Patents

Literature

344results about How to "Increase transmission speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

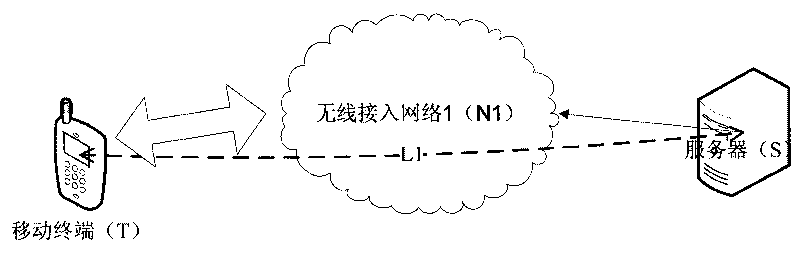

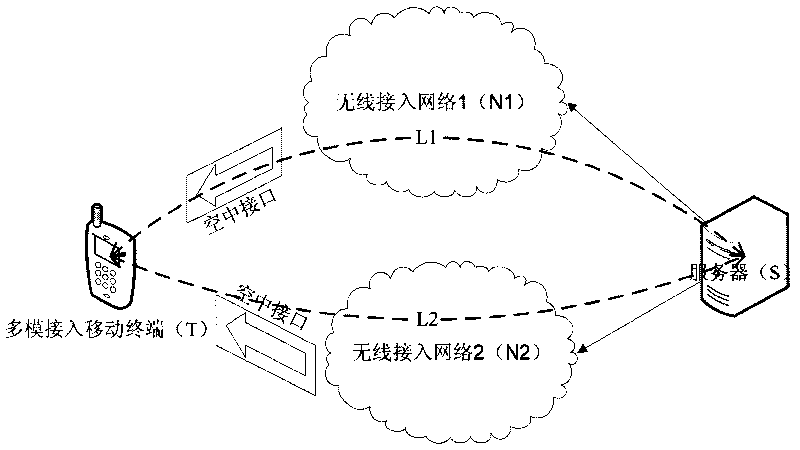

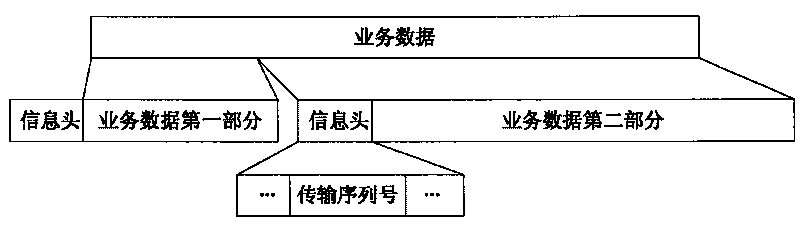

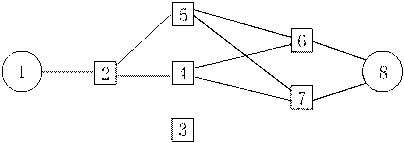

Method and system for multilink transmission data

InactiveCN101715209AAccelerateImprove user experienceNetwork traffic/resource managementConnection managementData transmissionData shipping

The invention discloses a method and a system for multilink transmission data, and belongs to the field of communication. The method comprises the following steps that: an initiating direction receiver applied by service sends a multilink transmission data request used for requesting the receiver to simultaneously transmit service data of the service through a plurality of links, wherein the multilink transmission data request carries identification information of the plurality of network links of initiator request transmission data; when the receiver receives the multilink transmission data request and accepts the multilink transmission data request, an initiator negotiates with the receiver about transmission rules of the multilink transmission data; and the initiator and the receiver transmit data applied by the transmission service according to the negotiated transmission rules after finishing the negotiation. The technical scheme effectively uses access capability of a terminal and obviously increases the speed of service data transmission.

Owner:ZTE CORP

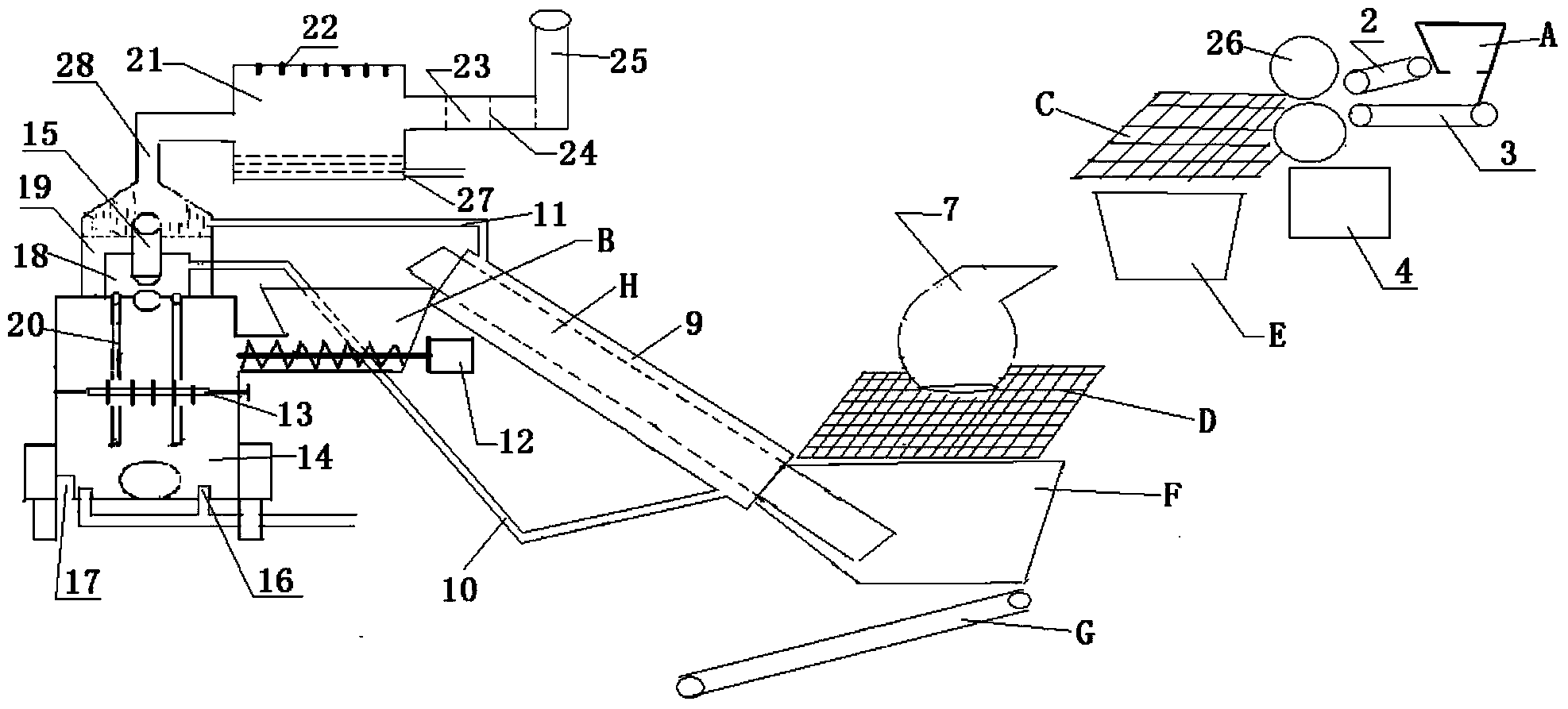

Solid waste combustion system

InactiveCN103398383AIncrease profitTake advantage ofIncinerator apparatusImpellerResource utilization

The invention provides a solid waste combustion system. The solid waste combustion system comprises a squeezing and water removing device, a screening device, a crushing device, a drying device, a combustion device and a smoke treating device, wherein the squeezing and water removing device comprises a waste feeding hopper; the feeding hopper is connected with a roller by a pressure conveying belt; the crushing device comprises a crusher and a shaking type screening net located on the bottom of the crusher; the combustion device comprises a hearth; the outer part of the hearth is connected with the feeding hopper and dried wastes are conveyed to the feeding hopper by a drying device conveying belt; a spiral conveying impeller is mounted on the connection part of the feeding hopper and the hearth; the hearth is internally provided with an agitation device; the smoke treating device is connected with the hearth; an opening is formed in the connection part of the hearth and the smoke treating device; the smoke treating device comprises a dust removing device and a desulfuration and deodorization device. The solid waste combustion system provided by the invention is high in combustion efficiency; the treated wastes can be utilized sufficiently so that the resource utilization rate is improved and a working process is environment-friendly and pollution-free.

Owner:黎汉东

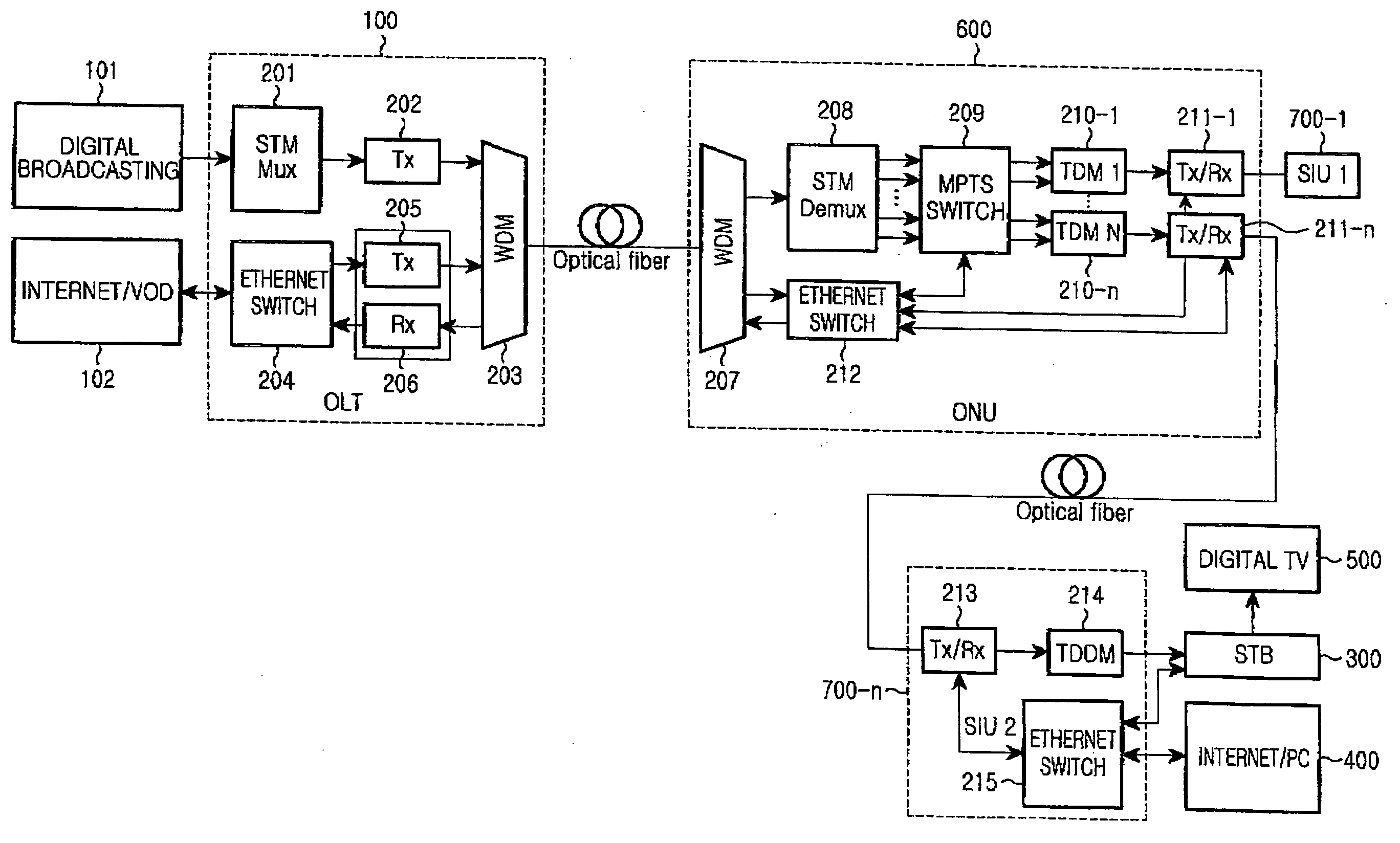

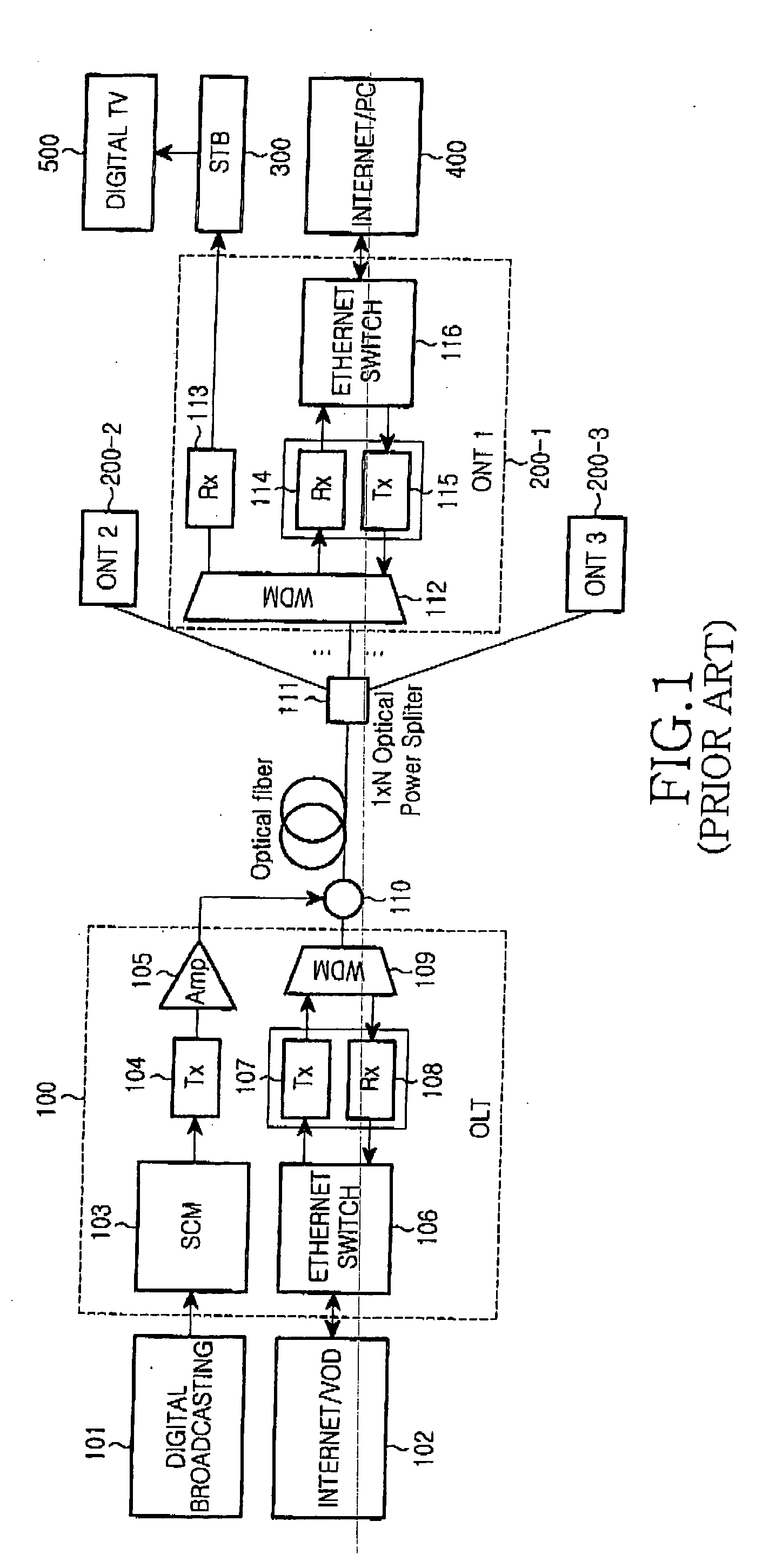

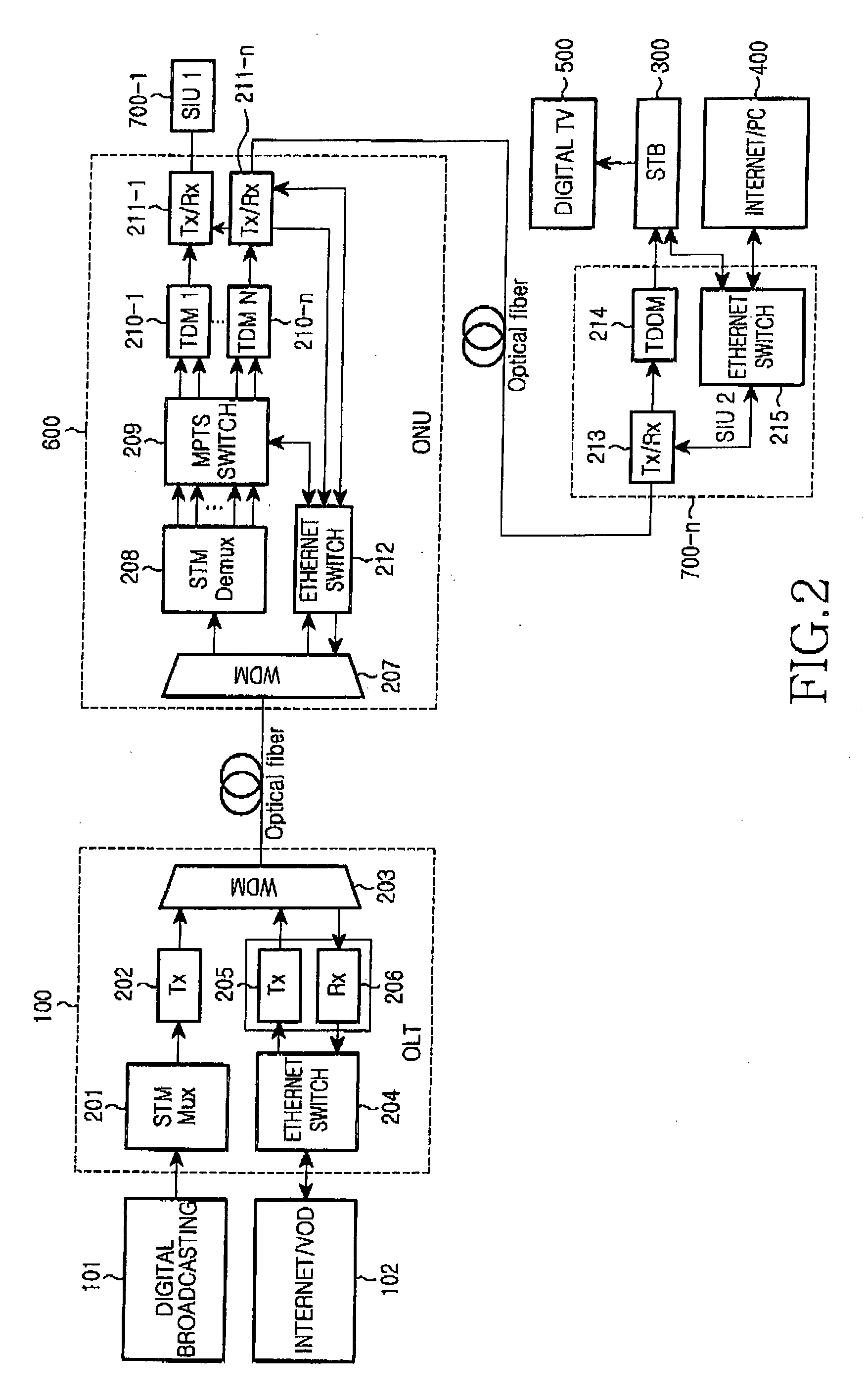

FTTH system for convergence of broadcasting and communication through switched broadcasting

InactiveUS20050053376A1Easy to useLow priceBroadband local area networksOptical transmission adaptationsMultiplexingFiber

A fiber to the home FTTH network for convergence of broadcasting and communication is disclosed. The network includes: an OLT for receiving and converting a first predetermined number of broadcast signals and an Ethernet signal into a plurality of converted optical signals, combining the converted optical signals into converged optical signals for subsequent transmission by an optical wavelength division multiplexing method; and an optical network unit (ONU) for classifying the optical signal transmitted from the OLT into the first predetermined number of broadcast signals and the Ethernet signal, switching a second predetermined number of broadcasting signals of the first predetermined number of broadcasting signals according to each SIU by channel selection information contained in upstream Ethernet information, and switching the Ethernet signal to be transmitted to the SIU according to each SIU so as to transmit the switched signal.

Owner:SAMSUNG ELECTRONICS CO LTD

Polyvinylidene fluoride hollow fiber membrane for hemodialysis

InactiveCN1579601AIncrease transmission speedShorten dialysis treatment timeSemi-permeable membranesSuction devicesHemodialysisPolyvinyl chloride

The invention relates to hollow a fibre membrane of polyvinylidene fluoride used for hemodialysis. Thickness of the membrane is 10-50micon and bore is 100-500 micron. The membrane is made of polyvinylidene fluoride resin of 15-35 percent, filature impregnant of 60-80 percent, hydrophilicity macromolecule of 1-5 percent and spinning raw liquor of 1-9 percent. It is made by dry-jet wet-spinning process. The hydrophilicity macromolecule includes polyethylene glycol, polyvinyl alcohol, polyvinyl pyrrolidon and (or) polyvinyl chloride. Spinning solvent is polar solvent.

Owner:TIANJIN MOTIAN MEMBRANE ENG & TECH

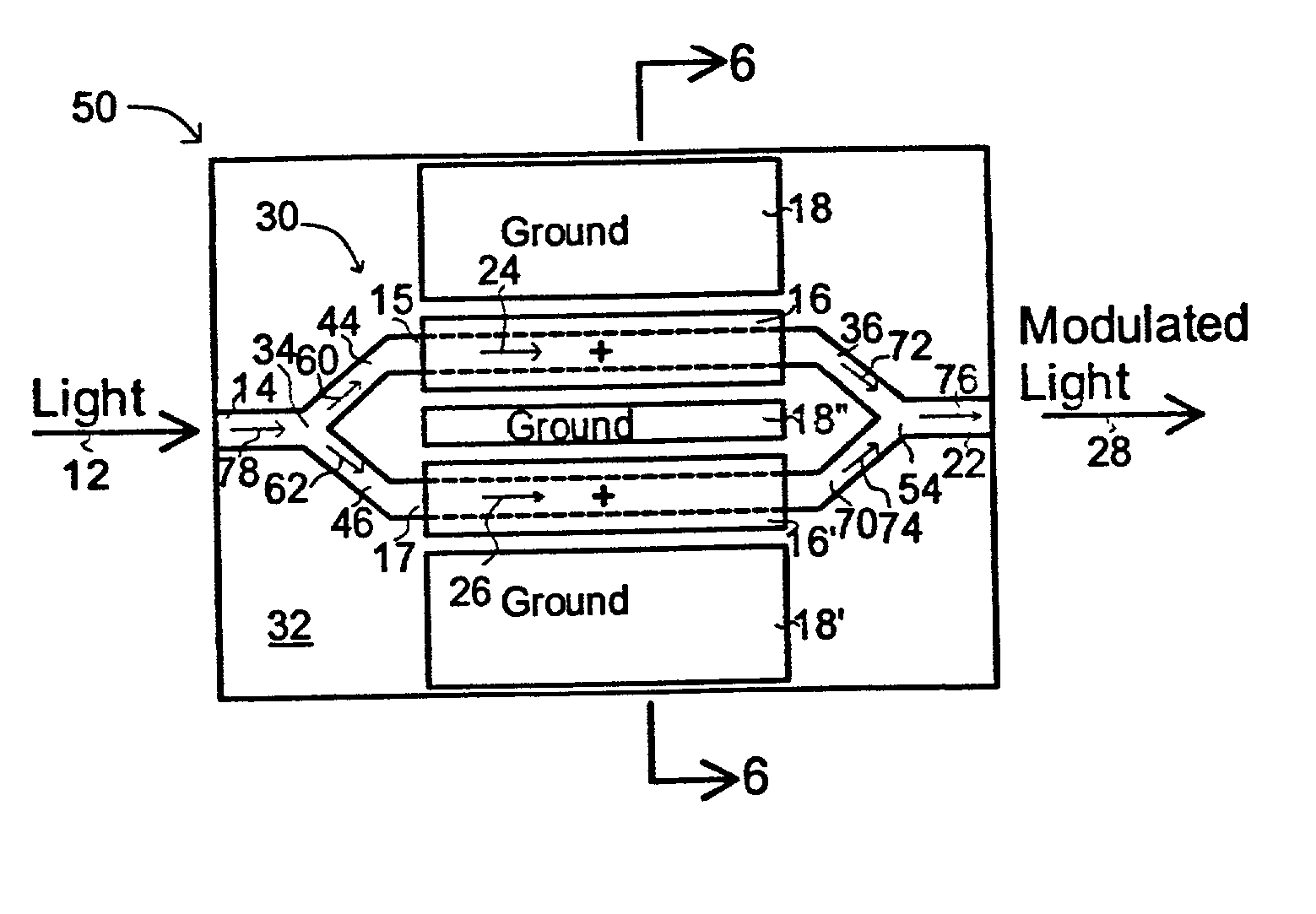

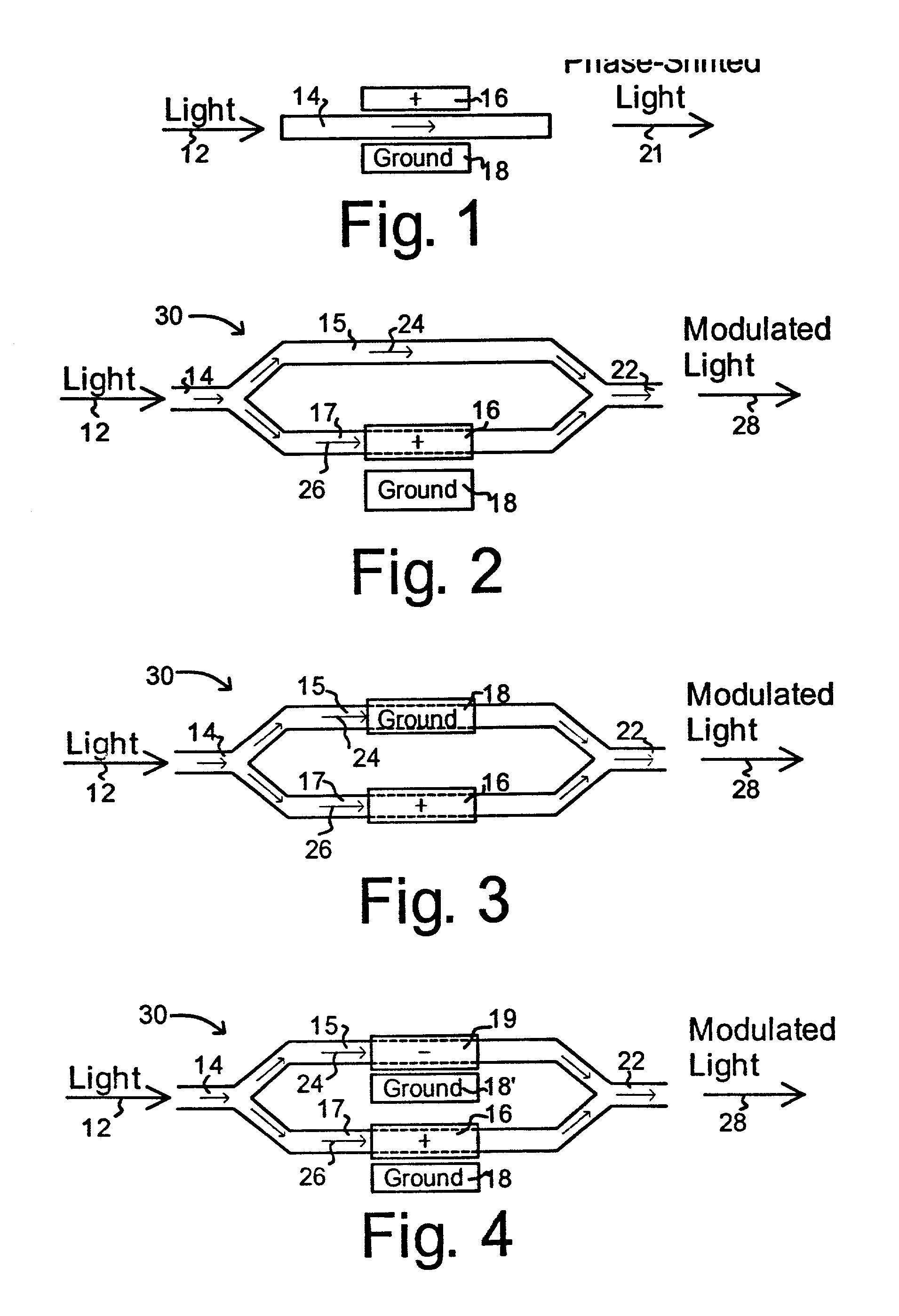

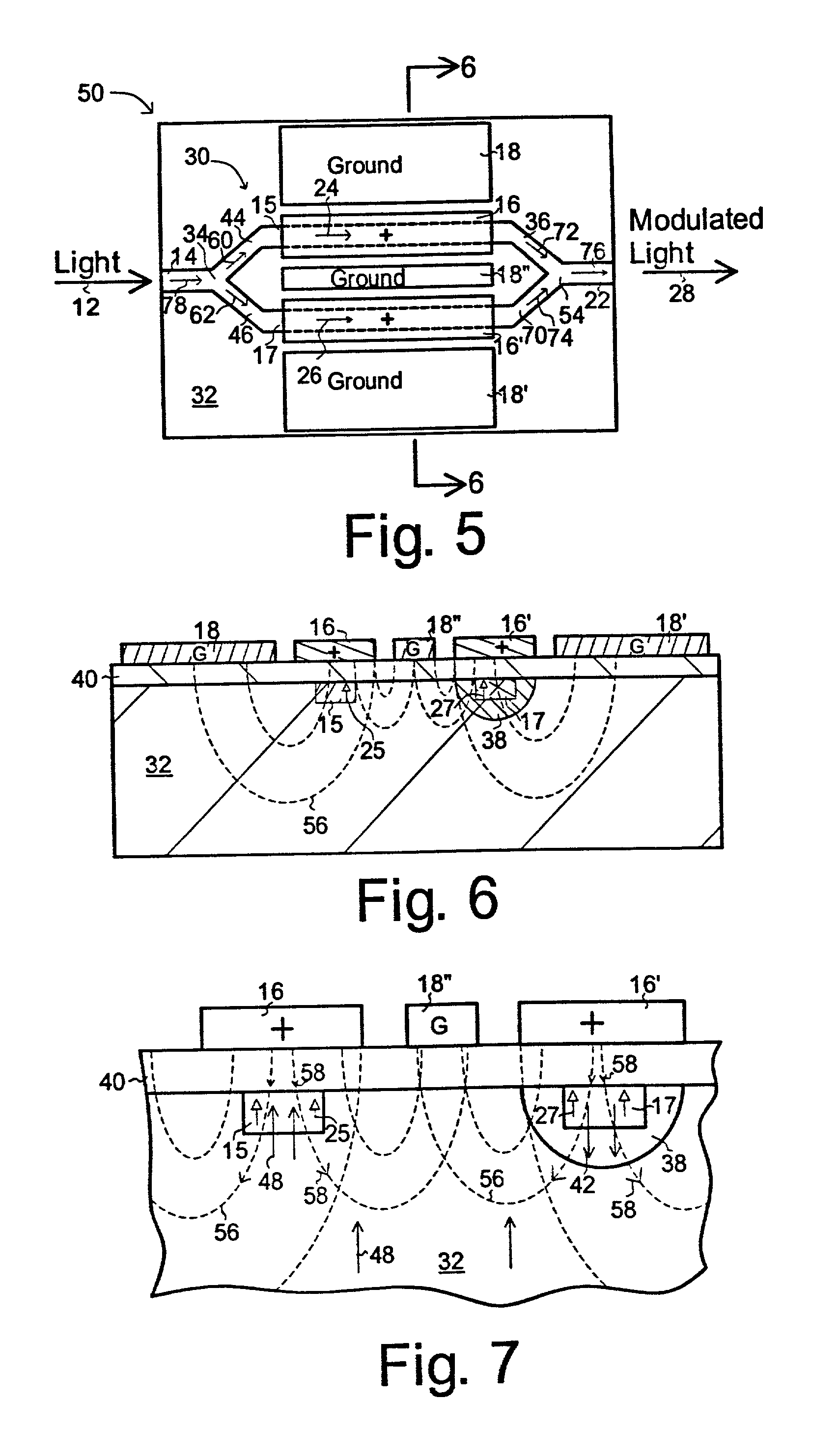

Optical modulator

InactiveUS20020131665A1Increase transmission speedIncrease distanceCoupling light guidesOptical waveguide light guideWaveguide channelOptical modulator

An optical modulator has optical channels formed in a waveguide substrate in which two of the waveguide channel branches have reverse polarity relative to each other. In addition, the optical modulator has at least one of the following: 1) an electronic signal electrode and an electronic ground electrode are placed in proximity with opposite faces of the waveguide substrate, 2) a portion of said waveguide substrate is removed to afford a reduced electronic signal refractive index, and 3) the waveguide substrate has a fixing substrate attached to it with the refractive index of the fixing substrate lower than said refractive index of the waveguide substrate.

