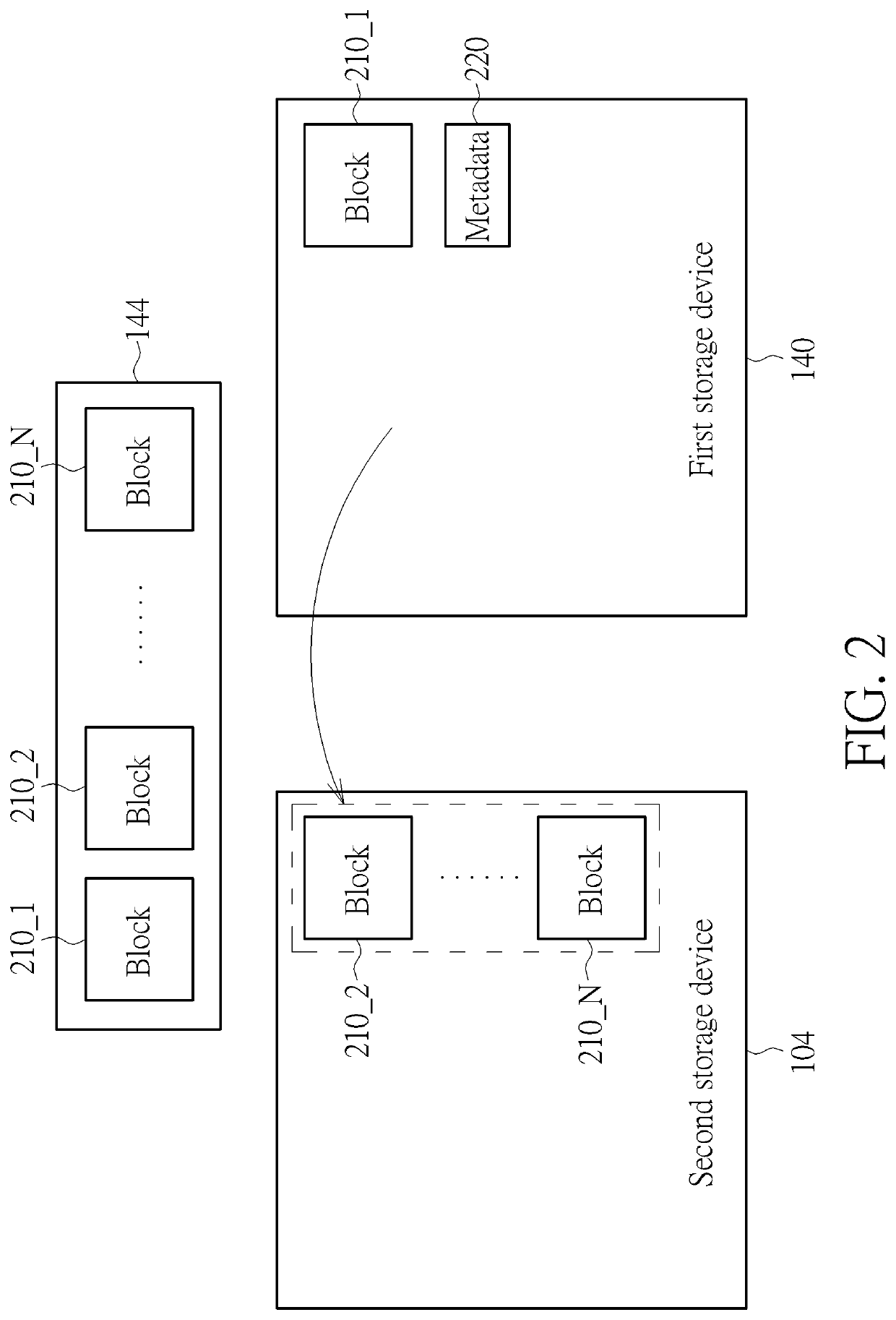

Server and associated computer program product using different tranmission speed for cold data tansmission

The present invention provides a sever which includes a network interface, a processor and a first storage device, wherein the processor is arranged for communicating with an electronic device via the network interface, and the first storage device stores data. In the operations of the server, the processor determines whether the data is cold data; and when the data is determined as the cold data, the processor moves a second portion of the data to a second storage device, and a first portion of the data is remained in the first storage device, wherein the data amount of the first portion is less than data amount of the second portion, and the access speed of the first storage device is higher than the access speed of the second storage device.

