Full-automatic glass slitting and edge-grinding assembly line

A fully automatic, assembly line technology, applied in the direction of work accessories, stone processing tools, stone processing equipment, etc., can solve the problems of incomplete automation and cutting accuracy, achieve high production efficiency, high degree of automation, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

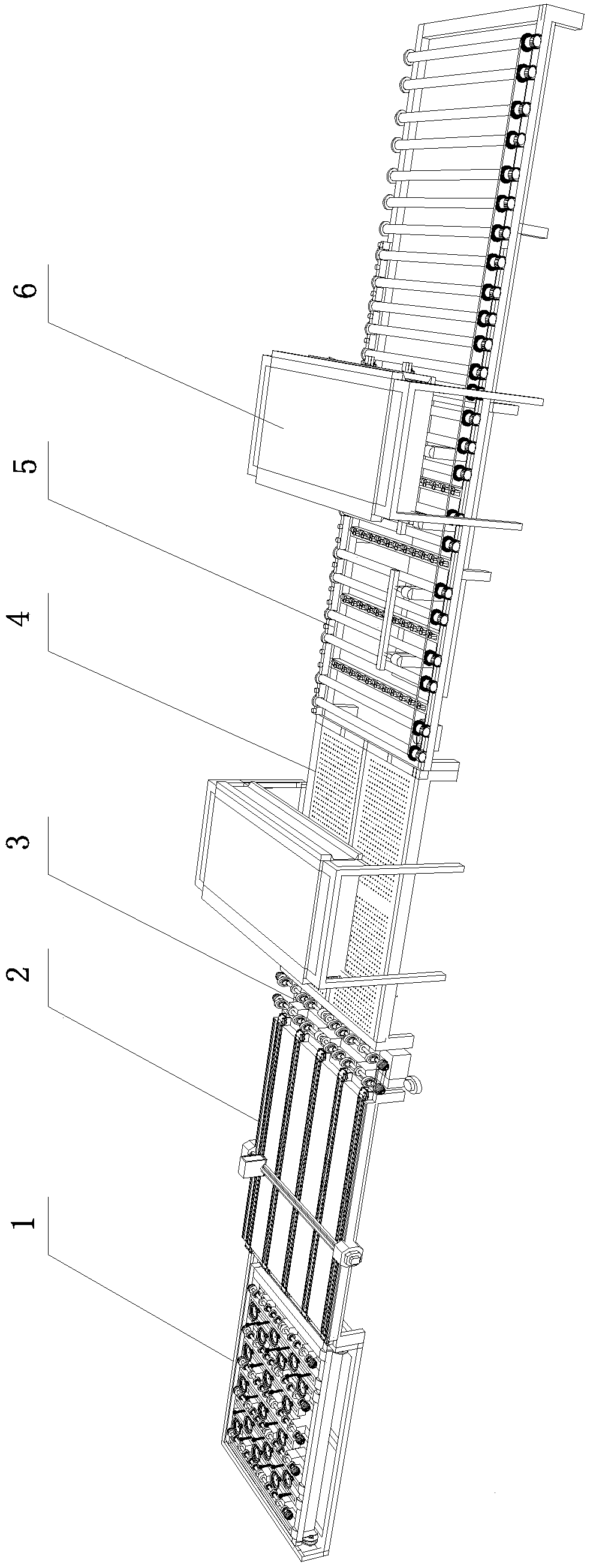

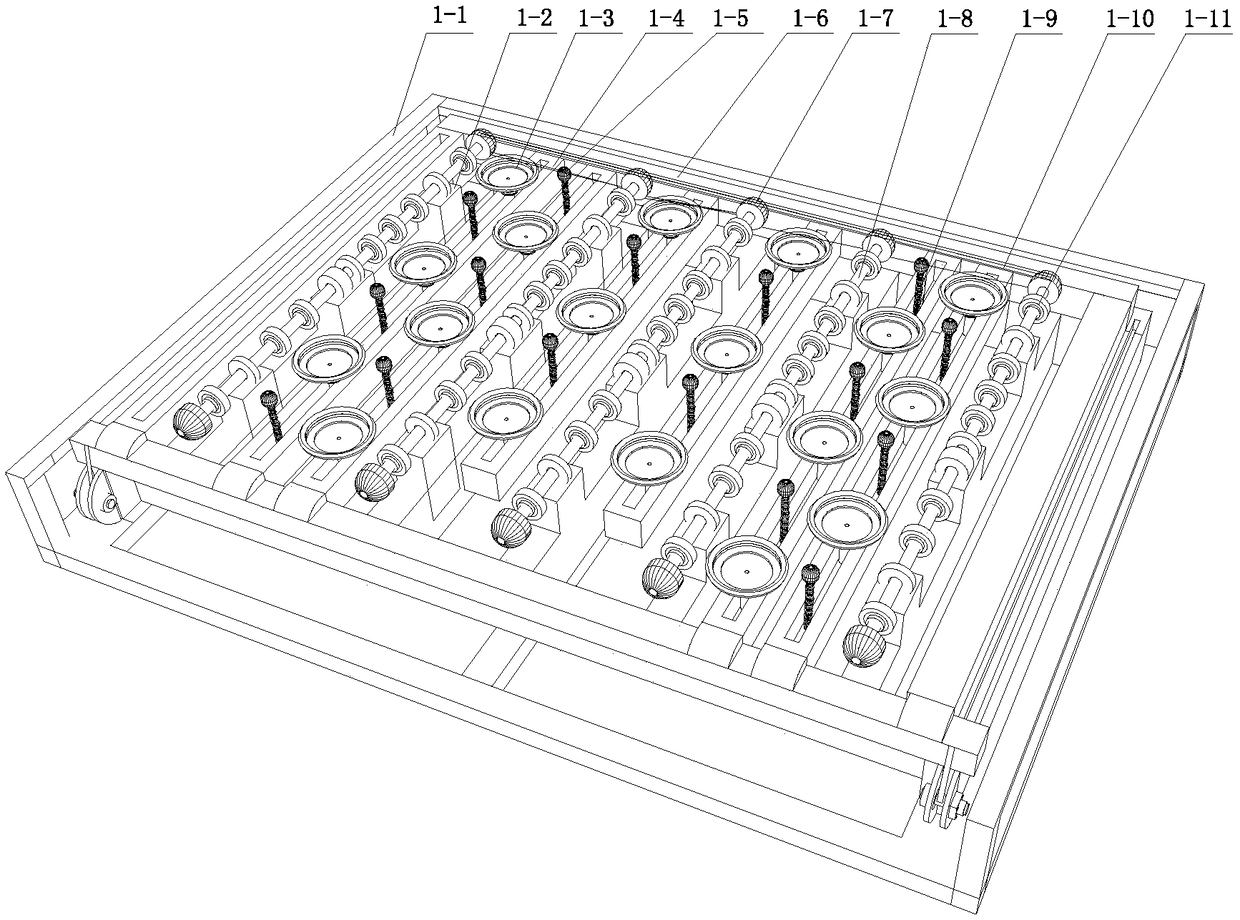

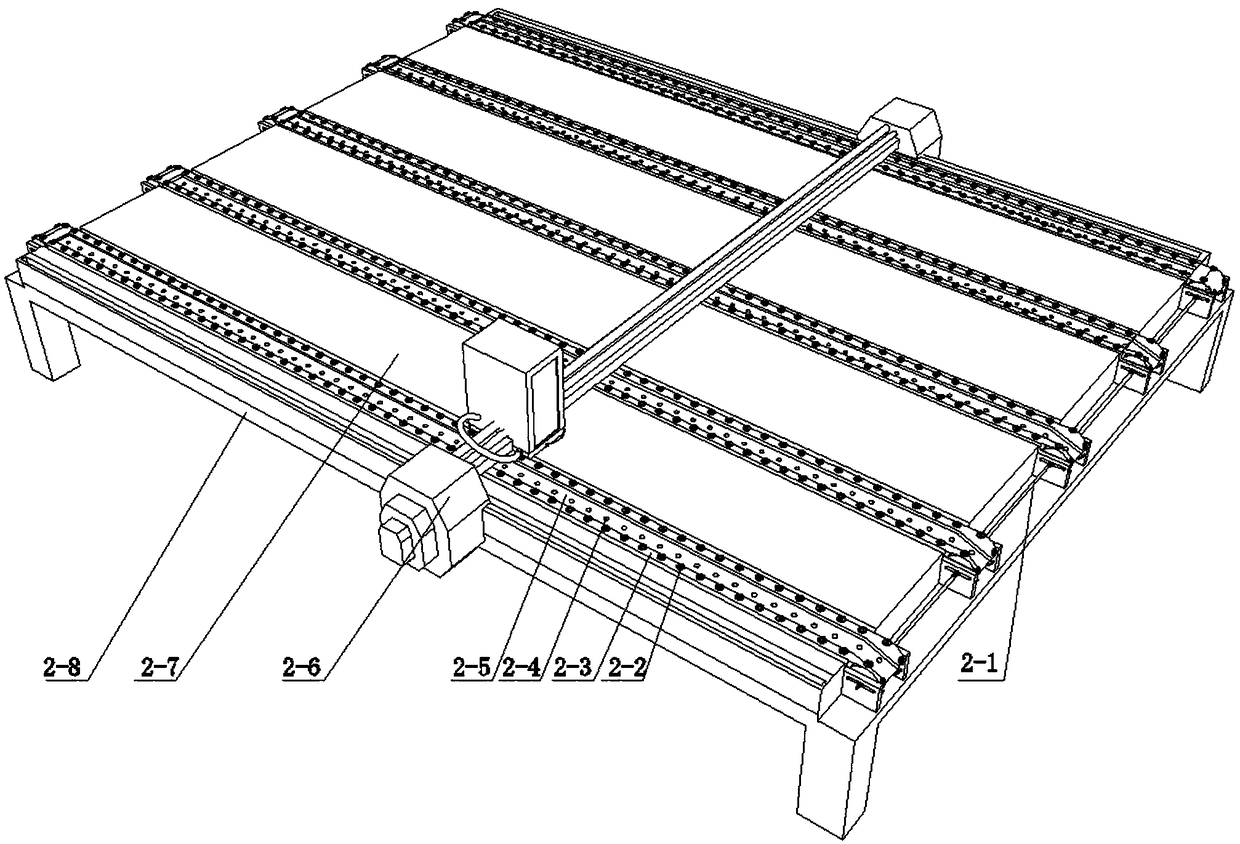

[0041] A full-automatic glass slitting and edging assembly line, a full-automatic glass feeding machine 1, a full-automatic glass cutting machine 2, an automatic glass breaking table 4, and a full-automatic glass edging machine 6 arranged in sequence according to the direction of glass movement; The automatic glass feeding machine is used to turn over the glass from the transfer rack to absorb and feed the material. The automatic glass cutting machine is used to cut the whole large glass delivered by the feeding machine according to the preset size. The automatic glass breaker The slicing machine is used for breaking the cut glass, and the automatic glass edger is used for edging the broken glass.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com