Owner:SRICO

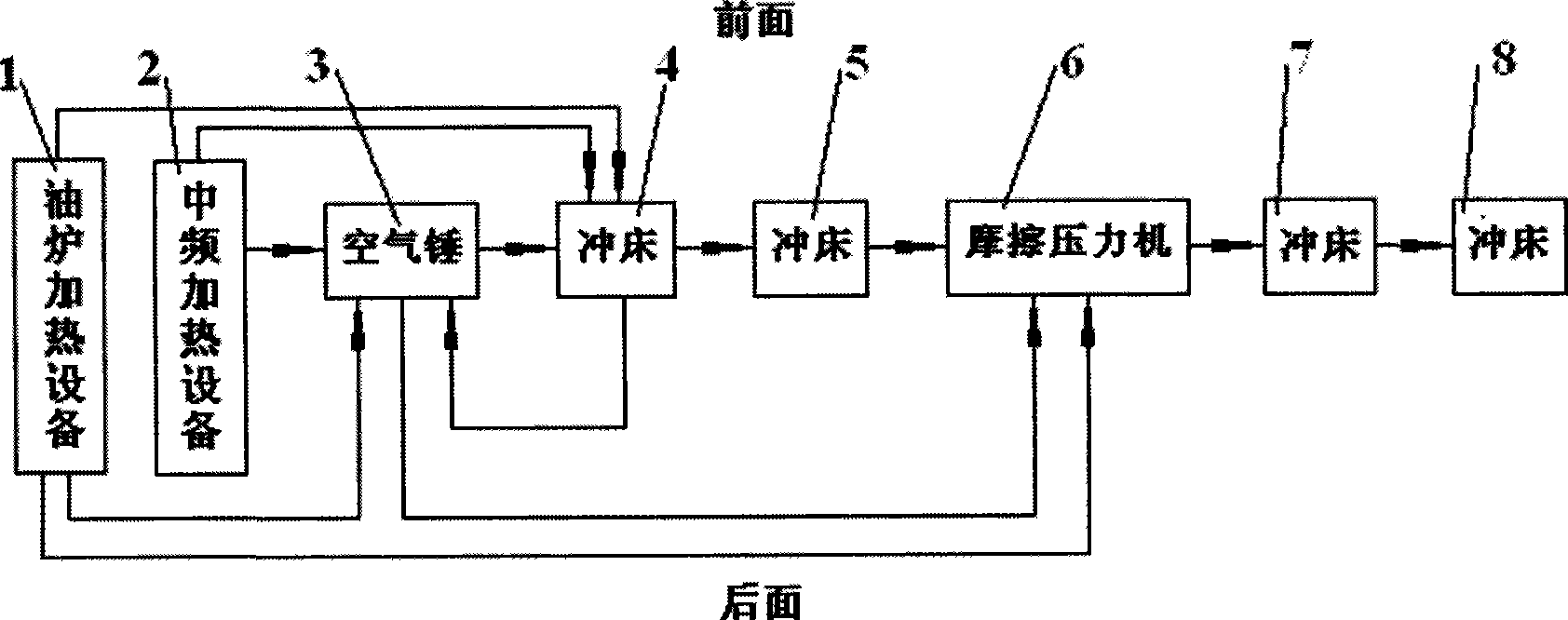

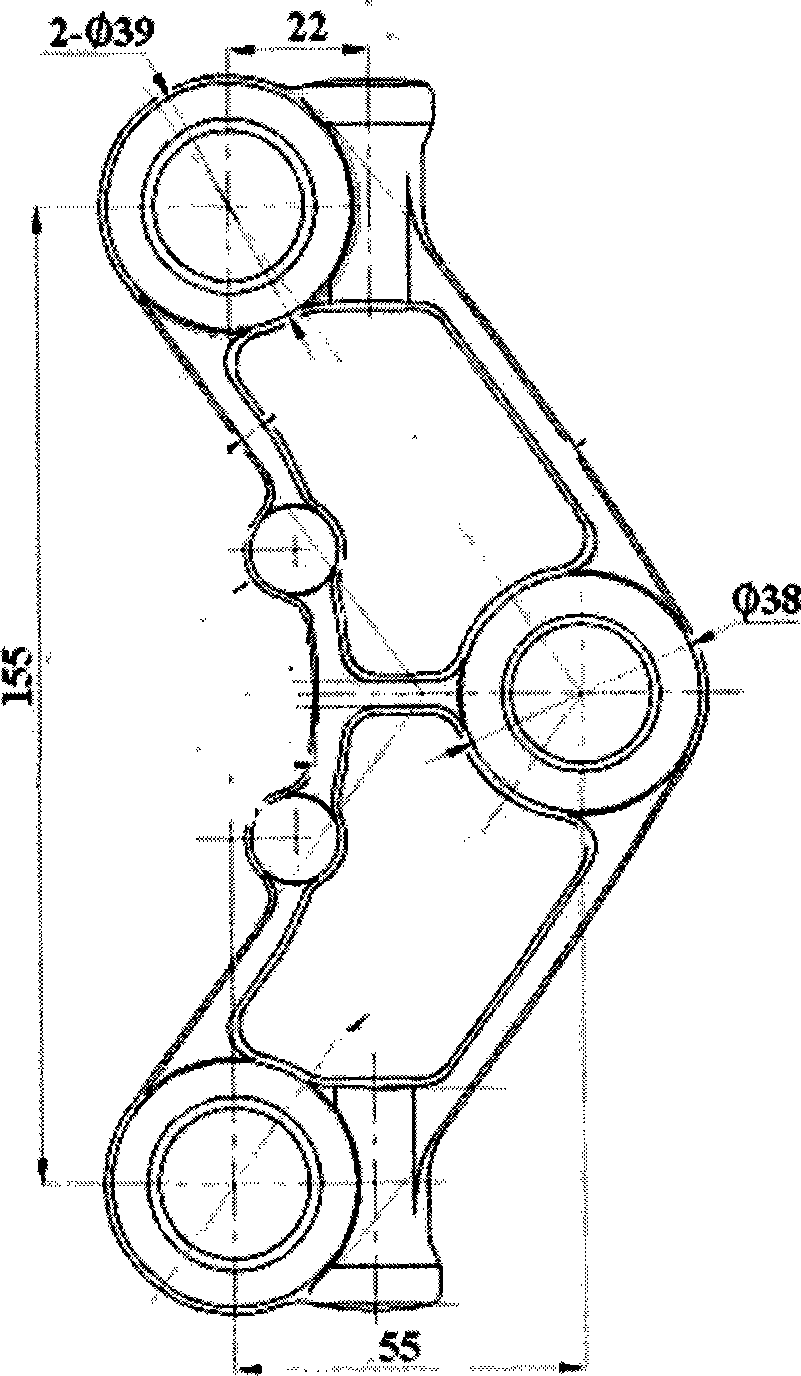

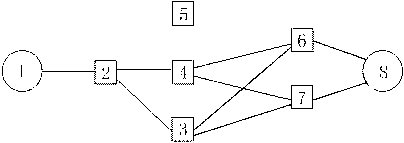

Forging device pipeline of complicated forging piece and forging production technique thereof

InactiveCN101456060AImprove surface qualitySolve billet problemsForging hammersForging press detailsProduction lineEngineering

The invention discloses a forging device production line for a complex forged piece, which comprises heating devices, a forging device and a transfer device. The forging device is a friction press (6) and is arranged according to forging technology, the number of the heating devices is two, and the two heating devices are arranged at two sides of the transfer device of the production line in parallel, wherein one heating device is a main heating device (1), and the other heating device is a double-heating device (2). The invention also provides corresponding forging production technology. The invention adopts a technical proposal to heat the shaped forged piece twice so as to meet the requirement of the forged piece with special request, and solves the repair problem of part of unqualified forged pieces at the same time.

Owner:安徽凯宇机械制造有限公司

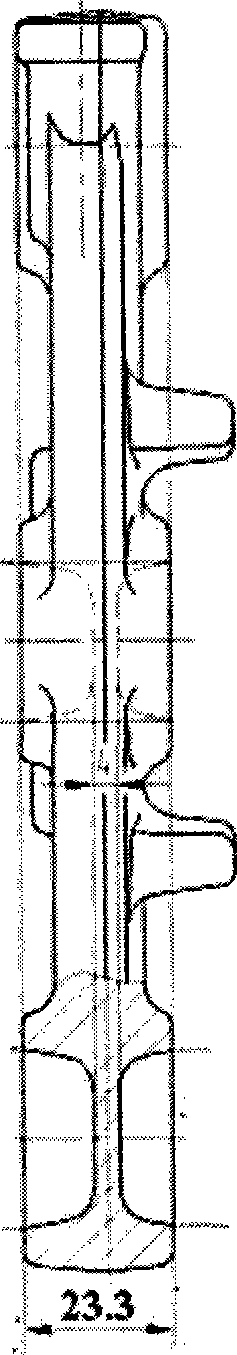

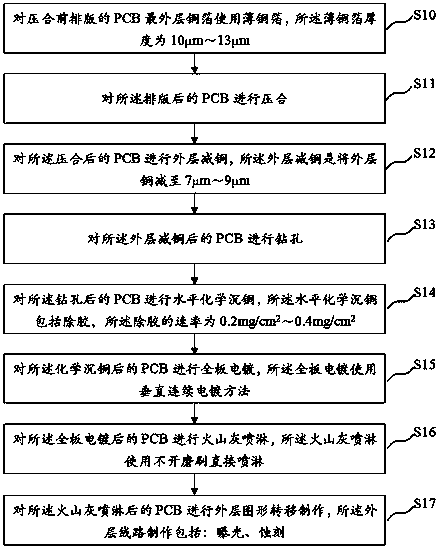

PCB circuit manufacturing method and PCB

InactiveCN110213895AAvoid over etchingMeet production needsInsulating substrate metal adhesion improvementInsulating layers/substrates workingEtchingDirect imaging

The invention discloses a PCB circuit manufacturing method and a PCB. The method comprises the following steps: using a thin copper foil with the diameter of 10 to 13 microns as the outermost layer ofcopper foil of a type setting PCB, then laminating, reducing the copper on the outer layer to be 7 to 9 microns after laminating, then carrying out hole drilling and low-speed chemical adhesive cleaning, using vertically continuous electroplating manufacturing in later electroplating working procedure, controlling the thickness of copper on the inner wall of the hole to be 15 to 20 microns and the thickness of copper on the surface to be 24 to 30 microns, then carrying out surface roughening in a cinerite spraying mode for turning off a polishing brush, then using a laser direct imaging exposure machine for exposure in the manufacturing process of an outer circuit, carrying out developing and etching by using a low-pressure and high-speed mode, and presetting 10% to 20% of a circuit compensating value in advance. The problems, such as a great number of too thin and too wide lines, excessive etching, under developing, short circuits and open circuits existing in the circuit manufacturing process, of the PCB product with fine circuits (for example, the ratio of line width to line gap is smaller than or equal to 2 mil / 2 mill) can be solved.

Owner:深圳市鼎盛电路技术有限公司

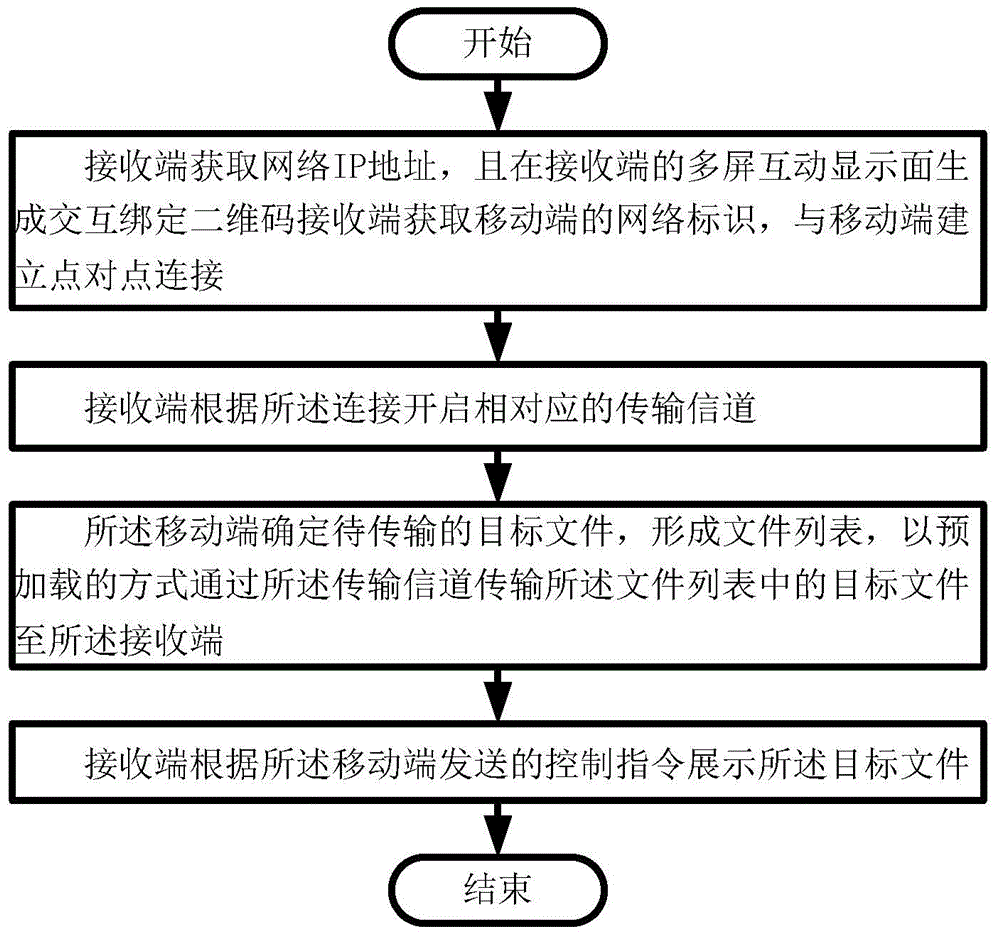

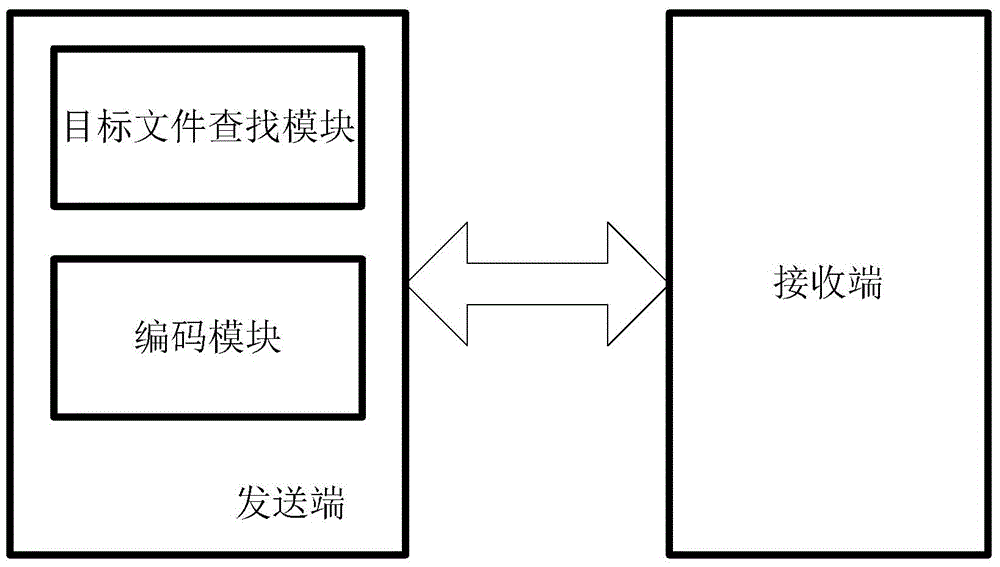

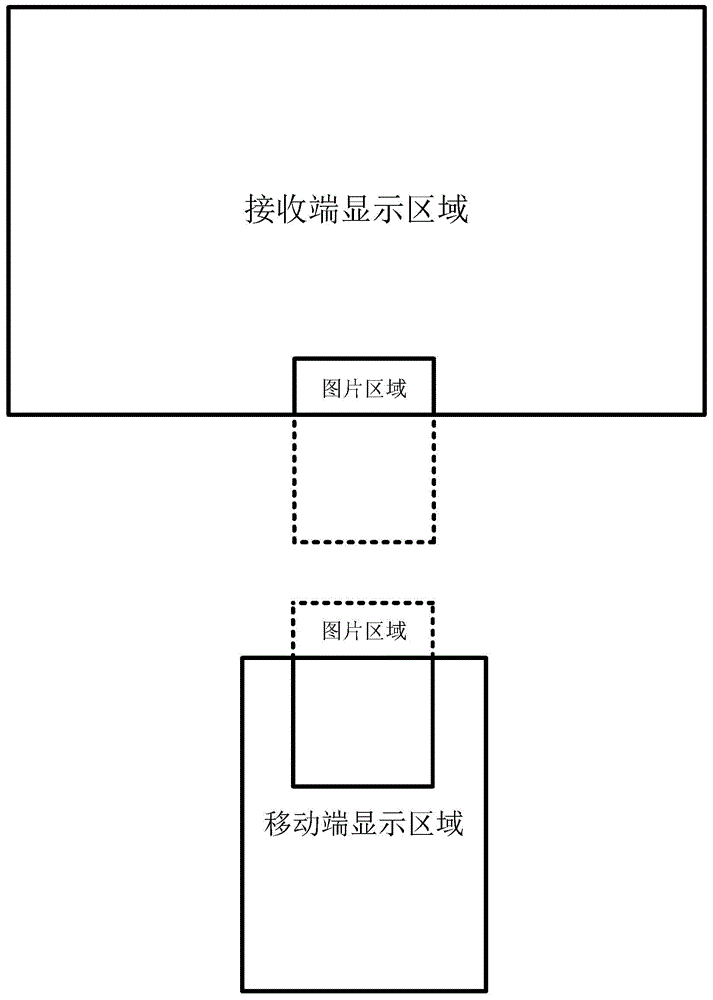

Multi-screen interaction method and system

InactiveCN105025094AIncrease transmission speedIncrease playback speedTransmissionTransmission channelMobile end

The invention provides a multi-screen interaction method and system. The method comprises the following steps: S1) a receiving end obtains a network identity of a mobile end and establishes point-to-point connection with the mobile end; S2) the receiving end opens a corresponding transmission channel according to the connection; S3) the mobile end determines object files to be transmitted to form a file list and transmits the object files in the file list to the receiving end through the transmission channel in a preloading manner; and S4) the receiving end displays the object files according to a control instruction sent by the mobile end. The receiving end establishes the point-to-point connection with the mobile end through obtaining the network identity of the mobile end, so that the terminals can be connected quickly without searching, and the requirement for multi-screen interaction is carried out. The files are transmitted in the arrangement sequence in the file list through the preloading mode, so that play speed of both the video files and picture files can be improved.

Owner:CHUANCHENG CULTURE & MEDIA SHANGHAI

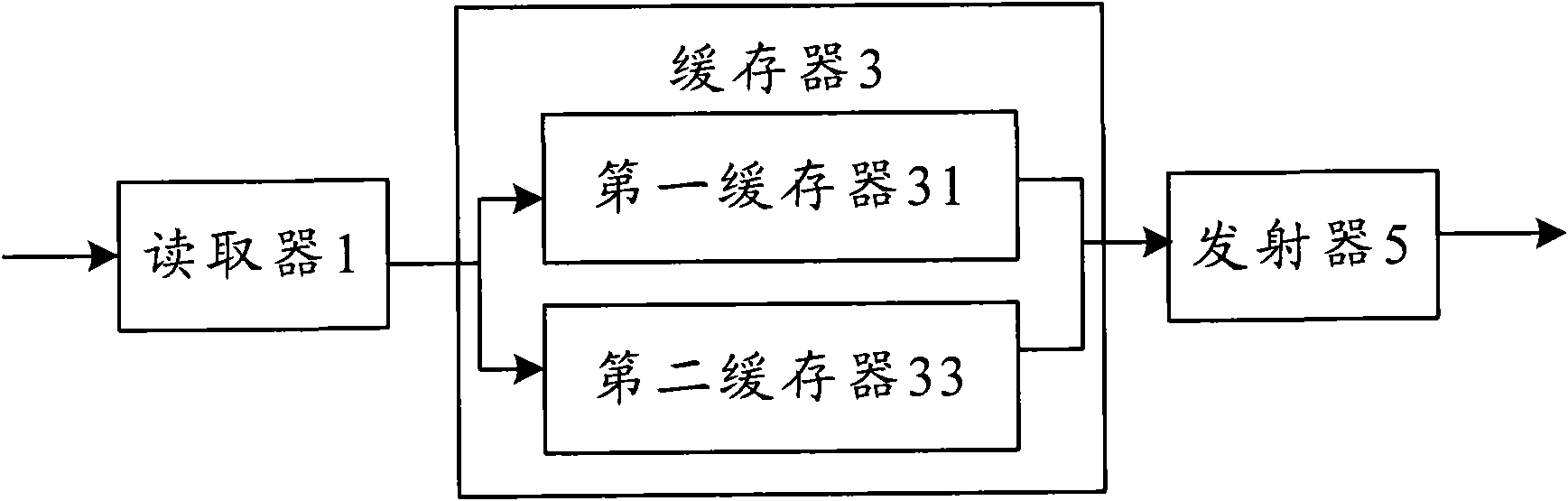

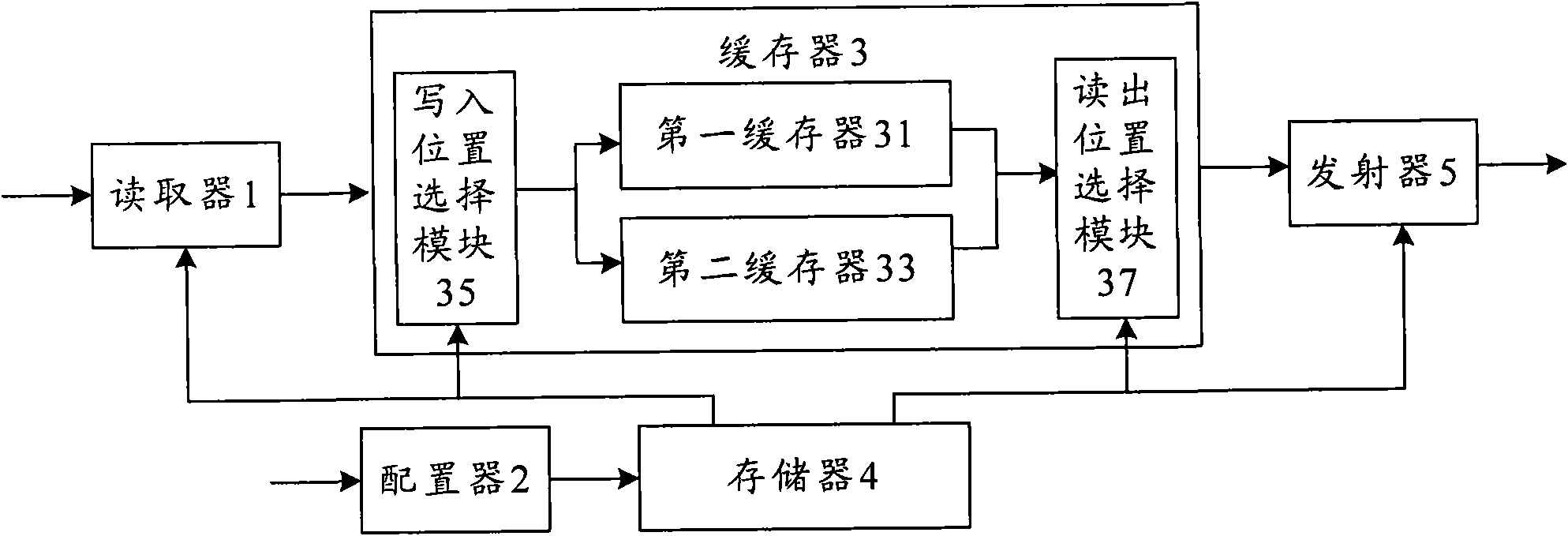

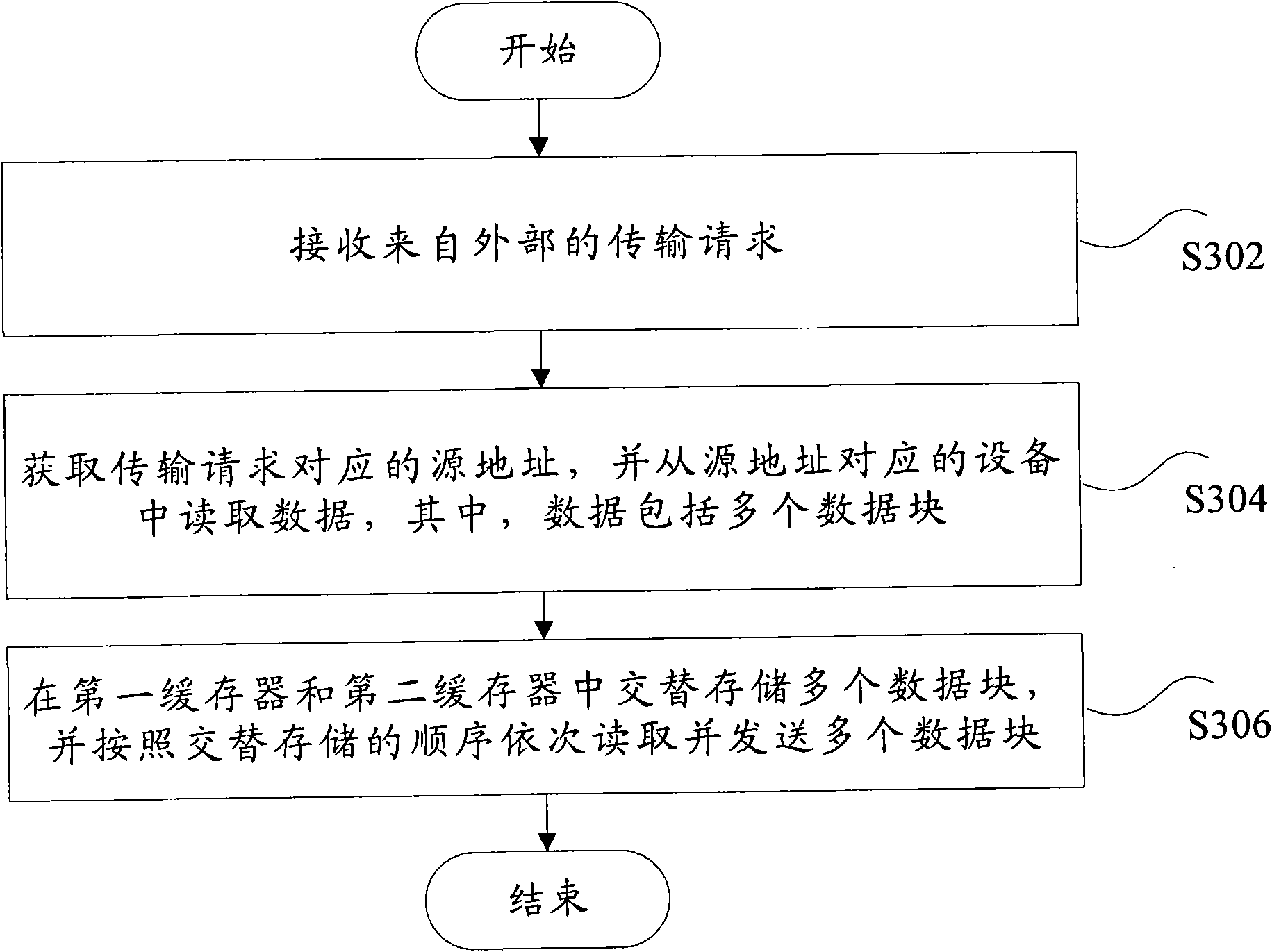

Direct memory access controller and data transmission method

InactiveCN101777031AImprove transmission efficiencyIncrease transmission speedElectric digital data processingDirect memory accessData transmission

The invention discloses a DMAC and a data transmission method, wherein the DMAC comprises a reader, a buffer and an emitter, wherein the reader is used for responding transmission requests from outside, obtaining source addresses corresponding to the transmission requests, and reading data from equipment corresponding to the source addresses, wherein the data comprises a plurality of data blocks, the buffer comprises a first buffer and a second buffer which are used for alternately storing a plurality of data blocks, and the emitter is used for sequentially obtaining and sending a plurality of data blocks from a buffer module according to the alternate sequence. According to the invention, through the arrangement of the first buffer and the second buffer between the reader and the emitter of the DMAC, data can be alternately stored into the first buffer and the second buffer, in addition, the parallel data reading and sending operation can be realized, and the data transmission efficiency can be improved, so the problem of slow DMA data transmission speed in the relevant technology can be solved.