Owner:SILICON MOTION TECH HONG KONG LTD

Textile machine and method of operation thereof

ActiveCN102674080BRegulation stabilityAccurate transmission speed adaptabilityFilament handlingFiberMechanical engineering

Owner:RIETER INGOLSTADT GMBH

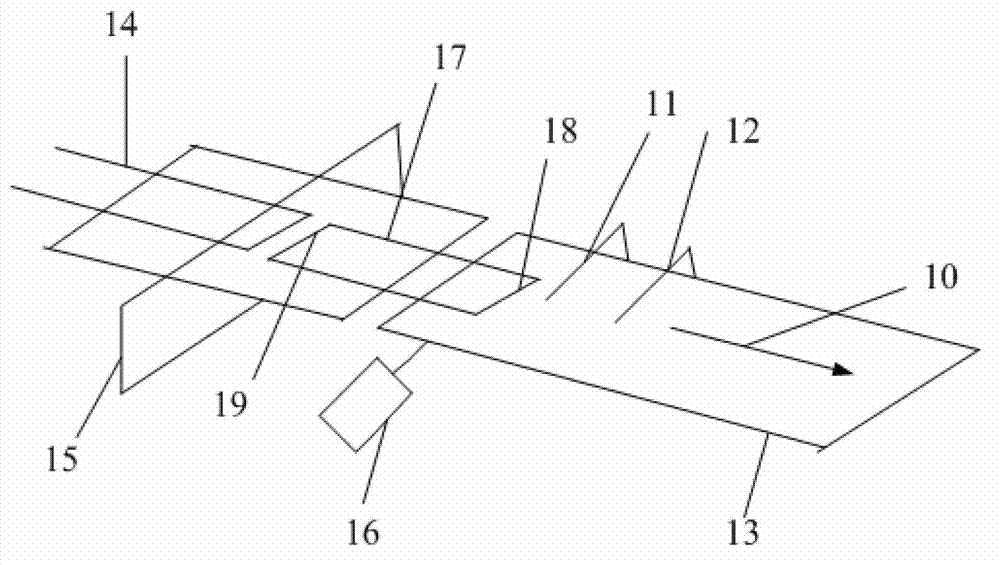

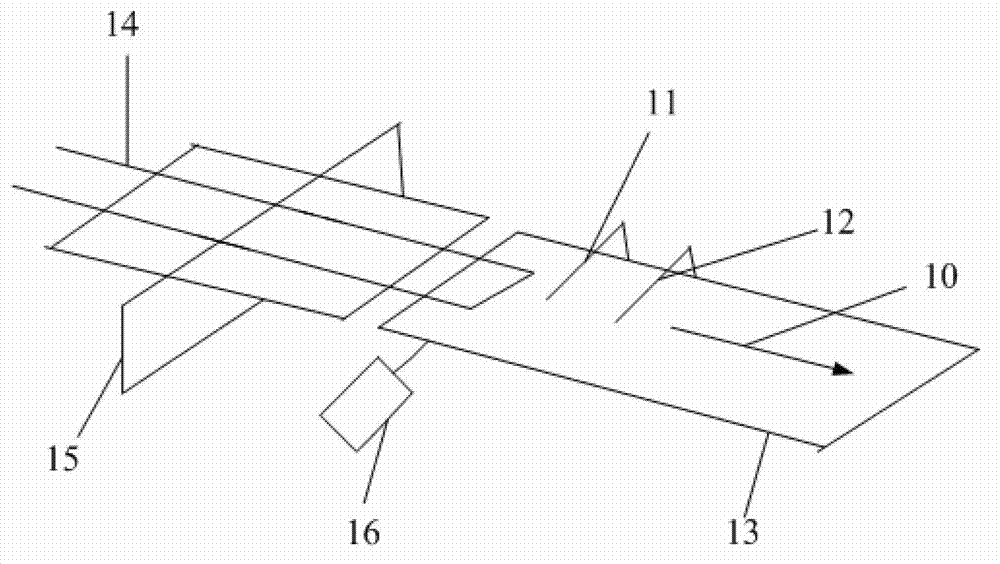

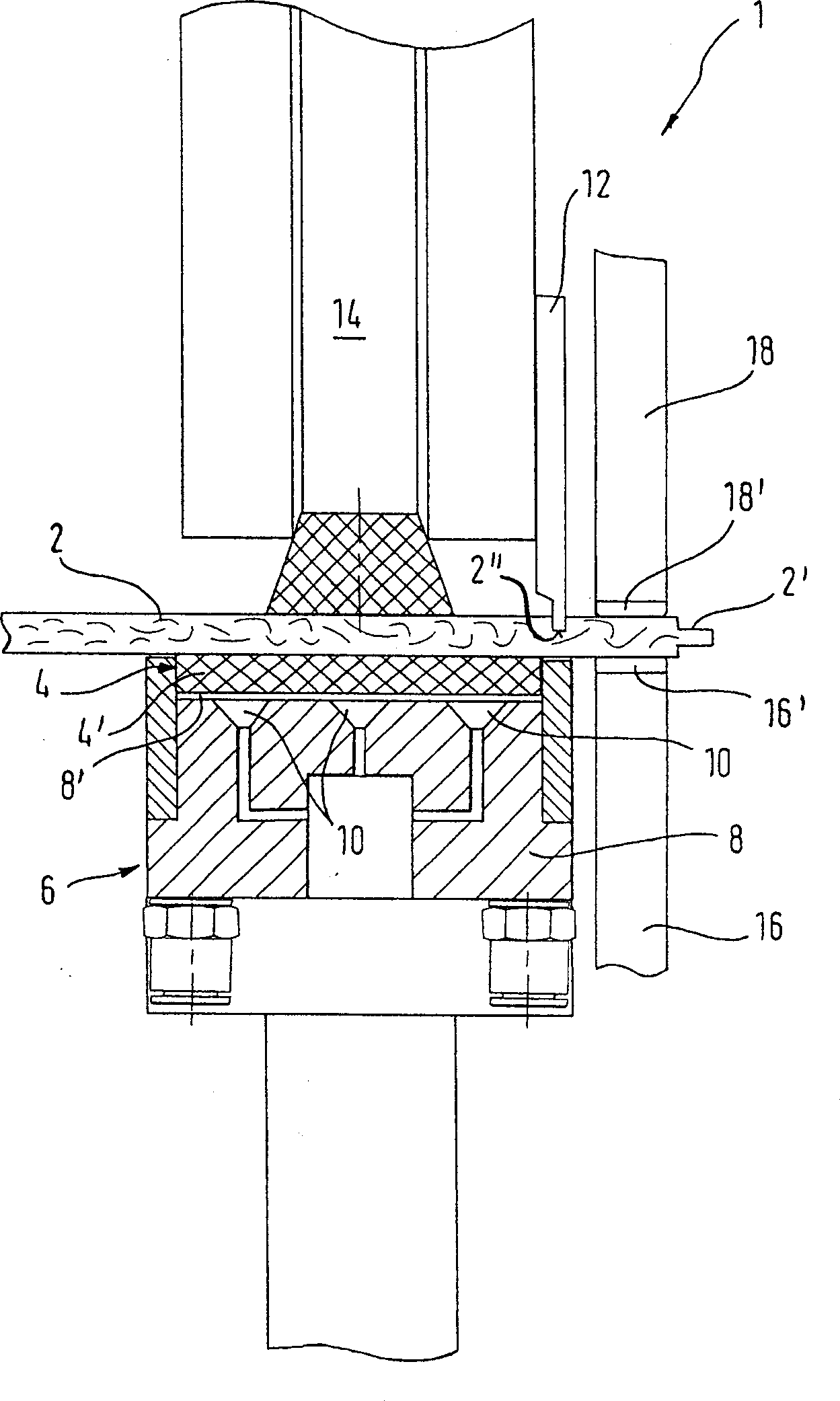

Workpiece transport device

InactiveCN1853855APrecise positioningNo transmission speed dropConveyorsProfiling/shaping machinesEngineeringMachine tool

A stationary linear guide fin (12), attached to one side of a pressing mechanism (14), engages a guide groove (2") cut on the upper surface of a workpiece (2). A workpiece supporting skid (16) is located beside a transportation belt (4) on which the workpiece is moved.

