Packing box provided with buffer airbags

A packaging box and airbag technology, which is applied in packaging, transportation and packaging, and containers to prevent mechanical damage, etc., can solve the problems of high packaging cost, low compression resistance, and easy crushing, and achieve low processing and production costs and good use effects Good, cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

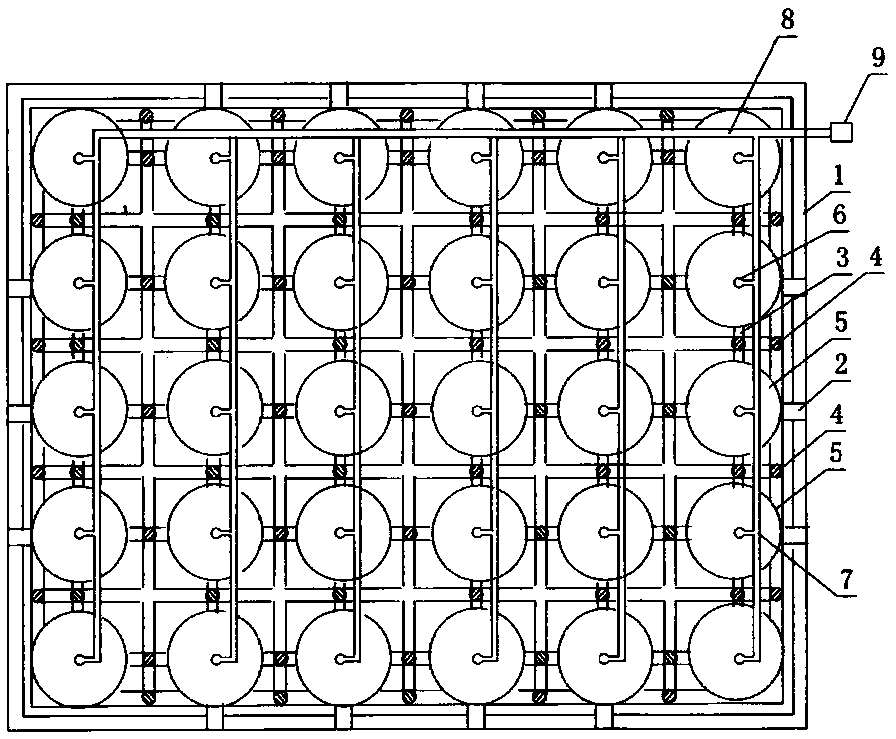

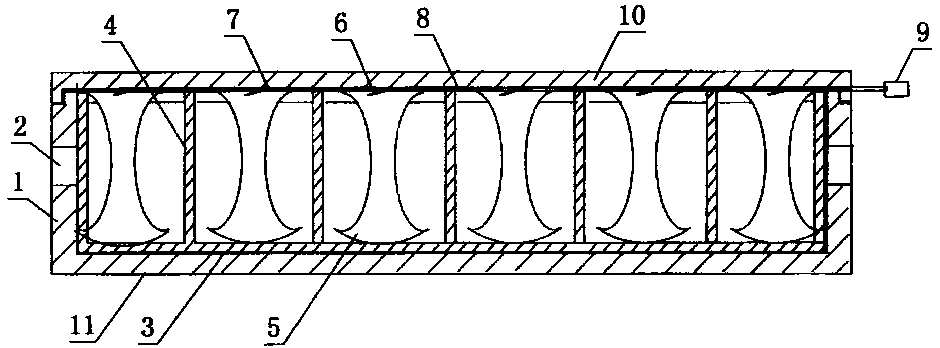

[0010] Figure 1-4 The four sides of the egg box 1 shown in are provided with egg box ventilation holes 2, the bottom end of the egg box is provided with a base 11, the upper end of the base is provided with a compression vertical and horizontal seat 3, and a plurality of compression vertical and horizontal seats are provided. Compression columns 4, a plurality of airbags 5 are arranged in the frame of the compression columns, a flat air intake pipe 6 is arranged above each airbag, and a flat air intake main pipe 8 is provided on the upper end of the box body, and the air intake main pipe is connected to There is a flat bronchus 7, the flat air intake pipe is connected with the flat bronchus 7, the flat bronchus is connected with the flat air intake main pipe 8, the air intake main pipe is provided with an air filling port 9, the air filling port is connected with an automatic inflator, and a box cover is provided above the egg box 10.

[0011] During use, poultry eggs are pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com