Owner:SANECHIPS TECH CO LTD

Method for accelerating VPN multi-route network

InactiveCN101719815AImprove transfer speed and securityEasy to useError preventionNetworks interconnectionRoute serverPacket processing

The invention discloses a method for accelerating a VPN multi-route network. In the method, multi-route network accelerating software is installed on a local computer for carrying out connection of at least two route servers; the software sends a data packet which is required to be sent to a corresponding terminal to all VPN tunnels corresponding to a node server of an corresponding terminal according to certain scheduling algorithm, thereby realizing circuit multiplexing; the corresponding terminal node server receives data of the VPN tunnel and processes the data packet; the software intelligently detects network state; when a current server network presents slowness or even disconnection, the software automatically switch all the data to another server with fastest speed in connection to transmit the data; another server with faster speed in connection is found out from the remained standby servers for connection; and the connection state of at least two route serves is kept. The invention has the advantages of no need of additional physical wires, convenient use, and easy fault locating, and can enhance transmission speed and safety of data without timely manual maintenance.

Owner:朴君

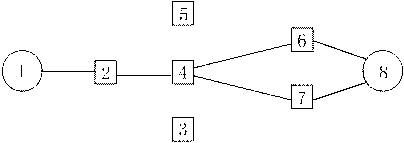

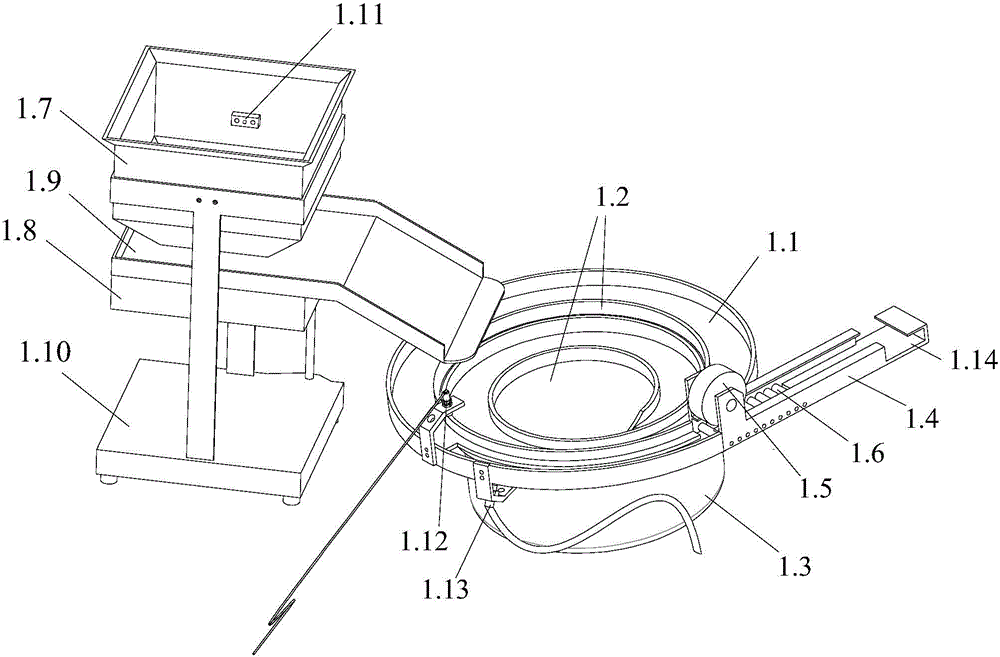

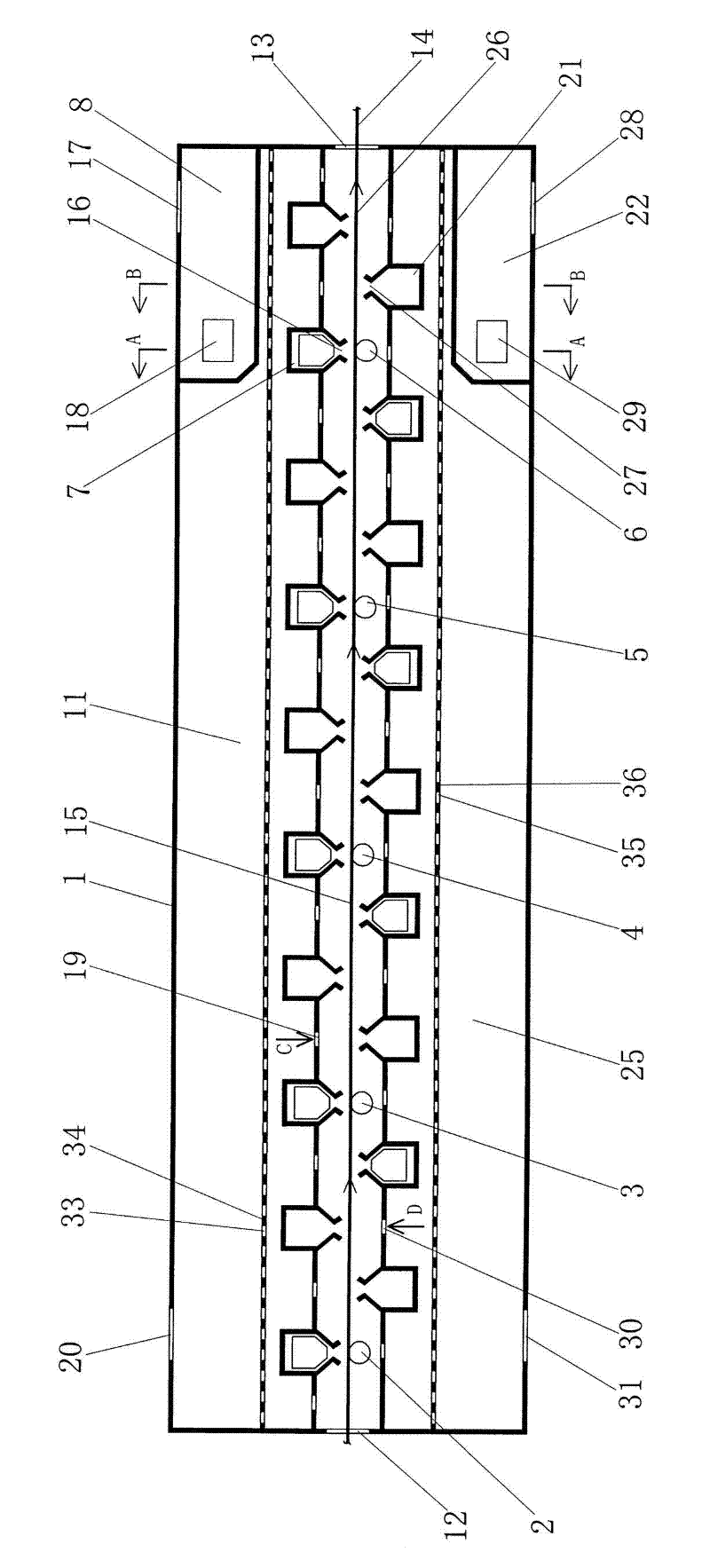

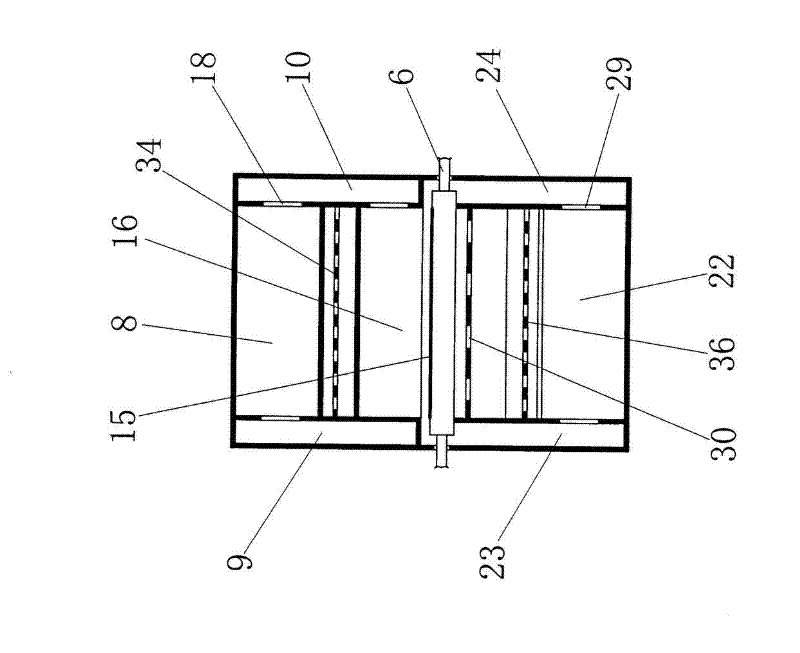

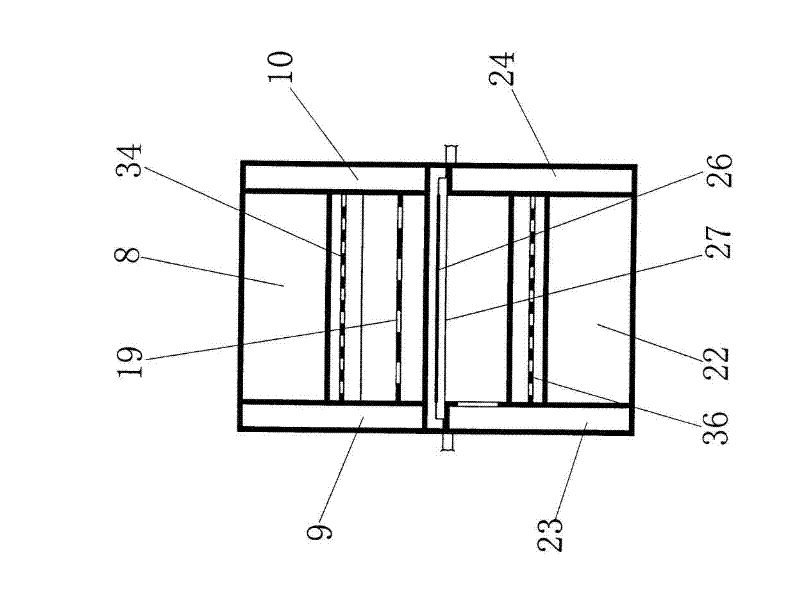

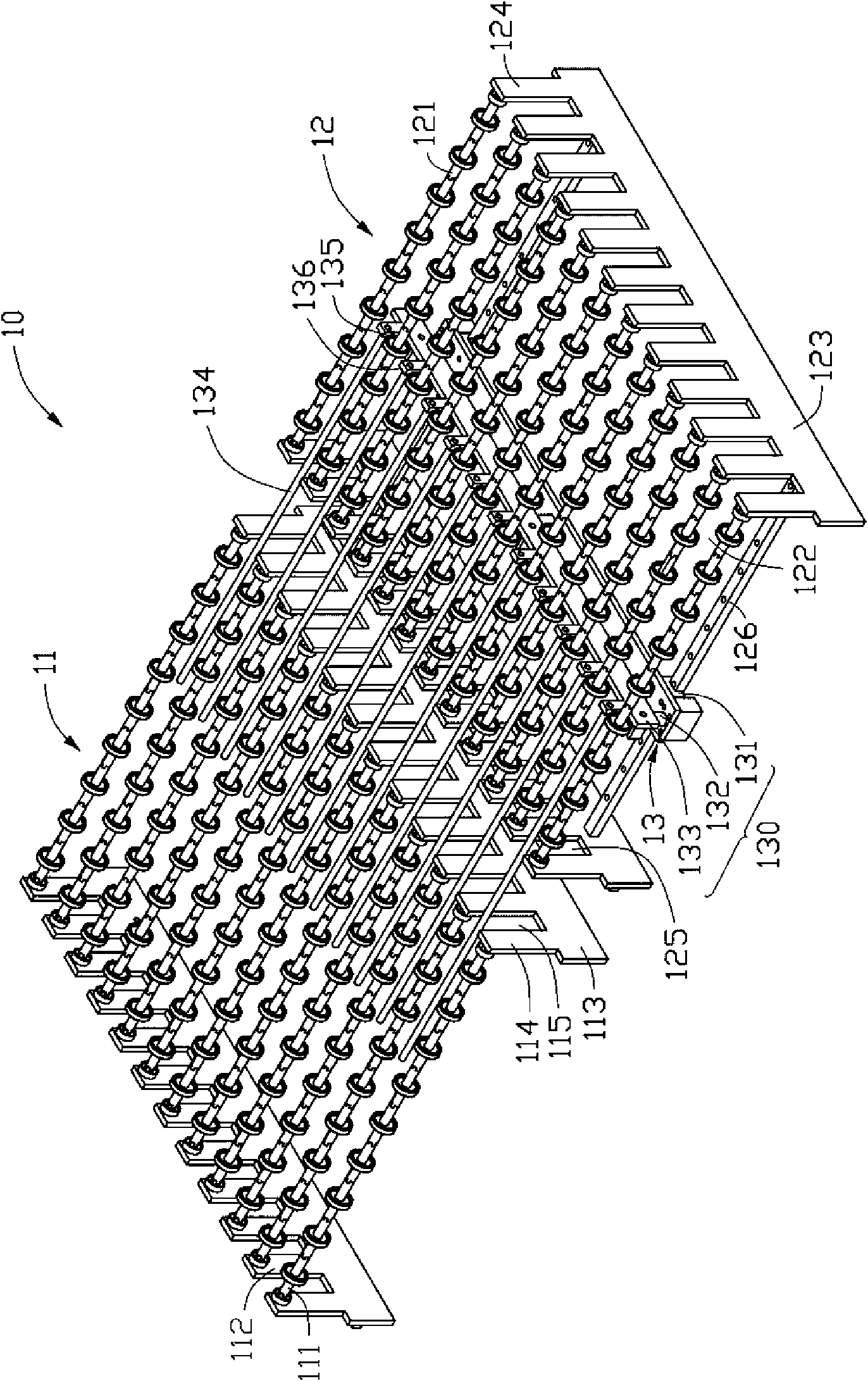

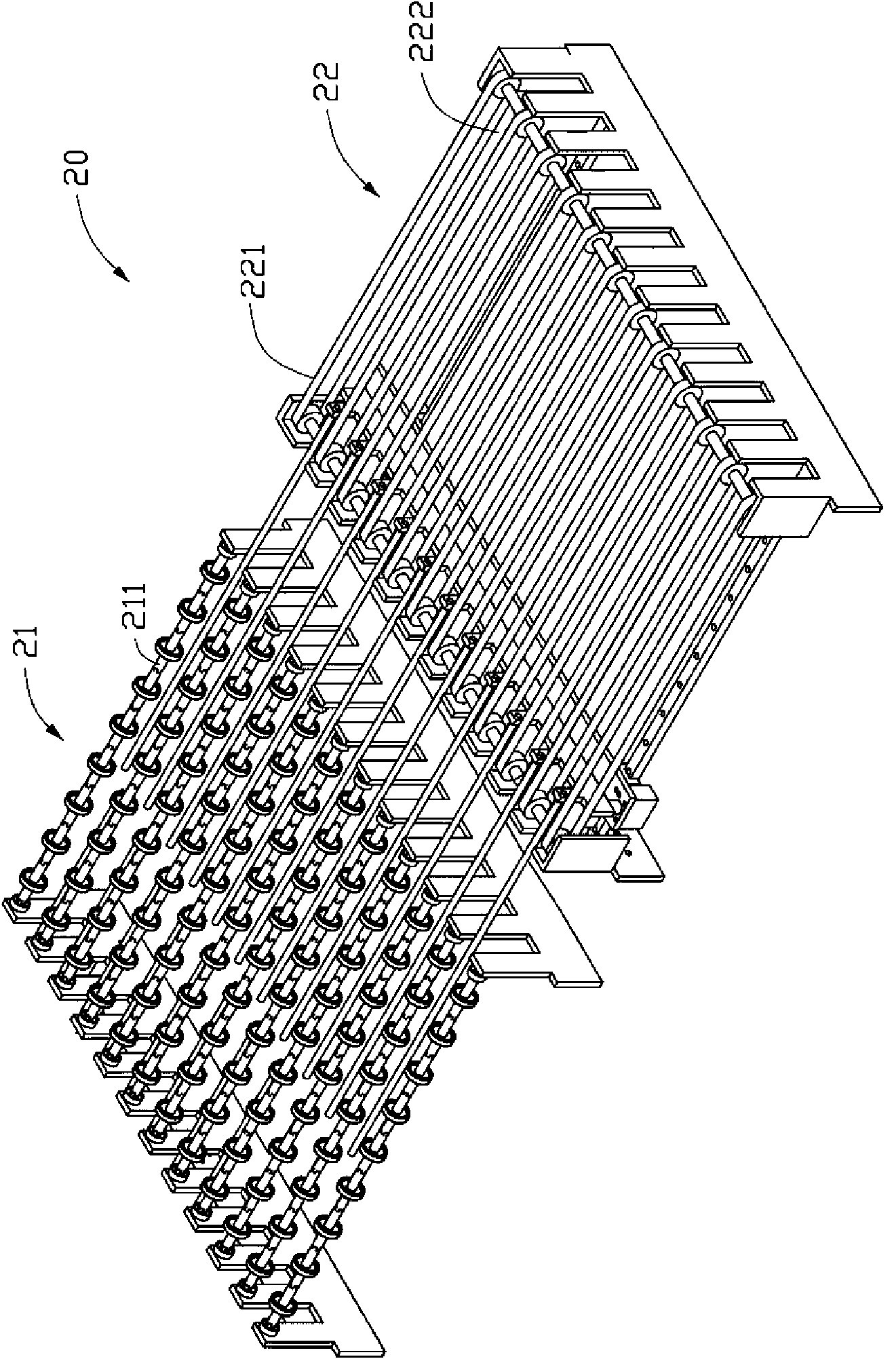

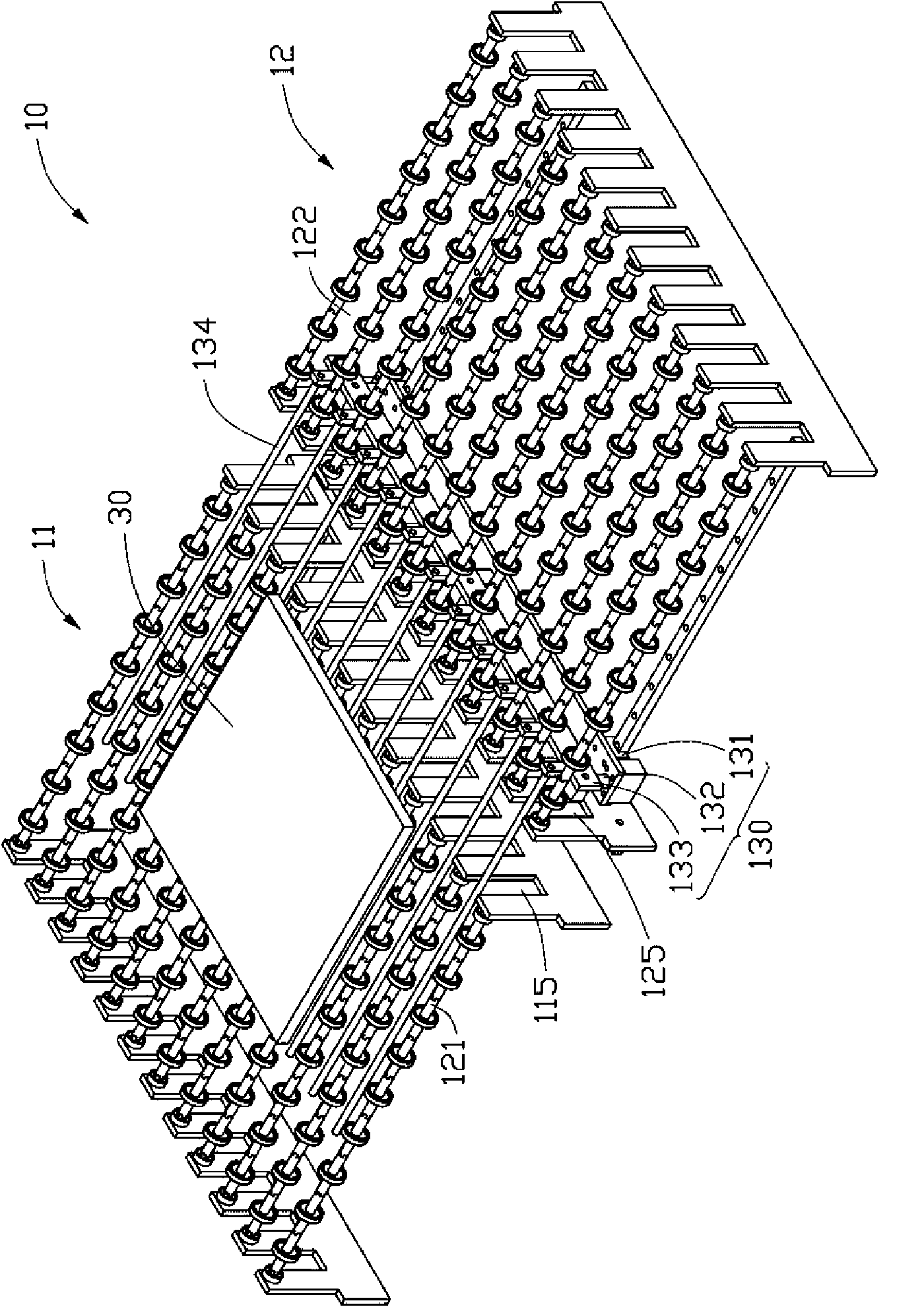

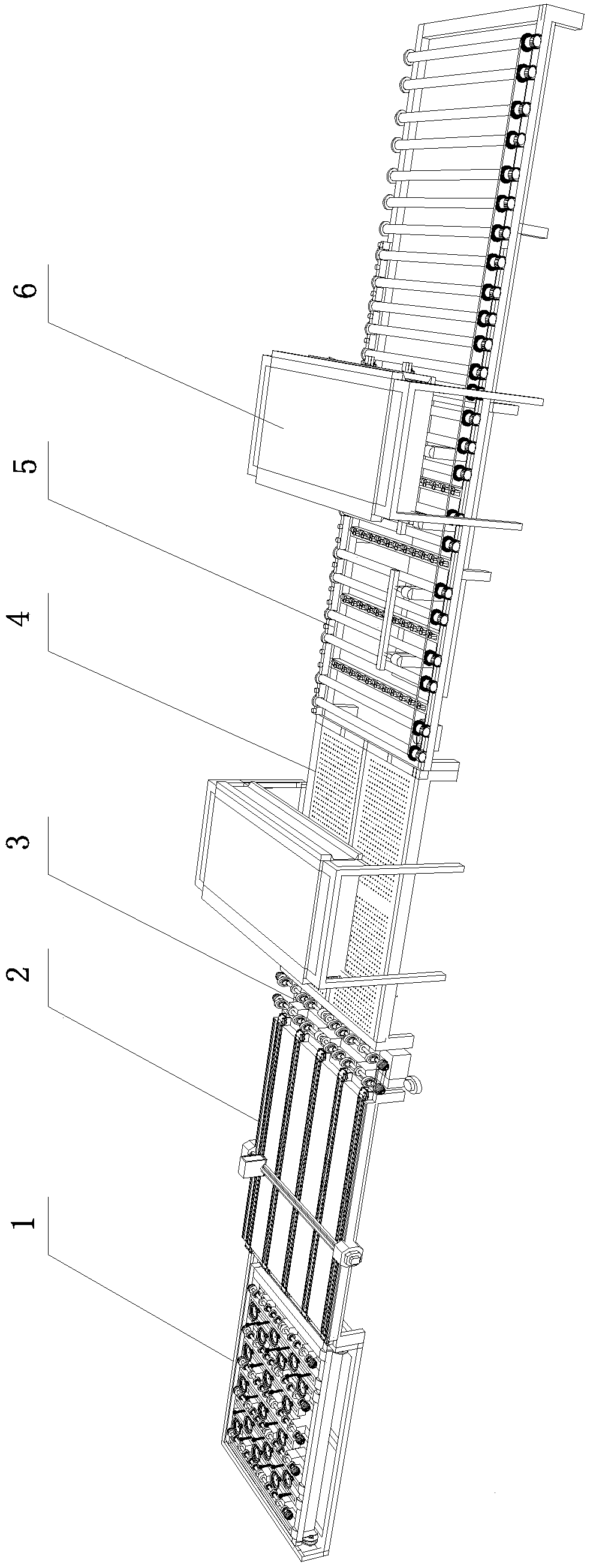

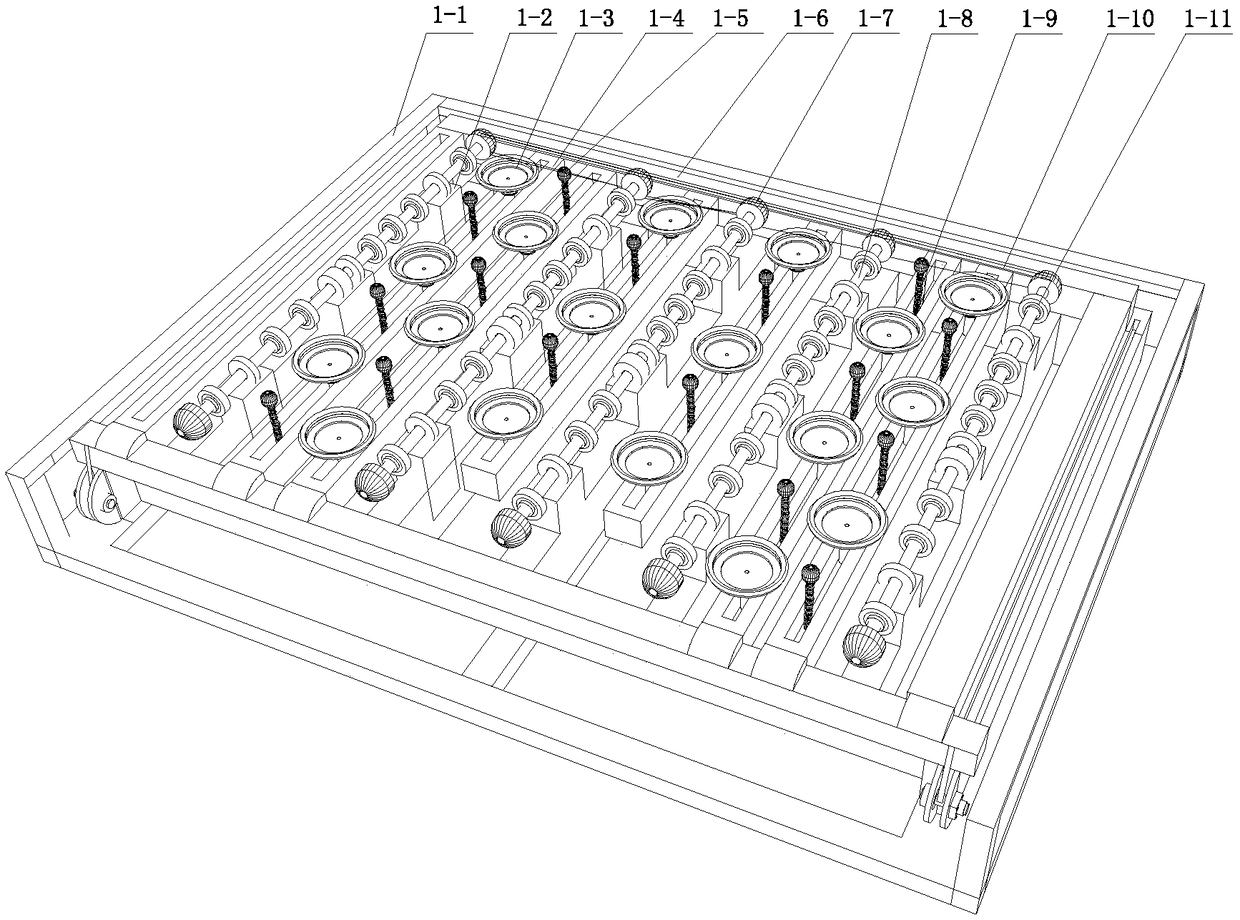

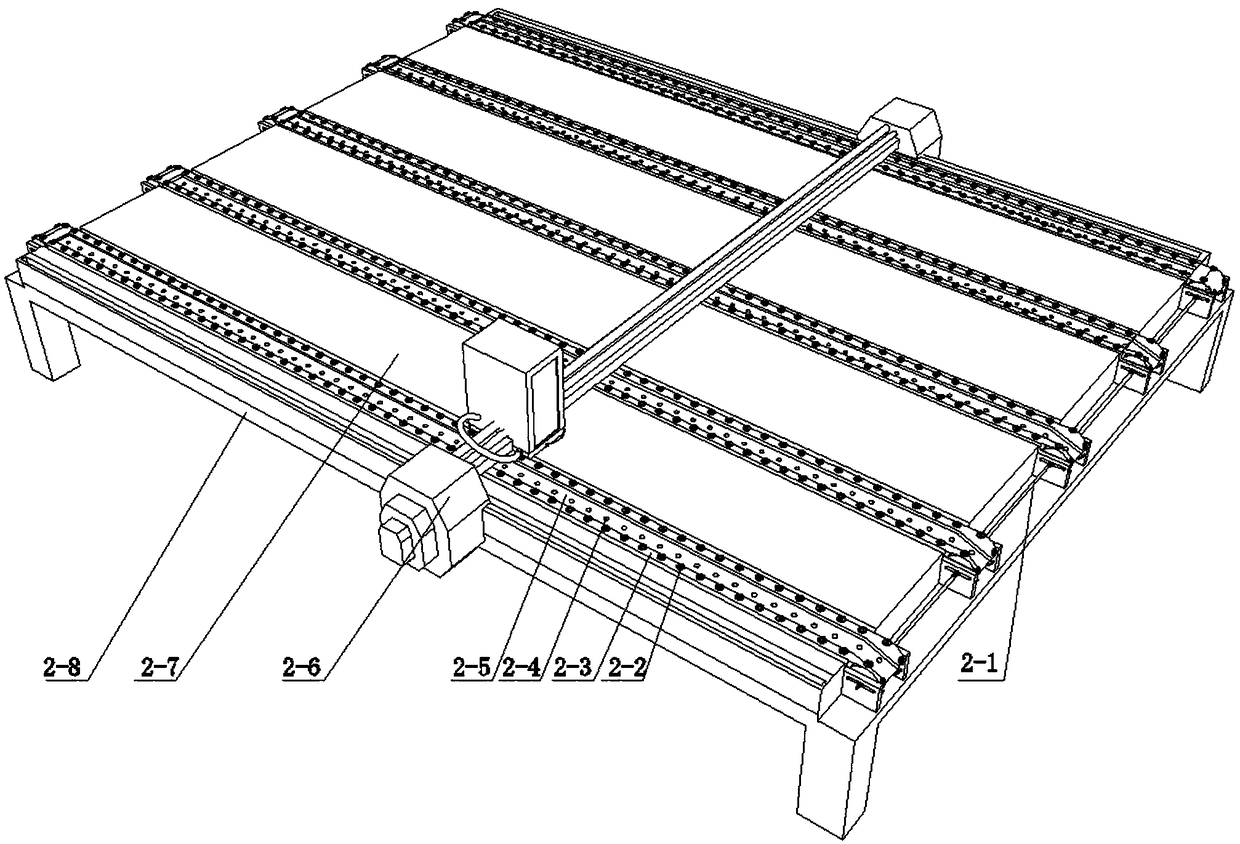

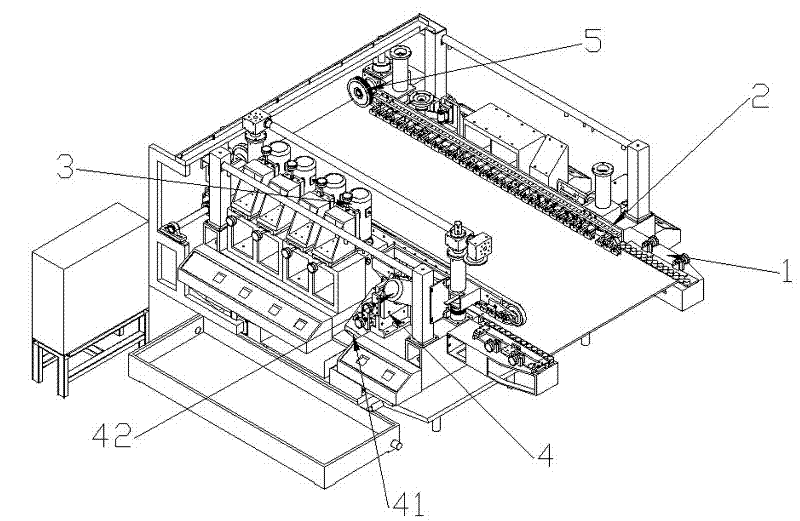

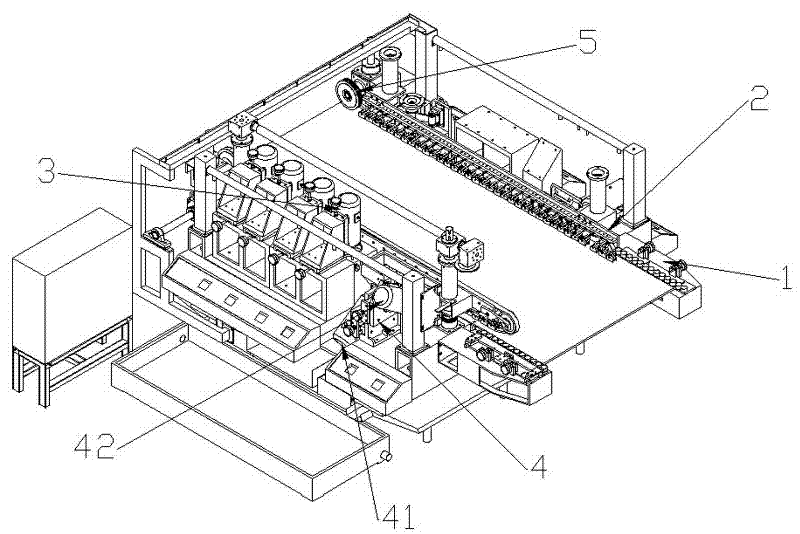

Automatic single-color mosaic-particle lay-up device and lay-up method thereof

ActiveCN104085241AImprove laying efficiencyHigh speedOrnamental structuresConveyor partsEngineeringAutomatic testing