Owner:豪迈木材加工系统公司

Anti-loosening device for rolling hot-rolled stainless rolled plate

ActiveCN114453455AAvoid elasticAvoid looseMetal rolling arrangementsHydraulic cylinderClassical mechanics

The invention relates to the technical field of hot-rolled stainless rolled plate machining, in particular to an anti-loosening device for hot-rolled stainless rolled plate winding, which comprises a winding roller, two pressing assemblies are arranged on the side edge of the winding roller, and each pressing assembly comprises a top pressing roller parallel to the winding roller and a hydraulic telescopic cylinder supported on one side of the top pressing roller; one end of the winding roller is connected with a continuously variable transmission, the continuously variable transmission is connected with a hydraulic adjusting mechanism, and the hydraulic adjusting mechanism is connected with a hydraulic telescopic cylinder in one pressing assembly on the side edge of the winding roller through a first conveying pipe assembly. A plurality of pinch rollers are arranged on one side of the winding roller in parallel, the pinch rollers are arranged on a sliding frame, and one side of the sliding frame is connected with a lifting adjusting hydraulic cylinder. The jacking roller capable of being pressed outside a rolled plate is arranged on one side of the winding position of the hot-rolled stainless rolled plate, and the jacking roller can always keep rolling pressing in the whole winding process of the hot-rolled stainless rolled plate; and the hot-rolled stainless rolled plate which is just rolled is tightly pressed and is prevented from bouncing off and loosening.

Owner:山东世纪正华金属科技有限公司

Round pipe grinding method

InactiveCN108296985ASolve the incomplete polishingEasy to solveRevolution surface grinding machinesGrinding feed controlEngineeringGrinding wheel

The invention relates to the technical field of grinding, in particular to a round pipe grinding method. The round pipe grinding method comprises the following steps that firstly, to-be-ground round pipes and a grinding device are prepared, the grinding device comprises a feeding pipe, a locating table, a base, conveying rolling wheels, rotating rolling wheels and grinding wheels, supporting plates and pull rods are arranged in the side wall of the feeding pipe, a locating groove is formed in the locating table, and the locating table and the base are fixed through pressure springs; secondly,the speed of each conveying rolling wheel is adjusted to be 0.2 m / s, the speed of each rotating rolling wheel is adjusted to be 3 r / s, and the speed of each grinding wheel is adjusted to range from 0.3 r / s to 0.5 r / s; thirdly, the round pipes are placed in the feeding pipe; fourthly, the round pipes fall into the locating groove, the supporting plates are pushed by the pull rods to move, and the bottommost round pipe in the round pipes and the round pipes in the locating groove are isolated; fifthly, the conveying rolling wheels convey the round pipes, and the rotating rolling wheels enable the round pipes to rotate; and sixthly, the grinding wheels grind the round pipes. According to the scheme, the round pipe grinding method aims to solve the technical problem that in the prior art, thegrinding effect is poor due to the fact that round pipe locating is inaccurate.

