Construction waste wood formwork and industrial sewing machine table manufactured by pressing production formwork leftover material

A technology for industrial sewing machines and wooden templates, applied in the direction of sewing machine components, sewing equipment, manufacturing tools, etc., can solve the problems of large wood consumption, easy deformation of the platen, high production cost, etc., and achieve long service life, good flatness, and low weight light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

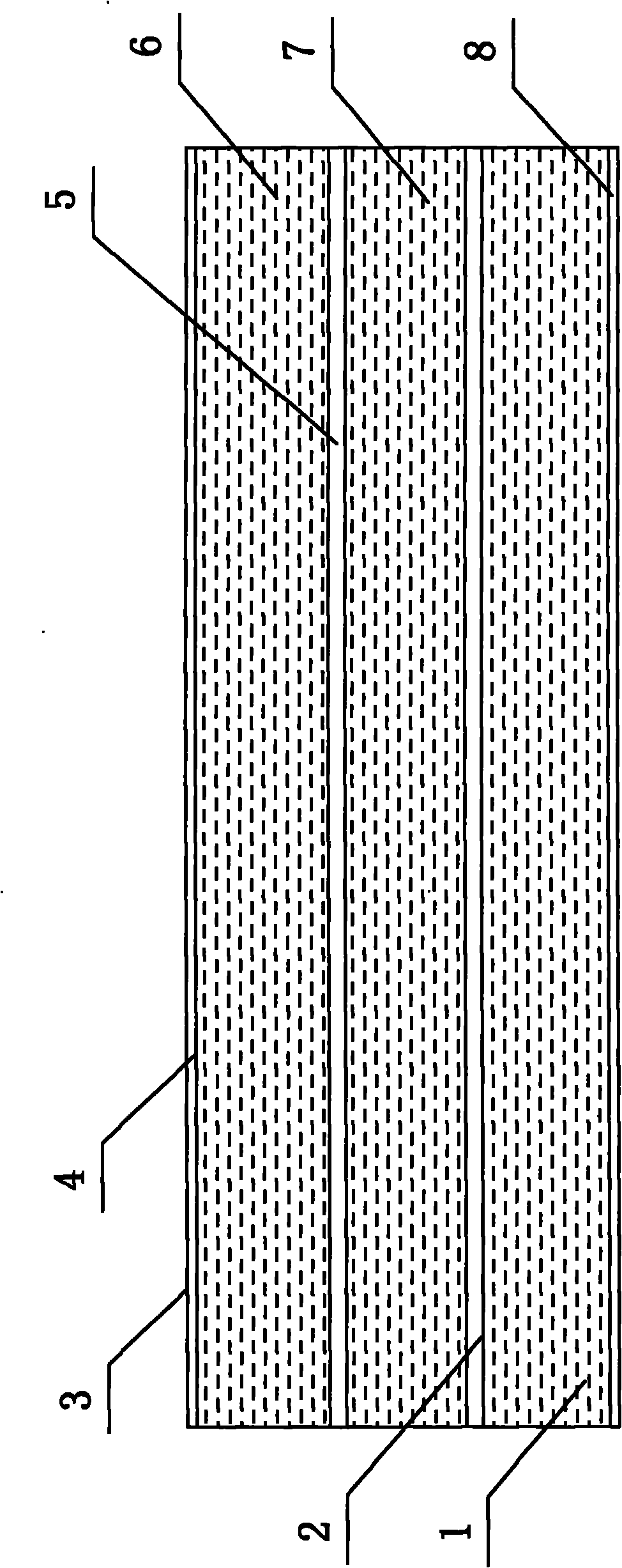

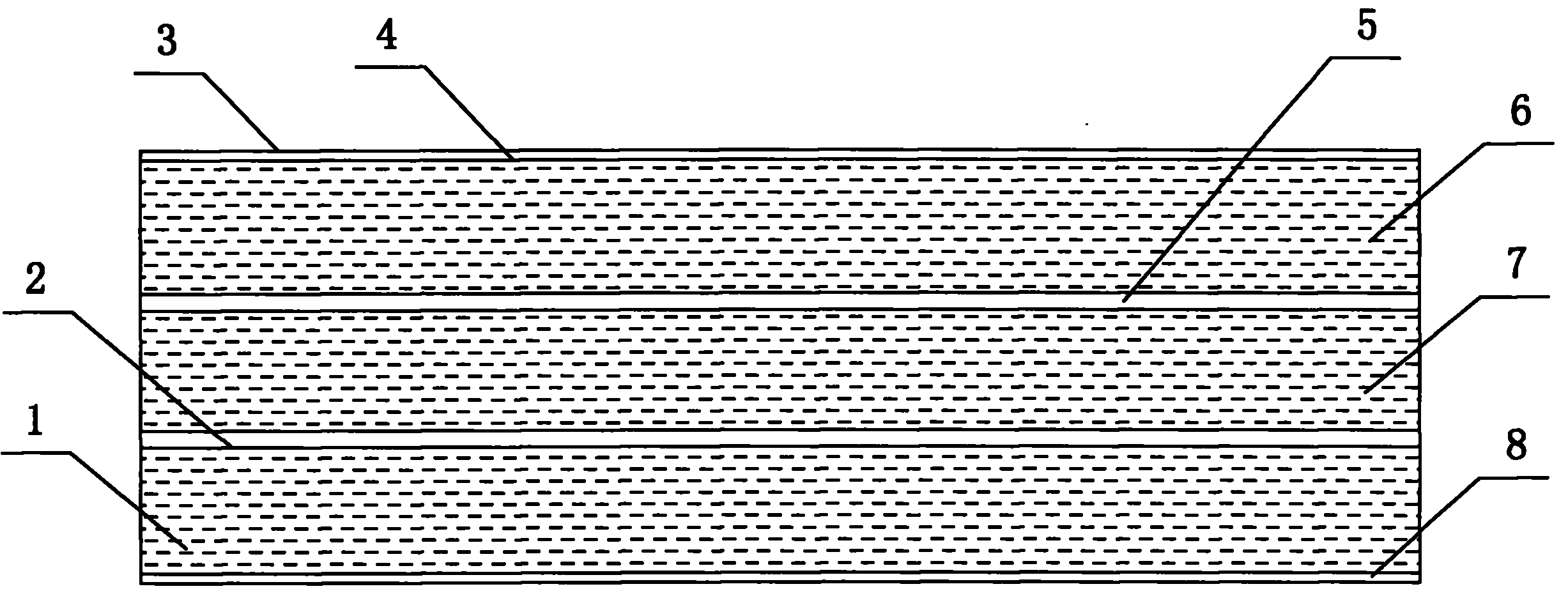

[0010] figure 1 The bottom of the industrial sewing machine table shown in is sealed with a poplar thin-skinned base plate 8, the upper end of the thin-skinned base plate is provided with a bottom layer of saw foam 1, the upper end of