The invention provides an automatic single-color mosaic-particle lay-up device and a lay-up method of the automatic single-color mosaic-particle lay-up device. The automatic single-color mosaic-particle lay-up device comprises a stander, a mosaic forming die which is arranged on the stander, at least one automatic mosaic-particle single-track lay-up unit, a loading device and a controller, wherein each automatic mosaic-particle single-track lay-up unit is used for gradually collecting mosaic particles one by one after transporting the mosaic particles one by one, arranging the mosaic particles into rows / columns according to a preset rule and then driving the entire row / column of mosaic particles to enter a loading procedure; the loading device is connected with the stander and used for sequentially transporting and loading the well-arranged entire row / column of mosaic particles in each automatic mosaic-particle single-track lay-up unit into the mosaic forming die; the controller is respectively connected with each automatic mosaic-particle single-track lay-up unit and the feeding device by signals. The automatic single-color mosaic-particle lay-up device is high in lay-up stability, high in lay-up speed and capable of effectively improving the lay-up efficiency and lay-up accuracy of the mosaic particles. The automatic lay-up method is used for substituting the traditional manual lay-up process, so that the problems that the current mosaic industry is low in automation degree and low in production efficiency can be solved.

Owner:FOSHAN UNIVERSITY

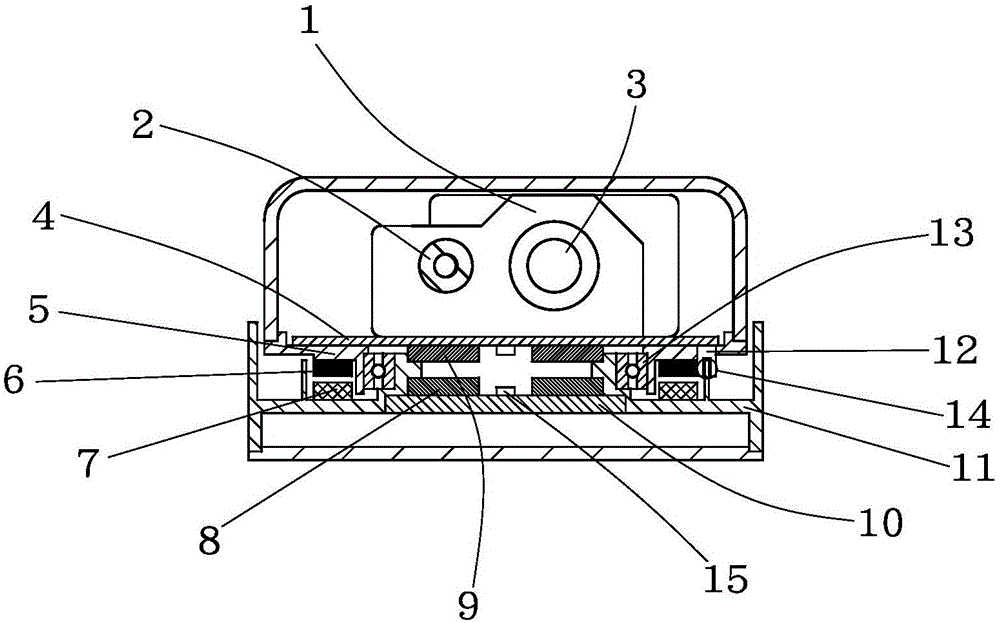

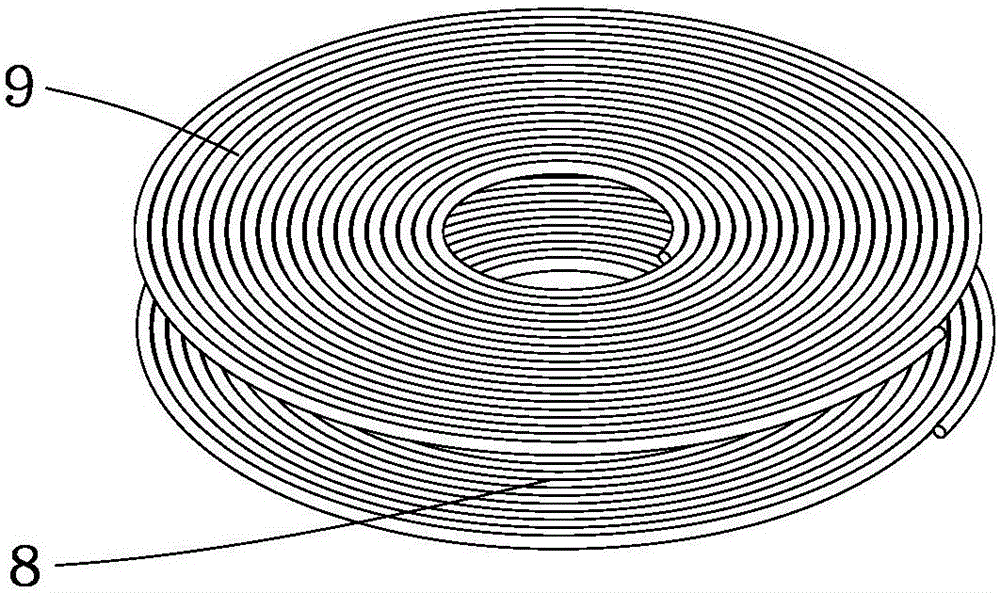

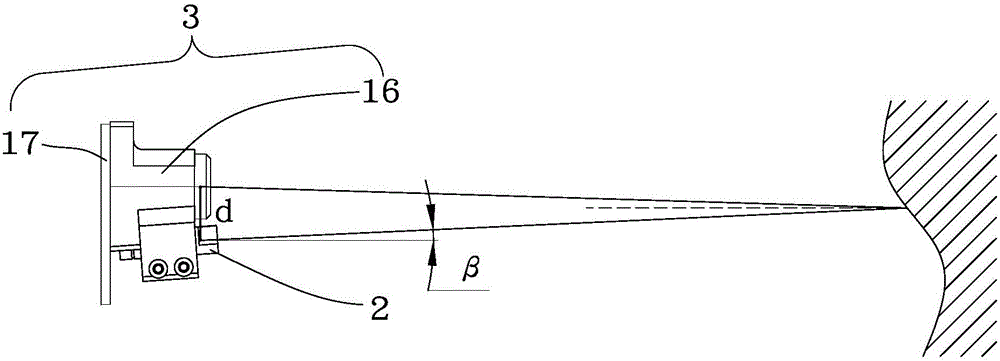

Laser scanning distance measuring device

ActiveCN105785383ALower vertical heightSmall footprintElectromagnetic wave reradiationLaser scanningStator

The invention provides a laser scanning distance measuring device. A rotation platform and a fixed platform are connected through a shaft bearing; rotors are installed on the rotation platform; stators are installed on the fixed platform; a drive transmitting circuit board is installed on the fixed platform; a receiving circuit board is installed on the rotation platform; a hollow transmitting coil is installed on the fixed platform; a magnetic isolating sheet is arranged between the hollow transmitting coil and the drive transmitting circuit board; a hollow receiving coil is installed on the rotation platform; a magnetic isolating sheet is arranged between the hollow receiving coil and the receiving circuit board. Compared with the prior art, the hollow transmitting coil and the hollow receiving coil are tiled in the direction vertical to the rotation shaft so that the vertical height of the laser scanning distance measuring device is shortened and therefore, the occupation volume of the whole structure of the laser scanning distance measuring device is reduced. In addition, when the vertical height of the overall device is reduced, the communication distance of spectrum diode for signal wireless transmission is reduced and therefore, the transmission speed of wireless signals is increased.

Owner:SHANGHAI SLAMTEC

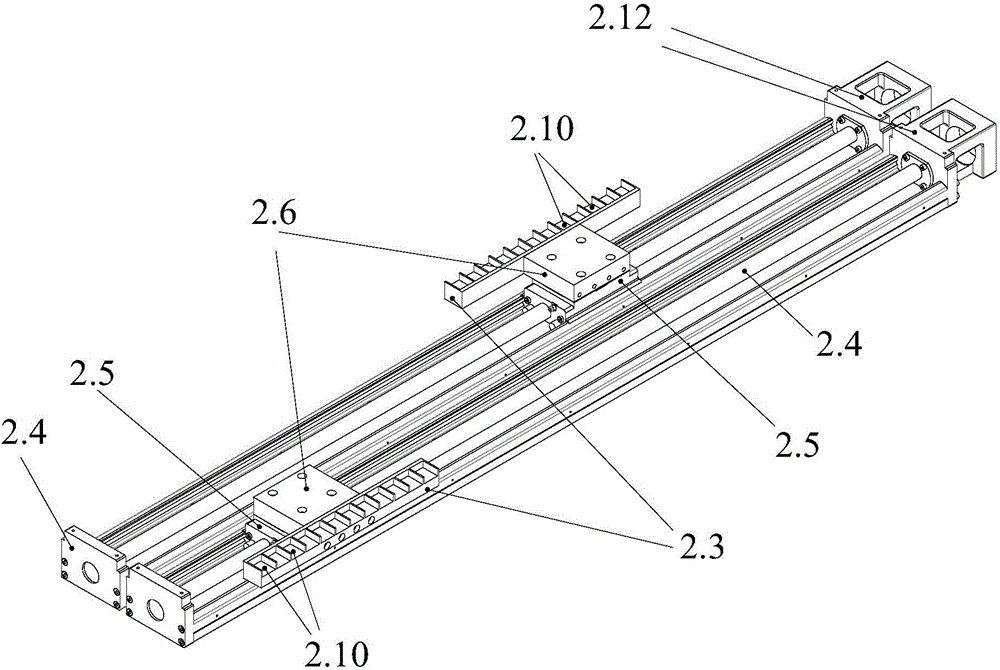

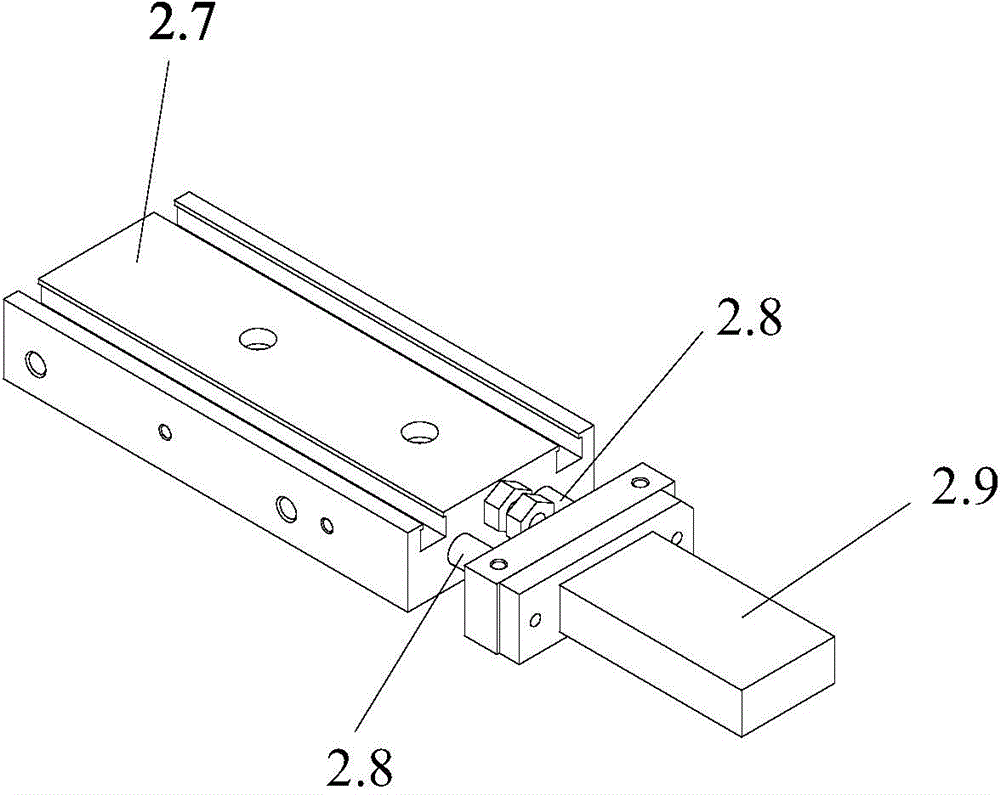

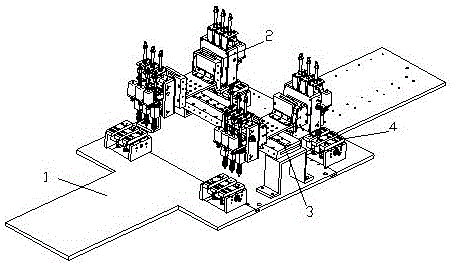

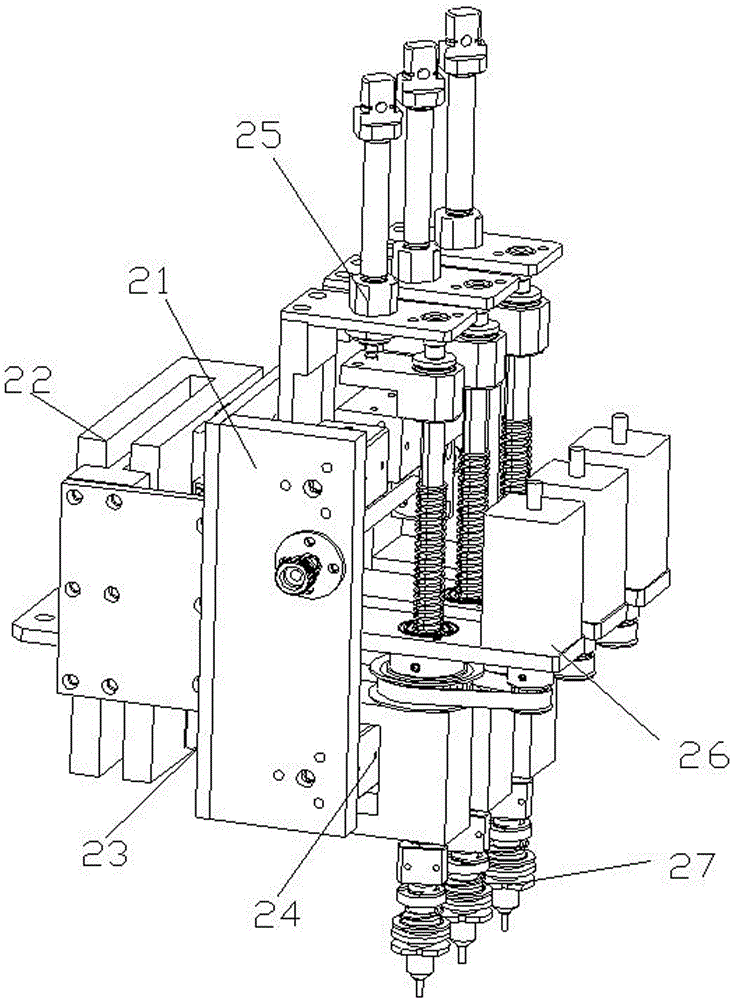

Linear motor driven chip mounter

ActiveCN105142356AAchieve the purpose of suctionSpacing is easy to adjustPrinted circuit assemblingLinear motorElectronic component

The invention discloses a linear motor driven chip mounter. The chip mounter comprises a base plate, a mounting head part, a mounting beam and a feeder; the feeder is arranged on the base plate; the mounting beam is arranged on the base plate; the mounting head part is arranged at the upper part of the mounting beam; the chip mounter is driven by the linear motor; the mounting head part and the feeder adopt equally spaced adjusting mechanisms, so that the chip mounter is suitable for mounting electronic components at different spacings; the mounting head part adopts a dual-lifting mechanism, so that the purpose of material suction and material dropping at the same time is fulfilled; and in addition, the chip mounter is simple in structure, convenient to operate, high in mounting speed, high in position precision and capable of effectively enhancing the productivity.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

An upper and lower hot air drying oven for single-sided printing or coating

ActiveCN102294883AImprove drying efficiencyIncrease transmission speedPrinting press partsEngineeringDrying time

The invention discloses an upper and lower hot air type drying box used for single-sided printing or coating. The invention aims to solve the defects in the prior art that the drying time is long when single-sided air supply is carried out on the base material oil ink or coating layer top surface to affect the drying efficiency and transmission speed, or a drying oven is long, and an operation field is big. The technical scheme has the key point that the upper and lower hot air type drying box is composed of a box shell, a plurality of parallel base material backup rolls in the box shell, a plurality of upper hot air supply pipes above the base material backup rolls, an upper hot air equalizing chamber, an upper hot air transmission path and an upper air return chamber, wherein the slice base material enters from a feed port, is supported on the base material backup rolls to operate and is discharged from a discharge hole; and each upper hot air supply pipe is provided with an air supply outlet parallel to the top surface of the slice base material, wherein the top surface is provided with a printing or coating layer. The upper and lower hot air type drying box is characterized inthat a plurality of lower hot air supply pipes, a lower hot air equalizing chamber, a lower hot wind transmission path and a lower air return chamber are arranged below the base material backup rollsby the box shell; and each lower hot air supply pipe is provided with an air supply outlet parallel to the back surface of the slice base material, and the back surface is provided with a printing orcoating layer.

Owner:SHANTOU OLGER PACKING MACHINERY

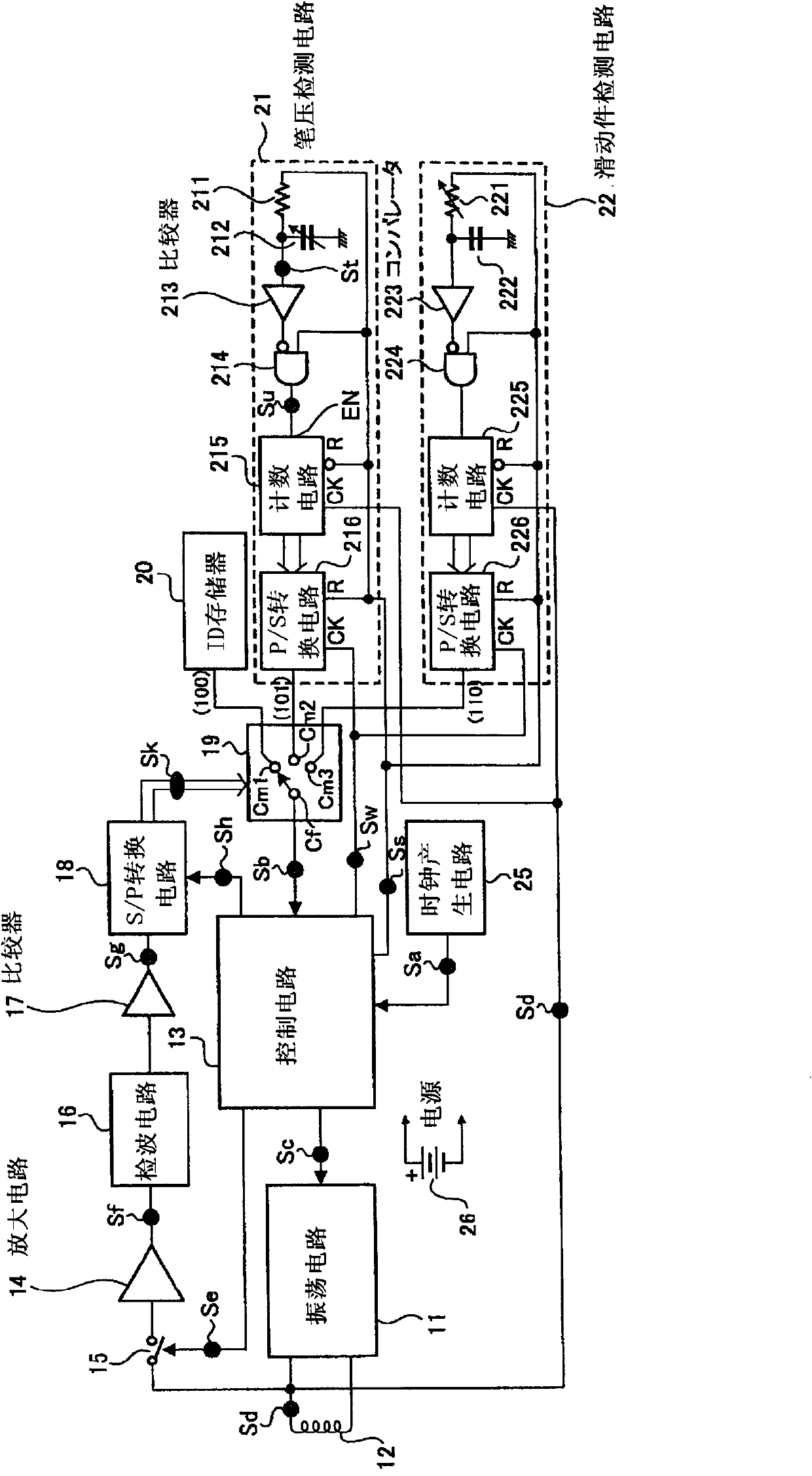

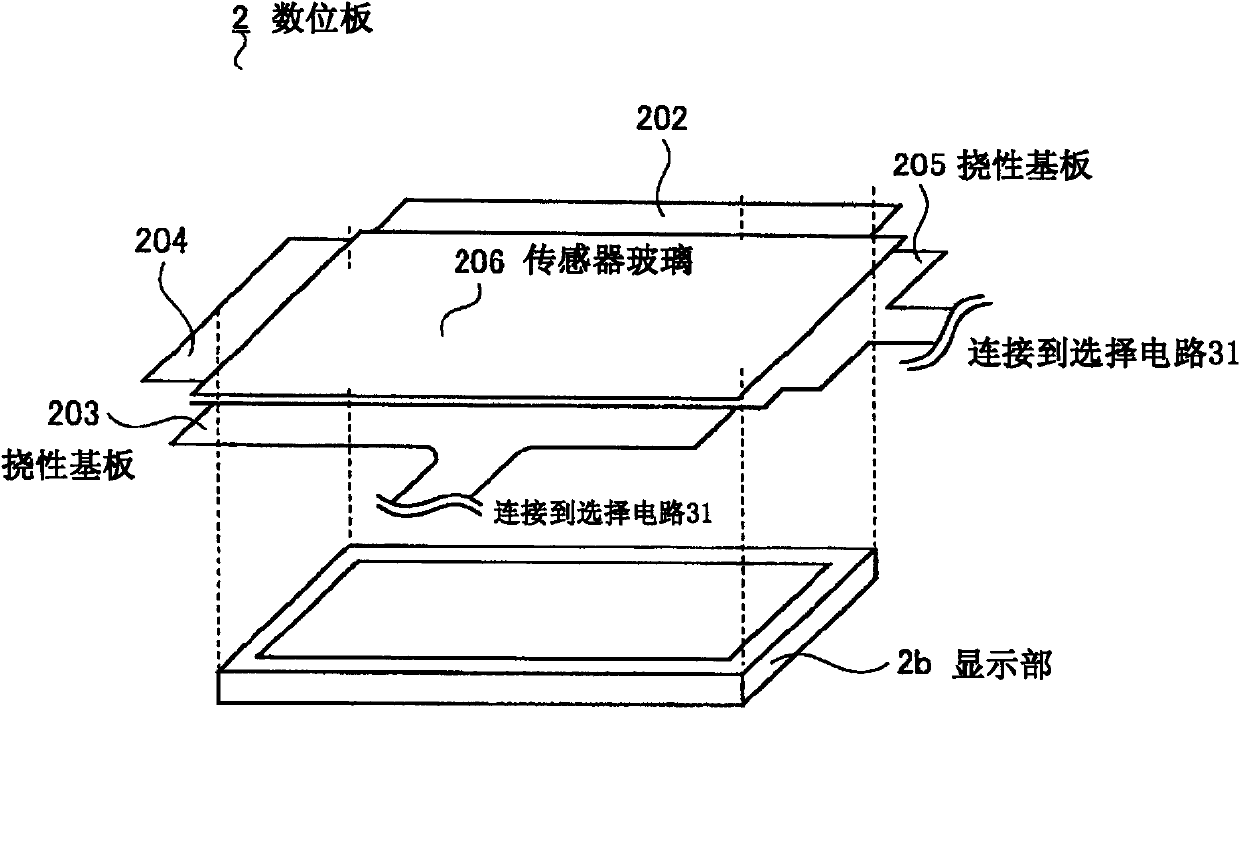

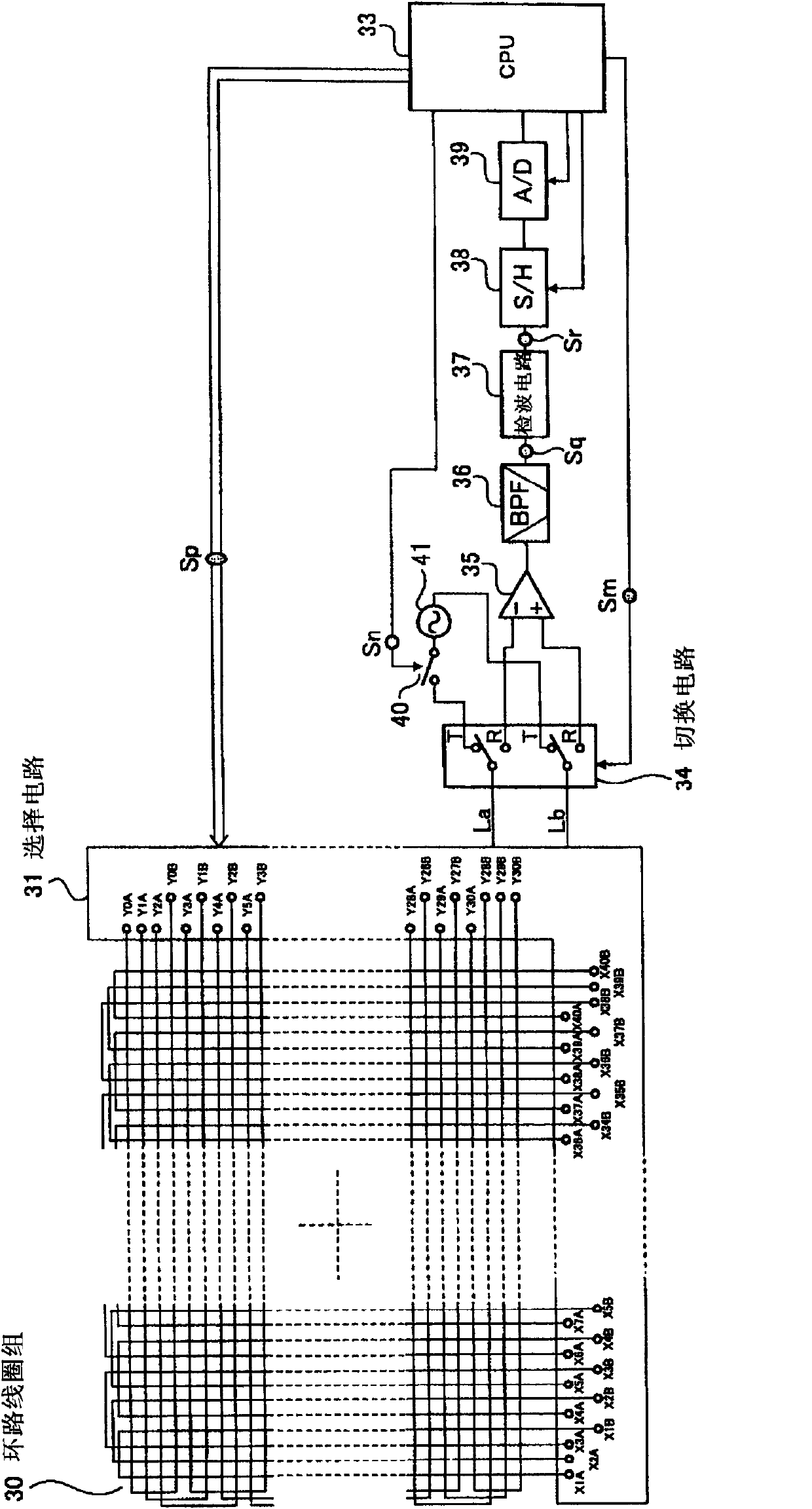

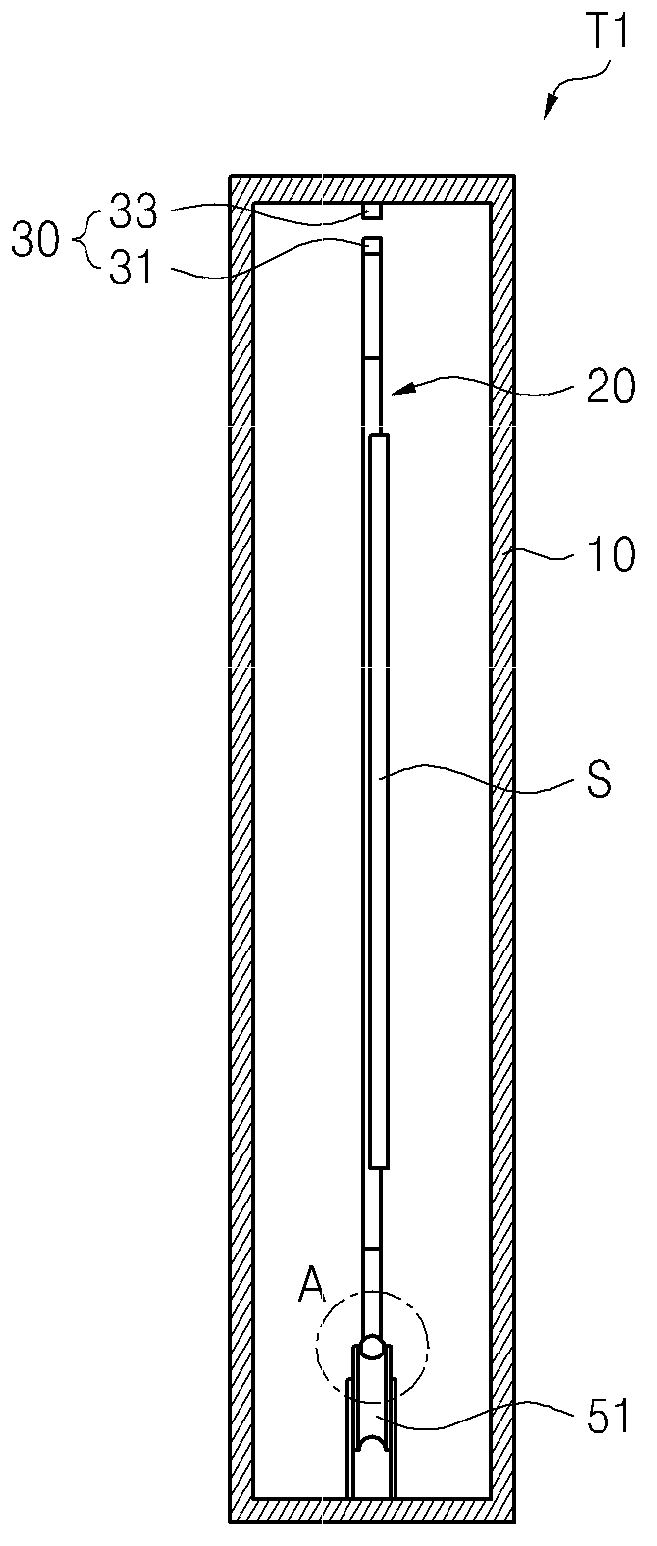

Position detector and position indicator

ActiveCN102043489ATransmission speed will not dropReliable sending and receivingInput/output processes for data processingInformation transmissionControl signal