Owner:重庆聚伯雅科技有限公司

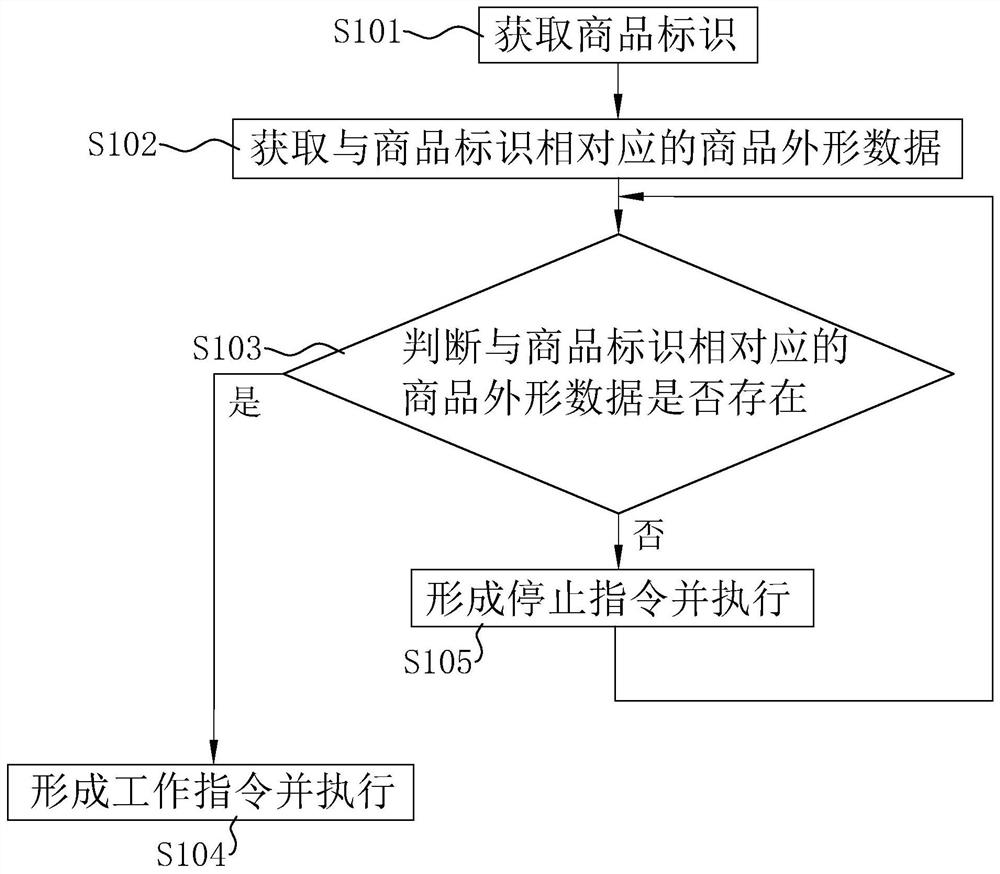

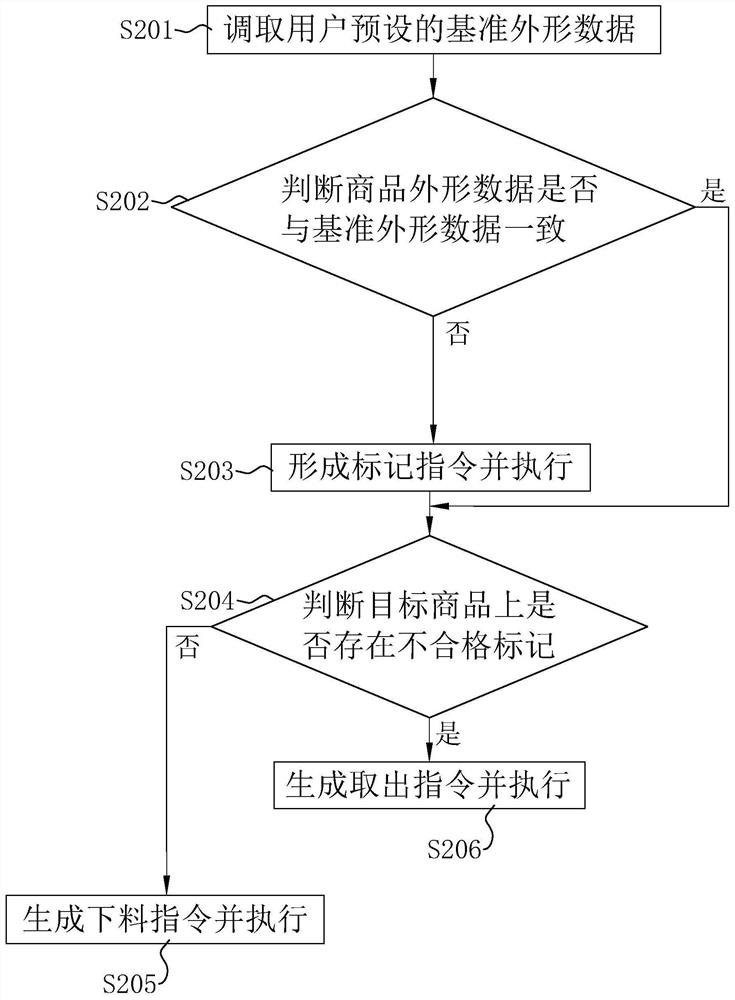

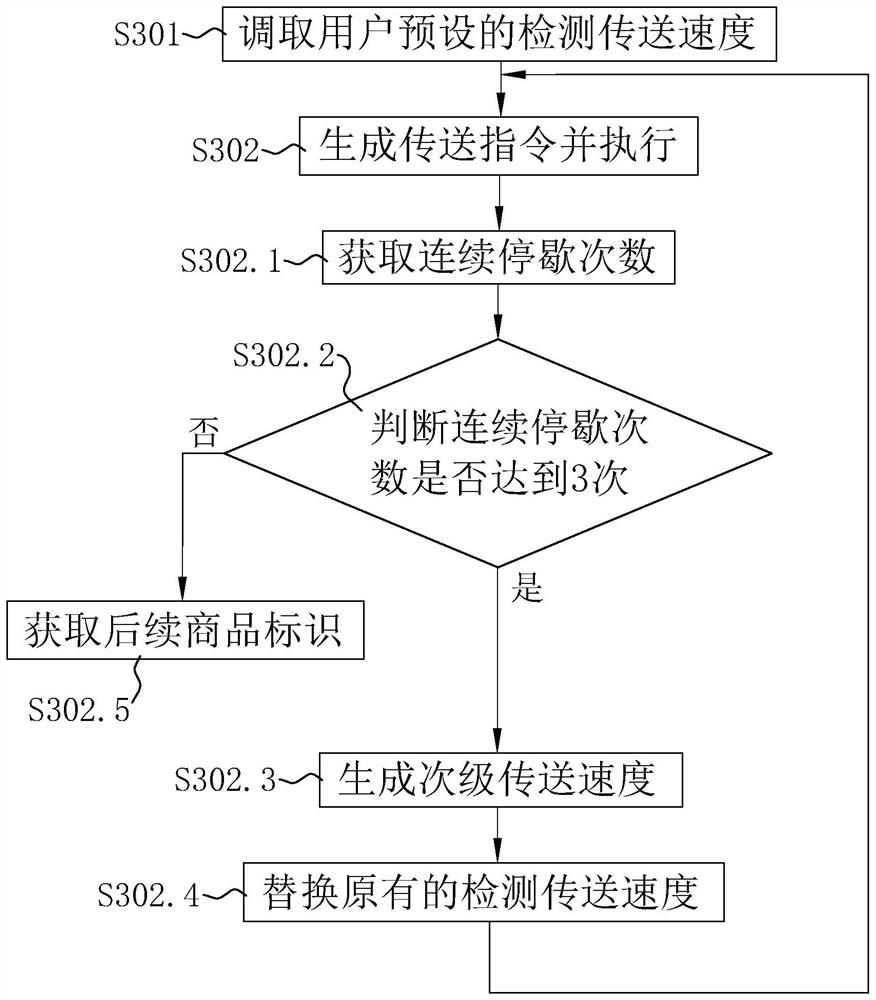

Robot code scanning conveying line detection method, system and device and storage medium

PendingCN113682766AReduce the possibility of missingEfficient detectionControl devices for conveyorsTotal factory controlReal-time computingSoftware engineering

The invention relates to a robot code scanning conveying line detection method, system and device and a storage medium, and relates to the field of conveying line product detection. The method comprises the steps that a commodity identifier is obtained; according to the commodity identifier, commodity appearance data corresponding to the commodity identifier are obtained; according to the commodity identifier, whether the commodity appearance data corresponding to the commodity identifier exist or not is judged; if the commodity appearance data corresponding to the commodity identifier exist, a work instruction is formed and executed, and the work instruction is used for controlling the conveying belt to convey commodities without shutdown; if the commodity appearance data corresponding to the commodity identifier do not exist, on the premise of judgment, a stop instruction is formed and executed, and the stop instruction is used for controlling the conveying belt to stop conveying the commodities; and the step of judging whether the commodity appearance data corresponding to the commodity identifier exist or not is repeated. The method has the advantages that the detection device can better detect all the commodities, and the possibility of detection omission is reduced.