the bottom layer of saw foam is provided with a lower wooden template 2, and the upper end of the lower wooden template is provided with a middle layer Saw foam 7, the upper end of the middle layer of saw foam is provided with an upper wooden template 5, the upper end of the upper wooden template is provided with an upper layer of saw foam 6, the upper end of the upper layer of saw foam is provided with a poplar thin-skinned top plate 4, and the upper end of a poplar thin-skinned top plate is provided with There are fire board panels3.

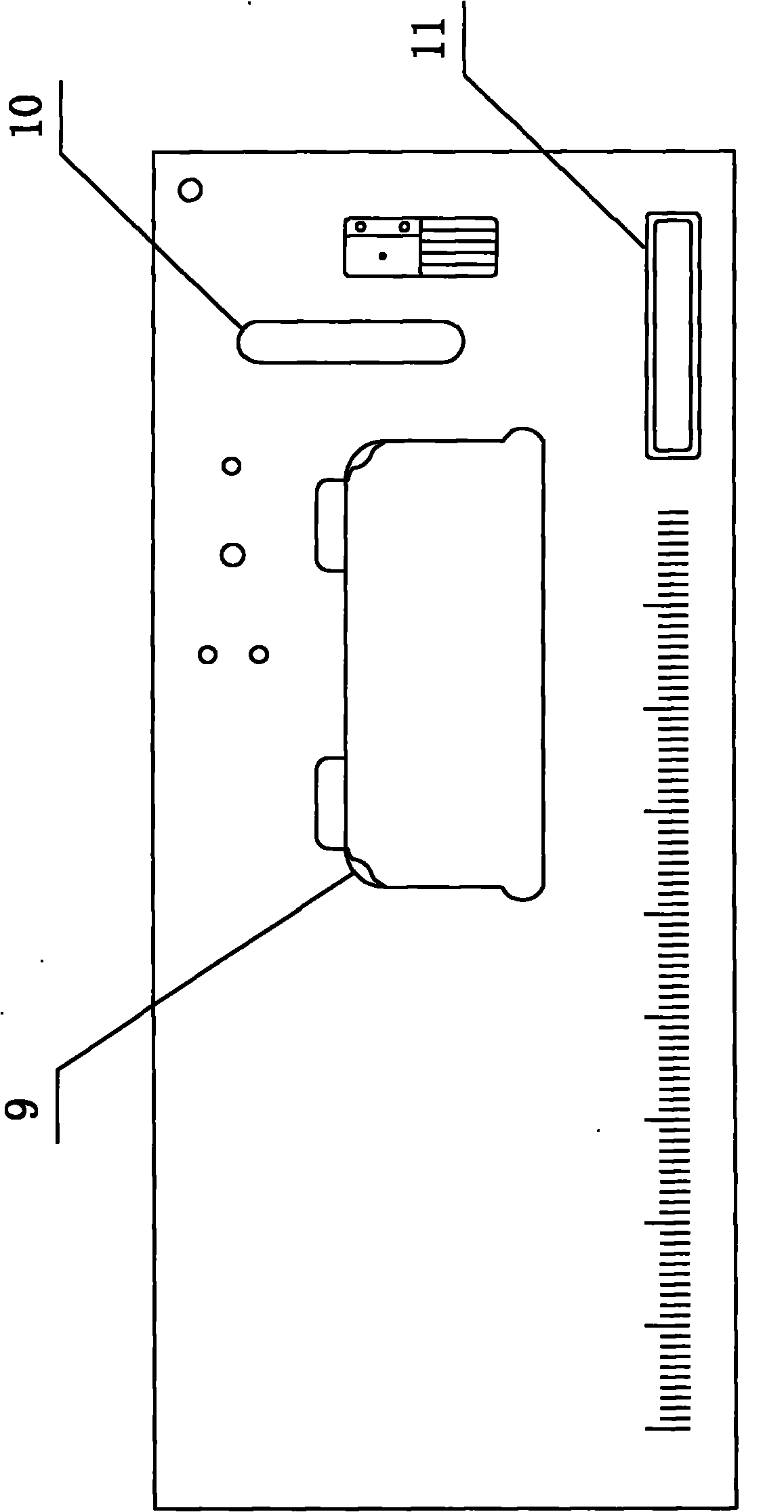

[0011] figure 2 The middle right side of the industrial sewing machine table shown in is provided with a sewing machine base mounting hole 9, the upper right side of the mounting hole is provided with a transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com