A position detector and a position indicator, wherein the position indicator stores various information to prevent transmission speed of information from decreasing in detection on a digital panel side. The position indicator includes an information storage mechanism for storing various information; a control signal receiving mechanism for receiving control signals from the digital panel; an information selection mechanism for selecting information from the various information stored in the information storage mechanism based on content of the control signal; and an information transmission mechanism for transmitting selected information to the digital panel. The digital panel includes a position signal receiving mechanism for receiving position indication signals; a timing information extraction mechanism for extracting a predetermined timing from the position indication signal; and a control signal transmission mechanism for transmitting a control signal to the position indicator. Furthermore, the position signal receiving mechanism of the digital panel receives position indication signals transmitted disconnectedly and transmits control signals to the position indicator in accordance with an extracted timing.

Owner:WACOM CO LTD

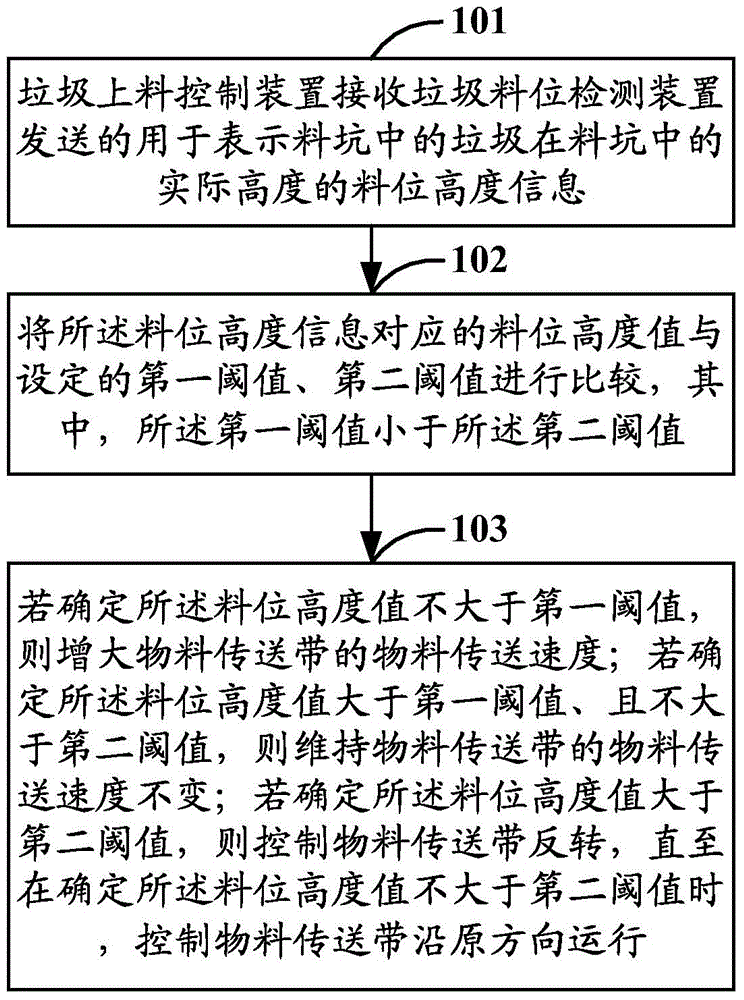

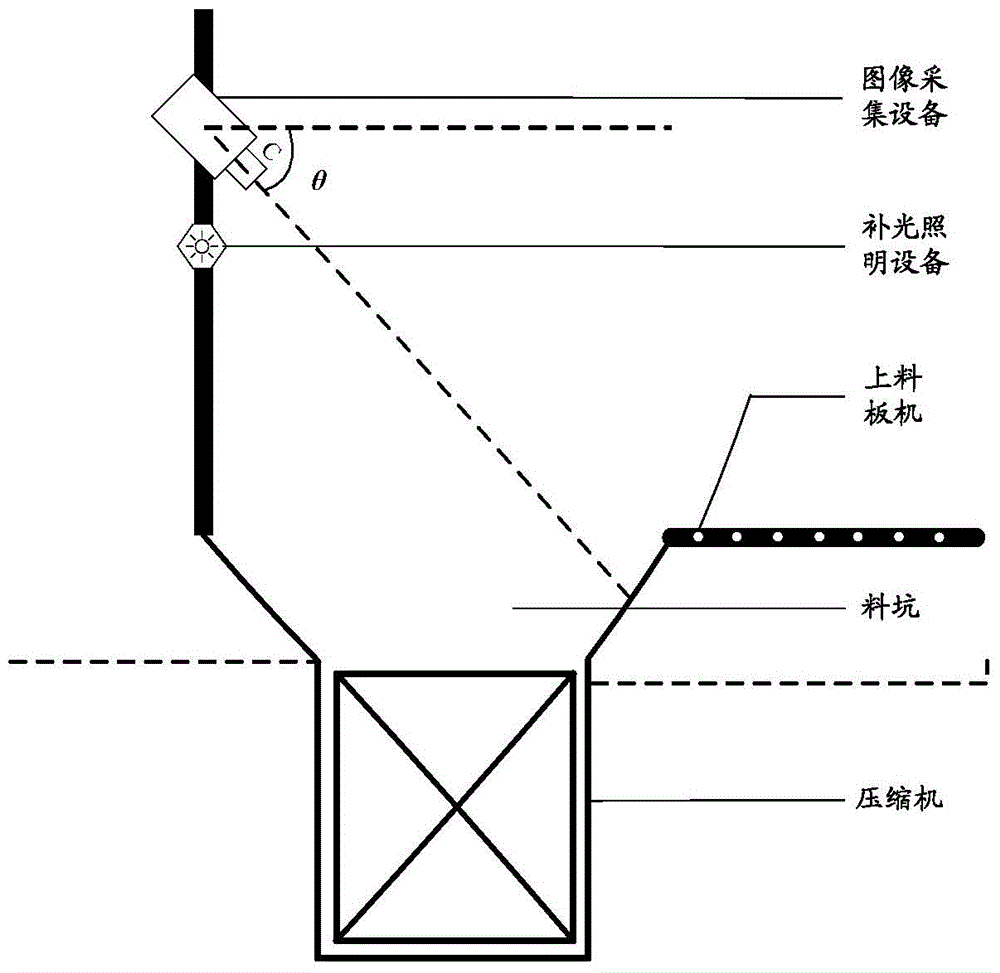

Garbage feeding control method and device and feeding trigger

ActiveCN105217198AImprove accuracyImprove control efficiencyRefuse transferringLoading/unloadingAutomatic controlMechanical engineering

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

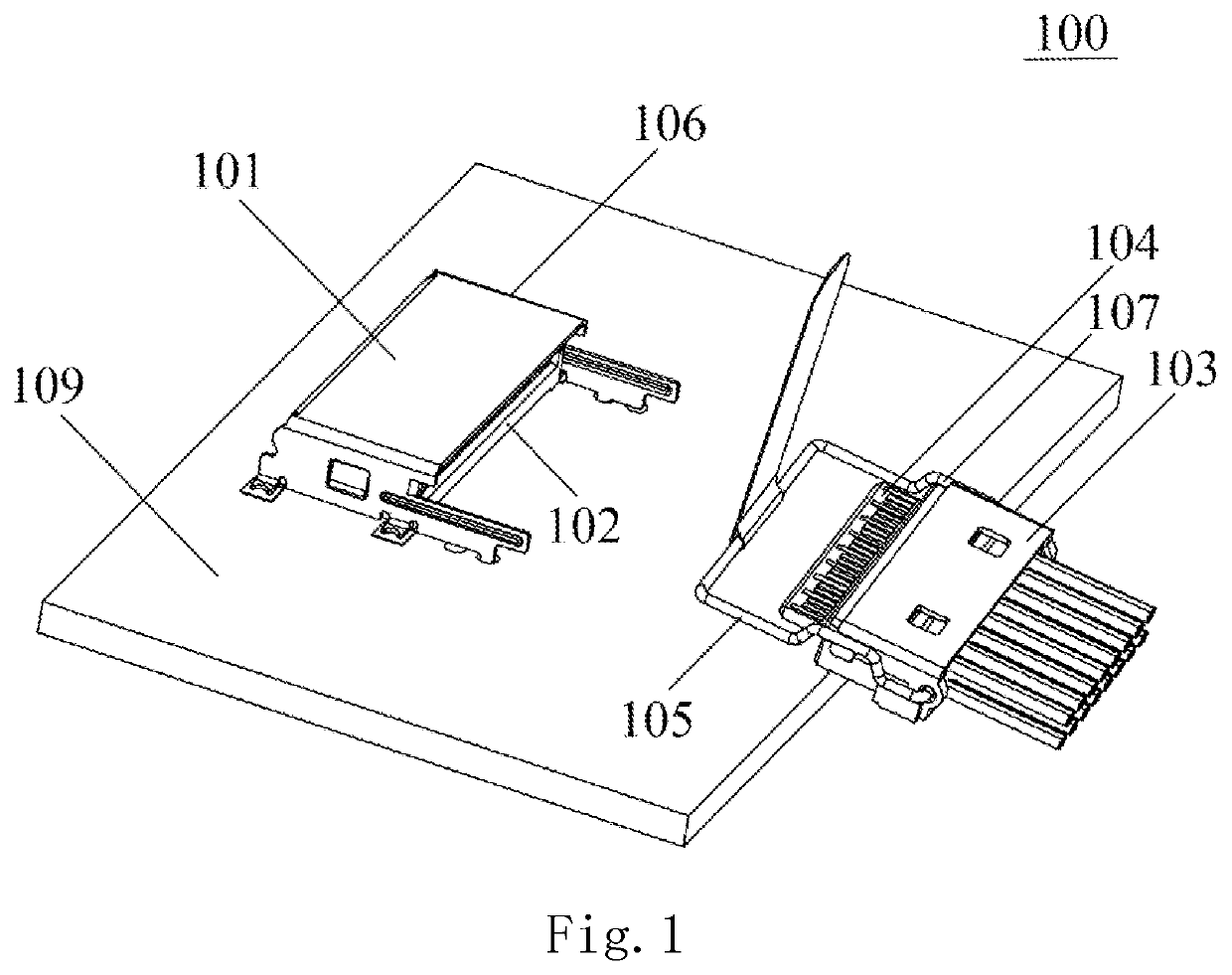

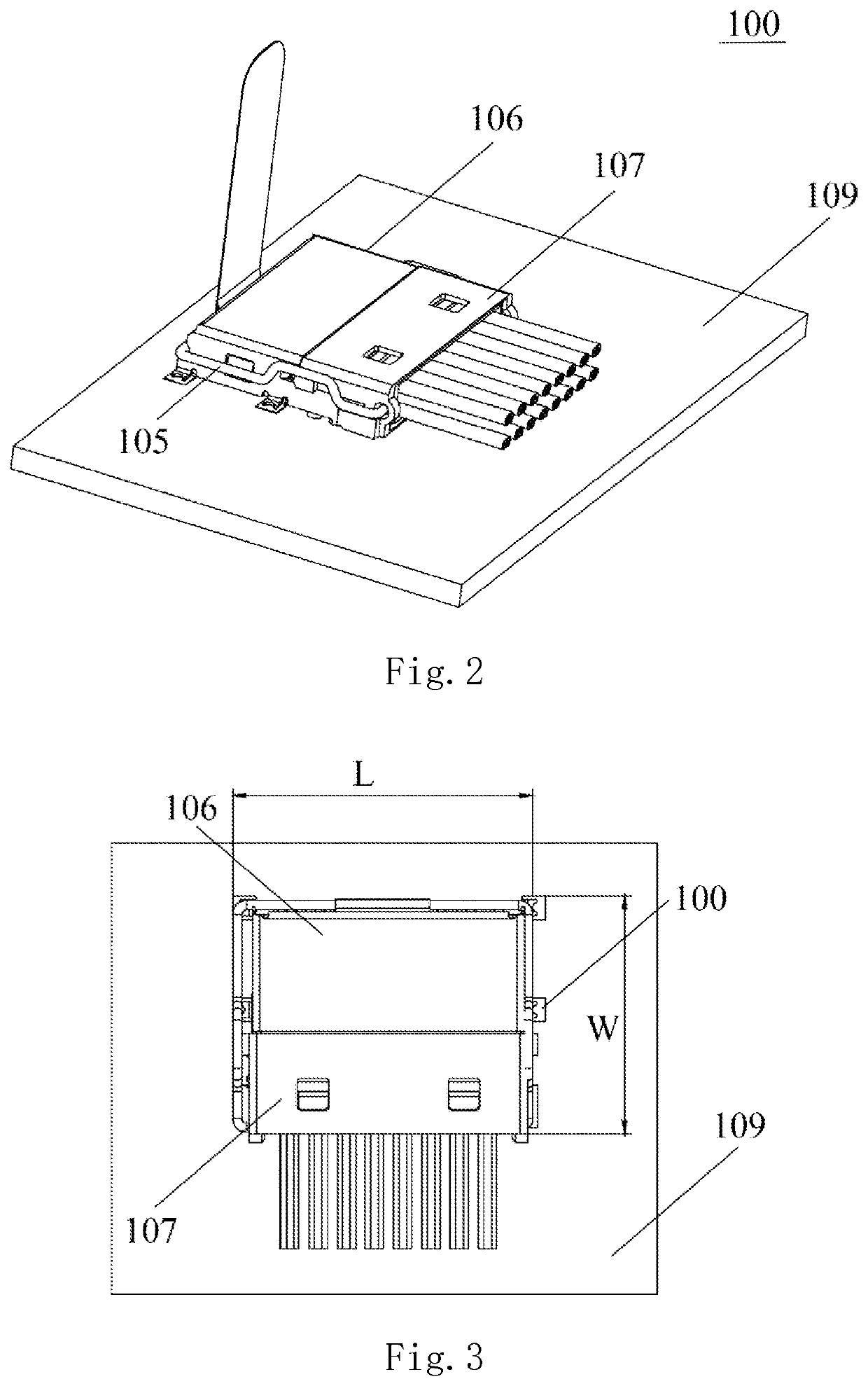

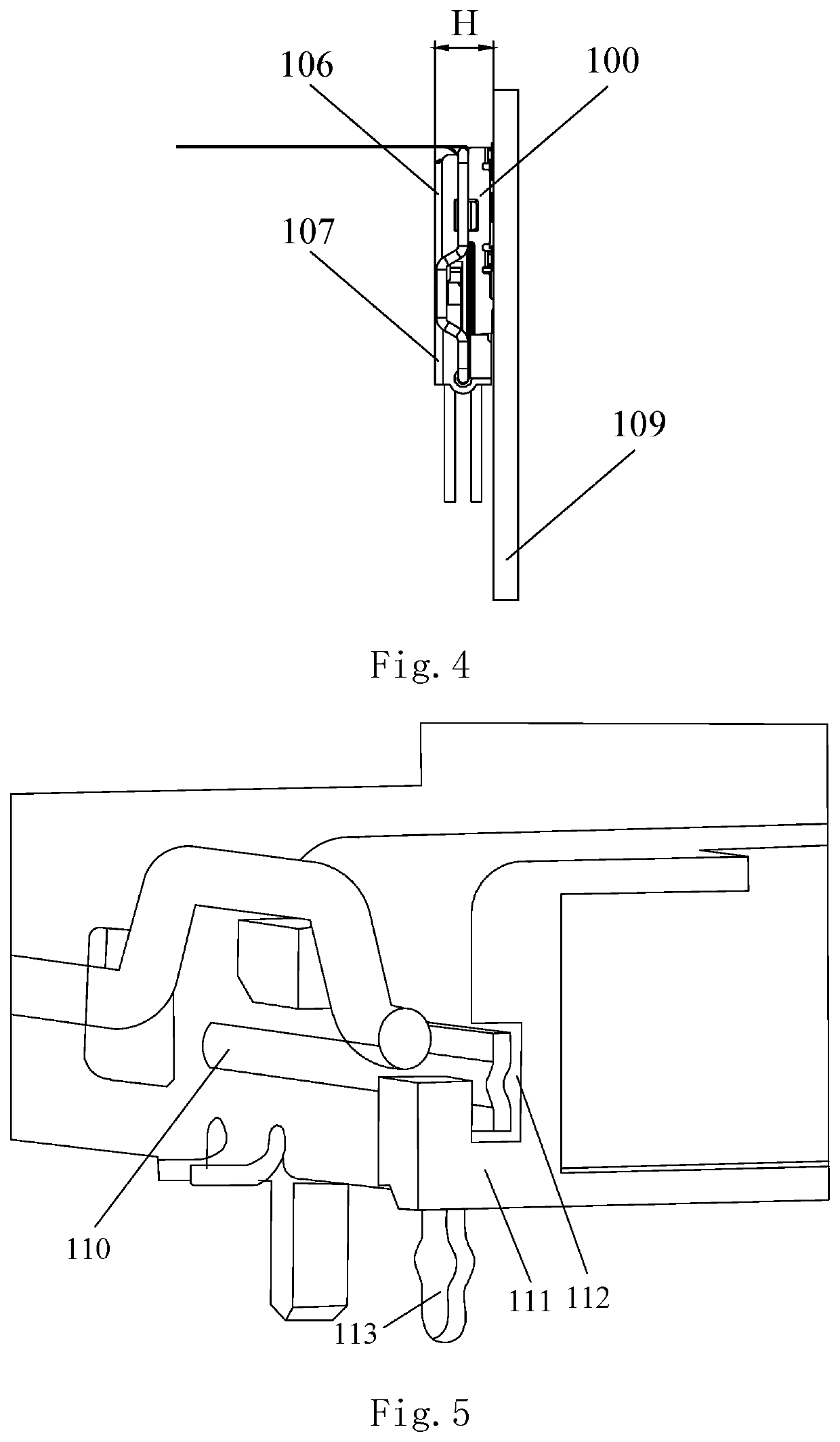

High-speed connector on high-density mini version chip side

ActiveUS20190372251A1Data augmentationImprove processing speedCoupling device detailsFixed connectionsHigh densityButt joint

The present invention provides a high-speed connector on a high density MINI version chip side, which comprises a board end connector, a wire end connector and a printed circuit board; the board end connector is arranged on the printed circuit board; the board end connector comprises a board end connector shell and a board end connector body arranged in the board end connector shell; the wire end connector comprises a wire end case and a tongue plate fixed to the wire end case; wherein at least one guide piece is extended from the board end connector shell, and the wire end case is provided with at least one guide slot for creating a butt joint with the guide piece. The connector of the present invention utilizes the space of the board end to the maximum extent, solves the problem that the CPU occupies the space of the board end due to the increased size of the heat dissipation module, and can realize high-speed data transmission.

Owner:LUXSHARE TECH INT INC

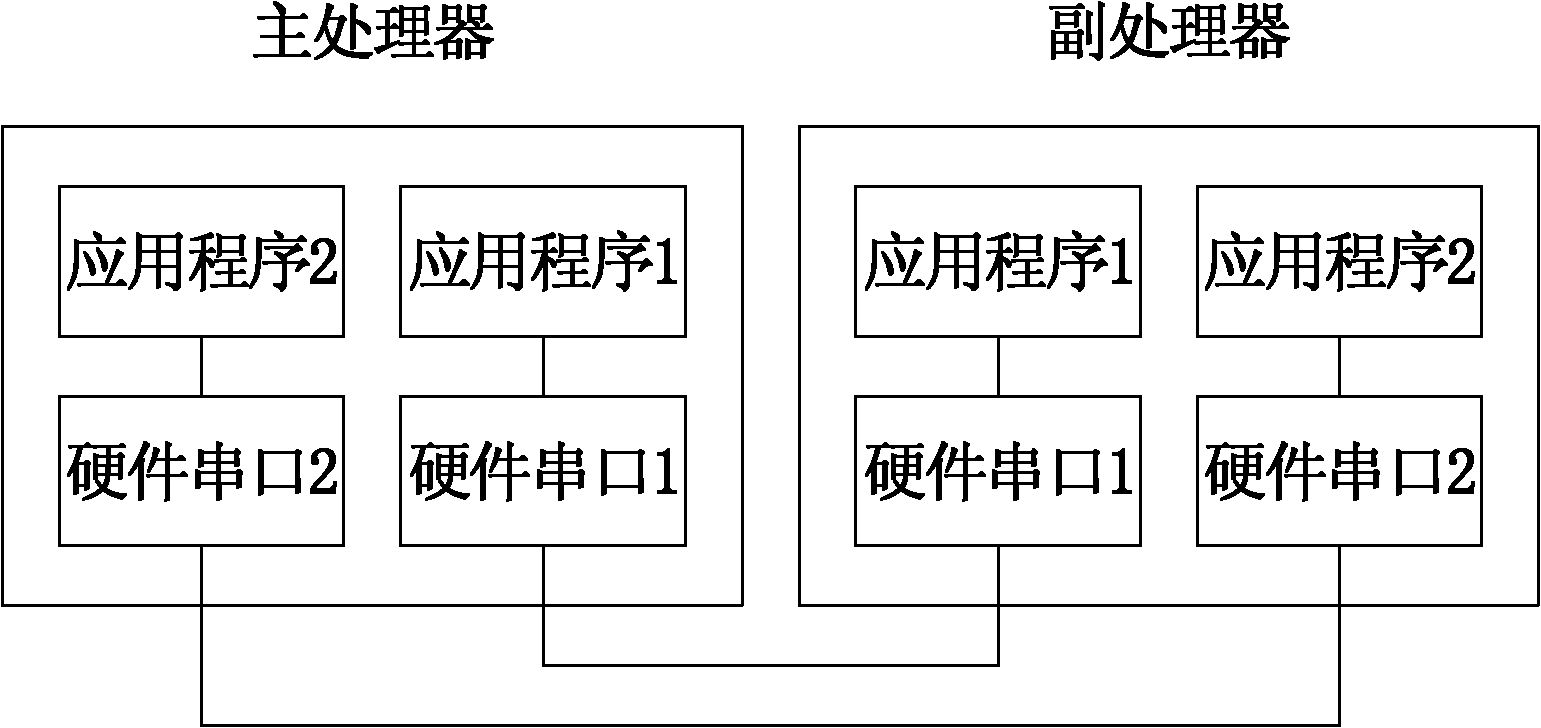

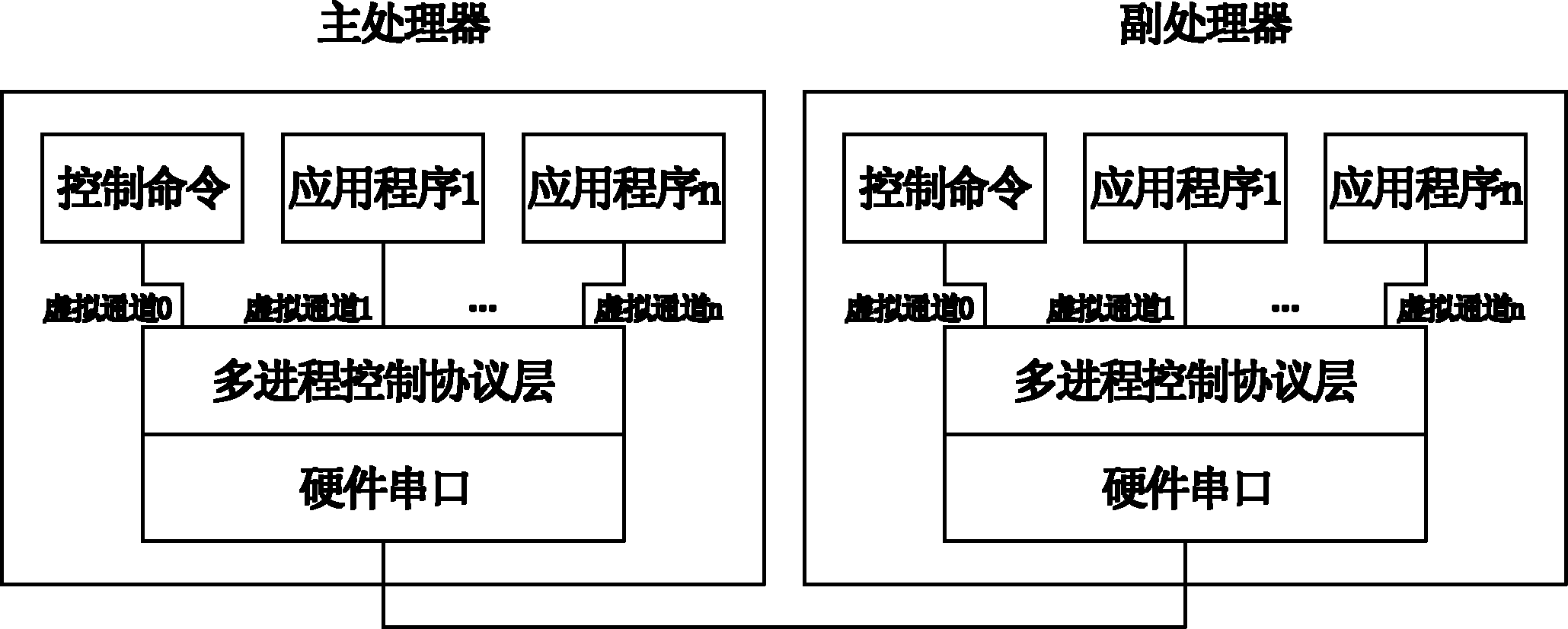

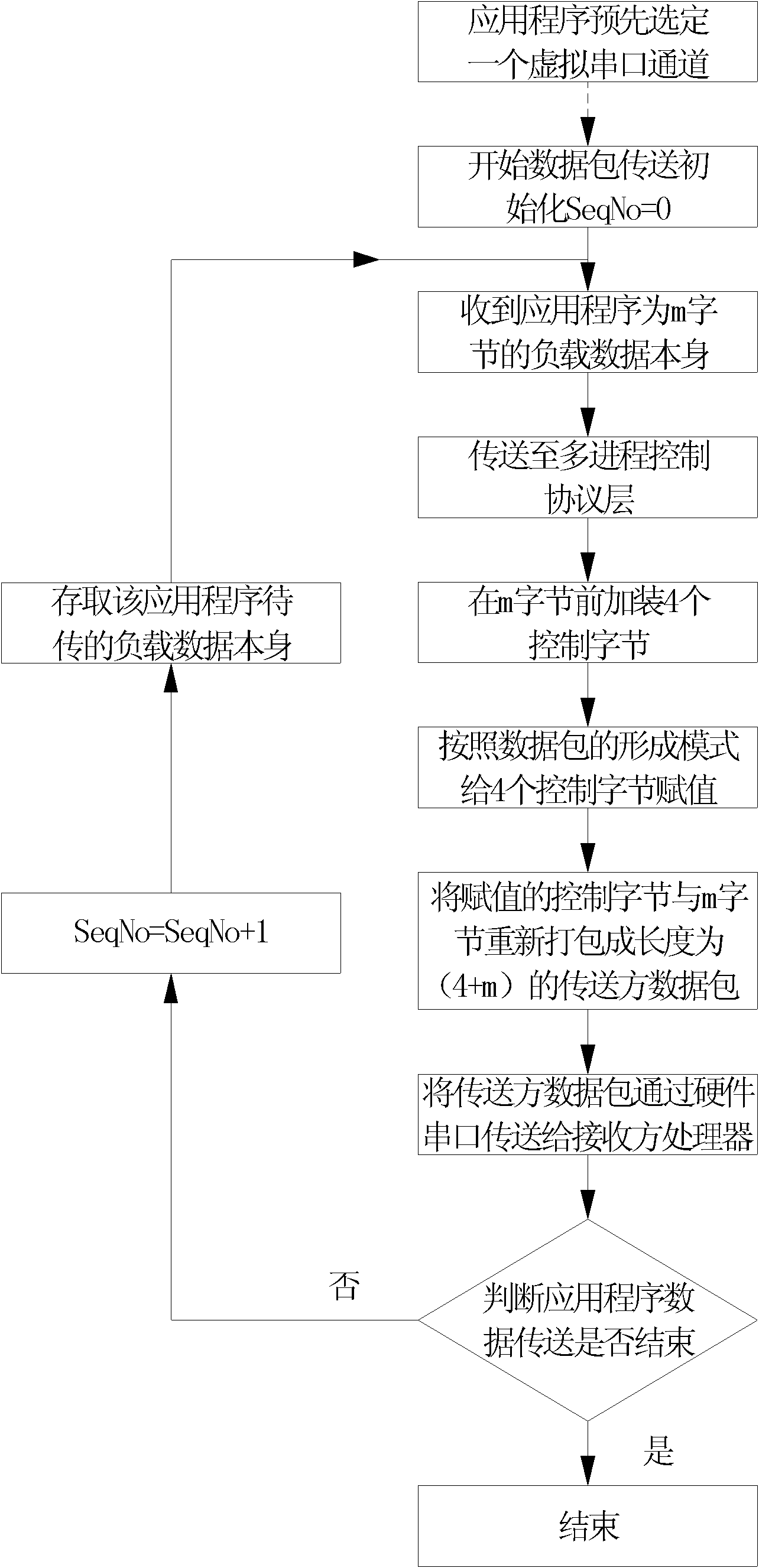

Communication method for implementing multi-process control through single hardware serial port

The invention discloses a communication method for implementing multi-process control through a single hardware serial port, which comprises the steps that: as much as 16 virtual serial port channels are provided on the single hardware serial port, a transmitting party transmits an application data packet to a receiving party on a multi-process control protocol layer according to the generation mode of the data packet, the receiving party unpacks and analyzes the data packet on the peer-to-peer multi-process control protocol layer. The method has the advantages that: multi-process control is offered to application by utilizing one essential hardware serial port, thereby saving the pin of hardware chip which increasingly becomes valuable in product design and being favorable for chip minimization; only 4 bytes are used as the control bytes for the data packet, which greatly improves the transmission speed and efficiency of data on the hardware serial port; and the data packet adopts the simple and effective generation mode which only takes up quite less memory and calculation resource, so the communication method is particularly suitable for high-speed data transmission and portable electronic products.