Owner:深圳市佳康捷科技有限公司

Potato multi-stage conveying separation excavator

InactiveCN104855033BExtension of timeHigh transmission speedDiggersAgricultural engineeringExcavator

Owner:GANSU AGRI UNIV

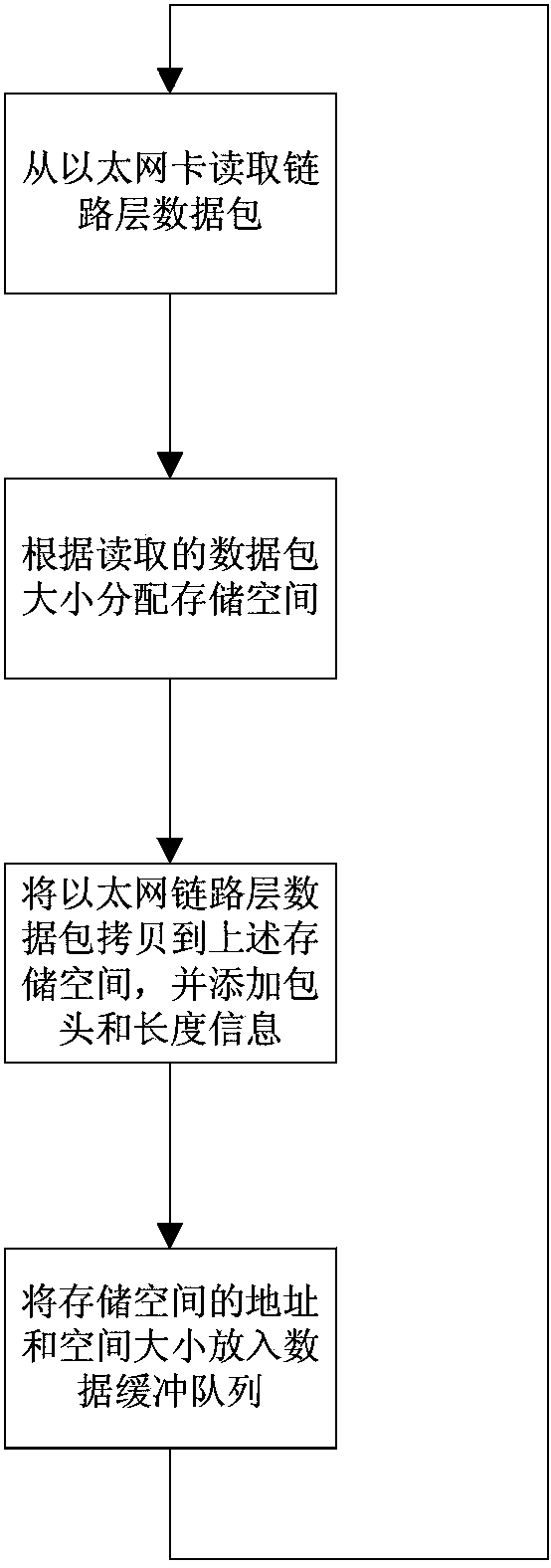

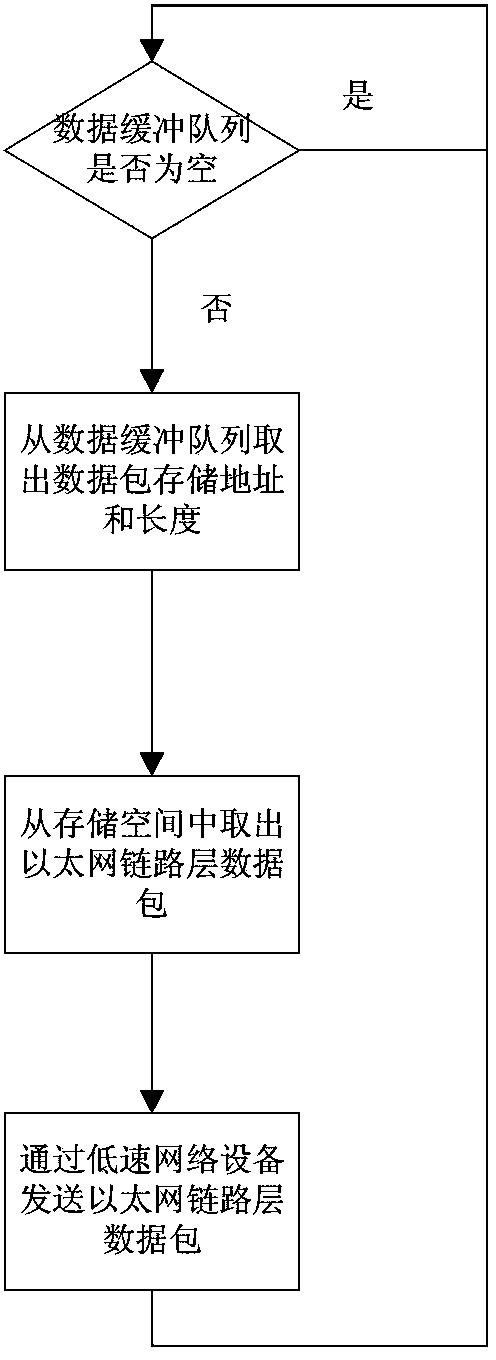

Heterogeneous network communication system-based data processing method

InactiveCN104184680AEfficient receptionReduce transmission speedError preventionData switching networksCommunications systemEngineering

The invention discloses a heterogeneous network communication system-based data processing method, thereby realizing data transmission between the ethernet network and a low-speed network. The ethernet network adds a customized packet header and a data packet length field to a read ethernet link layer data packet and then stores the packet, and an address and a data packet length of the storage space are buffered into a data buffering queue; the low-speed network obtains the address and the data packet length from the data buffering queue and then takes the ethernet link layer data packet out of the storage space and sends the packet out; when the low-speed network sends data to the ethernet network, received data packets are spliced into an ethernet link layer data packet for sending. According to the invention the data received by the high-speed ethernet network are processed into one in a data format that can be identified by other networks and the data transmitting speed is reduced by a buffering way, so that the low-speed network can receive the data completely. Therefore, data transmission between the heterogeneous network communication systems can be processed with high efficiency.

Owner:CHENGDU LINHAI ELECTRONICS

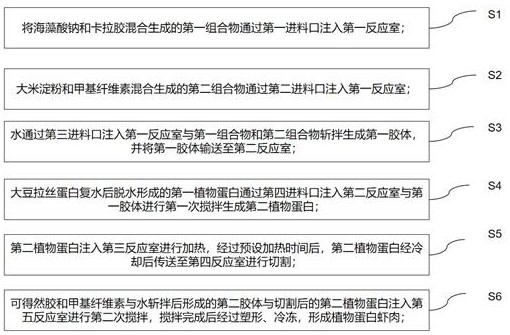

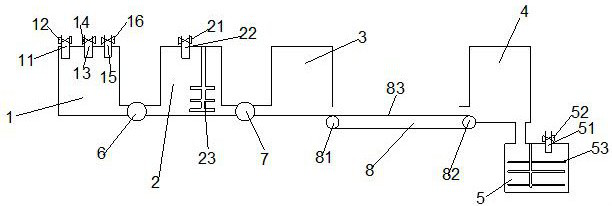

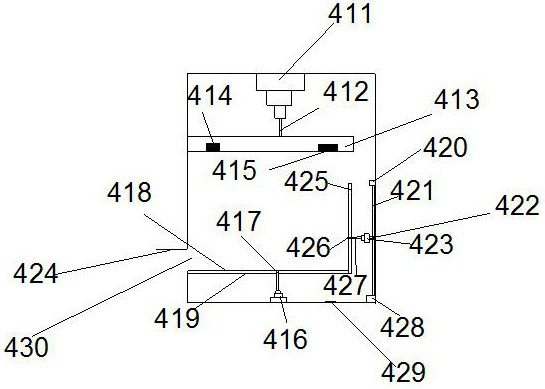

A kind of preparation method of vegetable protein shrimp meat

ActiveCN113142379BResilience impactAccurate toughnessVegetable proteins working-upBiotechnologyCellulose

The invention relates to a method for preparing vegetable protein shrimp meat, comprising: injecting a first composition formed by mixing sodium alginate and carrageenan into a first reaction chamber through a first feed port; mixing rice starch and methyl cellulose to form The second composition is injected into the first reaction chamber through the second feed port; water is injected into the first reaction chamber through the third feed port to mix with the first composition and the second composition to form the first colloid, and the first The colloid is transported to the second reaction chamber; the first vegetable protein formed by the dehydration of the soybean silk protein after rehydration is injected into the second reaction chamber through the fourth feed port and the first colloid is stirred for the first time to generate the second vegetable protein; The protein is injected into the third reaction chamber for heating. After the preset heating time, the second vegetable protein is cooled and sent to the fourth reaction chamber for cutting; curdlan and methylcellulose are mixed with water to form the second vegetable protein. The colloid and the cut second vegetable protein are stirred for the second time to form vegetable protein shrimp meat.

Owner:宁波市素莲食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com