Owner:INTEBYTE ZHENJIANG

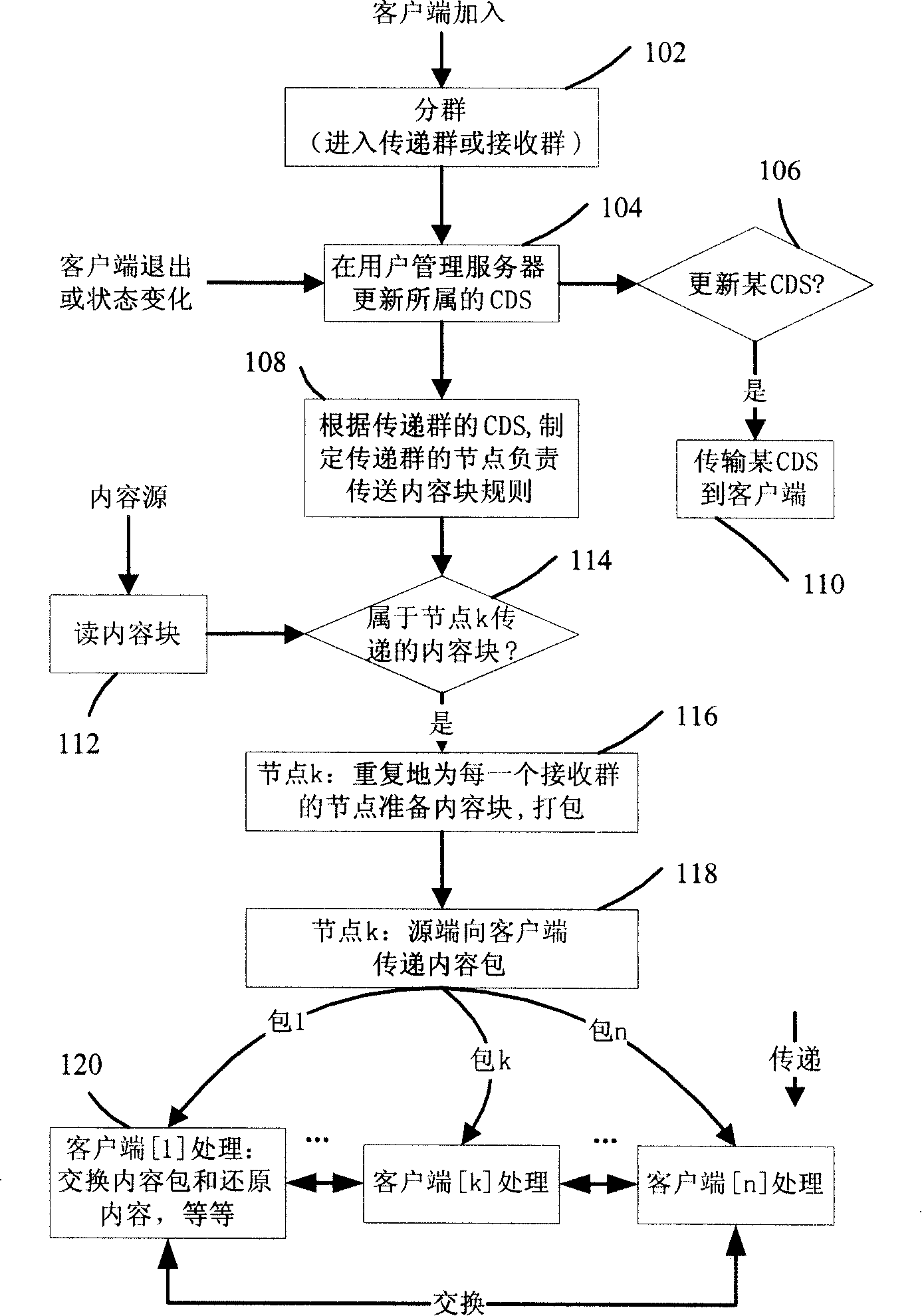

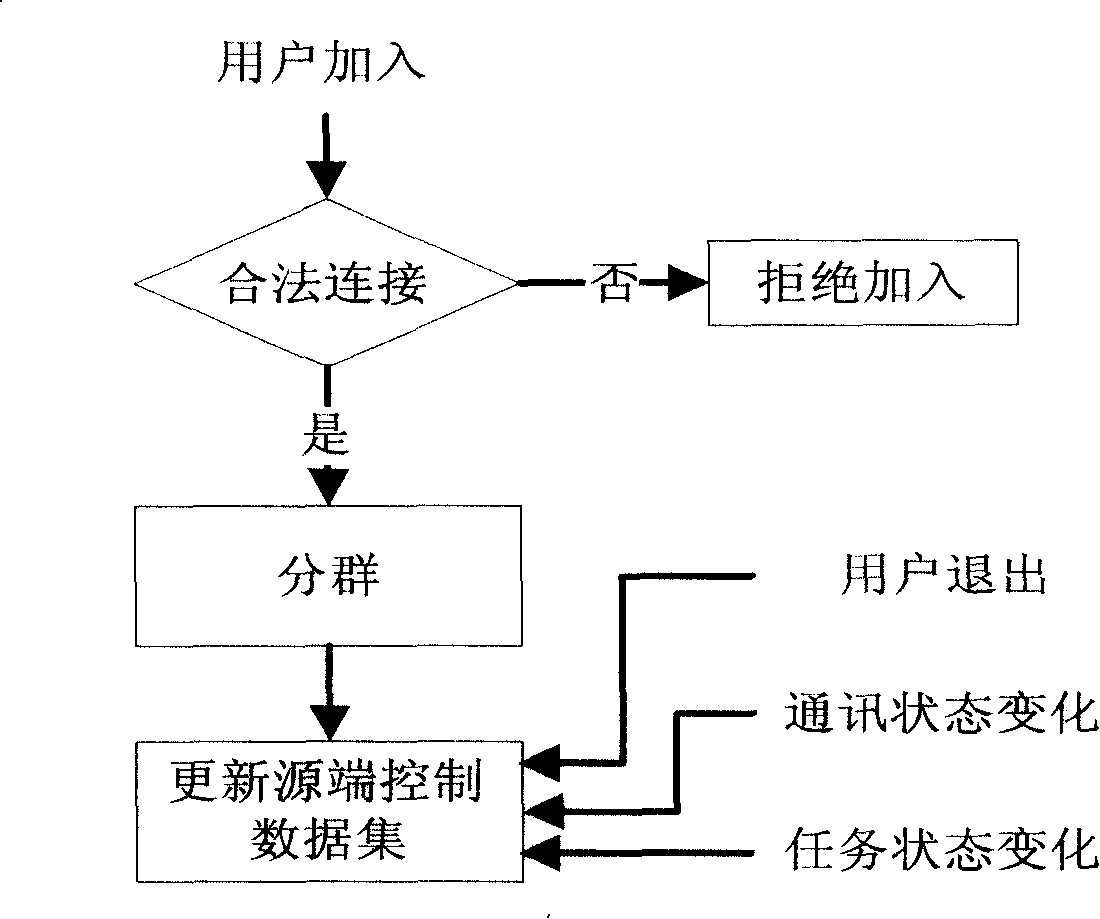

A content distribution method and system in computer network

InactiveCN101242337AReduce congestionIncrease transmission speedSpecial service provision for substationHybrid transportContent distributionData set

Owner:张永敏

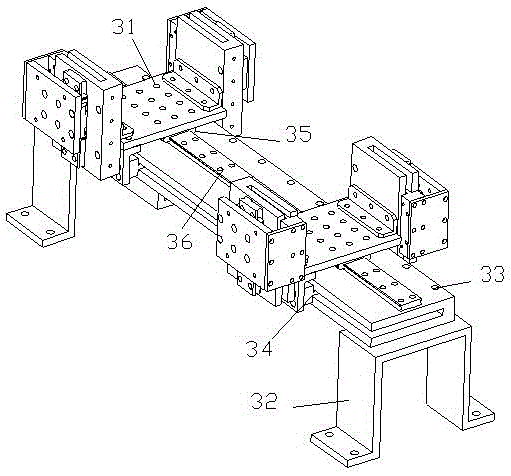

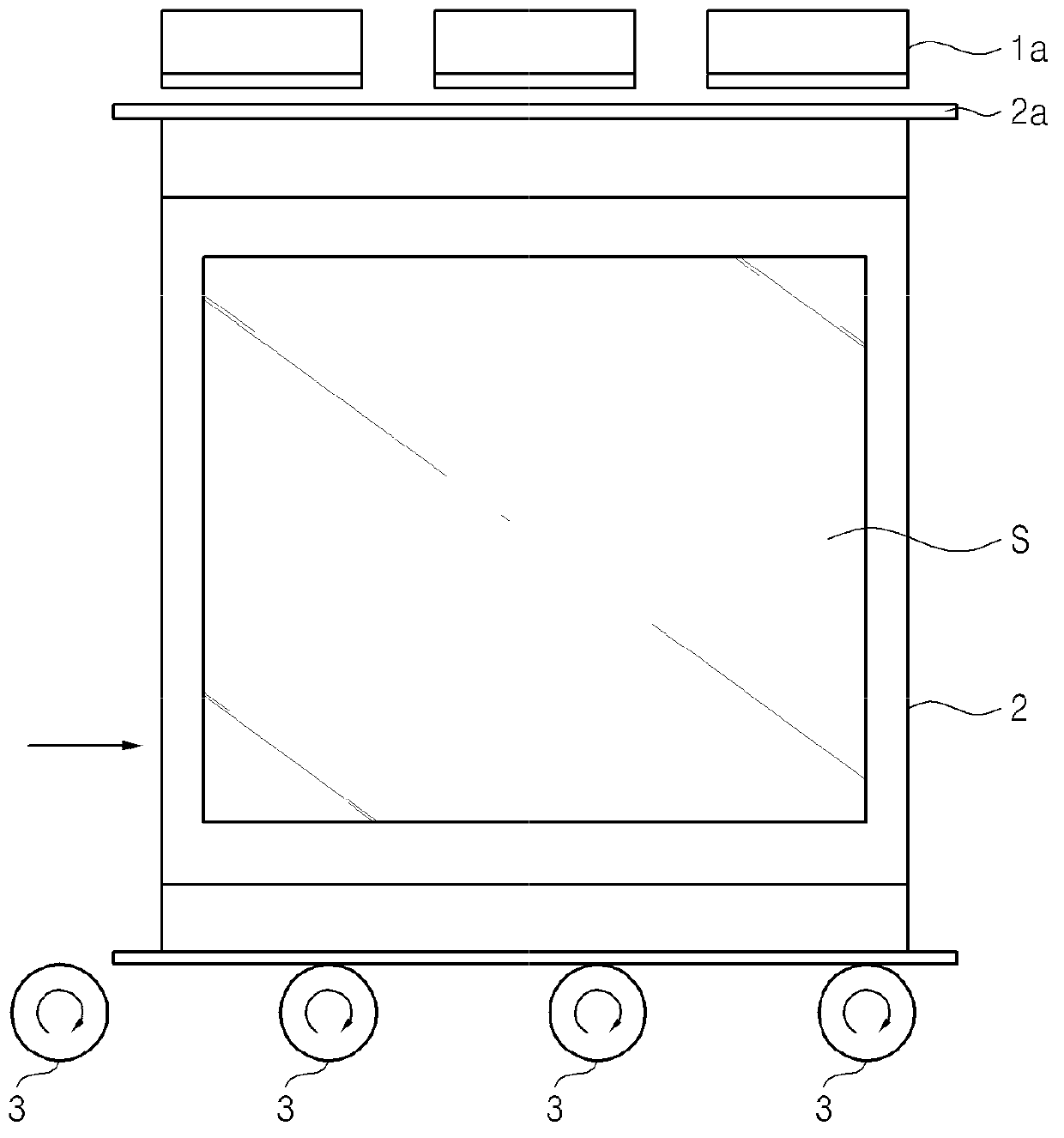

Substrate conveying system

InactiveCN101643145AIncrease transmission speedShorten the production cycleArticle feedersMultilayer circuit manufactureMechanical engineering

The invention provides a substrate conveying system which comprises a first conveying device, a second conveying device and a transferring device, wherein the first conveying device comprises a plurality of first conveying units which are distributed at intervals; the second conveying device comprises a plurality of second conveying units which are distributed at intervals; a first channel is formed between every two adjacent first conveying units, and a second channels is formed between every two adjacent second conveying units; the transferring device comprises a lifting device and a plurality of bearing pieces which are fixed on the lifting device; and the lifting device is arranged opposite to the first channels and the second channels in a slide mode so as to ensure that the bearing pieces can move along the first channels and the second channels. The substrate conveying system can conveniently switch the conveying direction of a substrate and has high conveying efficiency.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

Device used for conveying substrate

InactiveCN102849462AIncrease transmission speedIncrease/decrease transfer speedCharge manipulationSequential operation station machinesVacuum chamberMechanical engineering

The invention discloses a device used for conveying a substrate. The device used for conveying the substrate includes a vacuum chamber; a tray used for conveying the substrate in the vacuum chamber; an upper conveying unit used for transmitting driving force to the upper part of the tray in a manner of not contacting with the upper end part of the tray; a relative movement allowing unit coupled to the lower end part of the tray and capable of moving relatively to the tray; and a plurality of guide units used for contacting with the relative movement allowing unit and guiding the movement of the tray.

Owner:SFA ENG CORP

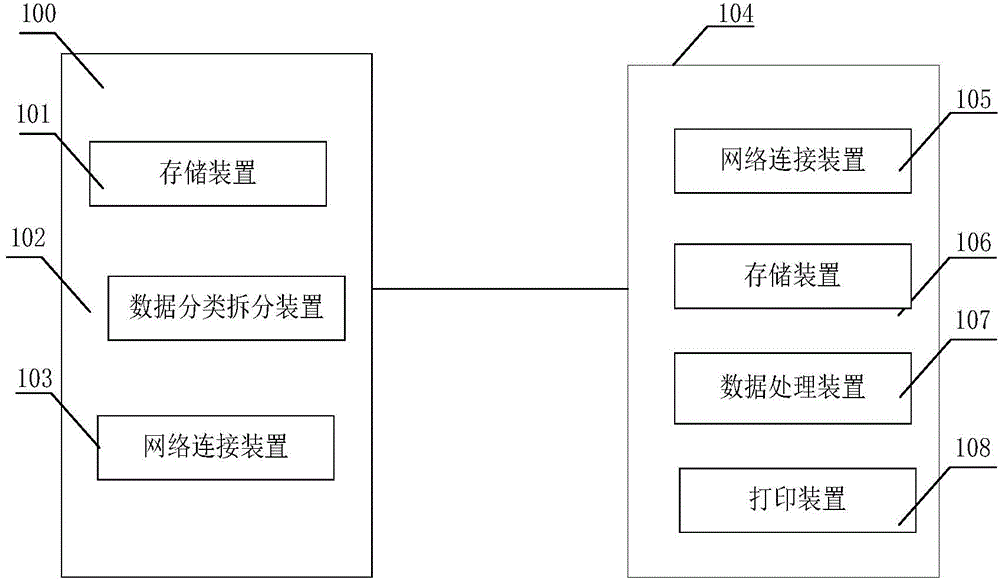

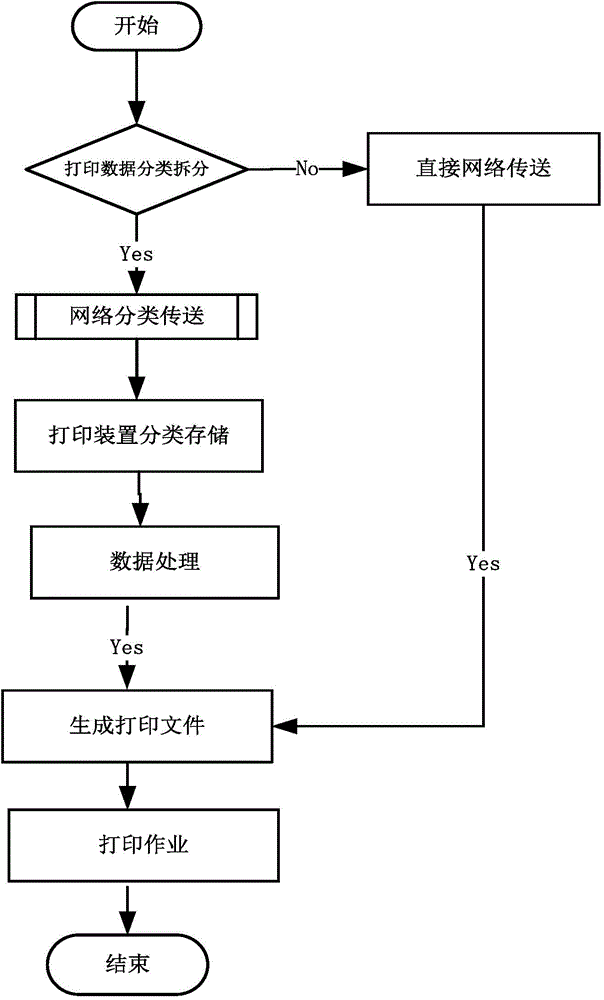

Network printing system and printing method for network printing systems

InactiveCN103559001AReduce trafficSave transmission resourcesTransmissionDigital output to print unitsData transmissionData splitting

The invention provides a network printing system and a printing method for network printing systems. The network printing system comprises a print data sending device and a printing device, wherein the print data sending device is used for dividing print data into two or more than two categories and sending the two or more than two categories of data to the printing device, the printing device synthetically processes various print data, and generated complete print file data are printed and output. By means of the printing system, occupation of network bandwidth resources by data transmission modes in existing printing systems can be reduced, therefore, the network transmission speed of data can be increased, and the network printing speed of files can be increased.

Owner:AETAS TECH ZHENJIANG

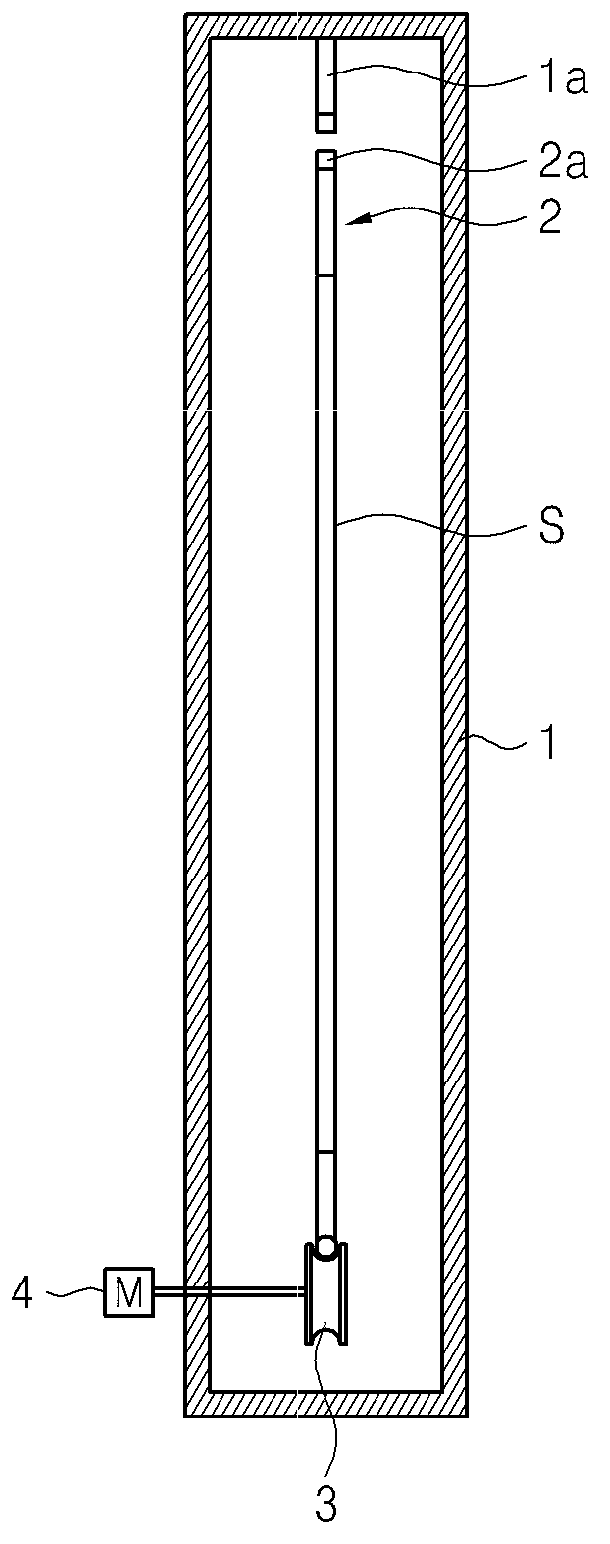

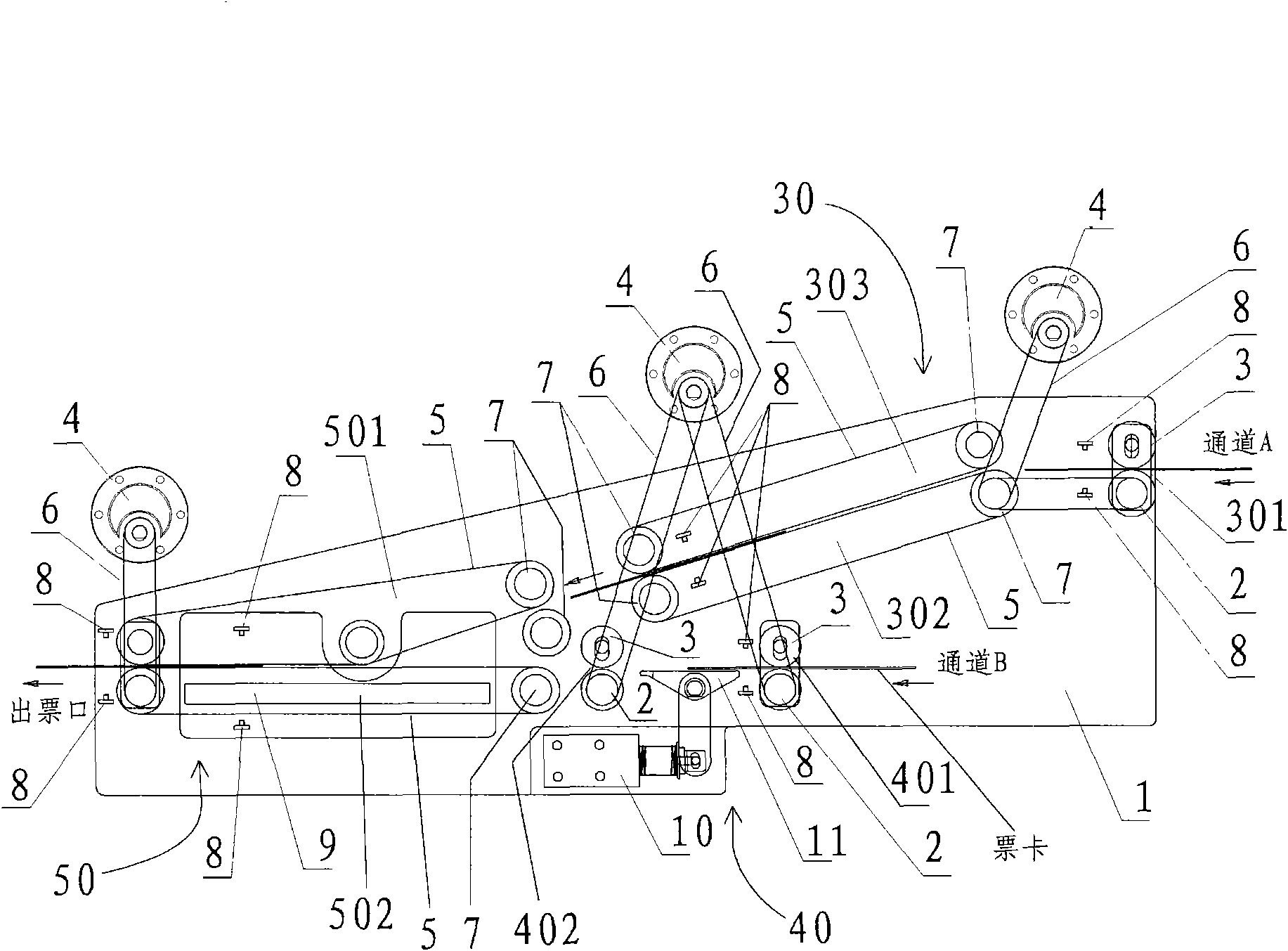

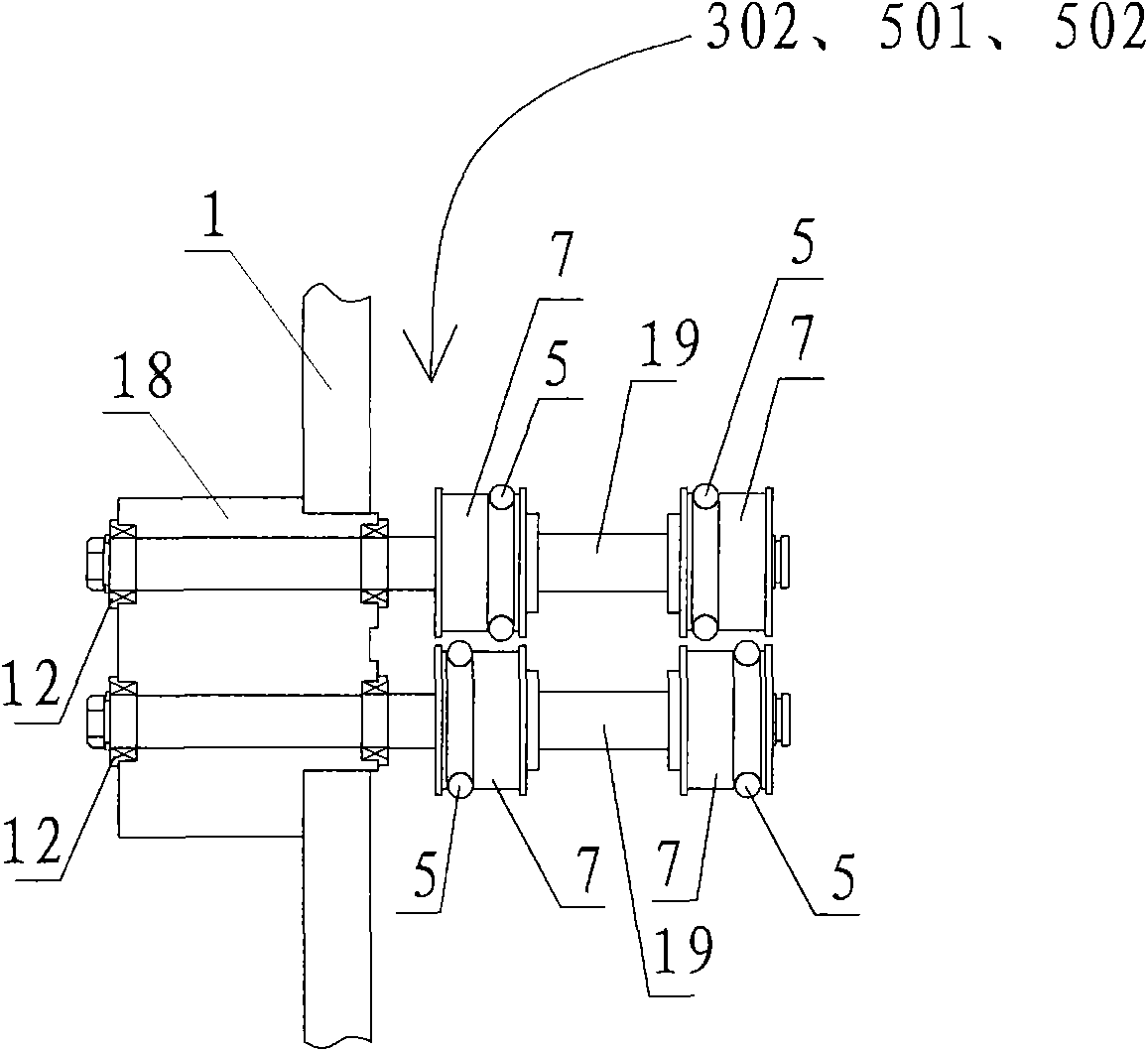

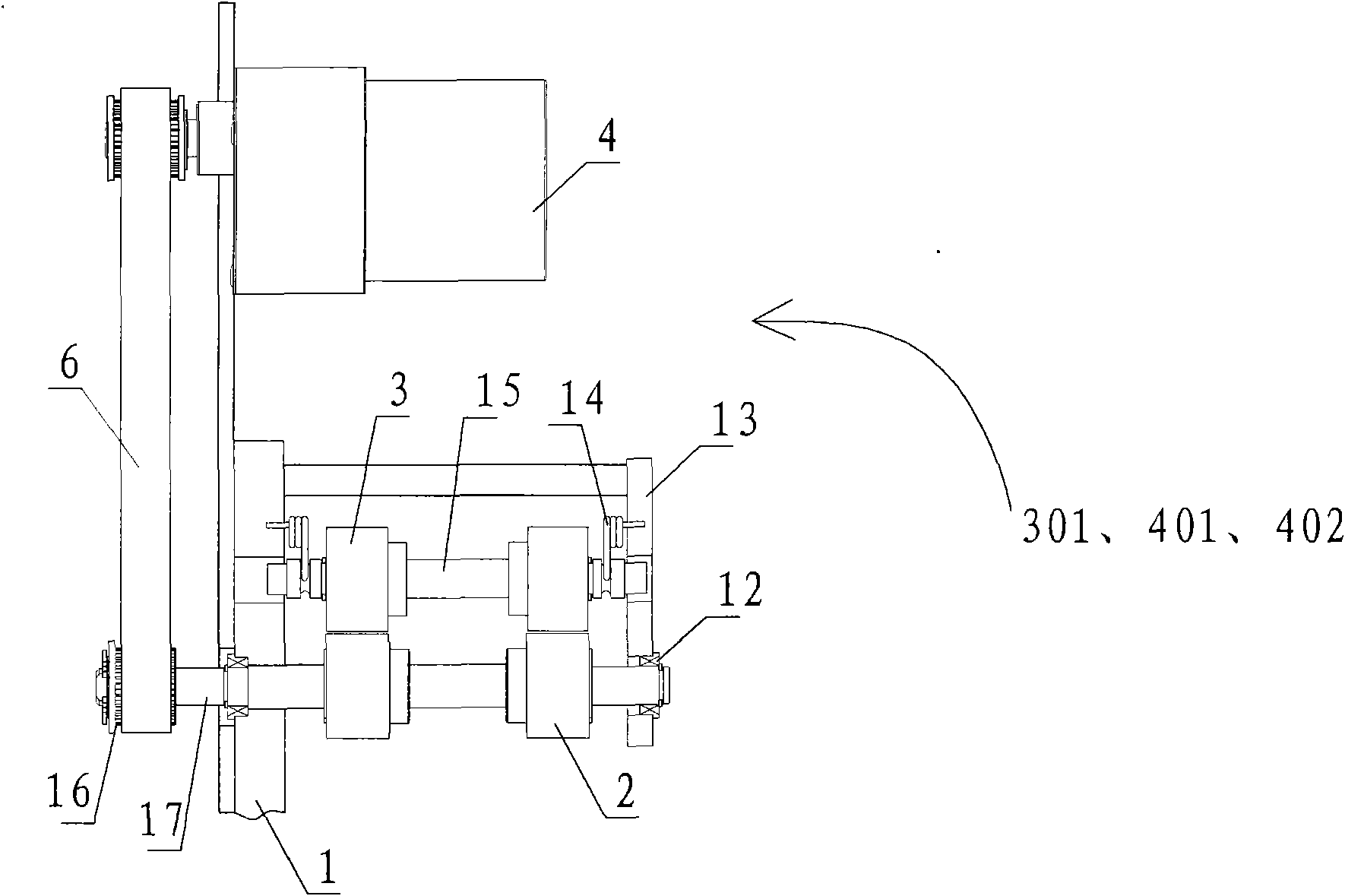

Delivery mechanism of ticket selling module

InactiveCN101577016ASolve the closing problemSolve efficiency problemsConveying record carriersAuxillary ticket-issuing devicesEngineeringPublic Venue

The invention relates to the core module of a ticket vendor in track traffic and public venue, namely the delivery mechanism of a ticket selling module. The mechanism comprises a first delivery mechanism, a second delivery mechanism and a ticket issuing mechanism which are arranged on a backing board as well as a motor and a synchronous belt which are used for driving the first delivery mechanism, the second delivery mechanism and the ticket issuing mechanism, and the mechanism also comprises a correlation sensor used for controlling the motor and the synchronous belt, wherein the first delivery mechanism and the second delivery mechanism can operate simultaneously or independently and can deliver the ticket to the ticket issuing mechanism. The delivery mechanism of the ticket selling module of the invention is in an open mode with two delivery mechanisms and one ticket issuing mechanism, can be convenient for operation and maintenance, and can greatly improve the ticketing issuing efficiency.

Owner:GAOXIN MODERN INTELLIGENT SYST

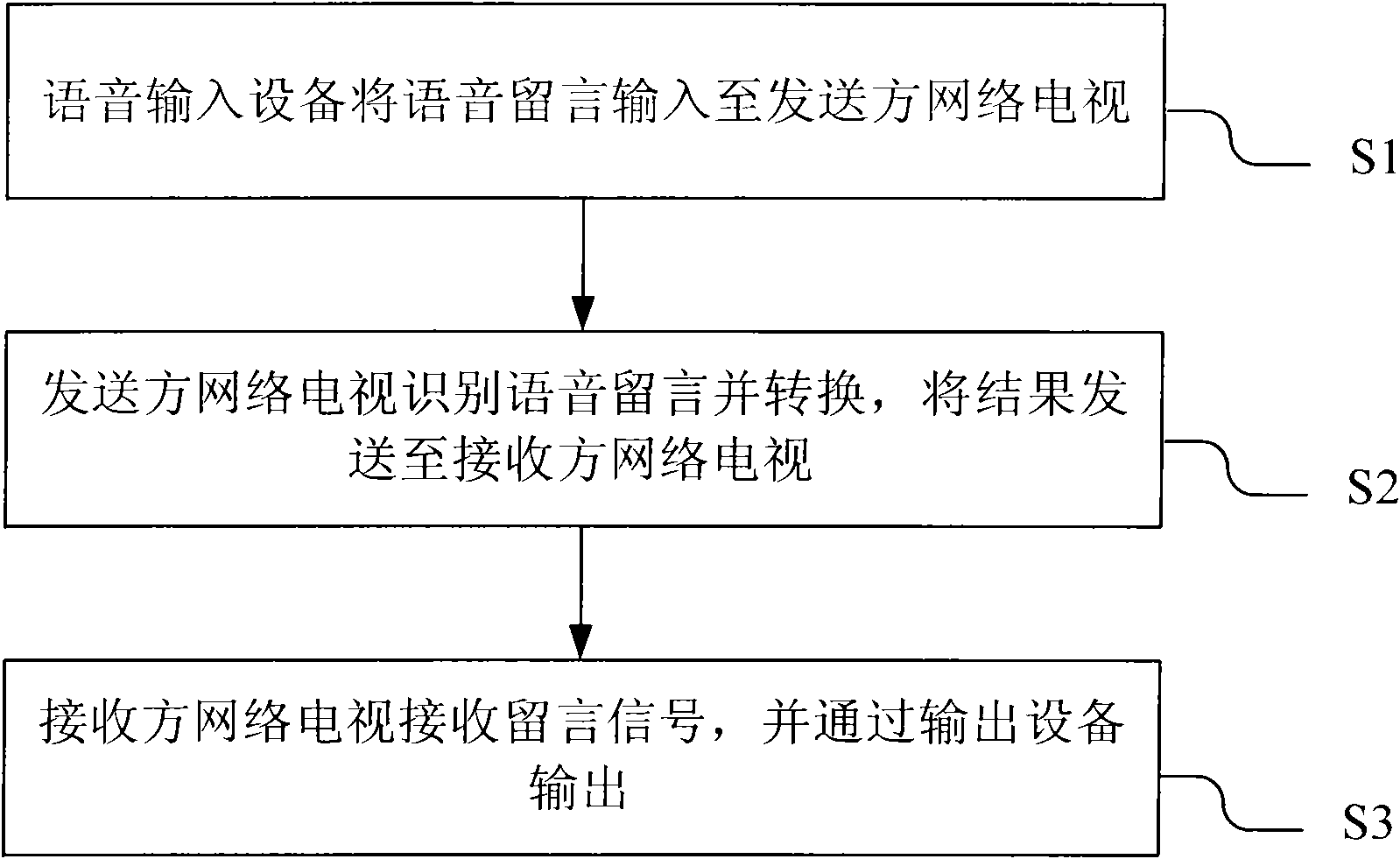

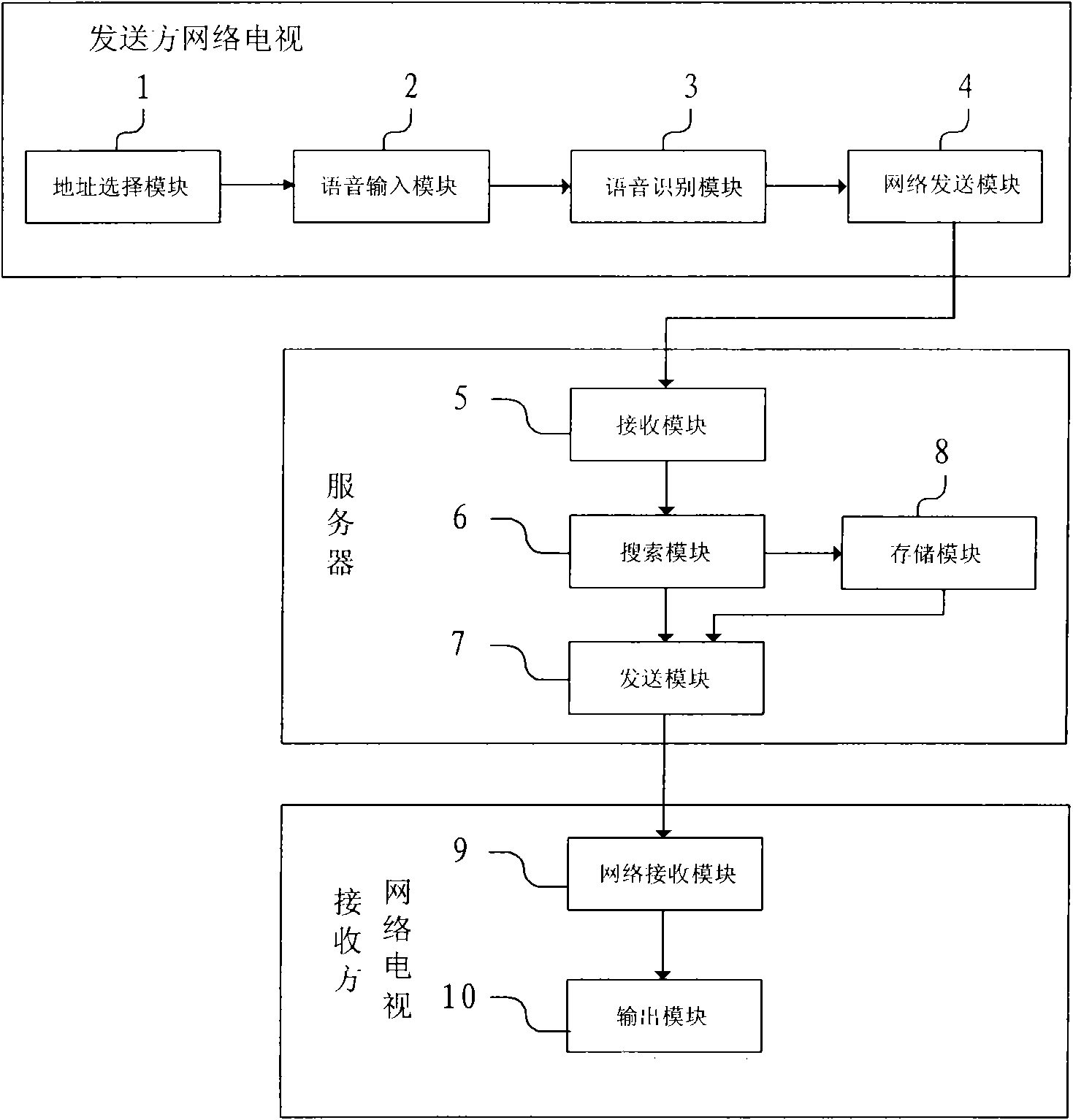

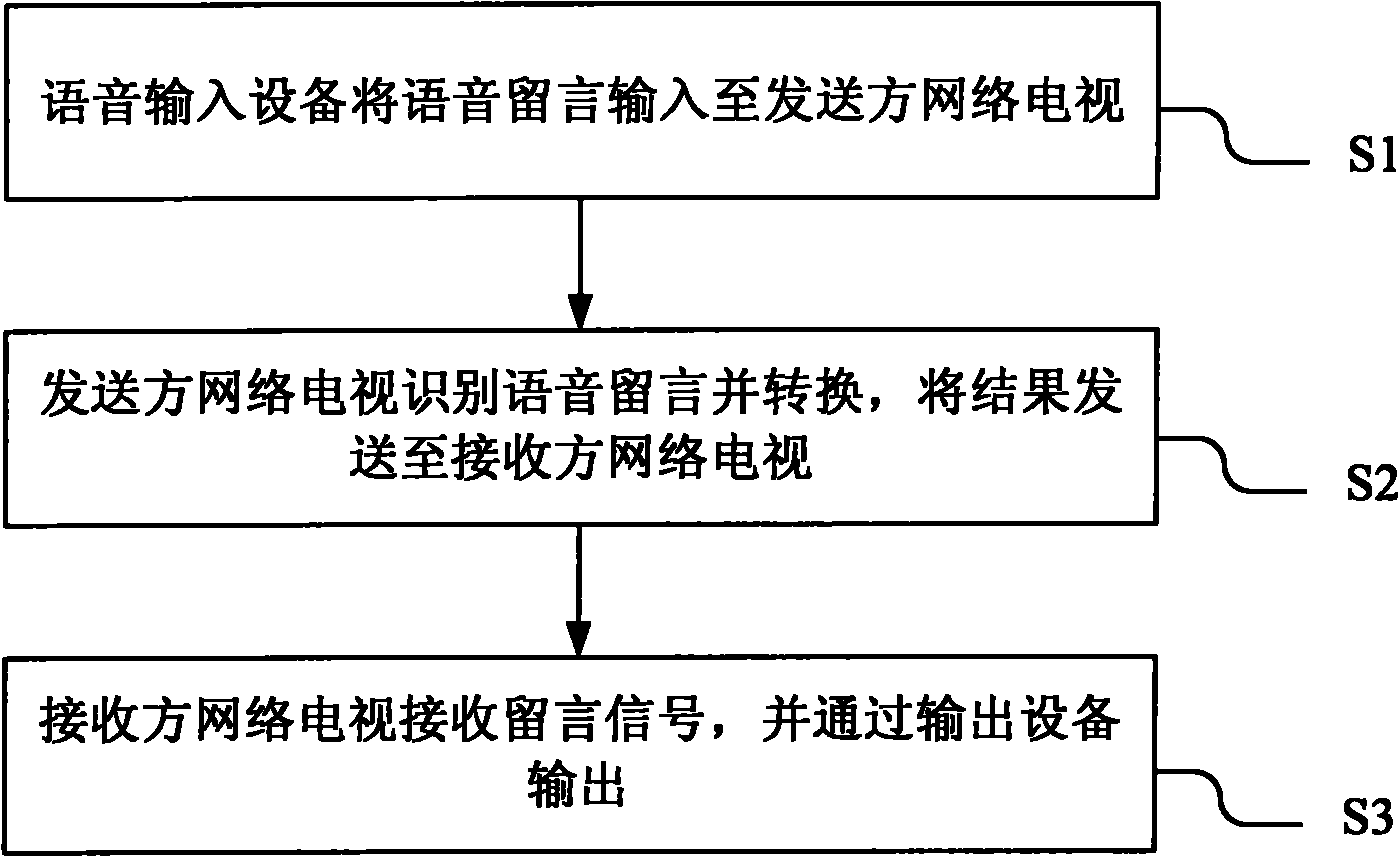

Voice message implementation method and system for network television

InactiveCN102082973ABroaden the channels of information communicationSmall footprintAutomatic call-answering/message-recording/conversation-recordingSelective content distributionSpeech inputInformation transmission

The invention discloses a voice message implementation method and a voice message implementation system for a network television. The method comprises the following steps that: a, a voice sending user inputs a voice message to a sending party network television through voice input equipment; b, the sending party network television recognizes the voice message, converts the voice message into a message signal and sends the message signal to a receiving party network television through a network; and c, the receiving party network television receives the message signal through the network and outputs the message signal through output equipment. Through the voice message implementation method for the network television, message leaving between network televisions is realized, and text information has a smaller occupied space and a higher transmission speed than a voice signal. Information is saved by a server, sending of a sending end is asynchronous to data receiving of a receiving end, and information transmission can be completed even though the two parties are not online at the same time.

Owner:HISENSE BROADBAND MULTIMEDIA TECH

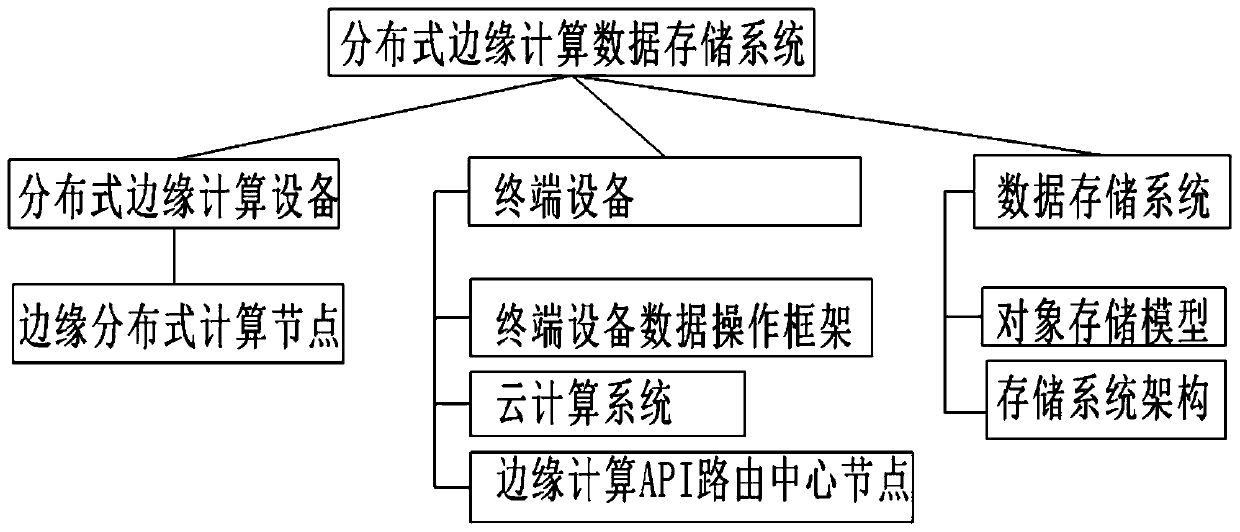

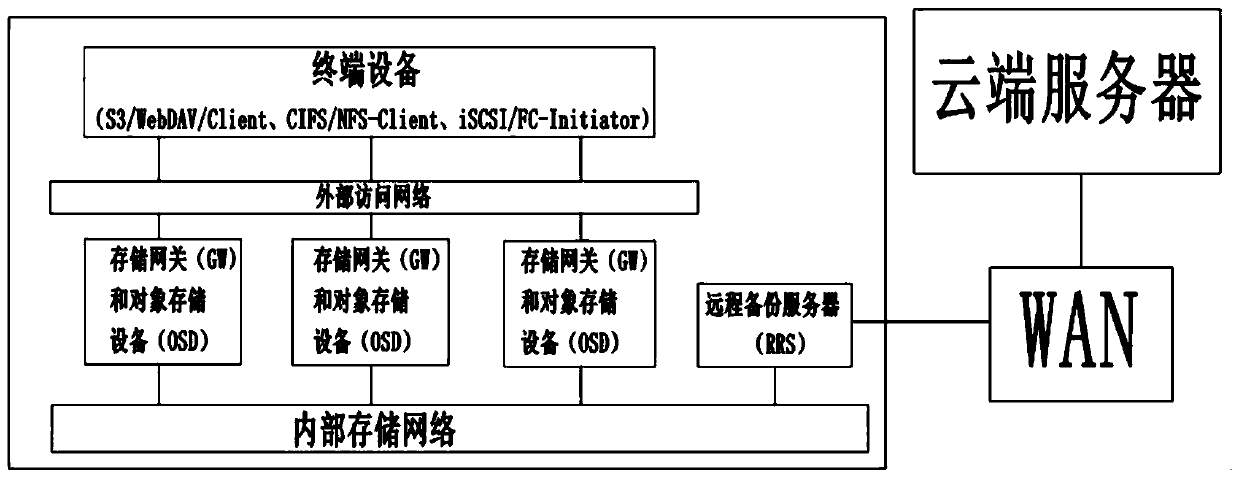

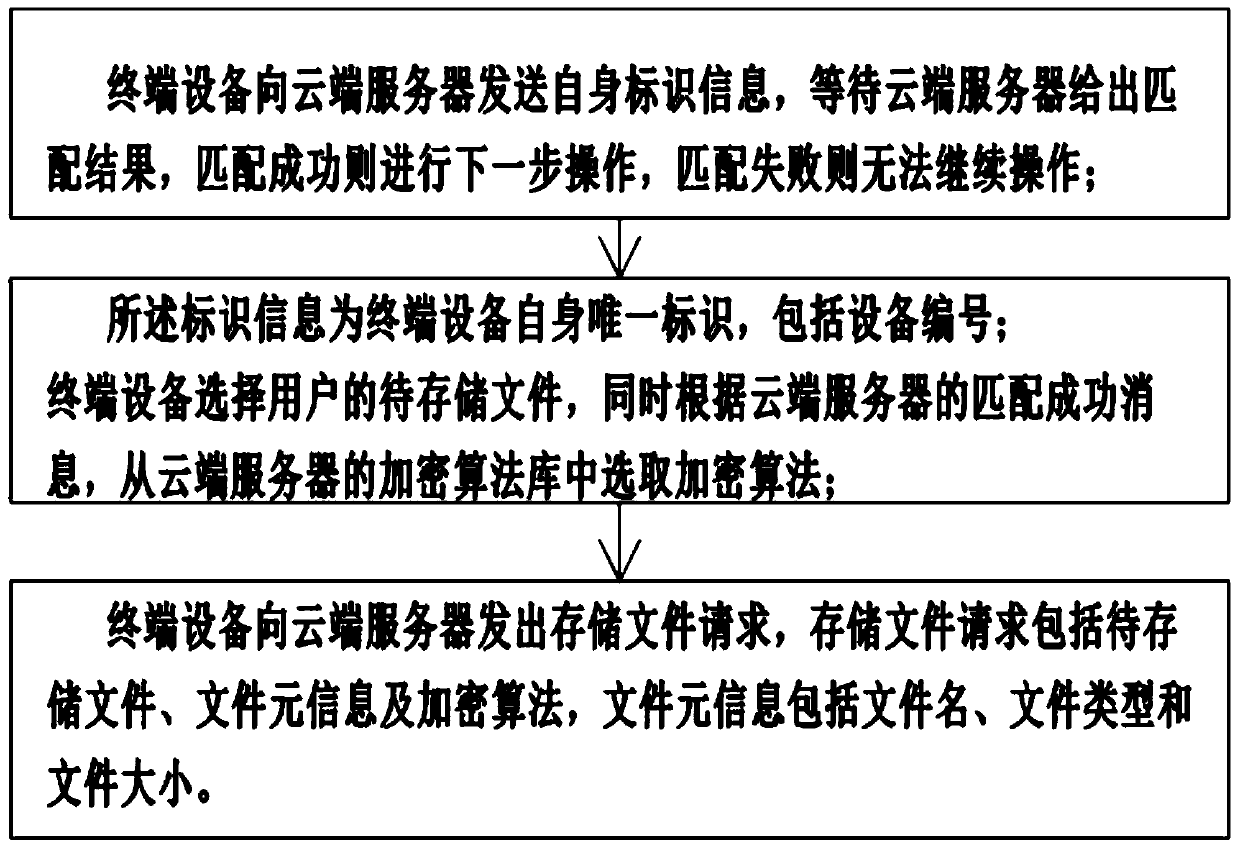

Distributed edge computing data storage system

PendingCN111339192AImprove access performanceImprove processing speedResource allocationDatabase distribution/replicationEdge nodeData store

The invention provides a distributed edge computing data storage system, which comprises distributed edge computing equipment for data processing and storage, terminal equipment for providing data forthe distributed edge computing equipment, and a data storage system, wherein the data storage system at least comprises an object storage model and a storage system architecture, the object storage model is used for segmenting user data into a group of small objects at the bottom layer, the group of objects are uniformly and consistently distributed on each equipment node of the whole cluster according to a certain algorithm, and when a user uses the cluster, the small objects are spliced into complete user data by the storage system and are provided for the user to use; the storage system architecture at least comprises a client, a storage interface, storage management, storage distribution, data storage and physical equipment. According to the invention, transaction processing can be carried out at each edge node, so that the system is more efficient and easier to manage, the data processing and transmission speed is accelerated, and the delay is reduced.

Owner:SHENZHEN POWER SUPPLY BUREAU

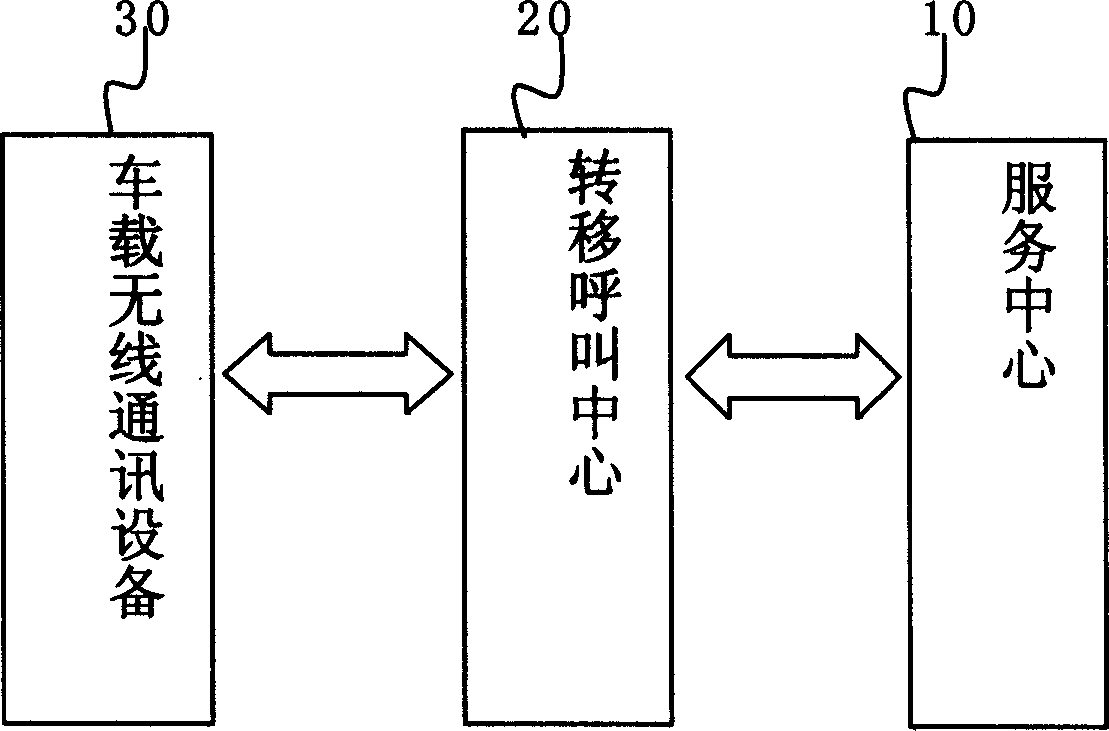

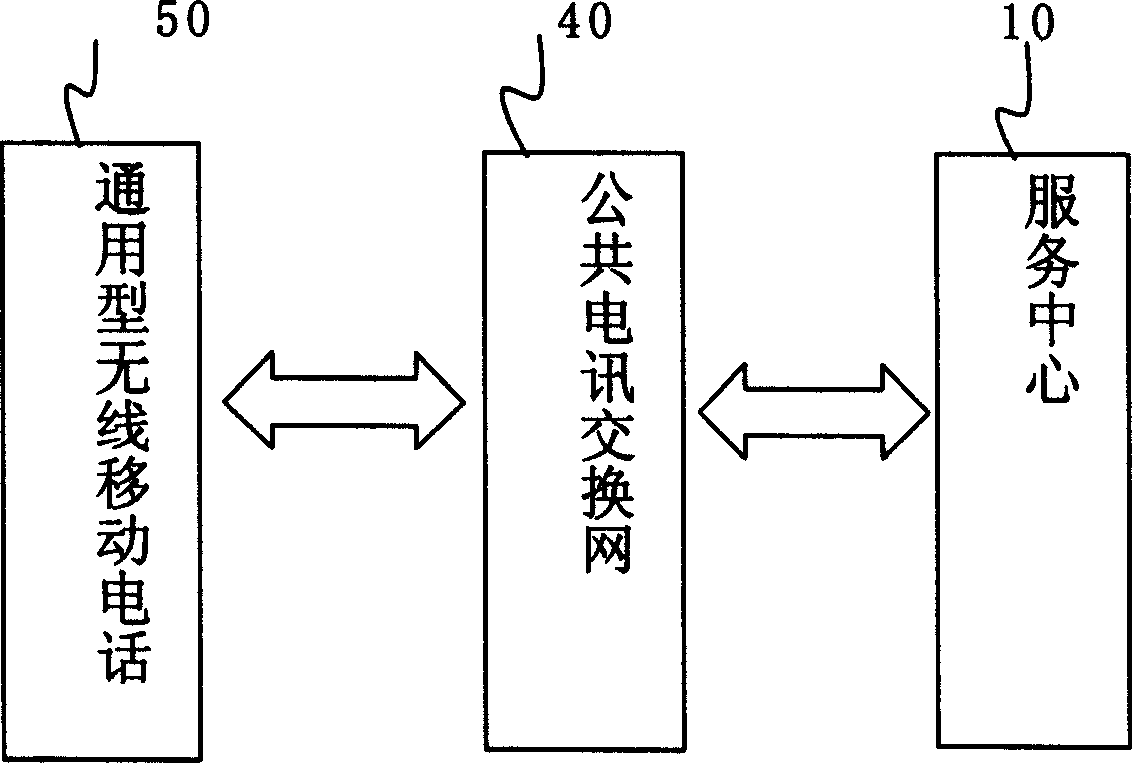

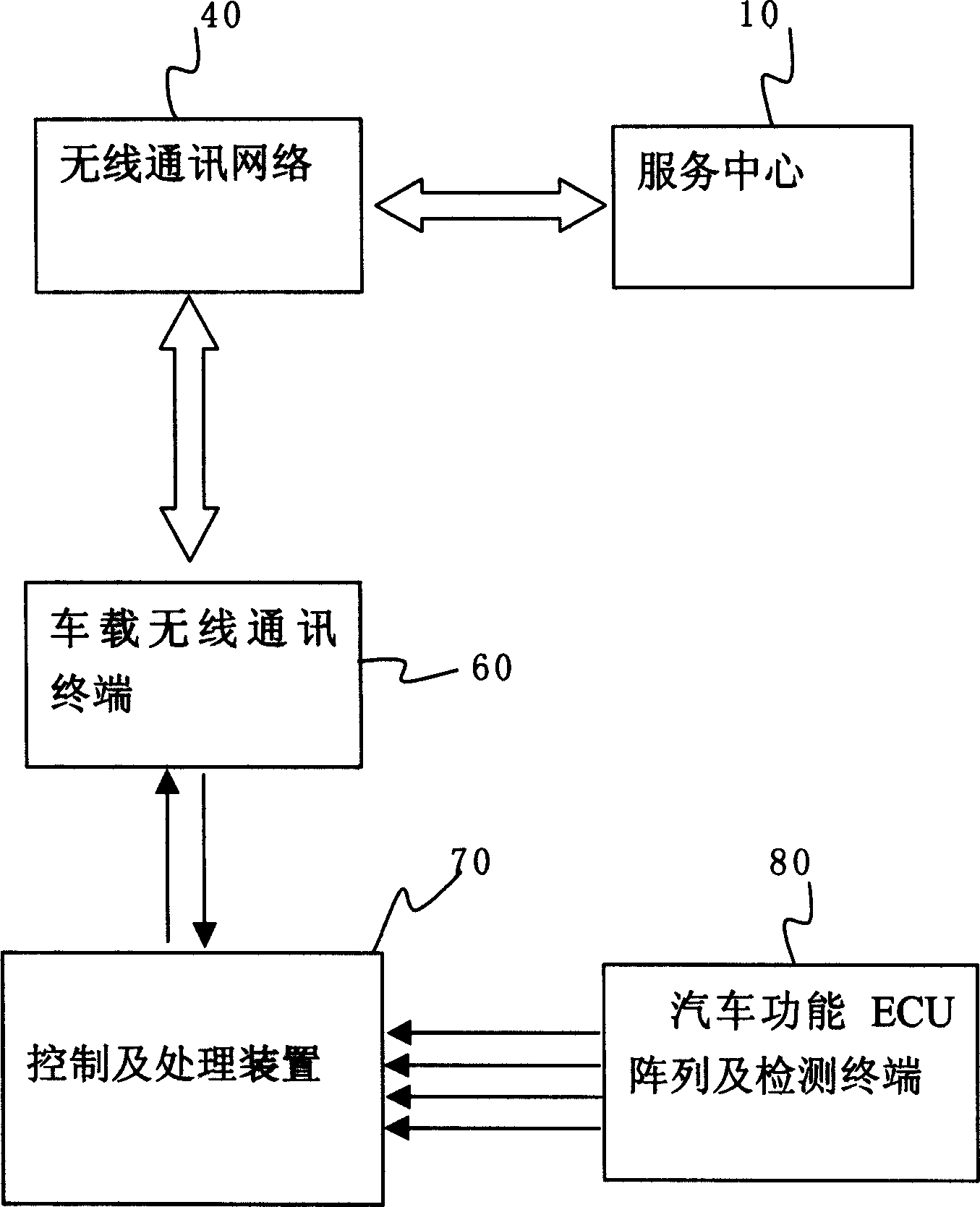

Vehicle-mounted information service terminal and vehicular special information service system

InactiveCN1572595AQuality improvementImprove efficiencyRegistering/indicating working of vehiclesRadio/inductive link selection arrangementsComputer terminalComputer science

A vehicle-mounted information service terminal and vehicular special information service system includes a vehicle-mounted wireless communication terminal which communicates with the service center by the wireless communication network of existing mobile communication operator and acquires the information service provided by the service center. The system further includes a control and process device having an input terminal connected to the vehicle function ECU and detection terminals and an output terminal connected to the vehicle-mounted wireless communication terminal. The control and process device receives the data from the vehicle function ECU and detection terminals and processes the data based on program and generates related information. The invention makes the service center of vendor can quickly make accurate judgment for the vehicle true status, and provide effective service in time for user.

Owner:BYD CO LTD

Full-automatic glass slitting and edge-grinding assembly line

PendingCN108943422ALow processing and production costsHigh degree of automationWorking accessoriesStone-like material working toolsTime efficientWater resources

The invention relates to a full-automatic glass slitting and edge-grinding assembly line. The assembly line is sequentially provided with a full-automatic glass loading machine, a full-automatic glasscutting machine, an automatic glass breaking table and a full-automatic glass edge grinding machine in the moving direction of glass. The assembly line can achieve the effects of full-automatic glassloading, feeding, cutting, breaking and edge grinding, the trouble of manual glass loading, manual cutting, manual breaking and manual edge grinding is avoided, moreover, the production environment protection efficiency of workers in each link is improved, machining of the glass is finer, the resource waste is reduced by utilizing recycling of the water resources, meanwhile, the equipment is protected, the automation degree is high, the production efficiency is high, the product percent of pass is high, the labor is saved, the time is saved, the glass slitting cost is reduced, and the safetyis high.

Owner:鹏凯(天津)玻璃有限公司

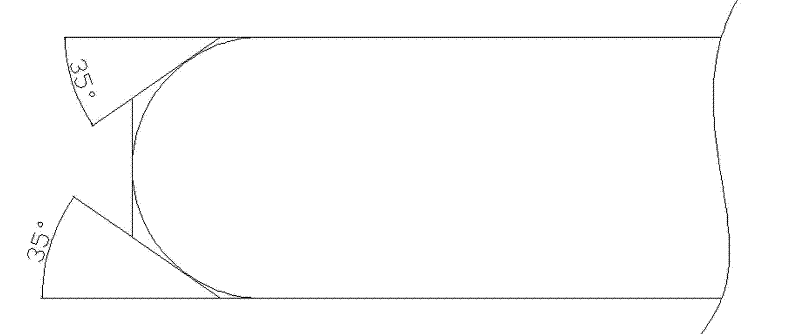

Edging machine of glass round edges

The invention discloses an edging machine of glass round edges. The edging machine comprises a machine base, a pre-grinding device and a round edge grinding device, wherein the machine base is provided with a delivering device for delivering glass; the pre-grinding device is positioned at the front side of the round edge grinding device in the glass delivery direction; the end part, adjacent to the glass, of the pre-grinding device is provided with a grinding wheel; and the grinding plane of the grinding wheel and the surface of the glass form an included angle of 35+ / -5 degrees. Based on the structure, the edging machine provided by the invention has the following advantages: the glass delivery speed can be improved, and the glass manufacturing efficiency is improved; and the loss of a C-type grinding wheel can be reduced, and the service life of the C-type grinding wheel is prolonged.

Owner:张家港市恒久玻璃机械有限公司

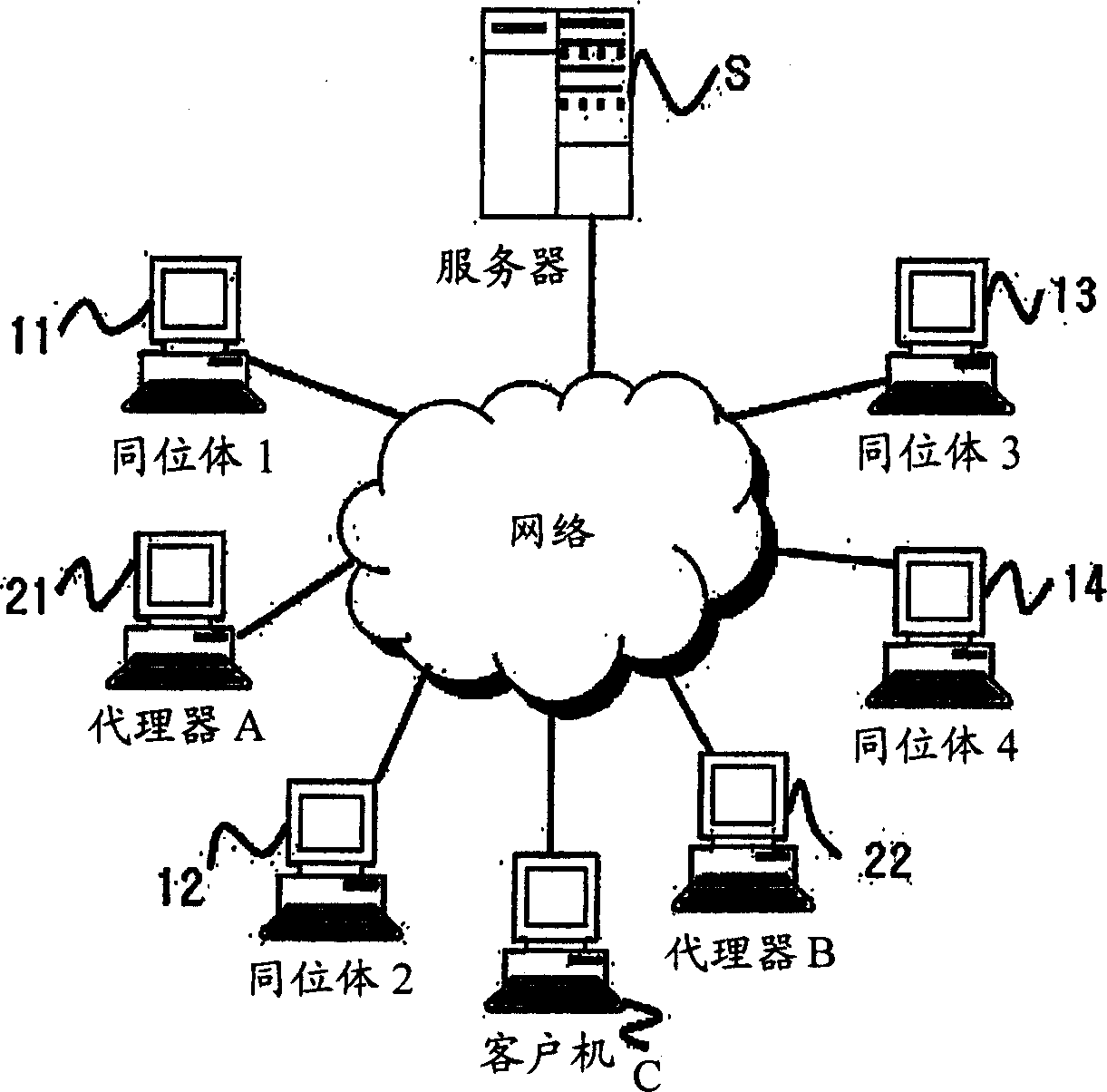

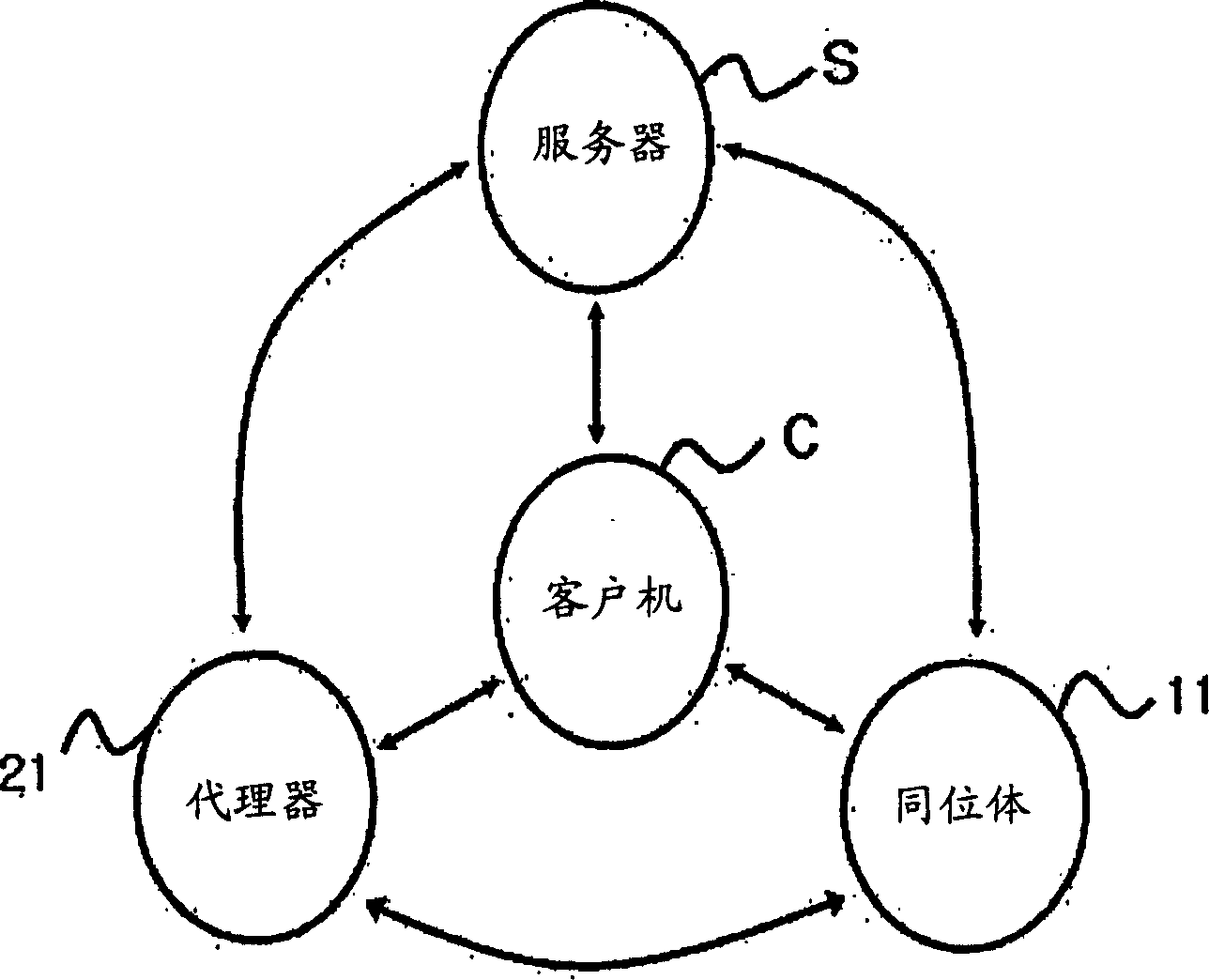

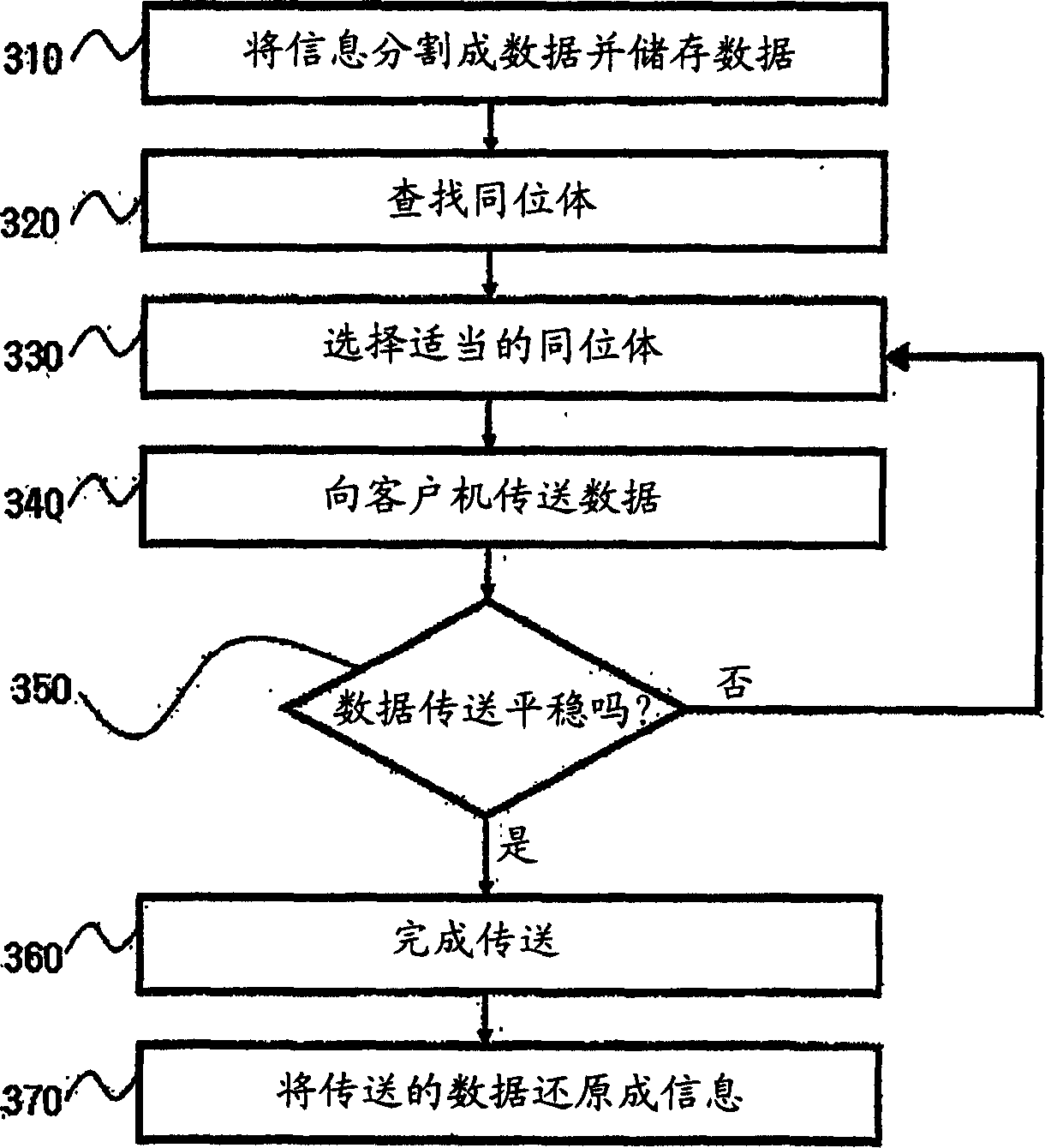

Parallel information delivery method based on peer-to-peer enabled distributed computing technology and the system thereof

InactiveCN1550088AIncrease transmission speedReduce loadData switching networksInformation deliveryDistributed computing

An information delivery method based on a peer-to-peer enabled distributed computing technology on a network is described. The parallel delivery system and method comprises a server for dividing information to be delivered into data of a predetermined size and storing the divided data; client for requesting arbitrary information; a plurality of peers including Peers for redundantly storing the divided data and performing delivery of the data of the predetermined size on behalf of server. Since information is delivered not through one-to-one delivery between the server and the client but through parallel delivery among a plurality of peers and the client, time required for delivering data of the same size can be remarkable reduced. In addition, since the central server does not centrally control all requests from all clients but the plurality of peers simultaneously process the requests in parallel, load of the server can be greatly reduced.

Owner:文义善

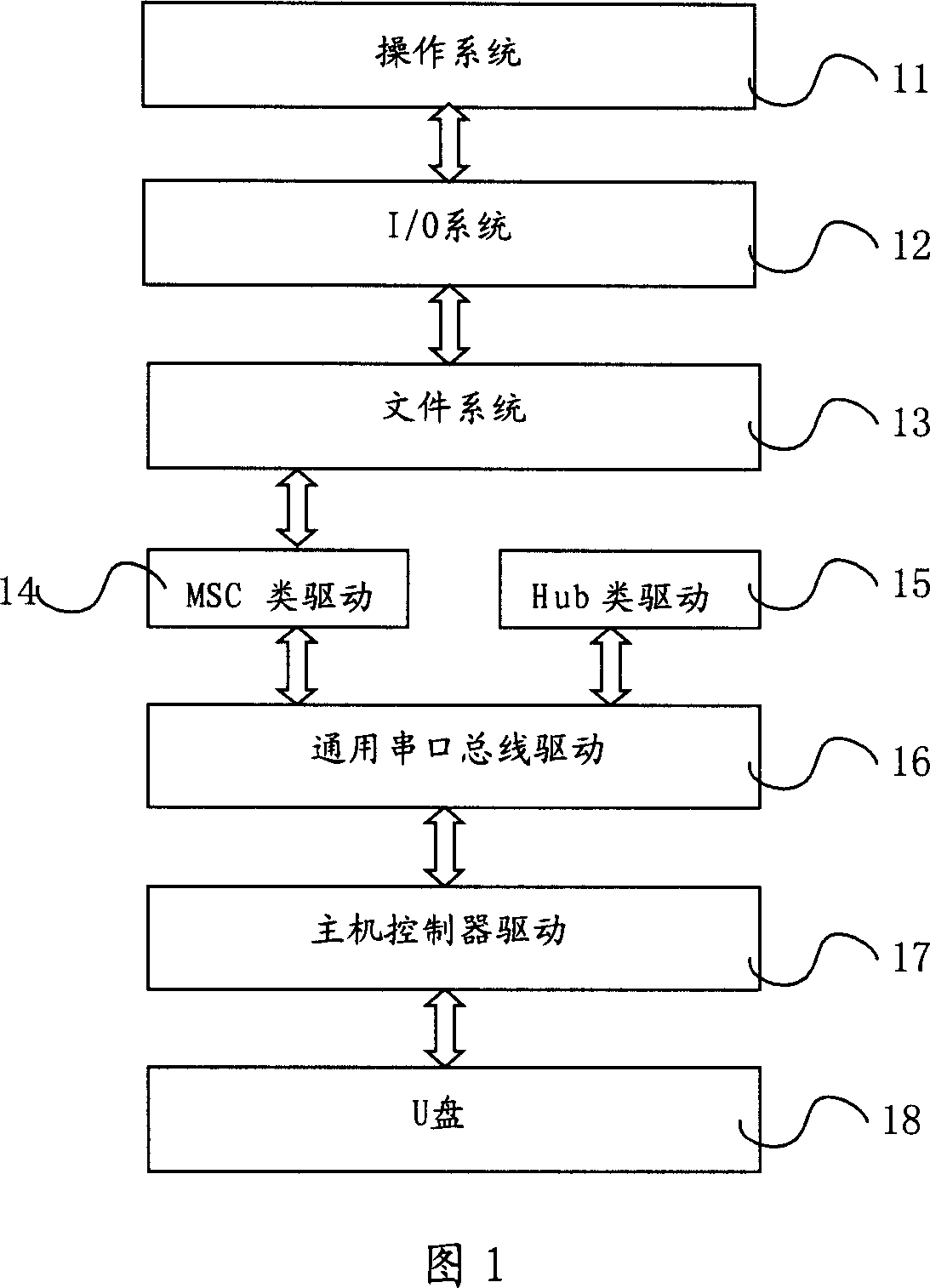

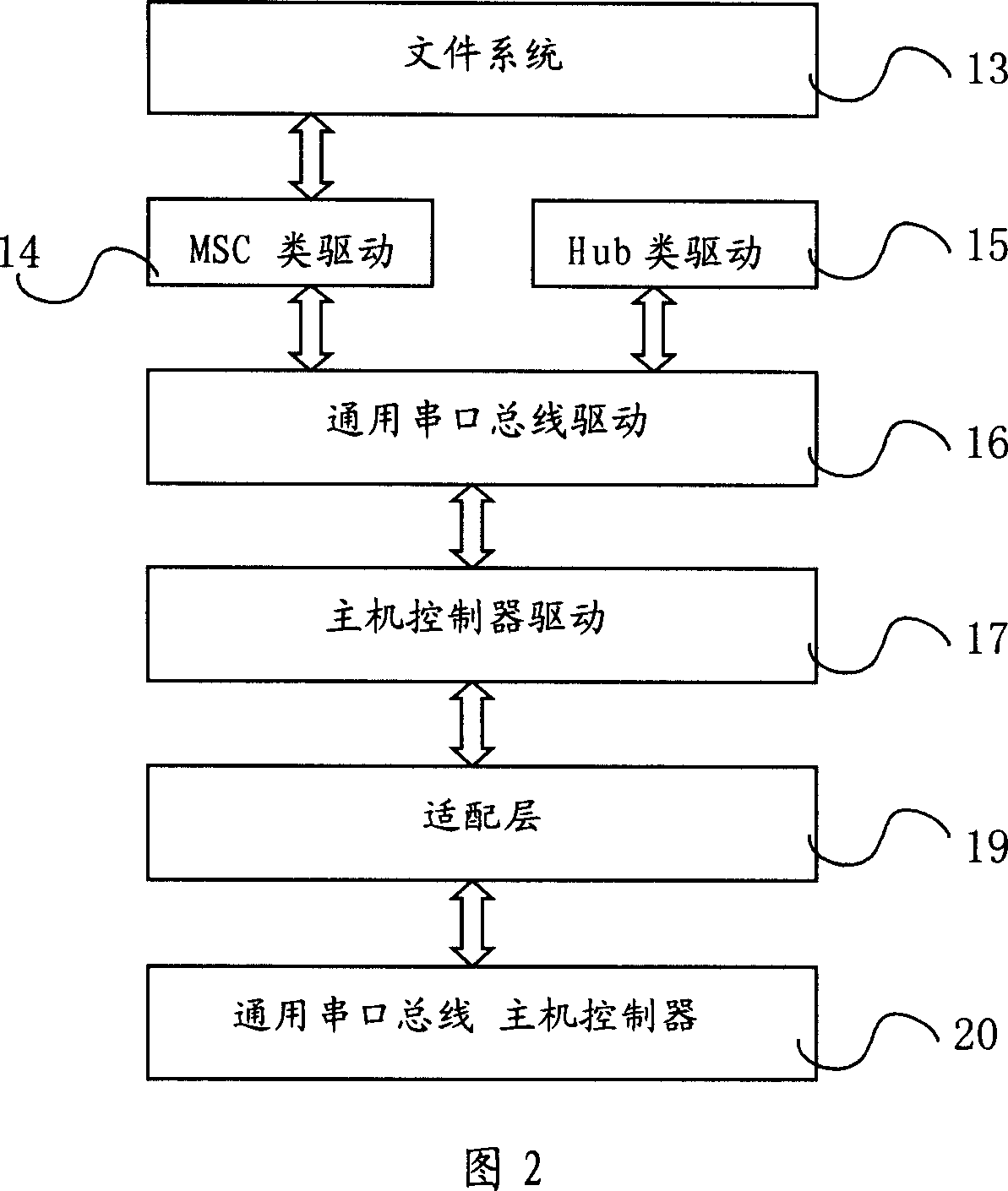

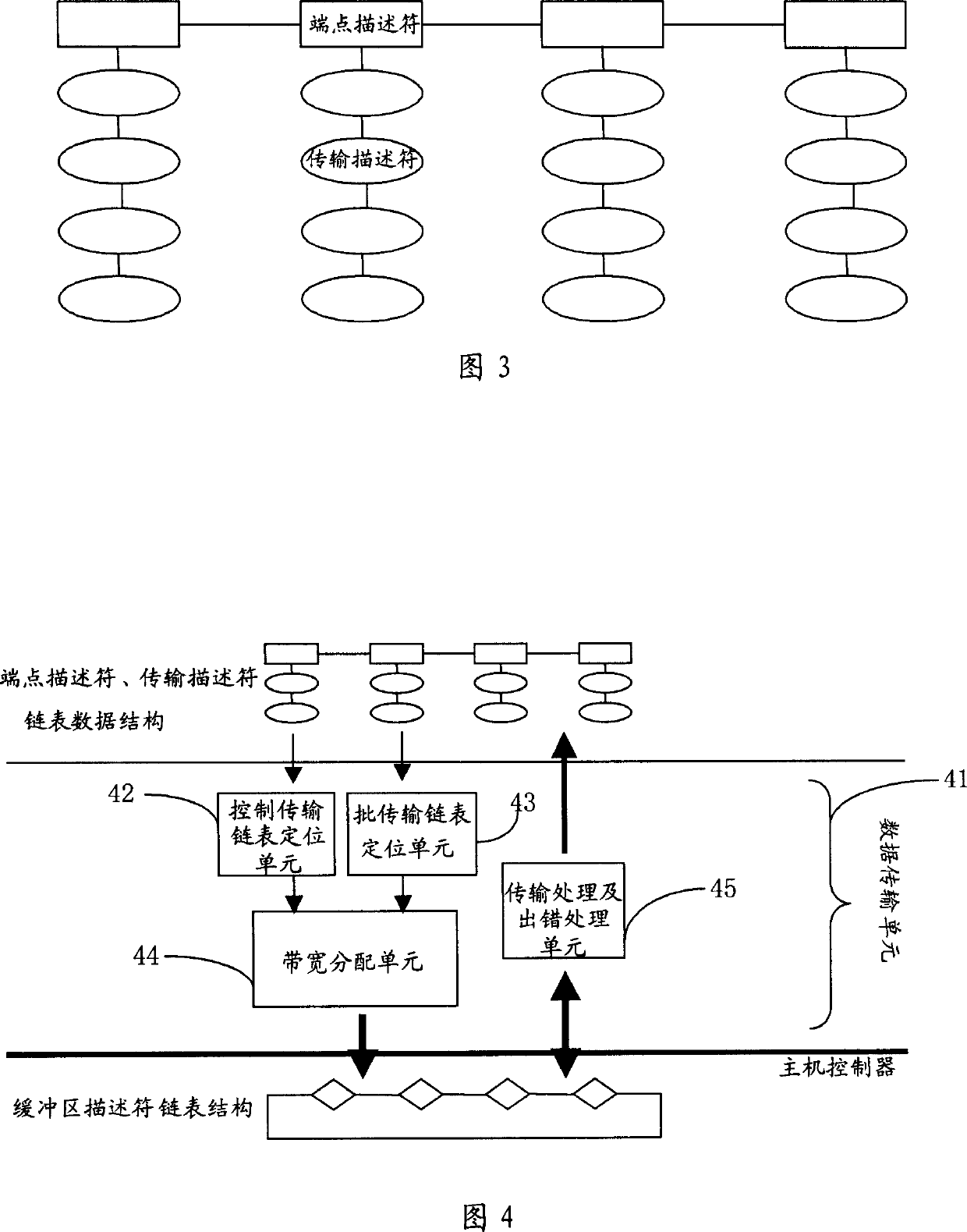

Universal serial port bus data transportation processing method

ActiveCN1828571AFast transferGuaranteed normal transmissionElectric digital data processingData informationFile descriptor

The disclosed method comprises: scanning endpoint descriptor and transmission descriptor to find out the one with data transferring; filling the data information into at least two buffer descriptors, setting its state label into one; scanning the buffer descriptor with label as one by the main controller to send data; if there is no back state of descriptor, resending data; or else, continuing to next transmission. This invention can improve transmission speed more than one time.

Owner:NEW H3C TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com